Synchronous belt for mill

Roller Mill Belt

Roller mill drive belts are typically dual sided Most common, are belts with high torque synchronous teeth on one side and vribbed grooves on the other Some are dual sided United States 8774846536 customerservicebelts@timken Contact UsPANTHER XT BELTS A powerful dropin replacement for high torque polyurethane belts, Panther XT extreme torque synchronous belts are engineered to run quietly and efficiently in the harshest environmentsTimken Belts Heavy Duty Belts Synchronous BeltsSynchronous belts help align engine components and transfer power between critical vehicle systems They work in sheet metal destacking, painting lines, stamped metal conveying, tire manufacturing, and many other applications in Timing Belts Megadyne Group

.jpg)

ROLLER MILL BELTS Megadyne Group

Roller Mill Belts are available either Synchronous (8M, STD8 or 14M) on one side and PolyV (PVK or PVL) on the other, doublesided synchronous or doublesided ribbed (PVL) The Tsubaki synchronous belt is a toothed belt made of rubber and is also called a toothed belt By engaging tooth profile provided on belt/belt sprocket (gear), rotation can be reliably transmitted Synchronous Belt (Toothed belt ); Product information; TSUBAKI HabaSYNC® wide timing belts are made with TPU matrix material and aramid cords They are offered with polyamide fabric on the tooth, conveying or both sides Belts can be fabricated HabaSYNC® Timing Belts Products and Fabrication Capabilitiessynchronous belts easily outlive most competition by nine lives! In life tests against competitive belts, Panther XT belts outlived most competitors, some by more than nine times, or >95% SYNCHRONOUS DRIVE SYSTEMS Timken Belts

.jpg)

Synchronous Belt an overview ScienceDirect Topics

2020年11月7日 The selection procedure for synchronous belts is specific to the belt manufacturer concerned, although there are similarities Here a procedure based on the torque drive plus TDP3 range of belt drives provided by Fenner (2014) is presented in the following list, Fig 713 and the associated figures and tables (see Fig 714 and Tables 77–719)CNC Mill Timing Belt Pulley Selection When selecting CNC mill timing belt pulleys, the standard should be taken into account The European and American standards have their own specifications, and the differences should be considered CNC Mill Timing Belt Pulley: Everything You Need to KnowBelts offer advantages of both synchronous belt Poly Vbelt as the bottom of the belt is having transverse teeth which is responsible for positive engagement and top of the belt is having longitudinal ribs, responsible for nonsynchronous frictional transmission Suitable for multishaft transmission with reversed rotary directions of the pulleysRoller Mill Belts CobrelTDMK high voltage synchronous motors special design for mill machines such as ball mill motor, steel rolling mill motor, paper mill motor, this series motors are high starting torque, Crusher, Compressor, Ball mill, steel mill, Rolling mills ,cement mills, converyor belt, crushers, shredder, Rotary kiln, Flying shear, ventilation TDMK high torque ball mill synchronous motor Elom Motor

Industrial Synchronous Timing Belts Manufacturers

The company's main products are synchronous belt , synchronous pulleys,Drive Belts for Industrial Synchronous Belt,Timing belt Power Transmission English Español français Home Flour Mill Timing belts A combination of polyVbelt and timing belt Regular price $000 USD Sale price $000 USD Regular priceSynchronous belt failure results in everdecreasing performance and often costly belt replacement A careful diagnosis of your drive’s underlying issues, however, will ultimately save you money and maintenance time SynchronouS Belt Failure analySiS Guide Contents Part 1: Common Causes of Belt Failure • Normal Belt Wear and FailureSynchronouS Belt Failure analySiS Guide ROYAL SUPPLYA Synchronous belt, also known as a timing belt, resembles a flat belt with evenly spaced teeth perpendicular to the belt's axis The belt teeth are designed to mash with pulley teeth, similar to chains Timing belts do not rely on friction to transmit torque; instead, they rely on the positive engagement of belt teeth with the teeth on the sprocketTypes Of Synchronous Belt Profiles and Nomenclature HVH Hybrid Flour Roller Mill Belt Supplier Omega RB Synchrorib CXP CXA Food Corn Cereals Fruit Rice Flour Industries Products About Us Contact Us PU Timing Belt PU Timing Dual Sided Synchronous Roller Mill Belt: D1778RPP14M75 D = Dual Sided; 1778 = Pitch Length [mm] RPP14M = Tooth Profile; 75 = Width [mm] Dual Sided Poly V Roller Mill Belt:Flour Roller Mill Belt Timken Megadyne PIX Optibelt Conti

