Powder processing technology of quicklime marble

.jpg)

Decarbonising the lime industry: Stateoftheart ScienceDirect

2022年10月1日 In this review, the current state of the lime industry and its processing configurations is visualised This is followed by a detailed description of the current status of 2021年10月4日 In semidry processes, lime is supplied as aqueous solution or suspension, ie as milk of lime or as a lime slurry solution During the reaction Natural and enhanced carbonation of lime in its By using quicklime, unsuitable finegrained (cohesive) soils or mixedgrained soils can be processed immediately to a condition that allows a smooth and timely production flow of Soil improvement with quicklime – longtime behaviour and 2024年9月11日 To address these issues, this study introduces a novel approach involving the chemically converted waste marble powder (CCWMP) treatment of soil In this process, Effective Utilization of Waste Marble Powder by Chemical

.jpg)

A comparative study of the physicochemical properties of Mg

2014年10月14日 We studied the physicochemical properties of quicklimes derived from typical carbonate rocks, focusing on variations in chemical composition and their effects on reactivity2018年11月12日 This work is concerning to production of quicklime (CaO) from thermal decomposition of the calcite limestone (CaCO3) using analytical and instrumental techniques (TGA and MS) to evaluate kinetic(PDF) Characterization of quicklime as raw material to 2020年5月20日 There is considerable change for soil B with marble powder, a decrease in friction angle and an increase in cohesion The results show that marble powder could be used Enhancement of the Geotechnical Properties of Soils Using Marble Hydrated lime is produced by adding water to quicklime in a process called 'hydration' or 'slaking', where the calcium oxide and water combine chemically to form calcium hydroxide Limestone Lime An Introduction

