HOME→40 tons per hour electrolytic aluminum waste slag grinding machine calcium carbonate crushing station

40 tons per hour electrolytic aluminum waste slag grinding machine calcium carbonate crushing station

.jpg)

Efficient lithium recovery from electrolytic aluminum slag via an

Wu et al (2021) developed a new way to recover Li from waste electrolytes by saturated sodium carbonate roasting at 650 °C for 2 h and then leaching with HNO 3 Roasting with saturated 2022年12月12日 In this paper, the ultrahigh pressure contact molding technology is used for the first time to prepare highperformance building materials with aluminum ash and calcium Comprehensive performance study of aluminum ash and calcium 2023年4月25日 This article analyzes and summarizes the composition and hazards of the overhaul slag and the current development status of domestic and international electrolytic Research Progress of Electrolytic Aluminum Overhaul Slag Disposal2022年10月10日 In this work, electrolytic aluminum carbon anode slag was separated by flotation Using the selectivity index ( SI ) as an indicator, the influencing factors of the carbon Recovery of carbon and cryolite from spent carbon anode slag of

.jpg)

Clean Process for Selective Recovery of Lithium Carbonate from

2023年9月1日 This study employed hydrometallurgical processes to selectively leach lithium from Licontaining aluminum electrolyte slag, using sodium carbonate solution as the leaching 2023年10月1日 Waste aluminum electrolyte is a typical hazardous waste from the aluminum electrolysis industry In this paper, the process of “sulfated roasting–calcine water Efficient extraction and recovery of lithium from waste aluminum 2024年5月23日 Here, we review carbonrich solid wastes with focus on sources and hazards, detoxification, separation, recovery, recycling and disposal Treatment techniques include The recycling of carbonrich solid wastes from aluminum 2016年10月24日 For a largecapacity prebaked anode reduction cell (400 kA–600 kA), an advanced control system is essential to achieve high current efficiency and lower energy Progress in Aluminum Electrolysis Control and Future Direction for

Research on Using Carbide Slag to Mineralize the Carbon Dioxide

2024年2月2日 This study proposes the technology of using waste carbide slag to treat carbon dioxide in the tail gas of electrolytic aluminum and innovatively designs a Venturi 2020年4月7日 In general, ZG35Cr25Ni20 electrolytic aluminum slag grabber has become a leader in the electrolytic aluminum industry with its hightemperature, corrosionresistant 310S Electrolytic Aluminum Slag Grab Sino Machine2022年10月9日 1 Department of Mining Engineering, Shanxi Institute of Technology, Yangquan, China; 2 Department of Mining Engineering, Balochistan University of Information Technology, Engineering and Management Sciences Recovery of carbon and cryolite from spent carbon 2022年1月10日 The recovery of spent carbon anode (SCA) materials plays important roles in environment protection and resources recycling, while this cannot be efficiently achieved without liberationSelective comminution and grinding mechanisms of

Plastic Scrap Grinder Machine Pet Bottle Grinding

40 kg per hour to 1 ton per hour: Blade Size: 18 inches: Phase: 3 phase: Voltage: 440 V: Power: 10 hp: The ADIT brand Abs Plastic Grinder is a highperformance recycling machine designed for grinding plastic waste into small, The mobile crushing station, mounted on wheels or tracks, can do mobile crushing or portable crushing between sites to form an efficient crushing and screening plant It can be used for coarse, medium, fine crushing or sand making of hard rocks and minerals on any harsh site, with an output range of 10 to 650 tons/hourA Catalog of All Mobile Crushing Station Fote Machinery2023年9月1日 Lithium (Li)bearing aluminum electrolyte slag is an inevitable byproduct of the aluminum industry, and improper disposal or stacking it may lead to potential environmental hazards This study employed hydrometallurgical processes to selectively leach lithium from Licontaining aluminum electrolyte slag, using sodium carbonate solution as the leaching agent Clean Process for Selective Recovery of Lithium Carbonate from Waste 2022年12月12日 Based on the research on bulk solid waste contact molding technology by our team [49], the comprehensive performance of pressed bricks with different ratios of aluminum ash and calcium carbide slag was investigated, the ratios of aluminum ash and calcium carbide slag are 9:1 ∼ 1:9 and pure aluminum ash and calcium carbide slag, the pressing pressure is 300 Comprehensive performance study of aluminum ash and calcium

.jpg)

