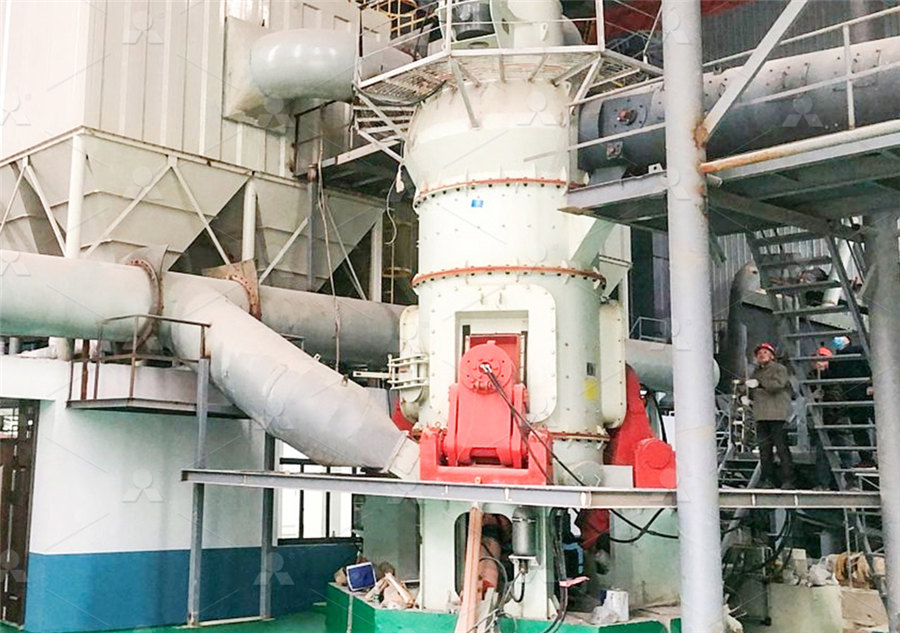

Calcinated petroleum coke production line

The History and Future Challenges of Calcined Petroleum Coke

Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, andPetroleum coke calcining is a three step process, including drying, devolatization and densification The coke calcining process is a timetemperature function, conducted in an oxygen deficient atmosphere Important control variables are Petroleum Coke Calcining Systems Metso2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHe´roult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively low cost This article provides a review of the history and use of calcined petroleum coke for anode productionThe History and Future Challenges of Calcined Petroleum Coke 2014年1月1日 The quality of calcined petroleum coke used in primary aluminum production is affected by each of the refining and calcining processes (PDF) Calcinations of Petroleum coke ResearchGate

.jpg)

SELECTION OF KEY PARAMETERS FOR GREEN COKE CALCINATION

The article deals with the main problems of a modern industrial technology for producing calcinated petroleum coke from green coke in a tubular rotary kiln A high quality calcinated coke is obviously necessary both for metallurgy and chemical industry, hence its properties should meet the corresponding high requirements Petroleum coke is a nice2024年1月1日 Although the suitability of petroleum coke as a precursor for different applications is largely predetermined during the delayed coking, the subsequent calcination of green coke is also a thermallyupgraded process via the removal of Comparative study on devolatilization behavior, microstructural Rain Carbon is a global producer of calcined petroleum coke (“CPC”) and operates its largest coke calciner at Visakhapatnam (“Vizag”) in India The objective of this paper is to review the operation at Vizag with a focus on systems designed to minimize the impact on the environmentCB05 Sustainable CPC Production at the Vizag Calciner Rain 2021年7月23日 The structure of petroleum calcined needle decantoil coke was investigated with scanning electron microscopy (SEM) performed by Tescan Vega 3 LMH An electron microscopic picture of the sample particles was obtained in secondary electrons (SE) in resolution scanning mode, in 16 and 66 μm fields of viewTechnology of Petroleum Needle Coke Production in Processing of

.jpg)