Quicklime application instantly increases soil aggregate stability**

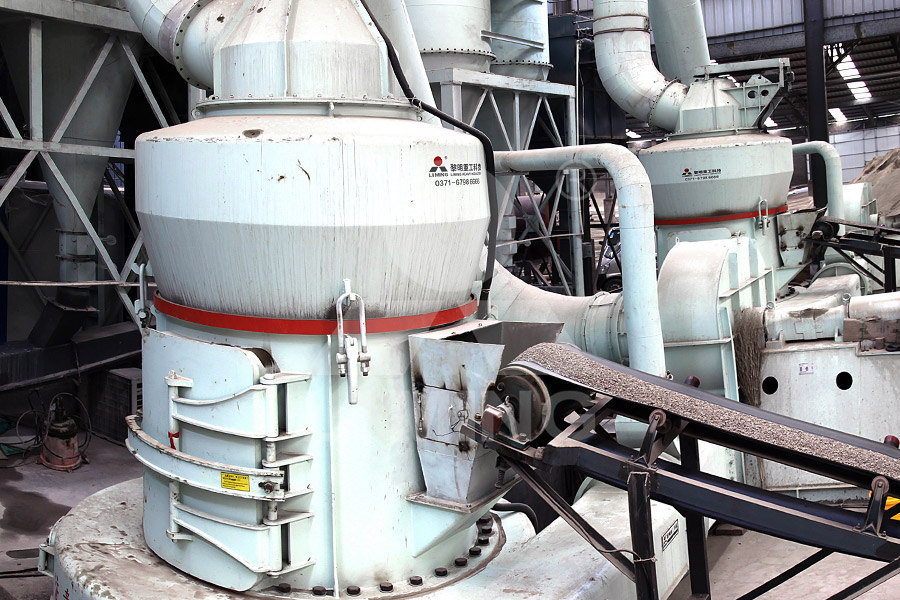

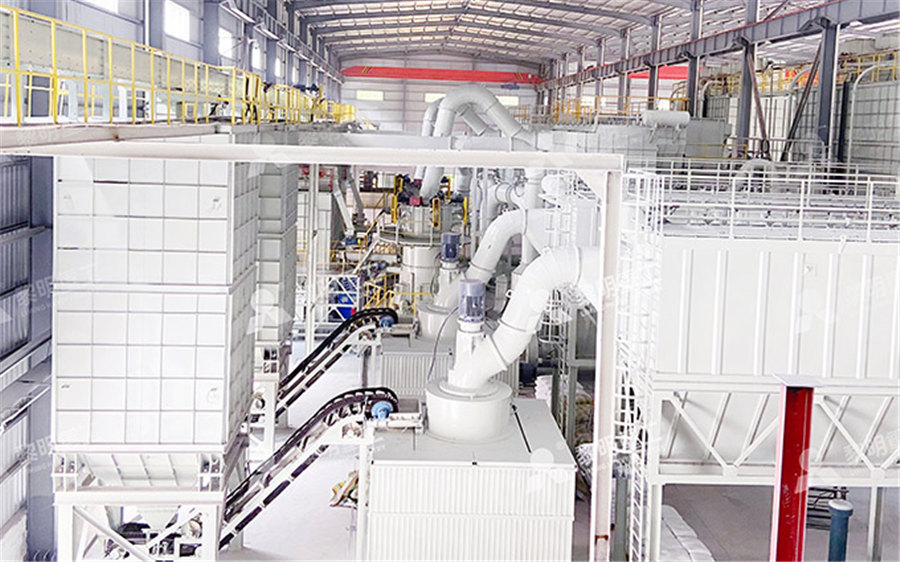

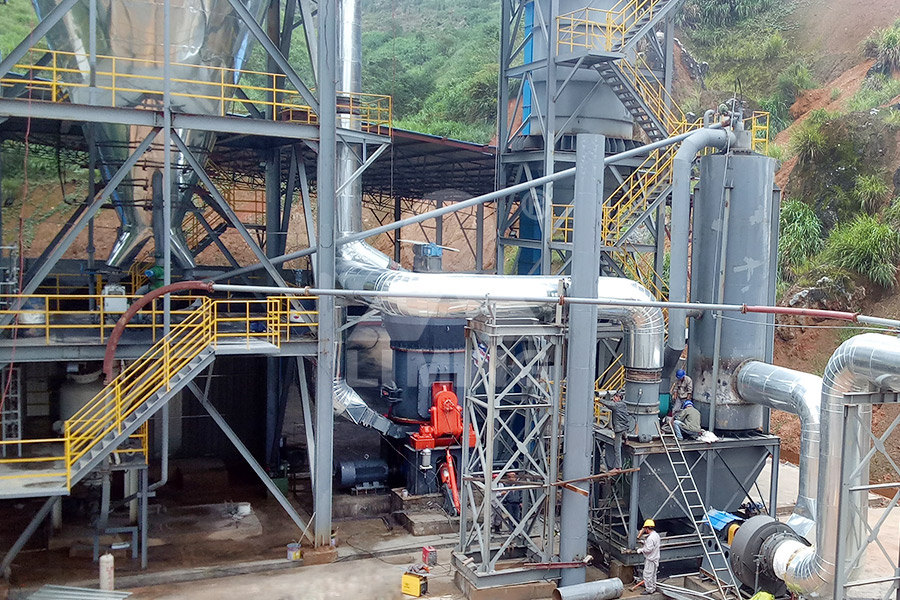

ble amelioration stra tegy is the application of (structural) lime In this study, we tested the effect of two different liming materials, ie limestone (CaCO and quicklime (CaO), on soil aggregate Quicklime milling is generally divided into four types: coarse powder processing (03mm), fine powder processing (20 mesh400 mesh), ultrafine powder processing (400 mesh1250 mesh) quicklime processing plant, quicklime grinding machine, quicklime 2024年8月23日 Using marble powder and rice husk ash as soil additives can improve soil expansion rate and expansion pressure 8 Used in the production of composite materials A certain amount of marble waste can be mixed with ceramics or polymers to study the production of composite materials Choudhary et al used marble waste powder to fill glass fiber10 ways to comprehensively utilize marble tailings and waste It can also be grounded to a powder to be used as a filler in concrete, asphalt and other materials, and for other processes that benefit from calcium The rest of the limestone or dolomite is calcinated in a lime burning plant and transformed QuickLime — ZEQL

EVALUATION OF MARBLE SLURRY WASTE FOR PREPARATION OF COMMERCIAL GRADE

2015年1月1日 The slurry, composed of water and marble powder, is a matter of fundamental worry in marble processing Its surface release contaminates the soil, water, and air, an essential aspect of the Quicklime, also known as burnt lime, is a chemical compound called Calcium oxide (CaO) It is a white or pale gray, odorless, crystalline solid or granular powder having a melting point of 2572 °C and a boiling point of 2850 °C This compound is widely The Amazing Uses of Quicklime You Probably Didn’t KnowConversion of Waste Marble Powder into a Binding Material Mohammad Adeel Khan a*, Bazid Khan a, Khan Shahzada b, Sajjad Wali Khan b, which varies with the processing technology [6]Conversion of Waste Marble Powder into a Binding Material2016年5月7日 With the recent increase in demand for highstrength concrete, higher cement content is utilized, which has increased the need for cement The cement industry is one of the most energyconsuming (PDF) Marble Powder’s Effect on Permeability and Mechanical

