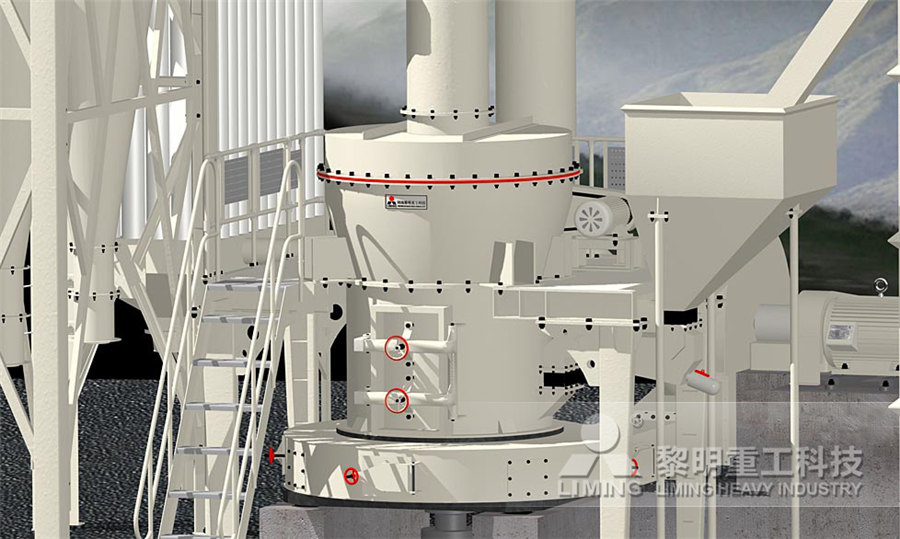

Limestone crusher smelting waste slag treatment powder making process

.jpg)

(PDF) Nickel Laterite Smelting Processes and Some ResearchGate

2019年9月3日 Industrially, the pyrometallurgical treatment of laterites is mostly accomplished with a wellestablished method, namely, the rotary kiln–electric arc furnace (RKEF) process, 2023年9月11日 Compared with the traditional slagging steelmaking process, the use of limestone instead of limeslagging steelmaking in converter steelmaking to meet the needs of smelting is based on an effective increase in the rate of The Kinetic Mechanism of the Thermal Decomposition The iron/steel slag processing flow is schematically shown in Fig 2 Steelmaking slag is subjected to the following four processes: ① solidify and cooling of the hot molten slag, ② crushing Processing and Reusing Technologies for Steelmaking Slag2017年8月1日 Some industrial trials of utilizing limestone as a new kind of slagmaking agent instead of lime for slagging during LDsteelmaking process are discussed and analyzed in the The Research Process on Converter Steelmaking Process by Using

.jpg)

Preparation of High Activity Admixture from Steel Slag, Phosphate

2023年1月1日 The paper demonstrates the feasibility and explains the principle of the composite system in terms of the composition of the phases, hydration temperature, and microscopic 2024年6月21日 In this review, we will examine the distribution of lithium ore, flotation and extraction technologies for obtaining lithium, and the utilization of lithium slag We will also Review: The formation, characteristics, and resource utilization of 2023年5月14日 Using appropriate mixing composition, BFS and limestone mixture can be used for green cement production This works explores the potential to convert slag waste into Blast Furnace Slag Cement Clinker Production Using Limestone 2022年11月1日 The upstream process includes the production of raw materials and auxiliary materials as well as the extraction of energy The main treatment process includes the Life cycle assessment of melting reduction treatment for iron and

.jpg)