CB01 Petroleum coke shaft calcining technology final ICSOBA

Calcined Petroleum Coke (CPC) is a vital component in aluminium smelting with a minimum consumption equivalent to one third of the weight of primary metal produced The traditional specifications and quality limits for CPC in anode production for smelters are becoming less strict in the tightening market2024年8月23日 Introduction Petroleum coke is a fundamental byproduct in the energy industry, derived from the refining process of crude oilThis carbonaceous material, obtained in the final stages of crude oil distillation, is fundamental for Petroleum Coke: What it is, Function and Industrial Raw/Green coke as produced Coke calcined at 2375 °F Fixed carbon, wt % 80 − 95 980 − 995 Hydrogen, wt % 30 − 45 01 Trends in Petroleum Coke Production • Petcoke production in the United States is increasing at a significantly slower pace than overall worldwide productionPetcoke Fact Sheet KCBX ChicagoPetroleum coke is a solid byproduct of petroleum refining and is used in the production of carbon electrodes for the aluminum industry, graphite electrodes for steel making, as fuel in power generation, and as fuel for cement kilns In the United States, more than 15 million tonnes (168 × 10 6 tons) of petroleum coke are used by major utilities, as shown for 2000 in Table 57Petroleum Coke an overview ScienceDirect Topics

CB04 Impact of Quality Changes in Calcined Petroleum Coke

CB04 Impact of Quality Changes in Calcined Petroleum Coke (CPC) on Anodes Used for Aluminium Production Binuta Patra Improvement in oxidation behaviour of calcined petroleum coke used for production of anodes in aluminium industry, NALCO Patent, Filed 363/KOL/2014, Dated 21032014 Title: Travaux No49 ICSOBA 2020 ProceedingsWe began assessing anodegrade calcined petroleum coke (CPC) on a monthly basis in May 2013 at the request of the aluminum industry The US Gulf CPC price assessment was the first to reflect the spot tradable value for CPC used by aluminum smelters, in a market where most purchases are done quarterly or semiannually, and often retroactivelyCalcined Petroleum Coke SP Global2023年1月29日 There are two main types of petroleum coke: green coke and calcined coke 1 Green Coke Green coke is the raw material used to produce calcined coke It is the solid carbon byproduct of the oil refining process Green coke has a high moisture and volatile matter content 2 Calcined Coke Calcined coke is the product from the “calcining Petroleum Coke Types, Uses and SpecificationsCalcined Petroleum Coke (CPC) is manufactured from Raw Petroleum Coke (RPC) by the process known as high temperature pyrolysis The process is carried out in a rotary or vertical kiln at temperatures exceeding 1300 deg C Calcination of CPC is essentially a high temperature treatment in which the carbon to hydrogen ratio of RPC is increased from 20 to 1000 and above:: Welcome to Pioneer Carbon Company :: Calcined Petroleum Coke

Petroleum Coke: A Comprehensive Guide to Production,

2024年1月14日 The production of petroleum coke began in the late 1800s and early 1900s After that, Raw (or green) coke contains 051% nitrogen and 02 60% sulfur, which become emissions when coke is Calcined Heating Value: Petroleum coke is highly combustible and has a high heating value, often between 8,000 and 10,000 BTU/lbanode production and use in an aluminium smelter This further enhances the sustainability of the calciner operation and its contribution to the positive aluminium life cycle story Keywords: Petroleum Coke, CPC, Calciner, Anode, Carbon Footprint 1 Introduction Rain CII Carbon Vizag Limited (RCCVL) operates a 500 000 t/annum petroleum coke CB05 Sustainable CPC Production at the Vizag Calciner Rain the thermal behavior of petroleum coke were experimentally studied Experimental Petroleum coke (A and B) obtained from two petroleum coke production enterprise were used as raw materials in this research The two petroleum cokes had been calcined at approximately 1100°C Chemical compositions of the two petroleum cokes are presented in Table 1ThermoPhysical Properties of Petroleum Coke during Calcining Medium sulfur calcined petroleum coke Generally used in aluminum smelting, mainly used in prebaked anodes and cathodes for electrolytic aluminum Highsulfur calcined petroleum coke It can be used in chemical production, silicon Calcined Petroleum Coke Large Production Capacity

