hydraulic industrial roller Mill related knowledge

.jpg)

Optimization of working parameters of highpressure roller mill

2024年11月15日 In order to improve the crushing efficiency of highpressure roller mill and reduce energy consumption, the optimal parameter combination of highpressure roller mill is The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design Describing the key VERTICAL ROLLER MILLS A holistic VRM approach2010年12月19日 The performance of hydraulic system plays an important role in roller mill The hydraulic system was regarded as a vibration system with a single degreeoffreedom and the The study on hydraulic system of roller mill ResearchGateAbstract: The performance of hydraulic system plays an important role in roller mill The hydraulic system was regarded as a vibration system with a single degreeoffreedom and the The study on hydraulic system of roller mill IEEE Xplore

Dynamics and stability analysis of rolling mill system during

establish a nonlinear dynamic model of the rolling mill during variable gauge rolling process The model takes into account the dynamic rolling force and the nonlinear features of the rolling mill 2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) Analysis of vertical roller mill performance with changes in material 2004年9月1日 Hydraulic actuator systems are especially used in steel rolling mills due to their relative small extension compared to the available forces Possible applications are, eg, the Energy Based Control of Hydraulic Actuators in Steel Rolling MillsRoller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and Roller Mill Springer

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants 2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the (PDF) Performance Evaluation of Vertical Roller Mill 2017年1月17日 Online running condition monitoring of the vertical roller mill (VRM) is significant to assess the equipment performance degradation and reliabilityReliability assessment of the vertical roller mill based on ARIMA A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, Energysaving and Efficient Vertical Roller Mill Fote

Automatic Control System of Hydraulic Tension Pilot Warm Rolling Mill

2021年3月1日 Low temperature deformation behavior of warmrolled Fe28Al2Ti alloy was investigated by tensile tests This alloy shows superplasticity in 600700°C under strain rates of 125×104s1 and 25 2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC toolsFully Hydraulic Three Roller Mill; TRICHILLED ROLLER MILL MODEL : HMA1625 TriChilled Type Three Roller Mill incorporate all of the newest design features and advanced technologies on production size ThreeRoller Mill Wide range of applications for low to high viscosity massesThree Roll Mill HWA MAW MACHINE INDUSTRIAL CO, LTDhydraulic roller presses Combining the latest generation in bearing monitoring technology, SPM HD®, with sophisticated vibration analysis provides a complete, reliable and costefficient solution for hydraulic roller press monitoring The roller press is an important part of cement mill configuration and is typically rated highly criticalROLLER PRESS SPM Instrument

.jpg)