Advances in the Safe Disposal and Comprehensive Utilization

2021年11月1日 Advances in the Safe Disposal and Comprehensive Utilization of Spent Carbon Anode From Aluminum Electrolysis: Prospects for Extraction and Application of Carbon Resources From Hazardous WasteGet info of suppliers, manufacturers, exporters, traders of Slag Crushing Machine for buying in India IndiaMART Get Impact Crusher Mild Steel 20 Ton Automatic Slag Crushing Machine ₹ 11,50,000/ Piece Get Dist Paschim Bardhaman Birudiha, Near Lalbaba Ashram, P O Panagarh Bazar District Burdwan, Station Panagarh E Railway, Birudiha Slag Crushing Machine at Best Price in India India Business 2024年5月23日 16 Million metric tons of spent carbon electrodes modify carbonrich solid wastes from aluminum electrolysis are produced annually, threatening ecosystems by cyanide and fluoride pollutionThe recycling of carbonrich solid wastes from aluminum electrolytic What Is Grinding Slag Removal? Slag is a specific type of sand that’s traditionally made from steel It often forms as a coarse waste product resulting from deburring or smelting processes To remove slag, metal processing facilities require grinding and slag removal Slag grinding processes efficiently remove all of the heavy slag produced Grinding Slag Removal Apex Machine Group

.jpg)

Rotary Dryers FEECO International Inc

Waste Heat; Biogas; We can offer cost competitive designs for pilot scale units that process as little as one ton per hour to heavy duty units in excess of 17 foot in diameter that process hundreds of tons per hour Rotary Dryer Tire 30 to 40 Ton per hour Aggregate Crushing Plant Consists of: Feed Bin, VGF, 400 x 600 Jaw Crusher on steel frame; Feed conveyor to screen; 12ft x 4ft triple deck screen complete on structure; Over size conveyor to Cone Crusher; Telsmith 40 ton per hour Complete Aggregate Crushing Plant2020年4月7日 ZG35Cr25Ni20 electrolytic aluminum slag grab, with its excellent high temperature resistance and corrosion resistance, is unique in the electrolytic aluminum industry The grapple is made of highquality 310S heatresistant steel castings, which maintain excellent stability in hightemperature environments, ensuring that the grapple can operate stably in Electrolytic Aluminum Slag Grab Sino Machine2016年6月1日 Slag to precipitated calcium carbonate process (Slag2PCC) is an innovative ICCU concept towards commercialization of highquality calcium carbonate production from industrial waste, ie Case study for production of calcium carbonate from carbon dioxide

.jpg)

