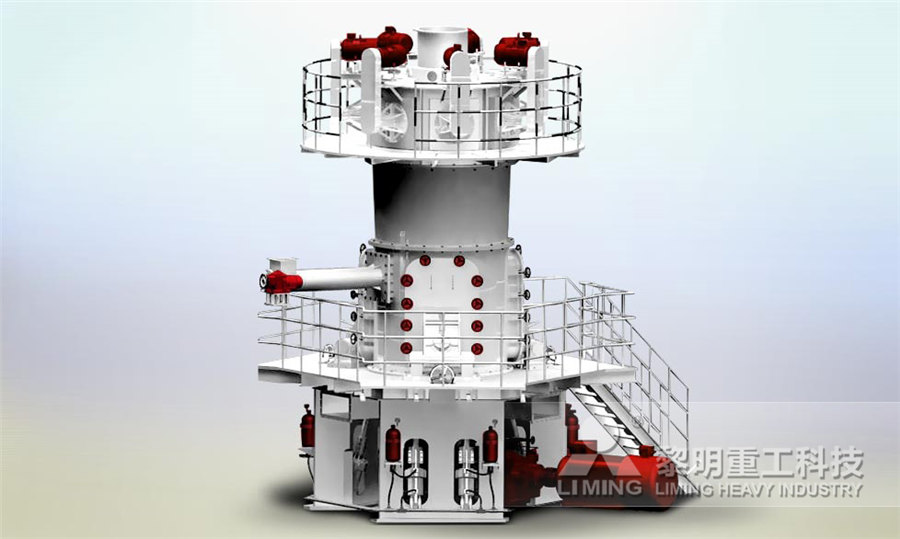

Internal structure diagram of slag vertical mill

.jpg)

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical The vertical mill has complex structure, which is composed of mill stand, main motor, gear box, grinding table, rocker arm, grinding roller, powder separator, separator motor, millVertical mill and its schematic diagram: (a) vertical mill and (b 2007年11月1日 Today more than 30 MPS vertical roller mills of the BC series for slag, cement and binding agents with capacities from about 20t/h up to 300t/h are used or under contract for MPS vertical roller mills for slag and slag cementsslag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as 2 µm 5 µm Loesche

.jpg)

VERTICAL ROLLER MILL TECHNICAL DETAILS Download Scientific

Diversified operating conditions, inputoutput constraints, and parametric variations in the Vertical Roller Mill (VRM) make it to have complicated dynamics and closedloop instabilityThrough the analysis of the main structure of the vertical mill, we use the assembly function of the solid edge threedimensional solid software to implement the assembly link of the main Solid Edge’s Application in Vertical Mill Design SpringerHere authors from KHD Humboldt Wedag compare the company’s systems to a vertical roller mill Below Figure 1: 1st Generation roller press (left) and stateoftheart roller press (right) For GLOBAL CEMENT: SLAG GRINDING KHD Humboldt Wedag2023年7月4日 Structure diagram of vertical roller mill Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding Roller Mill SpringerLink

.jpg)

SikaGrind® for vertical roller mills

Vertical Roller Mills (VRM) have a clearly higher energy eficiency than ball mills, even if the ball mill is combined with a roller press This and further arguments led to the increased share of Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materials2022年5月31日 Mineral crushing is the main source of energy consumption in mineral processing According to statistics, this consumption accounts for about 35–50% of the total cost of the mine (Curry et al, 2014), or even higherIt may also account for 18% of the global electrical energy consumption (NapierMunn, 2015)More efficient crushing equipment needs to be Analysis of vertical roller mill performance with changes in 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding Performance of

.jpg)

Solid Edge’s Application in Vertical Mill Design Springer

Vertical mill structure Fig 2 Internal structure of the vertical mill Solid Edge’s Application in Vertical Mill Design 1097 2 Introduction to Solid Edge Solid Edge is a threedimensional solid modeling software developed on the basis of Spill tray diagram Fig 4 Cage rotor2023年1月10日 As the core equipment in the production process of slag grinding, the LM slag vertical roller mill of SBM integrates fine crushing, grinding, drying, powder selection and transportation, ensuring the continuity and stability of slag powder production and improving the efficiency of slag grinding 1Slag Vertical Roller MillThis paper is focused on the inherent characteristics of the main drive system of the F5 coldrolling mill in a steel plant First, the main transmission mechanical structure was simplified to a Structure of 1780 hot rolling mill Download Scientific DiagramRequest PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill

An investigation of performance characteristics and energetic

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose 2023年7月4日 The basic structure of the vertical roller mill with vertical arrangements comprises the engine body, the grinding table device, and the driving device A centering structure for determining the rotation center is set between the body and the grinding table device, and a rotary guide rail is arranged at the bottom of the grinding table, which can be rotated and supported Roller Mill SpringerLinkWhat is the difference between Raymond mill and vertical mill? Vertical mills and Raymond mills are similar to "standing work", and they are quite different from horizontal ball mills Strictly speaking, Raymond mill is a kind of vertical mill, but they are also different, and the production time is not the same, the internal structure is not vertical roller mill clirikultrafine vertical mill, Raymond vertical Download scientific diagram The layout of the coal mill with a rotary classifier from publication: An investigation of performance characteristics and energetic efficiency of vertical roller The layout of the coal mill with a rotary classifier

Diagram of internal structure of wood fiber mill (1

Download scientific diagram Diagram of internal structure of wood fiber mill (1feed inlet; 2chassis; 3scaleboard; 4top rack; 5side board; 6side rack; 7handle; 8grinding wheel; 9grinding The large vertical mill has complicated structure and tens of thousands of parts, which is a critical grinding equipment for slag and cinder As large vertical mill always works in severe Data flow diagram of health management system for large vertical mill The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an 2006 Slag Grinding With MPS Vertical Roller MillsDownload scientific diagram Schematic operation principle of a verticalrollermill from VRM technology was introduced in the mid'90s for grinding clinker and slag by LOESCHE Schematic operation principle of a verticalrollermill

.jpg)

Schematic diagram of the mill structure ResearchGate

Download scientific diagram Schematic diagram of the mill structure from publication: Dynamic Model of the Hot Strip Rolling Mill Vibration Resulting from Entry Thickness Deviation and Its Download scientific diagram Technical specifications of vertical roller coal mill from publication: An investigation of performance characteristics and energetic efficiency of vertical roller Technical specifications of vertical roller coal millDownload scientific diagram Schematic diagram of the ladle prototype; (a) vertical section; (b) porous plug arrangement from publication: Physical Simulation of Molten Steel Homogenization and Schematic diagram of the ladle prototype; (a) vertical section; (b Process introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screenCOAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

LM Vertical Grinding Mill SBM Mill Crusher

2023年3月15日 SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing grinding, separating and transport The structure is simple while the layout is compact Its occupational area is about 50% of that of the ballmilling Vertical Slag Mill Series Models and parameters: LM130N: LM150N: LM170N: LM190N 2021年9月1日 Slag from the conventional steelmaking process is one of the main byproducts of the iron and steel industry The production of each ton of steel generates 150200 kg slag [1], which is rich in (PDF) Phases Reconstruction and Foaming Modification of2022年5月31日 Fig 1 represents the schematic diagram of VRM utilized in the experiment and DEM simulations (DEM) coupled with MultiBody Dynamics (MBD) is proposed in this work to study Kisen Vertical Mill (KVM), an external circulation vertical roller mill developed by Sinoma International Intelligent Technology Co Steelmaking slag, Analysis of vertical roller mill performance with changes in In case of the vertical water mill, a control lever was posi tioned near the flour mill as shown in Figure 1, which controls the rpm of the mill by tight ening or loosening the lever from the topSchematic diagram of a vertical water mill

.jpg)