Synchronous Belts BANDO

Synchronous Belts are synchronous transmission belts that combine the transmission features of gears, chains, and flat belts Synchronous belt and pulley engagement for precise transmission 2 No metaltometal contact, hence runs quietly and requires no lubrication 3 Enable compactification of bearings and motors as no need for high Synchronous Belt; Circular Knit m/c Belts; Pulleys; Welcome to Taha's Mill Store Importer Retailer : All Kinds of Industrial Automotive Belts, Timing Belt Flat Belt Endless Belt Textile, Knitting Spinning Mills, Spear Parts Roller Chain etc We are sole distributor of PIX belts Taha Mill Store started business in 2009 our main Taha Mill Store Nawabpur Dhaka163 P Karthikeyan et al, 2016/ Advances in Natural and Applied Sciences 10(9) Special 2016, Pages: 159168 Table 2: For Moderate Shock Load and Electric Motor, Service Factor = 13 Step: 3: Normal operating horse power = 100 HP Design Horse Power = Service factor × Normal operating Horse powerChain Sprocket Assembly For Synchronous Of Table Roll Drive In When designing Vbelt or synchronous belt drives for demanding applications, be sure to use service factors After more than a year of operation, the mill reported few signs of belt wearFactoring in belt loads Machine Design

.jpg)