Recovery of RareEarth Elements from Molten Salt Electrolytic Slag

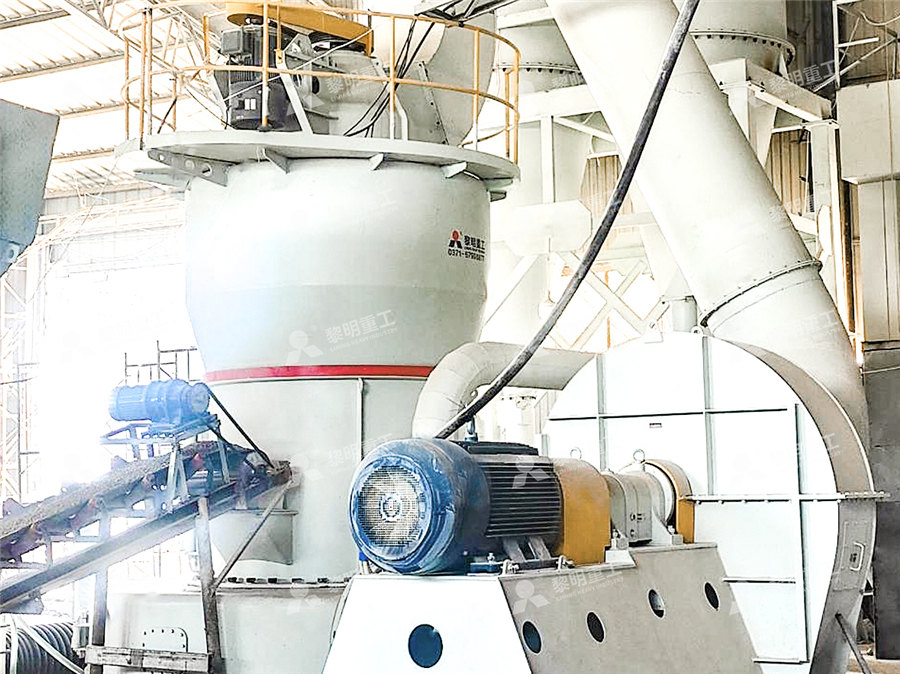

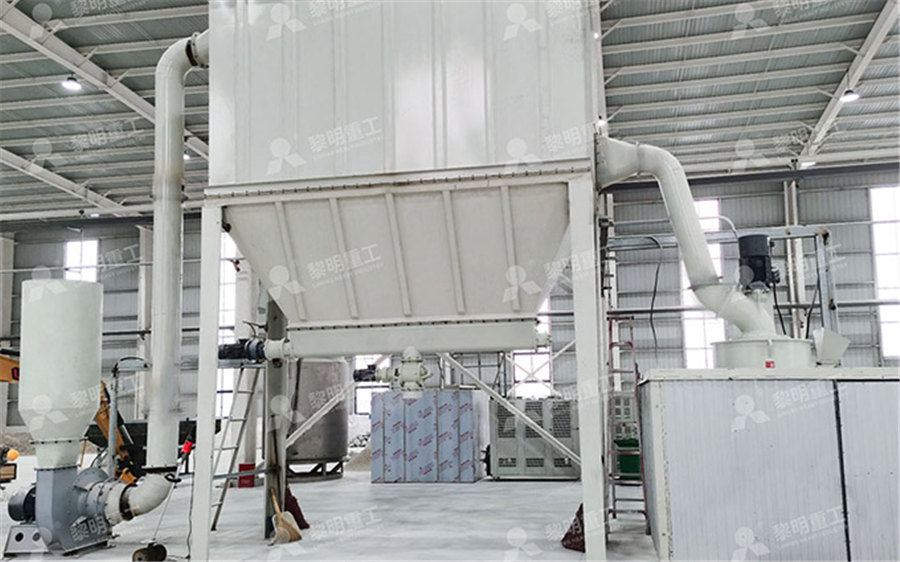

2022年2月19日 Recycling waste containing rare earth has always been a research hotspot The molten salt electrolysis process of rareearth metals and alloys generates a large amount of waste slag, which contains high rareearth content and, thus, has very considerable recovery value However, the high content of fluorine in rareearth molten salt slag brings challenges to the 2022年12月12日 Calcium carbide slag is a waste slag produced after the hydrolysis of calcium carbide to obtain acetylene gas, with very fine particles, offwhite color due to the presence of trace carbon and sulfur impurities, slightly odorous, with Ca(OH) 2 as the main component, and a slag liquid pH value of 12 or more, thus often causing serious pollution to the environment [18]Comprehensive performance study of aluminum ash and calcium 2021年6月16日 Aluminum and aluminum alloys are among the most used metals in fabrication,construction, and in the creation of good all around you It is such a useful and versatile metal, but there are some special considerations you need to make when working with it We have put together this expert guide to fabricating, grinding, and finishing aluminum to Ultimate Guide – Aluminum Fabrication, Grinding, and Finishing The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will provide you with some suggestions Production method of calcium carbonate powderHow to Choose a Calcium Carbonate Grinding Mill DASWELL

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; primary crushers have a capacity range of between 1,000 and 8,000 tons per hour Can primary crushing be used for nonaggregates applications 100t/h Slag Mobile Crushing Plant; Blog; About; Contact Us +86 info@crushing 2024年6月1日 Calcinating the slag with calcium oxide and aluminum sulfate at 1173 K achieved fluorine fixation to form rare earth oxides by 69, 70 recovery of waste sulfur slag, 71, 72 recovery of aluminum electrolytic waste residue, 73 Rare earth recovery from fluoride moltensalt electrolytic slag by sodium carbonate roasting REEs recovery from molten salt electrolytic slag: Challenges and 2023年10月1日 Cryolitealumina (Na 3 AlF 6Al 2 O 3) molten salt electrolysis is the only modern method for the industrial production of metallic aluminum (Ishak et al, 2017)Under the influence of direct current, Al 2 O 3 dissolved in the molten salt is reduced to monolithic aluminum at the cathode (Haraldsson and Johansson, 2020)As the blood of the electrolytic cell, the electrolyte Efficient extraction and recovery of lithium from waste aluminum Slag powder is a fine powder obtained by crushing and grinding slag, which has high activity and potential In the early years, slag materials were used as waste materials and had no application However, in recent years, more and more Slag Grinding Plant GGBS Plant Slag Mill, Slag