Research of iron ore grinding in a verticalrollermill

2015年3月15日 On the other hand, both the structure and grinding mechanism of a vertical roller mill employed in coal power plants are different from those of a conventional labscale mill2012年3月1日 Vertical roller mills are the mills traditionally used for processing granulated blastfurnace slag and for grinding composite cements From the energy aspect they are superior to grinding plant Operating experience with a vertical roller mill for grinding Download scientific diagram Blade internal structure and materials schematic from publication: Structural analysis of an offshore vertical axis wind turbine composite blade experiencing an Blade internal structure and materials schematicThis vertical slag mill can be installed in a slag powder production line with an output range from 45t/h to 300t/h The structure of the slag grinding mill is similar to the cement mill and raw mill, except that the feeding method is differentSlag Mill Vertical Slag Mill Provider SINOMALY

.jpg)

Schematic diagram of AG/SAG mill process mechanisms

Download scientific diagram Schematic diagram of AG/SAG mill process mechanisms after (NapierMunn et al, 1996) from publication: Multicomponent AG/SAG mill model The JKMRC has been Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral cement clinker, slag and coal slag It has the benefits of simple structure and low cost of manufacture and use Vertical roller mills have many different forms, but they work basically the same All of these forms Vertical roller mill Wikipedia2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of LOESCHE vertical roller mills for the comminution of2020年11月4日 Figure 8: Particle streamline diagram of the internal flow field of vertical roller mill T able 6: Classification efficiency of each particle size by numerical simulationEffects of Blade Parameters on the Flow Field and Classification

Vertical raw mill Cement Plant

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, 2020年3月13日 The large vertical mill is an ideal largescale grinding equipment 1 The granular and powdery raw slag and cinder are grinded into the required powdery materials, integrating crushing, drying, and grinding functions As A health management system for large vertical mill2020年3月3日 Figure 22 shows schematic sketch of a blast furnace indicating different sections, and Fig 23 shows the general constructional features of a blast furnace It is circular in cross section and around 30–40 m in height The outer shell of BF is made of steel plates, and refractory lining is at the inside of shellBlast Furnace Process SpringerLinkWhat Is Cement Vertical Mill The cement vertical mill is a type of grinding equipment that merges fine crushing, drying, grinding, and powder separating into a single, which simplifies the production process and has many irreplaceable advantages, such as high grinding efficiency, large feeding size, low power consumption (2030% less power than a cement ball mill), large Cement Vertical Mill Vertical Grinding Mill Vertical Mill

Parts of a CNC Milling Machine: Visual Guide MellowPine

2024年9月28日 It consists of a dovetail slide with vertical positioning screws to move the worktable up and down, ie, the knee facilitates the vertical movement of the milling table CNC milling machines consist of an automatic mechanism to position the knee accurately based on the input received from the CNC controller and a manual hand wheel to position it manually2012年4月1日 Ordinary Portland cement (OPC) is extensively used as a binder in cemented paste backfill (CPB) of mill tailings However, it is not particularly suitable for CPB of sulphiderich tailings mainly Utilisation of alkaliactivated blast furnace slag in paste backfill 2019年9月10日 NGOBA NZOUEGO NICK JORDAN ii DEDICATION This work is dedicated to my father, NGOBA PIERRE and my mother TENE YVONNE DESIGN OF VERTICAL THREEPHASE SEPARATORS WITH INTERNALS (MIST EXTRACTOR) NGOBA DESIGN OF VERTICAL THREEPHASE SEPARATORS WITH INTERNALS Low energy, the powder consumption of vertical mill is 20%30% less than that of ball mill With the incensement of moisture of the raw material, the powder consumption will decrease obviously The vertical mill saves 30%40% of energy consumption compared to the ball mill Vertical mill has less noise than ball mill, about 2025dBVertical Cement Mill, Vertical Roller Mill Buy Cement Mill From

Types of welding defects a porosity, b slag inclusion, c lack of

Download scientific diagram Types of welding defects a porosity, b slag inclusion, c lack of fusion, d lack of penetration, e suck back or root concavity [1] from publication: Nondestructive 2021年3月9日 Henan Yusheng Machinery Co, Ltd has been committed to providing customers with systematic solutions for vertical mills Since the first YSMS slag vertical mill was put into operation in 2005, great progress has been made in the largescale vertical mill, gradually developing slag vertical mill with annual output of tons, tons, tons, 1 Blast Furnace Slag Vertical Mill China Supplier in Zhengzhou, Slag