HOME→People and ore grinding machines and people and ore grinding machines and people and ore grinding machines

People and ore grinding machines and people and ore grinding machines and people and ore grinding machines

Ore Grinding SpringerLink

2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the 2019年4月16日 Numerous authors come to the conclusion that the conventional grinding systems used in the ore industry are reaching their efficiency peak So why not thinking out of (PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, (PDF) A comprehensive review on the grinding process: Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the separation of the Ore Grinding Methods and Process of Ore Grinding

A review of intelligent ore sorting technology and equipment

2022年7月25日 Intelligent ore sorting equipment not only improves ore use and enhances the economic benefits of enterprises but also increases the ore grade and lessens the grinding 2017年1月1日 Research in grinding tries to enhance economic and ecological properties and performance to extend grinding applications in the overall process chain—on the one hand, in Recent developments in grinding machines ScienceDirectGrinding is typically performed with grinding machines, equipped with elastic grinding disks, which are either attached directly to the rotor engine axis or come as a flexible extension shaft Grinding Mill an overview ScienceDirect TopicsThe comprehensive offering provides reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operations With customer needs and Grinding Metso

.jpg)

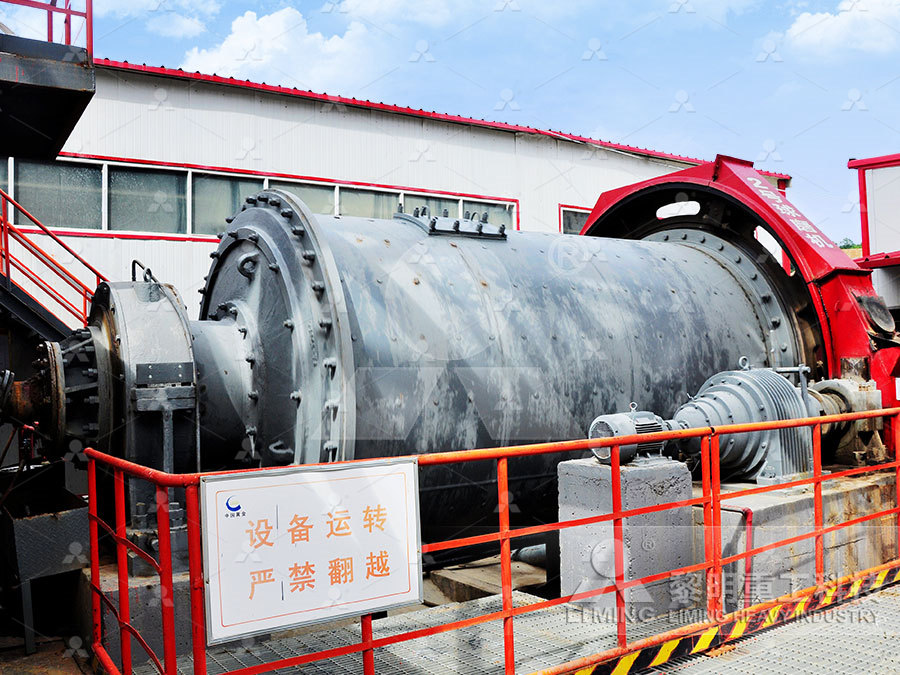

Grinding mills for mining and minerals processing Metso

Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills Grinding machines for grinding wheels are designed to hold bonded abrasives and provide greater rigidity or stiffness than equipment that is designed for flexible coated abrasives Profile, form, gear and other processes shape the grinding Grinders and Grinding Machines InformationIron ore is an important industrial source, is an iron oxide ore, a mineral aggregate containing iron elements or iron compounds that can be economically utilized, and there are many types of iron ore Among them, the iron smelting products mainly include Magnetite, siderite, and hematite and so on Iron exists in nature as a compound, and iron ore can be gradually selected after Iron ore grinding mill Grinding plants for Iron OreMedia Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using 82: Mining and Ore Processing Geosciences LibreTexts

.jpg)

