325 mesh limestone powder compacted sister moisture content

The Versatile Chemical Lime

**/ The angle of repose for both types of lime (hydrate in particular) varies considerably with mesh, moisture content, degree of aeration, and physical characteristics of the lime (Eg, for quicklime it generally varies from 50 to 55 degrees and for hydrated lime it may range as much as 15 to 80 Crushed limestone density, generally between 1,500 and 2,200 kg/m³, depends on particle size distribution, compaction, and moisture content Limestone powder density, usually from 2,600 Limestone Density kg/m³: Bulk, Crushed, and Powder2020年9月11日 (Ground, Screened, High Calcium Limestone) % passing 50 mesh screen 999% % passing 100 mesh screen 900% % passing 200 mesh screen 700% % passing 325 mesh (Ground, Screened, High Calcium Limestone) Arcosa Specialty Hubercarb® W Series calcium carbonate including Optifil® calcium carbonate has a purity level of 993% limestone that is produced in Quincy Products include fine median particle sizes The Huber Calcium Carbonates

43.jpg)

A review on effects of limestone powder on the ScienceDirect

2018年12月20日 Limestone powder (LS) is one of the mineral materials in concrete due to its wide availability and low cost This paper discusses effects of LS on the workability, setting 2021年4月1日 A guide to optimizing the quality of the material is suggested by blending 3/8inch aggregate with the crushed limestone finepowder material at a specified percentage ranging Characterization and assessment of crushed limestone powder DOLOMITE 4512 4012 (325 200 MESH) INFORMATION These are common Dolomitic Limestone powders used as fillers, for agriculture, acid neutralization, and a variety of other DOLOMITE CB MINERALS2020年5月10日 An appropriate content of limestone powder can contribute to a higher strength, denser pore structure, diminished total free shrinkage and higher sustainability efficiency The Optimization and characterization of highvolume limestone

.jpg)

Optimization and characterization of highvolume limestone

2020年5月1日 Results show that replacing high volume of binders by limestone powder is an efficient way to develop ecofriendly and lowcost UHPC Limestone powder shows a positive Volclay 325 mesh is a true micronized product that produces consistency and performance Multipurpose suspending, emulsifying, and binding agent used in industrial applications where low Volclay 325 Mesh Minerals Technologies Inc2021年4月1日 Characterization and assessment of crushed limestone powder and its environmental soil was compacted in a 1524mm diam eter mold using a 4448 N hammer The optimum moisture content is Characterization and assessment of crushed limestone powder The mass of compacted soil and the volume of the mold gives bulk density of the soil The water content corresponds to this point is called the Optimum water content (OWC) or optimum moisture content (OMC) Fig4 Compaction Determination of Maximum Dry Density and Optimum

.jpg)

POWDER SULPHUR 325 MESH BUOYANCY IMPEX

Sulphur content Moisture Ash content Acidity(HSO) Organic substance Color Solid 7704 1350 3207 g/mol 115°C Bright Yellow 19 21 g/cm3 325 mesh sand, etc) owing quality standards and propertiespalletized 34 9 S 41 120°C Powder Sulphur ep in air well Thermal Conductivity Residue on ignition Solubility in Toluene: Specific Gravity•Limestone •Fluorspar •Pulverized Ore •Ground Coal or coke •Soda Ash A natural repose angle of up to 35 degrees CLASS 3 – POWDERS, FLUIDIZABLE These materials are generally of fine particles size, 200325 mesh (or smaller) They are slightly permeable (Definition The permeability of a bulk material is a degree to whichTHE PROPERTIES OF SOLIDS Vibra ScrewPharmaceutical and animal feedindustries Powder Sulphur 9990% MIN with 325 Mesh size exported by Buoyancy® meets the following technical and quality standards Packing 25Kg and 50 Kg PP Laminated marking bags palletized or nonpalletized Storage Handling 1)Prevent moisture absorbing, keep away from heat, keep in air wellventilated areaPowder Sulphur 325 Mesh Buoyancy2022年6月22日 Study on effect of fly ash and limestone powder on compressive strength of roller compacted concrete for dam construction June 2022 Journal of Asian Concrete Federation 8(1):3750(PDF) Study on effect of fly ash and limestone powder on