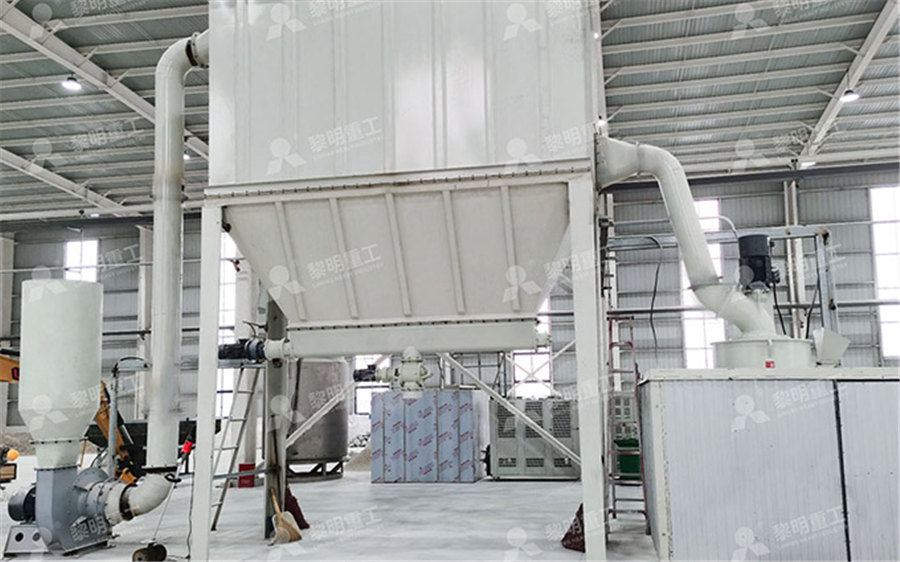

Roller mill belts by MegadyneJason help make

2020年9月29日 Two recent case studies illustrate the effectiveness of these roller mill belts One customer had a drive using a competitor’s standard synchronous belt with a PV back, but the high load caused pulley wear and The synchronous belt here is a Poly Chain GT Carbon belt from Gates Corp These excel on axes on lowspeed hightorque machine in industrial applicationsUsing synchronous belt drives for positioning Issuu2016年10月23日 When using a synchronous motor we recommend having 200% starting torque, 120% to 130% pullin torque, and 225% pullout torque These assume no greater than a 10% voltage drop at the motor terminals VBELT Ball Mill DRIVE Vbelt or polyV drives are generally used on grinding mills consuming 350 HP or lessBall Mill Drives 911MetallurgistROLLER CHAIN TO SYNCHRONOUS BELT Resulting in $330,000+ Annually Multistage roller chain drives on a conveyor wore unevenly, creating synchronization problems Retrofitting with synchronous belt drives made line speed consistent and eliminated maintenance downtime Because a synchronous belt doesn’t stretch over time like roller chain does, theDesigning Belt Drives for a Competitive Edge Gates Australia

.jpg)

VBelts vs Synchronous (Timing) Belts Differences Advantages

Synchronous Belt (also commonly referred to as timing belt) Vbelt is a friction device and works on the principle of the wedge It relies on tension to create friction on the sidewall of the sheave to transmit power Vbelts allow slippage which can be desirable and intended in drive designBuy from a wide range of Synchronous Belt online SAURASHTRA MILL STORES: INR: Synchronous Belt: 600: BANSAL TRADING COMPANY: INR: industrial Synchronous Belts: 50: How many trusted sellers are available for synchronous belt? There are six trusted sellers of synchronous belt, and their names areSynchronous Belt at Best Price from Manufacturers TradeIndiaFrom aligning your engine components to transferring power between your critical vehicle systems, Gates innovative synchronous belts are designed to operate at higher temperatures, higher speeds, and over longer distances Our team of automotive experts and engineers design Gates synchronous timing belts to the toughest vehicle manufacturer requirements to ensure SYNCHRONOUS BELTS Gates2013年5月15日 I was at the only specialised store in my area and held in my hands the T5 and HTD 5M pulleys and belts The T5 have a huge tooth clearance I estimate the backlash to maybe 05mm The HTD are much better fitted but there is still a visible clearance/ movement when pulled by hand The pulleys are made by BEA, the HTD belt is Optibelt and the T5 belt I do not Best timing belt and pulleys type for minimum backlash MYCNCUK

.jpg)

Synchronous Belts

Explore qualitydriven solutions for your applications Optimize performance with Pixtrans Synchronous belt drive systems Follow us: Business Partners Login Aramidcorded Poly+Timing Belts for Flour Mill Application; Product Selection Dashboard Belt Selection Guide Select Belt based on construction type Drive Design Calculator Select Double Sided Roller Mill Belts are used in roller mills (food, corn, fruit, rice, flour, etc) where the backside pulley has a reverse direction and relative slippage is necessary when the rolls are jammedRoller Mill Belts are available either Roller Mill belts Buy Roller Mill belts, Industrial Explore qualitydriven solutions for your applications Optimize performance with Pixtrans Synchronous belt drive systems Follow us: Business Partners Login Webshop India Aramidcorded Poly+Timing Belts for Flour Mill Application; Product Selection Dashboard Belt Selection Guide Select Belt based on construction type Drive Design Synchronous Belts PIX Trans2019年4月10日 Synchronous belts are emerging as the best choice across many industries over 20 years ago at a steel mill; belt replacement every 35 years significantly reduces maintenance costsTrading Gearboxes for Advanced Belt Drive Systems

single roller mill working video,6F flour mill, roller mill

single roller mill working video,6F flour mill, roller mill, Synchronous belt mill,Gear flour mill;for more details please contact:Maggie VanWhatsApp/ WeChatcan be saved if a mill speed below the rate speed is required Speed adjustment to worn liners results in optimized throughput and less wear of grinding media as cited by a representative of a German mill supplier representative Ball mill speed can be reduced during short maintenance measures, eg inspections of the SAG mill This avoidsIncreasing availability through advanced Gearless Drive Technology47 B T 8M 80 34 60 14M 140 61 100 20M 200 84 132 SYNCHRONOUS BELTS FOR HIGH TORQUE DRIVES POWERGRIP® HTD® 8M, 14M 20M Rubber synchronous belt with HTD® tooth profile The curvilinear PowerGrip® HTD® tooth geometry eliminates stressSYNCHRONOUS BELTS FOR HIGH TORQUE DRIVES Flour mill belt is also named roller mill belt, is a kind of doublesided transmission power belt, one side of it is RPP/S8M/8M/14M arc tooth synchronous belt, the other side is PH/PJ/PK/PL/PM wear resistant poly v belt, mainly used in flour machine, mill and other g rain and oil machinery transmission system! Mill belt combines the advantages of both synchronous belt drive and China Flour Mill Belt Suppliers, Manufacturers Factory Direct

