Micro powder grinding aggregate

.jpg)

Characteristics of Recycled Micro Powder Produced Using

The physical and chemical properties of 1#–6# recycled micro powders, cement, fly ash, and slag powder were studied The test results are presented in Table 3 These results indicate that: 1 (1) The specific surface area of recycled micro powder prepared by grinding recycled aggregate for 30 min is more than 展开2023年12月1日 Recycled micropowders were introduced into recycled concrete by adhering them to the surface of recycled aggregate, and a systematic comparison was conducted with Effects of recycled micropowders mixing methods on the Recycled micro powder is a kind of fine powder which can be used as mineral admixture of cement concrete, waste brick, and tile after grinding to a certain degree of fineness It is Characteristics of Recycled Micro Powder Produced Using 2022年8月5日 The reasons that RBP enhances the mechanical properties of concrete are (1) the microaggregate filling effect of RBP improves concrete compactness (2) The reaction of Performance of Building Solid Waste Powder in Cement

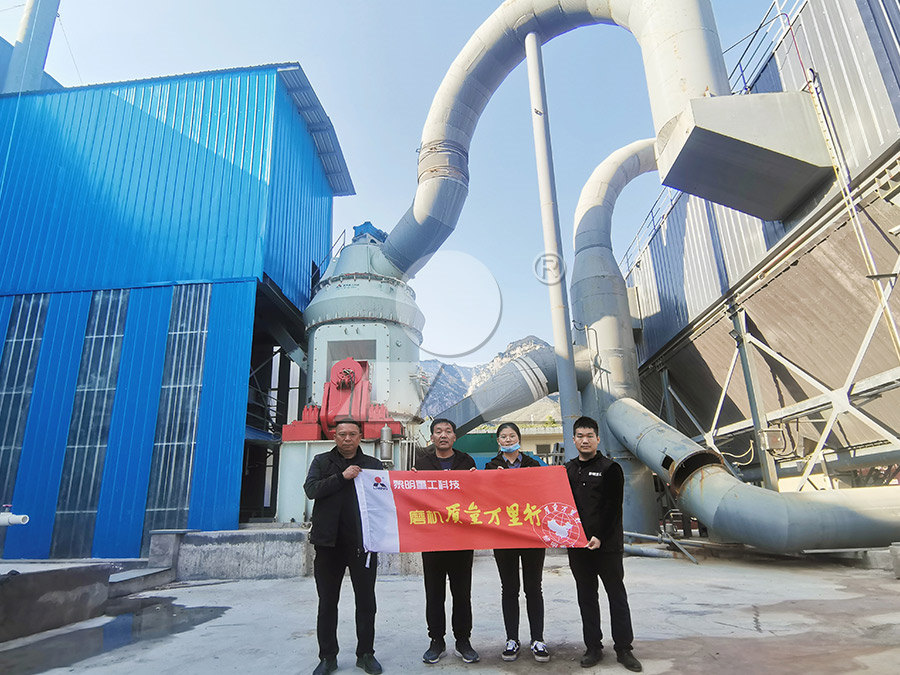

Micro Powder Mill Kefid

Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement The fineness can reach to 0006mm; Micro Powder Mill is mainly used for processing gypsum, calcspar, SBM micro powder grinding mill is a highly efficient industrial grinding mill, its finished products: 3253000 mesh; it's capacity: 0245t/h +17 [ protected] language >Shibang Industry Technology Group, Shanghai Micro Powder Grinding Mill2024年4月1日 Principle of Operation: Hammer mills operate on the principle of impact between rapidly moving hammers mounted on a rotor and the material being fed into the millThe material is struck by the hammers and shattered into smaller particles Applications: Hammer mills are used in a wide range of industries for grinding various materials, including grains, biomass, Grinding Mills For Activated CarbonBarite aggregate processing includes coarse crushing(jaw fine powder processing (20 mesh400 mesh), barite ultrafine powder deep processing (400 mesh1250 mesh), and micro powder processing (1250 mesh and the unqualified powder is classified by the classifier and returned to the main machine for regrinding Stage 4: Collecting PowderBarite Aggregate Processing JXSC Machine

.jpg)

Influence of coating recycled aggregate surface with different

2024年4月15日 The mechanical grinding method causes microcracks and fissures on the surface of the recycled aggregate, leading to a decrease in RAC's mechanical properties and durability Heat grinding and selective heat grinding methods have disadvantages such as temperature limitations and the inability to be used in highscale production because of the To improve the utilization rate of municipal solid waste incineration (MSWI) ash and achieve resource recycling, this article conducted research on grinding MSWI ash into fine powder for use as a concrete admixture Initially, the physical and chemical properties of the MSWI ash micropowder were tested Subsequently, different amounts of MSWI ash powder concrete were Experimental study on municipal solid waste incineration ash micro Its microstructured, Monocrystalline diamond powder is a popular choice for precision grinding, lapping and polishing of various materials Microdiamant MSY Precision size range Diamond crystallites of approximately 48 nanometers form clusters with an Micron diamond powders PureonOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Focus on the field of micro powder grinding 10+ Production experience 20+SBM Ultrafine Powder Technology Industrial Grinding Mill,