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023年5月27日 Insufficient grinding causes a loss in gold recovery Overgrinding results in higher unit cost in energy, grinding media, and reagent consumption Commonly used gold mills are ball mills and wet pan mills Ball Mill Yes, I am interested! Ball milling methods include "dry" and "wet" grinding Gold ore grinding plants often apply wet grinding2023年10月27日 At present, most of the world's titanium resources come from titanium rock ore, so this article focuses on titanium ore processing An efficient titanium ore processing plant An effective titanium ore processing plant mainly includes a comminuting unit (crushing and grinding), a beneficiation unit, and auxiliary equipmentHow to Process Titanium Ore (A Stepbystep Guide) Fote MachinerySafety while grinding work: Most injuries reported during grinding work are cuts to fingers and eye injuries from flying objects such as metal parts or sparksGrinding is the process of finishing the workpiece to remove sharp edges or maintain surface quality or maintain shape and dimensionsGrinding Safety Dos and Don’ts EHS HSE and Fire protection This mechanism breaks down large chunks of ore into smaller, manageable sizes, facilitating subsequent grinding and processing 2 **Grinding Efficiency:** Ore milling machines boast innovative grinding systems that enable efficient reduction of ore particles to desired sizesUnveiling the Efficiency and Significance of Ore Milling Machines

.jpg)

Iron ore grinding plant for ores milling process SBM

Main machines in ore grinding process are Iron ore mill equipment The most common Iron ore mills in mining are ball mill, raymond mill and high pressure suspension mill The selection of is according to customers’ requirements and the nature of the minerals Ore grinding can be divided into grinding with media and withoutStedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction with our mineral crushing machines industrial ore slag crushersIndustrial Ore, Mineral, Slag Crusher Stedman MachineHighend Mining Machinery Manufacturer! FTM Machinery Henan Fote Heavy Machinery Co, Ltd (FTM Machinery) is a large mining machinery manufacturer and exporter, located in Zhengzhou, Henan, China Our main product Fote Machinery Professional Mining Machinery 2015年4月9日 Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grinding Milling, sometimes also known Grinding Mills and Their Types IspatGuru

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 These mills utilize the ore itself as the grinding media, reducing the need for additional grinding media AG/SAG mills are typically used for coarse grinding, where large pieces of ore are efficiently broken down The grinding Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powders They are versatile tools that offer efficient and reliable grinding and mixing capabilitiesBall Mill Grinding Machines: Working Principle, Types, Parts 2023年4月23日 Comminution includes the blasting, crushing, and grinding of ore to liberate valuable mineral particles It consumes most of the energy used in mineral processing plants with grinding using up to (PDF) Grinding Media in Ball MillsA Review ResearchGate2017年6月2日 Autogenous grinding (AG) and semiautogenous grinding (SAG) mills use the material to be ground as the grinding media Autogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates Semiautogenous mills are basically the same autogenous mills, but with the addition of balls, similar to those in ball millsHow it Works: Crushers, Grinding Mills and Pulverizers

Recent developments in grinding machines ScienceDirect

2017年1月1日 This imposes strong requirements on grindingmachine technology and on the understanding of this finalising process While grinding has unique capabilities it is nevertheless in competition with other machining processes The evolution of grinding machines is driven by process requirements like accuracy, MRR, and subsurface integrityUsed Grinding Machines Find what you're looking for out of 179 secondhand machines starting from €1 in DE,CZ,FR,PT,ES,HU,AT,CH,BG,IT,NL,PL,RO! Precision rollers can only be created using a roll grinding machine These machines are produced by HARKOV, HERKULES, KELLENBERGER, SCHAUDT, WALDRICH and ZIMMERMANNUsed Grinding Machines Industrial Metal Grinders CNC2024年1月11日 Innovations in grinding wheel materials, such as using cubic boron nitride in CBN grinding wheels, enhance the machine’s ability to grind hard materials while maintaining a flat edge and desired surface quality The development of more efficient and precise grinding machines continues to address the evolving challenges in surface grindingSurface Grinding: A Guide to the Process and Precision okdor2024年7月17日 FTM MachineryGreen and Intelligent Mining Machinery Manufacturing and Export Base Based on high quality and perfect aftersales service, our products have been exported to more than 120 countries and regions FTM Machinery has become the first choice for over 2,000,000 customers Our customer service team is here to help you 24/7Types of Crushers: Choosing the Right One for Each Stage

Building machines that learn and think like people

2016年11月24日 Recent progress in artificial intelligence has renewed interest in building systems that learn and think like people Many advances have come from using deep neural networks trained endtoend in tasks such as object 2016年4月1日 Recent progress in artificial intelligence (AI) has renewed interest in building systems that learn and think like people Many advances have come from using deep neural networks trained endto Building Machines That Learn and Think Like People 2023年9月21日 In Kenya, as in many other countries, the grinding of metal ores is a crucial step in ore processing, particularly in the mining and mineral processing industry Grinding mills are machines used Kenya metal ore grinding mills machine2023年9月26日 Iron ore beneficiation is a crucial process in the extraction and refinement of iron ore resources Among the various stages involved in this process, grinding equipment holds a pivotal positionWhat Role does the Grinding Machine Play in Iron Beneficiation