Calcined Petroleum Coke Graphite India Limited

Size : CP Coke derived from the Kiln is in size of 0 mm to 30 mm The same can be further supplied in any size required by the Customer Packing : In 25/50kg PP bags Or in Jumbo Bags packing as per Customer’s requirement Certification : We are an ISO 9001:2015 Certified Division Customers Profile : We specialize in supplying Calcined Petroleum Coke to Steel, Calcined petroleum coke is a vital component in Micro Silica, Silica Fume, and Silicomix are also part of our product line We are engaged in manufacturing, exporting, and supplying highquality Calcined Petroleum Coke, backed by Calcined Petroleum Coke Guru CorporationYosomulyo Jajag started off from a humble beginning and has grown to become the leading producer and exporter of Calcined Petroleum Coke in Indonesia today Operation Our company's main operation is in the production of Anode Grade Calcined Petroleum Coke (CPC), a nearly pure carbon source used primarily for industrial applicationsPT Yosomulyo Jajag Carbon IndustryThe company’s product line includes petroleum coke, solvents and other products Fuel Coke Phillips 66 is the only producer and marketer of all grades of green and calcined specialty petroleum coke, serving Sulfur production supports a diverse range of end uses including the production of fertilizers, chemicals Specialty Chemicals and Petroleum Products Phillips 66

Production of petroleum coke (sponge coke) aramico

Furthermore, sponge coke serves as a crucial raw material in the production of anodes for the aluminum industry It is calcined at high temperatures to remove impurities and transform it into calcined coke, which is then used to manufacture carbon anodes These anodes are essential for the electrolytic process of aluminum productionCalcined Petroleum Coke (CPC) Description CPC is a high carbon content material used in several industrial processes including Aluminum smelting, Steel recarburization, Titanium dioxide production, Graphite electrode production and other specialty usesCalcined Petroleum Coke – Sanvira IndustriesOverview This page contains the latest trade data of Petroleum coke, calcinedIn 2022, Petroleum coke, calcined were the world's 645th most traded product, with a total trade of $602B Between 2021 and 2022 the exports of Petroleum coke, calcined grew by 597%, from $377B to $602BPetroleum coke, calcined The Observatory of Economic 2015年2月1日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively low cost This article provides a review of the history and use of calcined petroleum coke for anode production and describes the different calcining technologies used by the The History and Future Challenges of Calcined Petroleum Coke Production

Understanding Petroleum Coke: Production, Properties, and

Further processing involves calcining the green coke in a rotary kiln to remove residual volatile hydrocarbons, resulting in calcined petroleum coke This calcined form can undergo additional processing in an anode baking oven to produce anode coke with desired physical properties and shapes, predominantly used in the aluminium and steel industriesPetroleum coke is usually calcined in a gasfired rotary kiln or rotary hearth at high temperatures, around 1200 to 1450 °C, to remove moisture, drive offProduction and Application of Calcined Coke In Rotaryanode production and use in an aluminium smelter This further enhances the sustainability of the calciner operation and its contribution to the positive aluminium life cycle story Keywords: Petroleum coke, CPC, calciner, anode, carbon footprint 1 Introduction Rain CII Carbon Vizag Limited (RCCVL) operates a 500 000 t/annum petroleum coke CB05 Sustainable CPC Production at the Vizag CalcinerINDIA CARBON LIMITED (ICL), India’s leading producer of Calcined Petroleum Coke, provides the right blend of people products to serve the needs of the Aluminum, Steel, other Carbon consuming industries Calcined Petroleum India Carbon Limited

Evaluation of the PhysicalChemical Properties in Petroleum Coke

green coke and calcinated coke; green petroleum coke are mostly used as utility fuels and as feedstocks for further upgrading caltinations The calcinated petroleum coke are used in production of aluminium, anodegrade, graphite electrodes, needlegrade, TiO 2 pigments [1] A number of factors determine the quality of petroleum• Monthly consumption of calcined petroleum coke for each process line (tons) • Annual production of carboncontaining waste for each proce ss line (tons), if applicable • Monthly production of titanium dioxide for each process line (tons) • Monthly carbon content factor of petroleum coke from the supplier (percent by weight Titanium Dioxide Production US Environmental Protection With an annual capacity of 24 million metric tons of calcined petroleum coke (CPC), Rain Carbon Inc is one of the world’s largest producers of CPC, which is a crucial ingredient in the anodes used during the electrolytic production of aluminum worldwideCalcined Petroleum Coke Coal Tar Pitch Rain Carbon IncCalcined petroleum coke Synonyms: Coke CAS 6 Browse Calcined petroleum coke and related products at MilliporeSigma Skip to Content Products US EN Production We are a leading supplier to the global Life Science industry with solutions and services for research, biotechnology development and production, Calcined petroleum coke Coke MilliporeSigma

.jpg)