(PDF) Investigating the feasibility of producing sustainable and

2023年9月1日 Newly developed marblebased cement was prepared by burning waste marble powder and clay The marble cement was then blended separately with varying amounts of y ash (20, 30, and 40% by massSBM ultrafine powder technology co,ltd Is China's excellent ore mill supplier Stone Dust Making Machine For 325 Mesh Quicklime Grinding Plant Successful Test of HGM Ultrafine Grinding Mill for French Customer’s Eggshell Processing NeedsSBM Ultrafine Powder Technology Industrial Grinding Mill, 2016年11月1日 Characteristics of the marble processing powder waste at Shaq ElThoaban industrial area, Egypt, and its suitability for cement manufactureCharacteristics of the marble processing powder waste at Shaq El 2020年8月26日 The key objective of this study was to develop marblebased geopolymer concrete and examine the viability of its application as a sustainable structural material for the construction industry The results of the research demonstrated that marblebased geopolymer concrete can be developed, and its physical/mechanical properties were shown to have a very Sustainable Development and Performance Evaluation of Marble

7TOCS.jpg)

(PDF) Effects of marble powder on the properties of the air

2018年2月1日 The objective of the research is to investigate the effect of the partial replacement of ordinary Portland cement (PC) with waste marble powder (MP) on the physical and mechanical properties of 2001年4月1日 This study has examined the effects of limestone characteristics (microstructure and texture) and calcination temperature on the reactivity of the produced quicklime(PDF) The Effects of Limestone Characteristics and 2023年10月11日 How do you determine whether to use hydrated lime or quicklime? If dry, the process feed rate determines the choice between using hydrated or quicklime Just remember that quicklime is more “reactive” than hydrated lime However, in some processes, hydrated lime is not suitable even if we inject it dry, and vice versa with quicklimeQuick Lime Preparation, Properties and Uses Hebei Yayang 2023年9月30日 Journal of Technology and Innovation in the Marble Industry, 15(3), 7892 Technological modernization and environmental sustainability in marble processing Jan 2020(PDF) Marble workshop of the future: Technology, innovation,

.jpg)

Investigation on Strength Properties of Concrete with Partial

11 Marble Powder Marble has been commonly used as a building material since the ancient time The industry’s disposal of the marble powder material, consisting of very fine powder, today constitutes one of the environmental problems around the world Marble blocks are cut into smaller blocks in order to give them the desired smooth shapePowder Technology From landslides to concrete and from avalanches to chocolate Prof P Bowen (EPFL), Dr P Derlet (PSI) 1 This course discusses and presents the science technology of important powder processing steps like compaction, dispersion, sintering and novel densification technologiesPowder Technology EPFLFrom the moment it is burnt the material starts to degrade by ‘airslaking’ Combining Quicklime (CaO) and water (H20) produces Calcium Hydroxide (Ca(OH)2 slaked lime and heat There are three main ways of slaking the Quicklime: in an excess of water to produce a putty; in a shortfall of water to produce a powder hydrated or bag lime;Lime and its Production2019年4月11日 The chemical makeup of MP accelerates the flow of water and hydration processes, which improves fluidity In all SCC mixtures, Choudhary et al [57] determined that the slump flow improved with (PDF) UTILIZATION OF WASTE MARBLE POWDER AND SILICA

.jpg)

(PDF) Influence of limestone waste as partial ResearchGate

2012年12月1日 Besides, proportions of 5%, 10% and 15% marble powder were practiced in the concrete mixes The effects of limestone waste as fine aggregate on several fresh and hardened properties of the 2020年5月18日 Belgiumbased lime, dolime, and minerals firm Lhoist Group recently obtained a permit approval from the Texas Commission on Environmental Quality to build a new vertical lime kiln at an existing dolomatic quicklime facility in Marble Falls, TX Plans for the addition of the new asset at the Lhoist North America site stem from increased demand for highpurity dolomitic Lhoist to Expand Lime Production in US with New Kiln Powder2022年12月28日 This study looked into the use of marble dust powder in concrete, with varied percentages of marble dust (0%, 5%, 10%, 15% 20%) replaced by sharp sand in M20 grade concrete mixes, while the Strength Properties of Concrete Using Marble Dust This processing enables the structuring of hollow particles and a wide range of specific gravity (particle density) adjustments by modifying the surface texture d) Resin Coating Technology Particles can be coated with different types of organic resin to provide flow properties, electrical characteristics, and other functionsPowder Processing Powdertech Co,Ltd

limestone, quicklime and slaked lime chemguide

Limestone, quicklime and slaked lime This page looks at the origin and uses of limestone, and its conversion into quicklime, CaO, and slaked lime, Ca(OH) 2 Limestone and marble Chemically, limestone is calcium carbonate It is a sedimentary rock formed from the shells and skeletons of marine creatures which fell to the bottom of ancient seas2015年8月1日 In India, about 6 million tons of waste from the marble industry is released during the cutting, polishing, processing and grinding of marble Marble Dust Powder (MDP) is an emerging composite "Partial Replacement of Cement with Marble Dust Powder"2024年4月16日 Store your quicklime After you’ve let your quicklime cool, you need to prepare to store it Storing it properly is extremely important as quicklime is a potentially dangerous substance There are a number of things you should consider when storing quicklime Store it in a dry heavyplastic or metal container Seal your container wellHow to Make Quicklime: 10 Steps (with Pictures) wikiHow2024年6月18日 Marble waste powder is waste produced from marble industry Adding Marble Waste Powder (MWP) gives a phenomenal strength to concrete In this paper, the flow properties of SCC are studied with A Review on the Effect of Marble Powder on Properties of Self