.jpg)

Ore mill, Ore grinding mill All industrial manufacturers

Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchases2017年3月4日 Ball mills are used for wet grinding iron ore, g old/copper ore, nickel ore and other ores, as wel l as lime/limestone for flue gas desulphurisat ion systems, coal and other raw materials Rod mill :SIZE REDUCTION BY GRINDING METHODS ResearchGate2023年4月25日 12 Coppernickel sulfide ore grinding stage Adopt a twostage closedcircuit grinding process ① Use a gridtype ball mill for rough grinding And the grinding particle size range is 02~03mm ② Use an overflowtype ball mill for fine grinding And the grinding particle size is less than 5~10μm2 Types of Nickel Ore: Processing Methods and EquipmentGold Processing Plant Ball Mill Ore Grinding Machine, it is generally used as the grinding machine for metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, as well as limestone, barite, People who viewed this also viewed Gold Processing Plant Ball Mill Ore Grinding Machine

.jpg)

Ore Crushing SpringerLink

2023年7月22日 Ore crushing is the process of breaking, splitting, extrusion, impacting, and grinding of large solid ore with external force to reduce the particle size of large ore materials Ore crushing provides suitable particle size of material for subsequent ore grinding, beneficiation or smelting, which is the preparation process before beneficiation or smelting2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 Ore Pretreatment Methods for Grinding: Journey and ProspectsWorking Principle of Grinding Machine Grinding machines employ a rotating abrasive wheel that removes material from the workpiece through abrasion The grinding wheel is composed of abrasive particles bonded together, which vary Grinding Machine: Learn its working, types, and 2022年10月4日 21 Energy Rock drilling, blasting, and comminution (crushing and grinding) consume a vast amount of energy in hard rock mines As mentioned in Sect 1, statistics from hard rock mines indicates that drilling and blasting consumes 2% and comminution does 53% of the total energy input in the whole production chain from mining to mineral processing (Spathis Reduction of Fragment Size from Mining to Mineral Processing: A

.jpg)

Iron Ore Crushing and Grinding Machines liajones 博客园

2012年2月6日 Vibrating feeder is used to feed iron ore evenly to iron ore crushing and grinding machine vibrating screen is the screening machine It screens out the appropriate iron ore particles, these particles enter into ball mill for grinding Grinding mills used in iron ore grinding Ball mill is used as iron ore grinding millJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2024年1月27日 The most expensive type of grinding machine is typically a CNC (Computer Numerical Control) grinding machine These advanced machines offer unparalleled precision and control, integrating sophisticated software and automatic tool changers, making them essential for complex and highprecision tasks What Is the Cheapest Type of Grinding Machine?What is a Grinding Machine: Definition, Types, Components2022年10月13日 Grinding plays an important role in mining, construction, metallurgy, chemical, coal and other basic industries In terms of beneficiation, grinding is the most energy consuming operation So, reasonable grinding conditions according to the properties of ores is the key to obtain good grinding results and reduce energy consumption and resource waste In this Research on Grinding Law and Grinding Parameters Optimization

.jpg)

Machining 101: What is Grinding? Modern Machine Shop

2021年7月3日 Creep feed grinding is a slow, onepass operation that makes a deep cut of up to one inch in steel materials at low table speeds between 05 and 1 ipm It is not suitable for conventional grinding machines, but for those which are compatible with it, it offers high productivity and cost effectiveness2012年2月6日 Vibrating feeder is used to feed iron ore evenly to iron ore crushing and grinding machine vibrating screen is the screening machine It screens out the appropriate iron ore particles, these particles enter into ball mill for grinding Grinding mills used in iron ore grinding Ball mill is used as iron ore grinding millIron Ore Crushing and Grinding Machines CSDN博客Ore Grinding Wu Caibin1 and Xu Kuangdi2 1School of Resources and Environmental Engineering, Jiangxi University of Science and Technology, Ganzhou, China 2Chinese Academy of Engineering, Beijing, China Ore grinding is a process to Ore Grinding Methods and Process of Ore Grinding2024年2月26日 Oxidised pellets have become an indispensable highquality charge for blast furnaces Nevertheless, highquality pellet feeds are becoming scarcer and scarcer To broaden the range of sources of pellet feeds and reduce the production cost of pellets, more steel mills are predicted to use coarse iron ore fines with a relatively low iron grade and low impurities for the Grinding of Australian and Brazilian Iron Ore Fines for Low