Granulation and Heat Recovery from Metallurgical Slags

2019年12月9日 In this paper, the slag granulation and heat recovery options are reviewed and given a critical evaluation, aiming to provide a basis for future directions in slag handling The 2018年8月1日 Steel slag after taping is treated first, but the slagtreatment process (airgranulated process, rotary cylinder process, layerpouring process, and selfdisintegrating Steel slag in China: Treatment, recycling, and management2017年7月7日 Several different types of kilns are used for the calcination process These kilns can be rotary kilns or shaft kilns The type of the kiln to be selected strongly depend on the characteristics of the limestone, anticipated production rate, cost of fuel, investment costs, available fuel, local conditions, infrastructure and other thingsLimestone – Its Processing and Application in Iron and2019年5月23日 Steel slag is the waste generated in the steelmaking process and includes ferric oxide and the impurities of some infusible matters It is the byproduct when slagforming constituents (such as fluorite, lime, and deoxidant) are added for deoxidization, desulfurization, and dephosphorization in prehensive Utilization Technology of Steel Slag

Treatment process and utilization technology of steel slag in

2013年7月1日 Steel slag is a byproduct discharged from the steelmaking process, which is characterized by abundant free calcium/magnesium oxide, low cementitious properties, and high contents of heavy metals2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding processSteelmaking slag, or steel slag, is a byproduct from the production of steel during the conversion of hot metal to crude steel in a basic oxygen furnace, or during the melting of scrap in an EAFThe slag is generated as a melt and is a complex solution of silicates and oxides that solidify upon cooling 11 Depending on the specific steel production process, three different types of steel Steelmaking Slag an overview ScienceDirect Topics2017年1月1日 Copper smelting slag is the largest solid waste produced in coppermaking process, and slow cooling beneficiation technology is the most widely used method in recovering remaining treasures from (PDF) Reductivesulfurizing smelting treatment of smelter slag

Treatments of Magnesium Slag to Recycle Waste from Pidgeon Process

2011年12月1日 Thus some heat treatments may be necessary to transfer the Mg slag fines into volume stable slag products Some of the present authors have sintered Mg slag powder mixed with stabilizing agents at 2018年8月1日 Steel Slag Treatment Technology Standard (GB/T 295142013) Enacted May 9, 2013; Effective February 1, 2014: Manages the control of waste water, waste gas, and noise produced in the steel slag treatment process: Standard for Pollution on the Storage and Disposal Site for General Industrial Solid Wastes (GB 185992001)Steel slag in China: Treatment, recycling, and management2016年2月29日 When the smelting process is complete, the charge is poured into a mold Once the slag is cool, this can be separate from lead and precious metals by using a hammer or any device than can break the slag The metallic product is named button and have to be processed in the other smelting process called cupellationGold Smelting Refining Process 911Metallurgist2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel

Utilization and detoxification of gypsum sludge by replacing limestone

reductions smelting of high lead slag Herein, toxicity leaching experiment of sulfuric acid and nitric acid method was used to evaluate the safety of the cosmelting slag to provide a basis for the cosmelting of high lead slag with gypsum sludge 2 Experimental 21 Materials and reagents In this study, high lead slag as the experimental2020年6月3日 Smelting slag is a typical hazardous waste generated in the smelting and metallurgy industry 1,2 Slag contains high concentrations of heavy metals, such as Cu, Zn, Cr and Ni, which are harmful if Highpurity recycling of hematite and Zn/Cu mixture from waste smelting 2020年10月15日 Cotreatment of Waste From Steelmaking SS can be classified into many types according to the steps of the smelting process, including electric arc furnace slag (EAFS M, Benamor, A, AlSobhi, S, and Cotreatment of Waste From Steelmaking Processes: 2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can serve as a Steel slag in China: Treatment, recycling, and management