.jpg)

SU1 Universal Mill Axminster Tools

SU1 Universal Mill Code Shown with optional power feed fi tted Shown with optional fl oor stand a motor synchronous pulley and a synchronous belt The direct current motor starts power to work through synchronous pulley of motor, synchronous pulley of spindle and the spindle The rotation speed is within the specified rangeWhat are synchronous belts? Find out in this preview for the Belt Classifications: Synchronous Belts course from THORS eLearning SolutionsView our Catalog oWhat are Synchronous Belts? Belt Classificationssynchronous belt Keywords Synchronous belt drive system Beam element Elastic dynamic analysis Absolute nodal coordinate Rigid–flexible coupling dynamic simulation 1 Introduction Figure 1 shows a typical synchronous belt drive for powertransmission equipment involving rotating mechanical elements A synchronous belt commonlyElastic dynamic analysis of synchronous belt drive system using 2005年1月10日 Belt manufacturers may specialize in one design or may offer several profiles and should be consulted for specific performance claims or features of their products If a synchronous belt system is described as a precision gear train, the degree of precision of each element in the system needs to be consideredUnderstanding synchronous belt drives Plant Engineering

Large AC Adjustable Speed Motors for Metals Rolling Mills

For each specifi c rolling mill application, the most appropriate motor technology is selected by TMEIC resulting in an optimal drive solution, typically: Salient pole type synchronous motors are applied for large power and/or heavy torque applications, for example hot strip mill roughing and finishing stands • Excellent torque characteristics2015年12月1日 Two of these “things” are typically as important to that process as any other part, component or software suite — ie roller chain and synchronous belt technology From straightshot conveying systems to heavyduty power transmission, or from cleanroom type production to oil field rigs — belt and chain drives are integral to their reliable operationChains and Belts Play to Their Strengths Power TransmissionSynchronous belt and pulley engagement for precise transmission 2 No metaltometal contact, hence runs quietly and requires no lubrication 3 Enable compactification of bearings and motors as no need for high initial tension Structure 1Tooth Canvas (Nylon)Synchronous Belts BANDOB aa 11 sitspa SYNCHRONOUS BELT CHD A P N CHD 960 8M 50 “TOP DRIVE® HTD” belt Pitch length (mm) Pitch Width (mm) 3M Teeth no Pitch length [mm] 37 111 39 117 43 129 47 141 48 144 50 150 52 156 53 159 56 168 58 174 59 177 60 180 62 186 64 192 67 201 68 204 70 210 71 213 72 216 75 225 80 240 82 246 84 252 85 255 87 261 89 267 90 270 95 285 TOP DRIVEG HTD CHD DINAMICA

Asynchronous motors: Drive belt versus direct drive

2024年5月1日 Direct drive with synchronous motor A synchronous motor with direct drive has several advantages over an asynchronous motor It works even more efficiently and is considerably more lightweight for the same level of power In addition, it is available in various designs, which facilitates its integrationIntroduction CNC mill timing belt and pulley are mechanical components used in CNC milling machines The timing belt is a toothed belt made of reinforced rubber, which is used to transfer the rotational force from the motor to the C Mill Timing Belt and Pulley: Comprehensive Introduction The terms “timing belt” and “synchronous belt” are often used interchangeably to describe a class of toothed, positive drive belts But while the function of a timing belt is primarily synchronization, industrial synchronous belts have evolved into a power transmission system that rivals roller chain SynchronouS Belt DrIveS: DeSIgneDSynchronouS Belt DrIveS: DeSIgneD for roller chaIn applIcatIonS