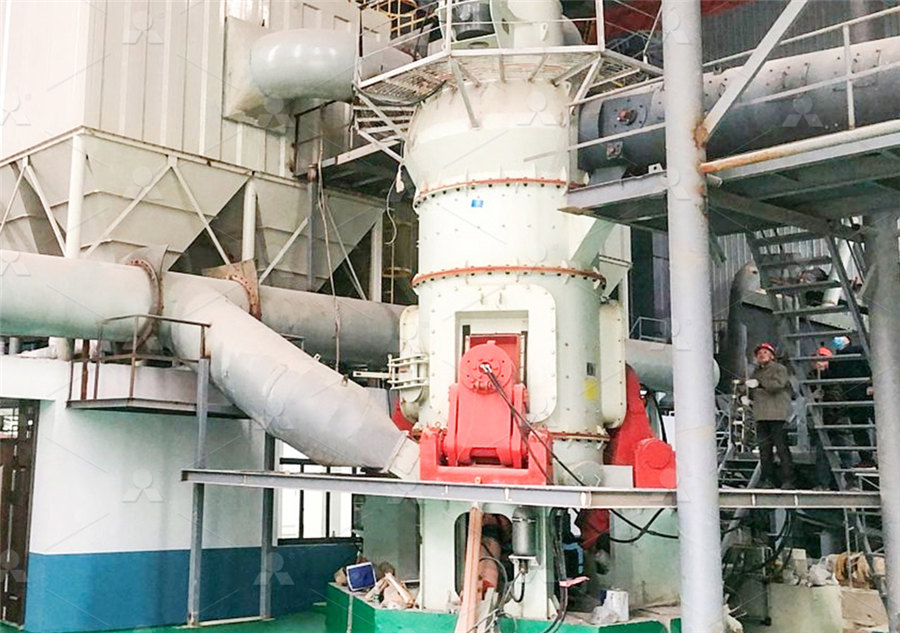

Polysius Roller Mills For grinding

uses the testroller mill Atrol (throughput approx 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills Roller mill for granulated blast furnace slag grinding in China Roller mill for cement raw material grinding in China Roller mill for cement clinker grinding in Mexico Coal grinding plant in PolandHydraulic Roller Press comminution subjects the feed material to a very high pressure between its counter rotating rollers over a short time roller mill ATOX® COAL vertical for coal grinding compact mill with rods VXPmill vertical for ore ultrafine See all FLSmidth DorrOliver Eimco products Relatedes Industrial press Hydraulic press HRP FLSmidth DorrOliver Eimco compression / roller2010年12月19日 The performance of hydraulic system plays an important role in roller mill The hydraulic system was regarded as a vibration system with a single degreeoffreedom and the differential equation of The study on hydraulic system of roller mill ResearchGateOur team at RMS is passionate about their business designing and maintaining industrial roller mills and related equipment We value and respect them as professionals and want them to feel empowered to use their expertise and About Our Company RMS RollerGrinder

.jpg)

Industrial Hydraulics Bosch Rexroth India

The future of Hydraulics: Connected Hydraulics will leverage the power and intelligence of Bosch Rexroth’s advanced hydraulics technology to break through limits and set new benchmarks for performance, functionality and lifetimeThe total vertical load acting on = 6645KN The total horizontal load acting on = 1973 KN the roller the roller The load of crushing is acting on the surface of roller so, it will be shown as uniformly distributed load on the loading Static Structural Analysis of Crushing Rollers of Three Flake thickness adjustment during operation increases plant uptime Manual and hydraulic adjustment of flake thickness can be roller mill POLYfloc™ BCFA horizontal food grain fluidized bed dryer OLHA continuous air filter MV series highpressure industrial dust See all Bühler Group products Relatedes Bühler mill; Bühler Roller mill OLFB Bühler Group horizontal / food / for the 2020年8月12日 PDF This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, Find, read and cite all the research you An investigation of performance characteristics and energetic

Vertical roller mill for cement and slag grinding

2024年5月10日 In addition, the vertical roller mill can achieve the comprehensive utilization of industrial waste such as slag, reduce dependence on natural resources, and achieve environmental sustainability Easy maintenance: The grinding parts of the vertical roller mill have a long normal service life, and the grinding roller can be lifted and lowered by itself to start mobile hydraulics Applications in industrial hydraulics The term industrial hydraulics comprises applications in which hydraulic components are used in fixed installations Application examples include machine tools, plastics processing machines and presses in the rolling mill industry Plastic injection molding machine Tower BridgeCompact knowledge Hydraulics – Basic principles Bosch 2019年10月14日 Market Overview: The global vertical roller mill market is projected to grow at a CAGR of 45% from 2017 to 2030 The growth of the global vertical roller mill market can be attributed to the increasing demand for cement and minerals in developing countries and the growing awareness of energyefficient technologies among consumersVertical Roller Mill Market Report Global Forecast From2021年1月6日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Review on vertical roller mill in cement industry its

Design and Realization Of Roller Mill Control System

438 QianHong Wang et al / Physics Procedia 33 ( 2012 ) 437 – 443 Among the rest, stable operation of the vertical mill vertical means that to ensure the material layer thickness of the disc 2022年5月31日 Mineral crushing is the main source of energy consumption in mineral processing According to statistics, this consumption accounts for about 35–50% of the total cost of the mine (Curry et al, 2014), or even higherIt may also account for 18% of the global electrical energy consumption (NapierMunn, 2015)More efficient crushing equipment needs to be Analysis of vertical roller mill performance with changes in 2024年8月5日 How To Choose Raymond Roller Mill? Raymond grinding mill, singlecylinder hydraulic cone crushers, PCX highfine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level Share Wulong industrial Park,Zhengzhou,China :[ protected] Tel:+86371 Whatsapp: +86 How To Choose Raymond Roller Mill? Baichy Heavy Industry2023年10月3日 Rocker Arms: The function of the rocker arm device of the cement vertical roller mill is to transmit the pressure provided by the hydraulic cylinder to the grinding roller, so that it can be transformed into the grinding force act on the material bed The rocker arm device is mainly composed of upper rocker arm, lower rocker arm, rocker arm shaft, bearing and What is a vertical roller mill (VRM)? A Comprehensive Guide to

.png)