.jpg)

Limestone Powder 250 mesh

No18 Son Ha Minerals Co,Ltd Mr Henry (Vice Director): Phone: +84 931 717 698 Fax: +84 (024) Office: No 69 Tran Quang Dieu Street, O Cho Dua Ward, Dong Da District, Ha Noi Capital, Vietnam2018年7月31日 The response of an instrumented flexible pavement structure in southern Sweden, subjected to seasonal freeze–thaw cycles, was investigated during the spring thaw and the recovery periods in 2010(PDF) Influences of Moisture Content on Resilient ResearchGateTin, 998%, powder, 325 mesh, Thermo Scientific Chemicals Structure; Print Tin, 998%, powder, 325 mesh, Thermo Scientific Chemicals Catalog No Please complete this form to provide feedback related to the content on this product Product Title Full NameTin, 998%, powder, 325 mesh, Thermo Scientific Chemicals2011年5月1日 Study on the Effects of Natural Pozzolan and Limestone Powder on Mechanical Properties of Roller Compacted Concrete Pavements May 2011 Advanced Materials Research 250253:36193623Study on the Effects of Natural Pozzolan and Limestone Powder

.jpg)

Moisture content as a deteriorating factor for common building

d UK Centre for Moisture in Buildings (UKCMB), London WC1H 0NN, UK Abstract Moisture content and its distribution within the rock mass can affect its deterioration This has not been considered in details in the context of their specific properties for the common building stones in London such as limestone, granite and marble2022年9月6日 This study aims to provide a thorough evaluation for the changes in the microstructure and evolution of strength of highly reactive clays that were treated with 7% lime over a period of curing time as a function of the mixing moisture content Three series of testing were carried out on specimens with 100%, 85% and 75% of bentonite content and prepared The Impact of Moisture and Clay Content on the Unconfined2018年3月10日 In spite of intrinsic limitations, neutron powder diffraction is, and will still be in the future, the primary and most straightforward technique for magnetic structure determinationEFFECTS OF MOISTURE ON NATURAL BUILDING LIMESTONES2021年1月15日 Thus, this industrial byproduct showed a very positive effect on soil stabilization as a partial cement replacement Similar results were stated by Bazarbekova et al [49], as the UCS of a silty (PDF) Potential of limestone powder to improve the stabilization