Calcined Petroleum Coke Market Size, Industry Share, Forecast

Calcined Petroleum Coke Market report summaries detailed information by top players as Oxbow Corporation, Atha Group, Rain Industries Limited, among 2020 Rain Carbon Inc, started its calcination and energy production at its Lake Charles facility in Louisiana, US after taking a direct hit from Hurricane Laura in August 2020 REQUEST Coke calcination is a process that involves the heating of green petroleum coke in order to remove volatile material and purify the coke for further processing Calcined coke is vital to the aluminum industry, where it is used to produce carbon anodes for aluminum production Calcined coke is also widely used asDevelopment of an Advanced Combined Heat and Power (CHP) 2022年9月27日 The processed coke will be used as anode coke for the aluminium industry RUWAIS calcined coke A new calcined petroleum coke production facility is set to begin operations at the Adnoc Refining's Ruwais West refinery in the UAE This new facility will produce anode grade calcined petroleum coke at a rate of around 430,000 tons per yearRUWAIS Expands Its Calcined Petroleum Coke Production in the Calcined Petroleum Coke (CPC) is a vital component in aluminium smelting with a minimum consumption equivalent to one third of the weight of primary metal produced The traditional specifications and quality limits for CPC in anode production for smelters are becoming less strict in the tightening marketCB01 Petroleum coke shaft calcining technology final ICSOBA

.jpg)

Calcined Coke from Crude Oil to Customer Silo SpringerLink

The quality of calcined petroleum coke used in primary aluminum production is affected by each of the refining and calcining processes including choice of crude, many of the initial refinery processing steps, coking, calcining as well as the handling systems between the refinery, calciner and final customer2021年7月13日 A subsidiary of staterun Saudi Arabian Mining Co (Ma'aden) signed a fiveyear contract on Tuesday to buy calcined petroleum coke from a Saudi company for its aluminium smelter facility in Ras Al Saudi Ma'aden signs deal for calcined petroleum coke for aluminium production of petroleum coke The production of petroleum coke has nowadays become cheaper than coal mining and coal coke production Beyond that, the world's resources of highquality atthracite coal are rapidly decreasing, while oil refinery plants have got a stable raw material base for petcoke production in necessary amountSELECTION OF KEY PARAMETERS FOR GREEN COKE 2023年11月9日 These involve mixing different grades of green coke to achieve the desired carbon content and reduce impurities The blending and homogenization steps are critical to ensuring that CPC consistently meets customer specifications 8 Conclusion: The Importance of Raw Materials Raw petroleum coke is the cornerstone of Calcined Petroleum Coke Raw Materials for Calcined Petroleum Coke Production: The

.jpg)

[PDF] Production and Application of Calcined Coke In Rotary

Calcined coke is the best material for making carbon anodes for smelting of alumina to aluminum Petroleum coke is usually calcined in a gasfired rotary kiln or rotary hearth at high temperatures, around 1200 to 1450 °C, to remove moisture, drive off volatile matters, increase the density of the coke, increase physical strength, and electrical conductivity of the material Rotary kilns have 2024年3月18日 This article explores the impact of operating parameters on the classification efficiency of a rotor classifier Based on the experimental data of calcined petroleum coke classification, a singlefactor experimental analysis is conducted to find the relationship between operating parameters and classification performance The cut size becomes progressively Research and Optimization of Operating Parameters of a Rotor The Plant has a capacity of approximately 93,750 tons per annum of CPC and comprises an area of around 30 acres with good infrastructure facilities like railway siding for facilitating unloading/loading of wagons, along with yard/shed to store raw petroleum coke/Calcined Petroleum CokeCalcined Petroleum Coke Atha GroupCalcined petroleum coke is a critical ingredient in the production for Aluminum, Titanium, Steel produced from Anode grade GPC Cathode blocks made from carbon graphite applied for the production of primary aluminum Cathode blocks are used in the lining of aluminum electrolysis cells INVESTMENT OVERVIEW MARKET OVERVIEWCALCINED PETROLEUM COKE (CPC) CATHODE BLOCK

.jpg)

Impact of Feed Properties and Operating Parameters on

Petroleum Coke General Properties: Volatile Combustible Matter (VCM) • VCM is unconverted pitch – Target 12% Max, fuel coke 9% to 10% – 14% VCM is very high; Coke will be soft • Increases green coke hydrogen content • Rules of thumb for control in fuel coke – Increase heater outlet 57 °F for 1% decrease in VCM