MILL DESIGN MILL OPERATION

NORMAL MILL PRACTICES Not to monitor lift of top roller It is assumed that top roller lifts only that value considered during mill setting calculations Normally actual lift of top roller during operation is higher than considered in mill setting calculation Higher thickness of cane/bagasse blanket passes through mills due to excessive lift of top rollerSmaller mills can he alrcady found in mineral processing as well for grinding of phosphate, limestone, gypsum and other industrial minerais Design of the LOESCHE mill The range of fineness of the feed for t1otation or related processes is very well covered by the LOESCHE mil! Residues of 1 5 % on 200 11mU Schaefer LOESCHE VERTICAL ROLLER MILLS FOR MINERAL Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceVertical roller mills FLSmidth CementRoller mill Metso Corporation Products Company; Products; horizontal Product applications waste, for tungsten carbide, concrete, for asphalt Other characteristics hydraulic, highpressure Output Max: 5,400 t/h (3,307 lb/s) Min: 60 t/h (37 lb/s) Description they can also refine softer materials like industrial mineralsHighpressure mill HRC™ Metso Corporation roller /

Current knowledge in hydraulic jumps and related phenomena

2009年3月1日 The nonbreaking undular hydraulic jump is discussed first Then the case of the hydraulic jump in translation is considered: ie, positive surges and tidal bores The last section discusses the air bubble entrainment in hydraulic jumps with roller, its physical modelling, the dynamic similarities and scale effectsTwo roller mills consist of only two rollers ie top and bottom roller100% of hydraulic load is available for compression at bottom roller Hydraulic load required is 70% of same size conventional 3roller mill which is not shared and directly transferred to the bottom roller 2 Roller has better drainage because of its Keywords Three Roller Mill, Proe, ANSYS Workbench, Design and Analysis of Hydraulic Jack for Sugar Mill SettingAWM Table Roller Mill The product is subjected to compressive stress between the grinding table and the grinding rollers The specific grinding force (contact force divided by the crosssectional area of the grinding roller) is in the range between approx 05 and 1 N/mm², whereby the effective pressures in the material bed are naturally much higherAWM Table Roller Mill Hosokawa Micron Ltd2024年5月22日 Roller mill production line MTW175 Grinding Mill Machine News / Product Knowledge / Roller mill production line MTW175 Grinding Mill Machine Factory Add:Wulong industrial Park,Zhengzhou,China :[ protected] Roller mill production line MTW175 Grinding Mill Machine

.jpg)

Conventional Roller mill Hydraulic load details

Download scientific diagram Conventional Roller mill Hydraulic load details from publication: Effect of manganese, silicon and chromium additions on microstructure and wear characteristics of This article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and ecofriendly features Understanding Vertical Roller Mill Technology Vertical roller mill (VRM) is a Application of Vertical Roller Mill in Cement ProductionSYP – a threeroll mill designed for universal applications and for meeting the most stringent quality standards Convenient, easy operation, handy design and easy to clean Versatile machine for low to high viscosity masses, eg all types of printing inks, artists’ colours, industrial and decorative paints, toners, coating masses, cacao chocolate paste etc Due to the wide Horizontal Hydraulic Three Roll Mill,triple roller mill Hydraulic system vertical roller mill operation SlideShare The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sides of the grinding roller mill, to replace the inside parts or repairroller mill hydraulic system KOOKS

.jpg)

The QUADROPOL roller mill

ing rollers can be swung hydraulically out of the mill housing; the two roller units remaining in the mill then continue the grinding process The new mill system from Krupp Polysius thus fulfils the prerequisites for »online operation« in the cement factory with a practically uninterrupted flow of material from the mill to the kiln2014年4月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) The latest innovative technology for vertical roller mills 2015年1月6日 These rollers are fed by two pressure feeder rollers which take prepared cane from a vertical chute and may be assisted by an under feed roller at the exit from the chute The arrangement of rollers in three roller mill is as followsFig No 1 Three roller sugar mill [7] Three rollers are used named as top, feed discharge rollerStatic Structural Analysis of Crushing Rollers of Three Roller Sugar MillFlaking roller mill machine is used for oilseed crushing, extraction of vegetable oil, and widespread use of cereal flacking like chiwra, dal, and corn flakes Industrial Flaking Roller Mill Machine is simple and with robust construction and easy in operation and maintenance Advance Roller Mill Machine Sifter International developed and supplied a new generation flacking Flaking Roller Mill

The important role of vertical roller mills in the cement industry

GRMK vertical cement mill has the advantages of compact structure and small volume It mainly includes high efficiency separator, grinding rollers, grinding table, hydraulic loading device of grinding roller, hydraulic lubrication system, reducer, motor, and electrical components 1 Separator is an efficient and energysaving powder selection