Steel Slag Grinding Plant CHAENG

The slag pot required for the transfer of steel slag in the steel plant is the leading product of the largescale foundry base of CHAENG The CHAENG slag pot adopts onepiece casting, which has the advantages of strong resistance to deformation and long service life: up to 6000 times, which is 20% higher than the the peersFind Slag Crushing Machine manufacturers, Mild Steel Slag Crusher Machine Capacity: 3500 Ton/Day Price: INR/Unit Get Best Quote Type Feed Grinding Machine, Gear Grinding Machine, Surface Grinding Machine, Cylindrical Grinding Machine Feature High Performance, Slag Crushing Machine TradeIndia2022年5月5日 Calcium carbonate grinding mill is an efficient industrial powder grinder machine It can grind 100+ kinds of ores into a fine powder (1503000 mesh)Calcium Carbonate Grinding Mill Powder Modify SBM 2023年3月12日 The aluminum electrolysis industry continually and unavoidably produces hazardous solid waste in the form of carbon anode slag Carbon anode slag poses a serious environmental pollution risk, and it must be disposed of in a harmless manner On the other hand, it contains a few valuable resources, as well In order for the aluminum electrolysis industry to Recovery of Carbon and Cryolite from Spent Carbon Anode Slag

Slag Crusher Plant Machine Manufacturer Bhupindra Machines

To develop the slag crushing plant is the big achievement for Bhupindra Machine PvtLtd We have developed the 100 TPH fully automized slag crushing plant on key basis Today BMPL have achieved the excellence and created a distinct identity for themselves in the business areaThe aluminum dross skimming from the smelting furnace is called primary aluminum dross, which is graywhite in appearance, mainly composed of a mixture of metallic aluminum and aluminum oxide, and the aluminum content can reach 15%~ 70%, also known as “white aluminum dross”; secondary aluminum dross is the waste after the primary aluminum dross is extracted from Aluminium dross processing/Brightstar Aluminum MachineryMORE The recycling technology and process of electrolytic aluminum byproduct,lithiumcontaining electrolytes by comprehensive utilization of electrolytic aluminum waste slag is relatively backward,failing to realize recycling of the expensive lithium resourcesThe structure and physical and chemical properties of the byproduct lithiumcontaining electrolytes are 电解铝废渣提锂工艺研究【维普期刊官网】 中文 2017年10月24日 Aluminum production is accompanied by production of fluorinecontaining solid waste Every year in the Bratsk Aluminum Plant 40000 tons of this waste is produced with a high fluorine and carbon content Technology for producing calcium fluoride is developed in order to regenerate fluorine Optimum conditions are studied and determined for leaching fluorine from Technology for Preparing Calcium Fluoride from Aluminum Production Waste

Hazardous aluminum dross characterization and recycling

2018年10月1日 In the secondary aluminum industry (aluminum scrap recovery), about 200 kg of aluminum is produced per each ton of secondary aluminum (Seng et al, 2006) By 2020, annual global demand for aluminum will reach to about 97 million tons and almost 32% of which that equals to 31 million tons is expected to be supplied from scrap recycling ( Tsakiridis et al, 2013 )320,000 tons in 2016[1] Electrolytic aluminum waste is a collective term for the waste generated during the electrolytic aluminum production process, including waste cathode carbon block, waste anode material Generally, electrolytic aluminum production enterprises will overhaul the electrolytic cell every five years, with aResearch on the Coprocessing of Mixed Electrolytic Aluminum Waste Recycling and utilizing slag instead of treating it as waste enable cutting costs and generating new revenue Solutions for companies processing and recycling slag Menu CloseSlag crushing Metso2017年3月5日 Steel slag is an inevitable solid waste of the steel manufacturing 400,000 tons of steel slag are annually used as aggregates for raw material for precipitation of pure calcium carbonate(PDF) Iron and Steel Slags ResearchGate

.jpg)

A Review of Secondary Aluminum Production and Its Byproducts

2021年7月30日 Secondary aluminum production is required for the conservation of the environment It can significantly reduce greenhouse gas emissions and energy consumption and reduce the consumption of alumina 2009年2月1日 Waste crab shells (CS) have the potential to mineralize CO 2 , yielding precipitated calcium carbonate (PCC) powder feedstock for use in the synthesis of monocalcium phosphate monohydrate (MCPM From waste to commodity: transforming shells into high purity calcium 2022年10月10日 Recovery of carbon and cryolite from spent carbon anode slag of electrolytic aluminum by flotation The sample was ground to −0074 mm using an HLXPMΦ120 × 3 threeheaded grinding machine (Wuhan The microscope observations of the raw carbon anode slag and the product of carbon anode slag after 40 min grinding were Recovery of carbon and cryolite from spent carbon anode slag of 2016年10月28日 The grinding efficiency of steel slag was obviously increased and the particle characteristics were improved after using grinding aids (GA), especially the particle proportions of 332 Mm were (PDF) Comparison of Grinding Characteristics of Converter Steel Slag

.jpg)

Research on the Preparation Parameters and Basic Properties of

2021年10月6日 Secondary aluminum dross is a byproduct of the electrolytic aluminum industry, whose main components are Al2O3, AlN and Na3AlF6 Secondary aluminum dross is a type of hazardous waste, with a 2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses