Coal mill safety

Coal Mill Safety, Explosion and Fire Protection

At CoalMillSafety , we are dedicated to providing comprehensive consultancy services aimed at ensuring the utmost safety of your operation of solid fuel systems Our expertise in fire and explosion protection helps eliminate the Coal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed These mills, used to grind coal into a fine Ensuring Safety in Coal Mills – Best Practices and PrecautionsEnsuring the safe operation of coal mills is crucial for preventing accidents, maintaining plant efficiency, and safeguarding the health of workers This article explores the key aspects of Coal Mill Safety: A Critical Aspect of Power Plant Operations Coal Safety and health in coal mines This code of practice is intended for the use of all those, both in the public and in the private sectors, who have responsibility for safety and health in coal Safety and health in coal mines International Labour Organization

COAL MILL Land Instruments International

Safe coal handling practices are designed to ensure that the fuel remains intact throughout its journey from the mine until the point at which it is ignited in the boiler Risks of unwanted Coal grinding is a critical process in various industries, particularly in power generation and cement production However, the process involves significant safety risks due to the combustible nature of coal dust and the mechanical hazards posed by the operation of the mill Ensuring safety during coal grinding is essential to prevent accidents, exAspects of Coal Mill Safety Coal Mill Safety, Explosion and Fire Baghouse Safety by Design In discussion: Coal Mill Safety Optimisation of coal mill systems, with fire and explosion protection Protección contra incendios y explosiones en sistemas de molienda de carbón: ¿en qué punto nos Fire and explosion protection of coal grinding systemsIn this episode of the DustSafetyScience Podcast, we interview Vincent Grosskopf, founder of Coal Mill SafetyHe has over 40 years of experience in bulk material handling industries, 25 of which were spent in dust explosion DSS055: Coal Mill Safety In Cement Production

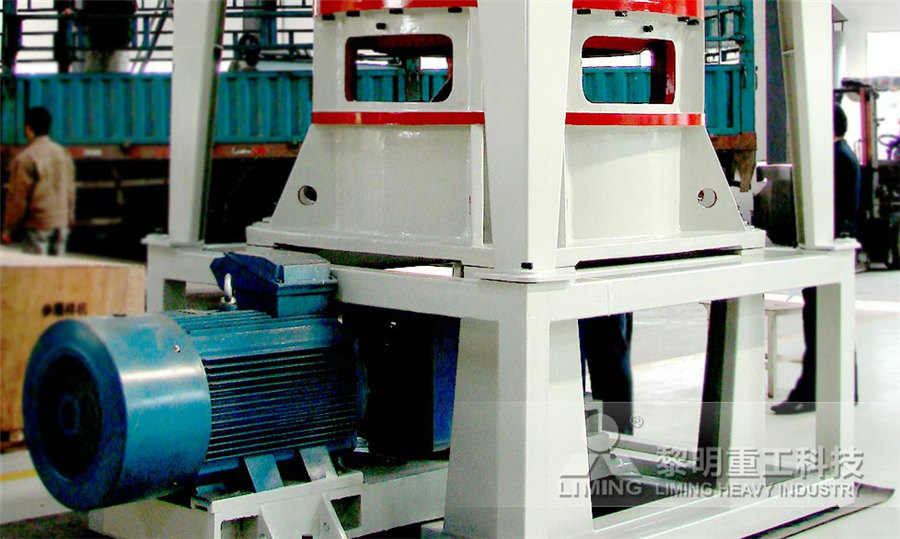

CFB石灰石脱硫剂制备96.jpg)

Contact Coal Mill Safety, Explosion and Fire Protection

Coal Mill Safety Pte Ltd 30 Cecil Street, #1906 Singapore info@coalmillsafety coalmillsafety Contact us Publications and InterviewsObserverBased and Regression ModelBased Detection of Emerging Faults in Coal Mills Peter Fogh Odgaard, Sten Bay Jørgensen, in Fault Detection, Supervision and Safety of Technical Processes 2006, 2007 2 THE COAL MILL The work presented in this paper, is based on a Babcock MPS 212 coal mill used at Elsam’s Nordjyllandsværktet Unit 3 However, the Coal Mill an overview ScienceDirect TopicsCoal grinding is a critical process in the production of energy and industrial products like cement It comes with inherent risks Ensuring the safety of workers and equipment in coal grinding operations is paramount This article outlines key safety measures and best practices to mitigate the hazards associated with coal grindingEnsuring Safety in Coal Grinding Operations Coal Mill Safety Coal Mill Safety In Cement Production Industries It may come as a surprise, but cement industry is not capturing nearly as many coal dust explosions that actually occur These incidents are often reported as boiler explosions or something else because there is no mention of the fuel involvedCoal Mill Safety In Cement Production Industries

.jpg)

Evaluation of Existing Systems for Safety Coal Mill Safety,

Why should you have the fire and explosion safety of your solid fuel or coal grinding systems evaluated? The answer is clear and compelling Most coal mill system designs have been in use for approximately three decades or more, and they were conceived in times when the full extent of fire and explosion risks wasn’t comprehensively addressed by standards and guidelinesGC: What led you to establish Coal Mill Safety? VG: I established Coal Mill Safety (CMS) as a consultancy after I ‘retired’ in 2011 If a cement producer wants to install a new coal grinding system, they can commission CMS to look at the supplier’s design and probe it from a safety angle If it has an existingIn discussion: Vincent Grosskopf, Coal Mill SafetyPublications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Industrial Explosion Protection Coal Mill Safety, Explosion and Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding The Peril of Coal Stockpiling Fires Coal Mill Safety, Explosion

.jpg)