.jpg)

JoyalThreering Micro Powder Mill,Threering Micro Powder

ZYM Ultrafine Powder Mill Grinding The JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite, gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar SEPPE is a industrial manufacturer integrating Aluminum Oxide materials in several conditions including sintered bauxite proppants, fused alumina, and bauxite materialsused in Ceramics Refractories, Oil Gas fracturing, Casting Foundry, Blasting Polishing , Abrasives Grinding, more than hundreds of application s worldwide The manufacturer covers an total area of 7 SEPPE Technologies HomeMilling Equipment Chemical Milling, Custom Processing, Custom Pulverizing, Micronizing, and Grinding from Small Batches to Truckloads Precision Jet Milling with Proprietary “I” Mill DesignJet Pulverizer : Leader in Super Fine Particle Size Reduction2024年9月20日 Phase separation of recycled concrete powder during grinding and consequent influences on its hydration behaviors in cement paste Cem Concr Compos (2023) An approach to effectively improve the properties of recycled concrete aggregate and recycled brick aggregate by micronano particle reconstruction Constr Build Mater (2024)Effect of recycled concrete powdercement composite coating

.jpg)

Microstructures and properties of microporous MgOMgAl

2024年5月3日 In this investigation, microporous MgOMgAl 2 O 4 refractory aggregates were prepared by utilizing Mg(OH) 2 powder and αAl 2 O 3 micropowder as raw materials through employing an in situ decomposition synthesis method We focused on the impact of αAl 2 O 3 micropowder contents on the microstructure and properties of the aggregates As the αAl 2 Dolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment It is mainly applied to ultrafine powder processing of nonflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤9Dolomite Micro Powder Grinding MillZenith Crusher provides kinds of aggregate crushers, including jaw crushers, cone crushers, grinding and mining equipment, sandmakers, precise micropowder mills and other hightech products with international standards 535,000 m 2 Production base in HenanAggregate Crushing Shanghai Zenith Company2022年9月29日 Recycled powder is a kind of powder particle with a particle size of less than 75 μm produced in the process of preparing recycled aggregate from construction waste with concrete and brick as the main components It has the potential to replace part of cement as an auxiliary cementitious material This has important engineering application value for promoting Short Review on the Application of Recycled Powder in Cement

.jpg)

Powder Grinding Mills Engineered by FTM Fote Machinery

②Ultrafine Grinding Mill: $14,600/set (the lowest price) It is an upgraded Raymond mill for making micro powder and fine powder Widely applied in metallurgy, mining, chemical, cement, construction, refractory materials, ceramics, and other industries2021年9月30日 The chalk micro powder mill is independently developed and produced by SBM It mainly includes 3 types, namely HGM ultrafine grinding mill (1503000 meshes), CLUM vertical mill (1503000 meshes), and wet stirring mill (3256000 meshes)Chalk Micro Powder Mill SBM Ultrafine Powder TechnologySuperfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is Superfine Slag Powder Production Line FTM Machinery1995年1月1日 The process of grinding of amorphous premullite powder has been investigated The powder has been obtained by solgel process followed by drying, calcination and wet milling in planetary ball (PDF) Particle aggregates in powder processing a review

Influence of coating recycled aggregate surface with different

2024年4月15日 Various pozzolans of different sizes and natures have been used to formulate pozzolanic slurry to improve recycled aggregate characteristics Due to their small size and high specific surface area, nanomaterials accelerate the hydration process of cement and fill the voids and empty spaces of concrete [22, 23]Microsilica and nanosilica are the most familiar names 2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber How does HGM micro powder grinding mill process 2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O Applications of Steel Slag Powder and Steel Slag 2014年1月1日 Mineral trioxide aggregate (MTA) is a are powder primarily composed of tri and dicalcium silicates with bismuth oxide (CaSO 4 2H 2 O) is blended with the powder, usually by grinding the materials together (intergrinding) After grinding, the calcium sulphate may be present as Microhardness has been tested for MTA Introduction to Mineral Trioxide Aggregate SpringerLink