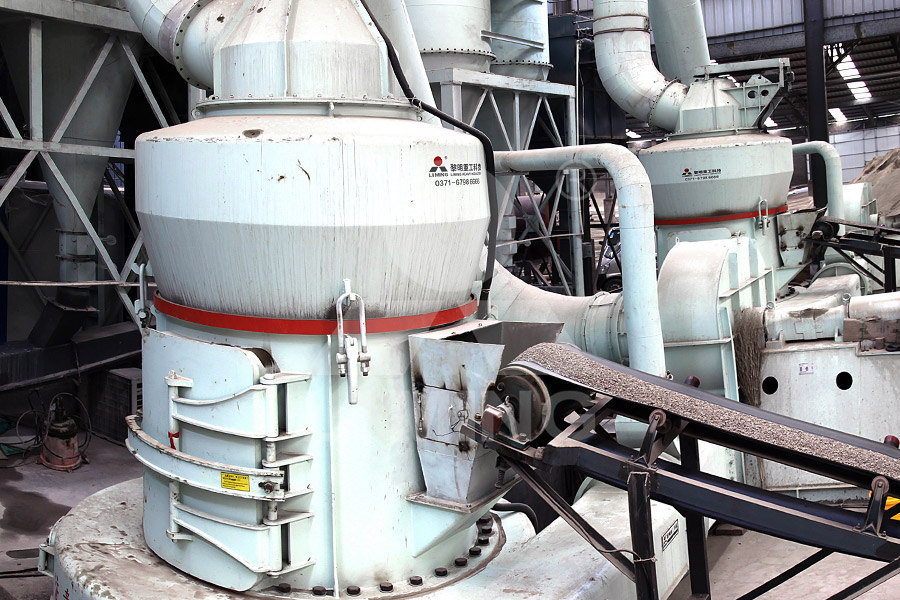

3253000 Mesh Ultrafine Limestone Powder Processing

This mill is widely used to grind any nonmetal minerals with Mohs hardness below 7 and moisture below 6%, such as talc, calcite, calciumcarbonate, dolomite, bentonite, kaolin, graphite, carbon black, etc 3253000 Mesh Ultrafine Limestone Powder Processing Technology; 3253000 Mesh Ultrafine Limestone Powder Processing TechnologyAdditionally, many factories in Erbil city in the Iraqi Kurdistan Region produce limestone powder for filler in the composition of asphalt mixture [39]It can benefit from these factories for soil The chemical composition of limestone powder ResearchGate2023年8月8日 Lateritic soil is a soil layer that is rich in high iron content, derived from the weathering of rocks formed under high temperature and heavy rainfall conditions and having reddish to yellow colorStabilization of Laterite Soil Using Quarry Dust and Limestone PowderThe study investigated the optimal amount of limestone powder that can be used in rollercompacted concrete to reduce cement and fly ash, finding that adding limestone powder can improve the mechanical properties and freezethaw resistance of RCC within a Influence of Limestone Powder and Fly Ash on the Freezing and

Dolomitic Limestone Powder: Cement Substitute in the

212 Dolomitic Limestone Powder Dolomitic limestone powders were prepared by random sampling The particle size distribution of the sample was determined through sieve analysis using sieve no 24, after coning and quartering a batch of sample of limestone (ASTM E877, 2013) Coning and quartering is a method used to reduce theNo18 Son Ha Minerals Co,Ltd Mr Henry (Vice Director): Phone: +84 931 717 698 Fax: +84 (024) Office: No 69 Tran Quang Dieu Street, O Cho Dua Ward, Dong Da District, Ha Noi Capital, VietnamLimestone Powder 120 Mesh2016年5月3日 Request PDF Effect of limestone powder as a partial replacement of crushed quarry sand on properties of selfcompacting repair mortars Selfcompacting repair mortars (SCRM) are particularly Effect of limestone powder as a partial replacement of crushed 2021年2月26日 In Europe, 300 kg/m 3 cement content for a powdertype selfcompacting concrete is commonly used with limestone powder (LP) filler [5] Generally, in SCC, the fillers can be classified into two Effect of limestone powder on selfcompacting

.jpg)

Effect of Lime Variation on the Moisture Content

2012年11月1日 For example in samples A the OMC increased from 13% at 0% lime content to 228% at 10% lime content while the MDD reduced from 18g/cc at 0% lime content to 157g/cc at 10% lime content This was Rollercompacted concrete Fly ash Limestone powder Durability Freezethaw resistance Relative dynamic modulus of elasticity Water requirement ratio 095 ≤ 105 Alkali content 077 Moisture content 012 ≤ 10 Loss on ignition 251 KSCE Journal of Civil Engineering 2503Influence of Limestone Powder and Fly Ash on the Freezing and 2024年11月7日 Limestone grinding machine 325 mesh limestone powder equipmentLimestone grinding machine 325 mesh limestone powder 2018年6月1日 Stabilised material are usually compacted at the optimum moisture content when the dry density at its maximum or at the wetter side nearly saturation line (Whitlow, 2001) For a given compactive effort, higher strength can be achieved by compacting the raw material at its optimum moisture content to ensure that the maximum dry density is achievedEffect of optimum compaction moisture content formulations on

.jpg)

(PDF) Mechanical properties and microstructure of roller compacted

2024年1月13日 Mechanical properties and microstructure of roller compacted concrete incorporating brick powder, glass ence of compaction delay on the optimal moisture content Retained on sieve No 年2月25日 Powder type of selfcompacting concrete (SCC) needs high cement content to achieve selfcompactibility, this will be undesirable in tropical climate of Sudan due to implication of high hydration heatEffects of Limestone Powder on Selfcompacting Concrete Properties2023年12月1日 Before the compression test, soil samples should be prepared with differing initial moisture content and compacted by light or heavy standard compactor Then samples for confined compression test were taken into a ring mold (618 mm in diameter and 20 mm height) and compressed under 25, 50, 100, 200, 300, 400, 600, Strength and deformation characteristics of compacted loess with 3252000 Mesh Talc Powder/Talcum Powder, Moisture % 0105 Asbestos % 0 Pesticides % 0 Dehp+DBP+Bbp% 0 Transport Package 25kg/Bag Specification so it is easy to split into flake trend and special lubrication and if the Fe2O3 content is 3252000 Mesh Talc Powder/Talcum Powder Talc Powder and Talc Powder

325 mesh SigmaAldrich

Find 325 mesh and related products for scientific research at Merck powder, −325 mesh, ≥99% trace metals basis:2016年1月13日 The mechanical characteristics of various sedimentary stones significantly depend on the water content, where 70 % loss of their mechanical strengths can be observed when saturated by water Furthermore, the clay fraction has been shown to be a key factor of their hydromechanical behaviour since it governs for instance the hydric dilation This work aims at Influence of Water Content on the Mechanical Behaviour of Limestone 2018年2月21日 The major environmental impact of concrete comes from the CO2 emissions, produced during the cement manufacturing process The main goal of this research project is to evaluate the efficiency of Evaluation of the Efficiency of Limestone Powder in 2014年5月1日 Current guidelines suggest that stabilized rammed earth materials be compacted at their optimum water content to achieve their maximum strength(PDF) Effect of compaction water content on the strength of

.jpg)

Flexural behavior of a box ferrocement beams consisting of self

2023年9月1日 Limestone Powder (LSP): This material is locally available in Iraq and has a specific gravity of 269 with a density of 1403 kg/m 3 It was utilized as a filler to produce selfcompacting mortar Limestone powder was used after passing through sieves of 300 μm, 150 μm, and 75 μm by 100%, 8753%, and 7345%, respectively2024年11月9日 325 mesh limestone powder grinding equipment325 mesh limestone powder grinding equipment The 19B350 is a 12' (3048mm) full height test sieve with a No 325 mesh This sieve, or sifter, is constructed with a stainless steel frame and stainless steel wire mesh cloth Full height 12' sieves have a 31/4' depth to the wire cloth and are easily nestable The No 325 mesh is a fine size US Standard mesh size with a 00017' (45µm) nominal sieve opening with a typical wire diameter No 325 Mesh Testing Sieve, 12" Dia, 31/4" Depth (Full), SS 2019年11月22日 Tunnel boring machine (TBM)crushed limestone material is a fine powder obtained during tunnel excavations This material is proposed for use as smart filler in clay–sand liners, which include highly plastic clay and are typically used in waste containment applications and other fields Replacing a part of bentonite in these liners with an inert, low plasticity Enhancement of Clay–Sand Liners Using Crushed Limestone Powder

Effect of Cement Type and Limestone Powder Content on

2020年7月8日 21 Materials The concretes’ binder were based on OPC Three cements varying in fineness were tested for their suitability for this project: CEM A with a specific surface A Blaine,A = 2,700 cm 2 /g, CEM B with A Blaine,B = 3,500 cm 2 /g as well as CEM C with A Blaine,C = 5,600 cm 2 /g The peculiarity of the examined cements is that they have the same 2021年7月28日 The common fineness of dolomite powder is 325 mesh, 400 mesh, 600 mesh, 800 mesh, 1000 mesh, 1250 mesh The purpose of modification is to change the surface alkalinity of dolomite powder, overcome the bonding performance between filler and rubber, reduce shrinkage and internal stress, prevent crack propagation, and improve the processing Dolomite grinding mill for 325 400 600 800 1000 1250 mesh