A TECHNICAL STUDY ON QUARRYING AND PROCESSING OF MARBLE

2013年2月1日 Marble waste is generally a high polluting waste due to both its high alkaline nature, and its manufacturing processing techniques, which impose a health threat to the surrounding2013年12月1日 [5] Performed various tests including compaction test, plasticity test and strength tests by adding different percentages of stone powder on the soil that was basically gravelly in nature and he Stabilization of Clayey Soil with Lime and Waste Stone Powder2022年9月5日 Waste granite and marble powder were provided from a stone processing factory in Macheng, Hubei province, China The chemical composition of waste granite and marble powder was determined by Xray fluorescence (XRF) and the main components are given in Table 1MgO with 9999% purity was bought from Sinopharm Chemical Reagent Co, Ltd, Recycling of granite powder and waste marble produced from 2019年12月1日 According to Mauna Loa observatory data, over the past decades, there was an increasing trend on the CO 2 emissions reaching about 40867 ppm on September 17, 2019 (Scripps Institution of Oceanography, 2019)It is predicted that if there are no more efforts to reduce the emissions of CO 2, the temperature will increase up to 5 °C by at the end of this Recycling wastederived marble powder for CO2 capture

.jpg)

Quicklime Preparation, Properties, and Applications with FAQs

It is unadvisable to inhale quicklime dust since it can cause irritation to the respiratory tract Difference Between Quicklime and Hydrated Lime The key differences between quicklime and hydrated lime lie in their reactivities and their chemical compositions Hydrated lime and quicklime are both chemical compounds of calciumRead the latest articles of Powder Technology at ScienceDirect, Elsevier’s leading platform of peerreviewed scholarly literature Skip to main content ADVERTISEMENT Journals Books; Help Particle characterization, particle mechanics, powder Powder Technology Journal ScienceDirect by Elsevier2020年5月20日 As quality soils become scarce and their location is more difficult and expensive, it becomes increasingly necessary to improve soil quality through soil stabilization The benefits of energy saving and resource conservation, effective recycling of all solid wastes (fly ash, slag, lime, marble dust, etc) has become a global concern that requires research and development Enhancement of the Geotechnical Properties of Soils Using Marble 2019年7月16日 The research focuses on the effect of using waste marble powder and quarry dust as partial sand replacement materials on concrete properties Massive exploitation of the nonrenewable natural Utilization of waste quarry dust and marble powder in concrete

.jpg)

Flow chart of marble production Download Scientific Diagram

During slab cutting in marble processing plants, about 2040% of the marble block is lost as marble dust (MD) in the form of sludge depending mainly on the thickness of the cutting saw 1,2 2023年6月25日 So far, unlike metal injection molding (MIM), conventional powder metallurgy technology (PM) has not been regarded as a method for producing structural elements from 174 PH powders, due to the Powder Metallurgy: Materials and Processing ResearchGate2022年2月1日 Decomposing limestone (CaCO3) into quicklime (burnt limestone; CaO) releases significant CO2 emissions, both from the combustion of fuel needed to heat the kiln to temperatures over 1,000°C, and by the release of CO2 from the reaction itself (CaCO3 → CaO + CO2) Because quicklime is a key ingredient in the production of cement, as well as being Reducing the carbon footprint of quicklime production2023年10月19日 According to the Ministry of Industry, Energy, and Mines of the Government of India, India is the world's thirdlargest marble producer Approximately 1200 marble processing units, 3600 marble quarries, and 400 marble block cutters are present in the Indian state of Rajasthan alone, which accounts for nearly 95% of marble production in IndiaExploring the potential of waste marble powder as a sustainable

Quick Lime Avani Group of Industries

Other Names: Burnt Lime, Lime, AntiMoisture Powder, Calcium Oxide: Chemical Composition: Calcium Oxide [CaO] Hardness [On Mohs Scale of 1 – 10] 35 – 40quicklime which is then turned and mixed with a rake as more water is added In large quantities, hydration is normally automated and done in large hydrators where measured quantities of water and quicklime are fed in and mechanically agitated During hydration, the quicklime lumps will disintegrate to a fine powder For high qualityLime An Introduction