Study on the modification effect and mechanism of tailings powder

2023年1月30日 Geng et al concluded that tailing powder after mechanical grinding reduces the relative crystallinity of major mineral phases, has higher volcanic ash activity, and can be used in concrete to reduce the but all due to the M0 group without tailings powder The microaggregate filling effect occurs after CGCBM is added to the 2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag powder 2024年7月1日 Kim, H J replacing fine aggregate with MSWI bottom ash, the mixtures were evaluated for compressive strength, heat of hydration, chloride content and shrinkage performance [19] The resultant MSWI bottom ash micro powder, post grinding and screening, exhibits brownishyellow powder particlesAnalysis of pore structure characteristics of MSWI bottom ash micro Architecture Engineering and Science 84 Hongyang Xie, et al Proportioning Design of Foamed Concrete Mixed with Recycled Micropowder of Construction Waste Hongyang Xie1 , Jianjun Dong1*, Yong Deng1,Yiwen Dai 1, Mingwei Deng2 1 School of Civil Engineering and Architecture, Nanchang Aviation University, Nanchang , Jiangxi, China 2 Practical Training Proportioning Design of Foamed Concrete Mixed with Recycled Micro

.jpg)

Effects of recycled micropowders mixing methods on the

2023年12月1日 Recycled micropowders were introduced into recycled concrete by adhering them to the surface of recycled aggregate, and a systematic comparison was conducted with recycled concrete prepared with the recycled micropowder admixture to examine the effects of the mixing modes of recycled micropowders on the workability and mechanical properties of 2021年8月18日 Mechanism: the grinding method is to spray the compressed gas into the grinding area after passing through a special nozzle, so as to drive the materials in the grinding area to collide with each other and rub into powder; After the air flow expands, it enters the classification area with the rise of materials, and the materials reaching the particle size are How to "Make" Metal Micro Powder? Meetyou CarbideRing roller mill is a type of grinding equipment used in various industries such as mining, construction, (micro powder roller mill,fine roller mill,ring roller mill,roller grinding machine,automatic roller mill) in such industries as the mining and processing of ore and construction aggregate; cement milling; and recyclingRing Roller Mill Manufacturer EPIC Powder MachineryWCA is an Alumina powder developed and introduced by Micro Abrasives Corporation in 1957 WCA is known throughout the world for its unique particle shape, aspect ratio and size distribution Each WCA particle is a discrete crystal of alumina having a purity of over 99%Aluminum OxideAlumina Powder Micro Abrasives Corp

.jpg)

Performance of Building Solid Waste Powder in

2022年8月5日 Recycled powder (RP) is a byproduct of preparing recycled aggregates from construction waste through debris removal, stepbystep crushing, screening, and mechanical strengthening It is a fine powder with a 2022年9月30日 Although extensive investigations have been carried out to produce reactive powder concrete (RPC), the majority of these investigations were conducted based on using fine sand with a maximum particle size of 600 microns and cured under certain conditions Crushing and grinding processes applied to obtain smaller aggregate sizes and applying heat curing Producing sustainable modified reactive powder concrete using Working Principle of Micro Powder Grinding Mill Material is sent to the storage bin by the bucket elevator after being broken, 150T sand and gravel aggregate production line; 300 tons of fine aggregate production line per hour; 600 t/h limestone crushed stone production line;Xzm 221 Micro Powder Grinding Mill with Large Capacity2023年12月1日 Recycled micropowders were introduced into recycled concrete by adhering them to the surface of recycled aggregate, and a systematic comparison was conducted with recycled concrete prepared with the recycled micropowder admixture to examine the effects of the mixing modes of recycled micropowders on the workability and mechanical properties of Effects of recycled micropowders mixing methods on the

Utilization of all components of waste concrete: Recycled aggregate

2024年4月1日 Recycled fine powder (RFP), which makes up roughly 19 % of the quality of waste concrete, is produced inexorably during the manufacturing of RA [27, 28]RFP can be obtained through crushing and grinding, which includes hydrated cement mortar and some unhydrated cement particlesAggregate Screening Units; Sonic Sifter Separator 3'' Sonic Sieve Shaker 8''/200mm; Grinding Elements: Model: Jaw Crushers, Cone Crushers, Roll Crushers: 165 mm: 65 mm: The Micro Mill Pulverisette 0 is designed for fine grinding of dry laboratory samples or Crushers, Pulverizers, Grinders Lavallab2024年10月15日 This study investigated the micromacro properties of engineered cementitious composites (ECC) with both waste glass powder (WGP) and waste glass aggregate (WGA) as substitutes for binder and silica sand, aiming to achieve sustainable ECC materials and recycle waste glass in a highvalue approachDevelopment of ecofriendly engineered cementitious composites It is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, Barite, gypsum, graphite, fluorite, phosphate rock, potassium ore, etc Micro powder grinding mill is double in capacity compare with Energy Micro Powder Grinding Mill