Coal fire protection Coal Mill Safety, Explosion and Fire

Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Coal Mill Safety Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online This document discusses safety aspects of coal mill operations It outlines the general safety Coal Mill Safety PDF Coke (Fuel) ScribdCoal grinding is a critical process in various industries, particularly in power generation and cement production However, the process involves significant safety risks due to the combustible nature of coal dust and the mechanical hazards posed by grinding machinery Ensuring safety during coal grinding is essential to prevent accidents, explosionSafety Aspects of Coal Grinding Coal Mill Safety, Explosion and Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding The Hidden Peril of Coal Stockpiling Fires Coal Mill Safety

Dust Explosions: Understanding the Risks and Preventive Measures Coal

Dust explosions pose significant hazards in various industries, often leading to catastrophic consequences including loss of life, substantial property damage, and prolonged operational disruptions Understanding the mechanics behind dust explosions, the conditions under which they occur, and the measures necessary to prevent them is crucial for ensuring workplace safetyCoal dust explosions are among the severe hazards in industries using coal, posing significant risks to personnel and infrastructure These explosions occur when fine coal particles become airborne and come into contact with a heat source in an enclosed environment, leading to a rapid combustion event Given the catastrophic potential of such incidents, robust measures for coal Coal Dust Explosion Protection: Ensuring Safety in industries using If the mill is restarted without first removing the hot coal, an explosion can occur when particles are suspended and exposed to the inrushing combustion air Even in routine mill shutdowns, there is a danger that any residual coal left within the COAL HANDLING SAFETY Land Instruments InternationalCoal Mill Safety takes ICR readers through the design of the part of the coal and petcoke grinding system to highlight the design required to operate a safe fuel grinding system Fuel grinding systems in cement plants require adequate protection against the hazards originated by potential fires and dust explosionsSafe Fuel Grinding Coal Mill Safety, Explosion and Fire

Comparison: CO₂ inerting Coal Mill Safety, Explosion and Fire

CO₂ is an odorless, colourless, inert gas that suffocates fires primarily by diluting the oxygene concentration that supports combustion processes It is effective on a wide range of flammable and combustible materials in both surface and deepseated fires The cooling effect of the CO₂ is rather low in comparison to the extinguishing respectively suffocation effectPublications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Explosion Isolation Coal Mill Safety, Explosion and Fire Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Pulverized Fuel Silo Fires: Understanding the Risks and Prevention At CoalMillSafety , we are dedicated to providing comprehensive consultancy services aimed at ensuring the utmost safety of your operation of solid fuel systems Our expertise in fire and explosion protection helps eliminate the difference between per chance (not very likely!) correctly protected and correctly protected in realityGet our Recommendations Coal Mill Safety, Explosion and Fire

.jpg)

Optimisation of coal mill systems, with fire and explosion

Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding system is nothing more than a miragePublications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Explosion and Fire Protection Consultancy(ES) Safe Fuel Grinding Safety considerations when purchasing a standalone coal mill grinding system Защита систем помола угля от пожаров и взрывов, Часть I (RU) Защита систем помола угля от пожаров и взрывов, Часть II (RU) Coal Mill Safety In Cement Production Industries Ideas on Emergency Inerting Safe operation of coal grinding systems: Raw coal yard Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Coal Storage: Methods and Considerations Coal Mill Safety,

.jpg)

COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS PEC

COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS Most rotary kilns use solid fuels as the main heat source to produce cement clinker Coal mill hot air inlet temperatures never be more than 600should F and the outlet temperature should not In coal combustion, the efficiency and safety of the process are paramount Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing This article explores the components, advantages, and operational considerations of indirect firing cIndirect Firing Coal Grinding Systems: Enhancing Efficiency and Safety Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Understanding Pulverized Coal: Benefits, Risks, and Safety 54 kg/sec of coal The greatest risk of fire occurs when the mill is shut down under load, as this leaves a large amount of pulverised fuel inside a hot mill The large surface area of the pulverised coal, as well as the high temperature inside the mill, leads to rapid oxidation of the coal This results in further heat buildup and the COAL MILL Land Instruments International

.jpg)

Coal Dust Explosion Hazards: Understanding the Risks and

Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Vincent Grosskopf, Coal Mill Safety I n cases when a complete clinker line is purchased, the attention paid to the details of the coal grinding system in regard to explosion and fire protection will normally be limited to a list of standards, codes, or rules to be complied with by the supplierSafety considerations when purchasing a standalone coal mill Coal Mill Safety takes ICR readers, through the design of a part of the coal and petcoke grinding system to highlight the design required to operate a safe fuel grinding system by Vincent Grosskopf, Coal Mill Safety, Singapore Figure I: example of a straightforward mill to dustCoal Mill Safety, Explosion and Fire Protection ConsultancyPublications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Pulverized Coal Storage: Essential Practices and Considerations Coal

Explosion and Fire Protection Consultancy

Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Serious fire and explosion protection issues are present in all coal grinding systems everywhere on the globe That includes your system(s) No part of the world is excepted! Practically there exist not a single installation and no operation with correct fire Talk at a virtual seminar, November 2023 Coal Mill Safety, Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding Storage Firing Coal Grinding Systems: Enhancing Efficiency and Safety Safety considerations when purchasing a standalone coal mill grinding system When a complete clinker line is purchased the attention paid to the details of the coal grinding system with regards to explosion and fire protection will usually be limited to a list of standards, codes and rules to be complied with by the supplierSafety considerations when purchasing a standalone coal mill

.jpg)

Coal Grinding Systems Safety Considerations PEC Consulting

Safety considerations, such as the prevention of fire or explosion are of utmost importance as is the knowledge of how to proceed under normal conditions About; Coal mill hot air inlet temperatures should never be more than 600 F and the outlet temperature should not exceed 200°F on Raymond coal mills