How to Process Slags (with detailed process)? Fote Machinery

2023年2月15日 Slag bricks Slag brick production process Slag brick is made by mixing, watering, grinding and pressing slag and limestone In the production process of slag brick, the particle size of the slag is generally smaller than 8 mm, and the steam temperature injected into the kiln is about 80 ℃ to 100 ℃, the maintaining time is about 12 hoursWilliams Crusher’s limestone mills and Pulverizers offer solutions for various sizereduction applications The limestone crushers and mills are effective for directinjection of dry sorbent lime or limestone during the CFB process and capable of handling 2,400 tons per hour—making it a reliable solution to limestone grindingLimestone Mills Limestone Crushers Pulverizers Williams Crusher2013年10月1日 Steel slag is a solid waste produced in crude steel smelting, and a typical management option is stockpiling in slag disposal yards Over the years, the massive production of steel slags and the Comparative Analysis of Steel Slag Characteristics and Treatment Process2021年5月11日 Practically, the matte grade is adjusted by the ratio of O 2 in the blast to concentrate feed rate, assuming a constant slag composition Due to the fact that the matte grade determines the extent of oxidation of Fe and S, it also determines the extent SO 2 evolution [], and it influences the partitioning of the elements between different phasesThermodynamic Analysis of Copper Smelting, Considering the Impact

Life cycle assessment of melting reduction treatment for iron and

2022年11月1日 China has the largest output of steel and iron in the world (Zhang et al, 2022)In 2021, China's average annual pig iron output arrived at about 869 million ton (Stewart et al, 2021) and crude steel arrived at about 103 billion tons (Zhao et al, 2022)Meanwhile, the output of steel solid waste keeps at a high level and generally the production of one ton steel will generate 2019年9月3日 Industrially, the pyrometallurgical treatment of laterites is mostly accomplished with a wellestablished method, namely, the rotary kiln–electric arc furnace (RKEF) process, which includes (PDF) Nickel Laterite Smelting Processes and Some2023年11月14日 There are three types of steel slag treatment processes, which are detailed as follows Steel slag crushing production line process flow Raw materials → Vibrating feeder → Jaw crusher → Cone crusher → Vibrating What are the technological processes for steel slag 2023年1月1日 So far, carbon dioxide sequestration by steel slag carbonization has been widely studied by many scholars Ding et al [8] proposed a new linear programming model to evaluate the economic cost of carbon dioxide capture and storage in Chinese steel plants, and believed that the adoption of carbon capture and storage technology in steel plants could obtain Carbon capture and storage technology by steelmaking slags:

Steel Slag Processing Plant Equipment Selection

2023年12月27日 The steel slag waste after various mechanical equipment processes will be reused in multiple industries, directly turning it into treasure For example, the steel industry produces a large amount of steel slag during the 2022年4月4日 Slag analyses from archaeological iron smelting sites are common Rigorous analyses of iron and slag from successful experimental smelting, however, are still rare Furthermore, thorough analyses from a series of smelts, and of the slag produced in different phases of the smelt, are exceedingly rare The present study investigates the effect of an iron By the hand of the smelter: tracing the impact of decisionmaking Taking copper slag as an example, copper slag is a solid waste containing iron, lead, and zinc produced in the process of copper smelting, which is a typical nonferrous smelting slag Besides oxides of Ca, Mg, Si, and Al, copper slag also contains 20 %–40 % total iron (TFe) and a certain amount of lead and zinc, which has a high comprehensive utilization value ( Zhang et al, 2020 Resource utilization strategy of Febearing smelting slag in China: 2021年4月30日 Fluoride evaporation from Mg slag samples was investigated F content in the original slag sample from an Mg factory was 165%, which decreases to 098154% in the samples heated at 10001400°C Magnesium Slag Generated by Reduction Smelting Using Pidgeon Process

Comprehensive utilization of steel slag: A review ScienceDirect

2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of 2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimizationRequest PDF On Jul 1, 2016, Jung Ho Heo and others published Recovery of iron and removal of hazardous elements from waste copper slag via a novel aluminothermic smelting reduction (ASR) process Recovery of iron and removal of hazardous elements from waste Based on this observation, the slag minimum refining process (SMP), low slag process (LSP), zero slag process (ZSP) and slag recycling process (SRP) were developed in the 1980s After the desiliconization and dephosphorization processes, the lowsilicon hot metal is charged to converters, the main tasks of the converter operation were reduced to decarburization and more metal less waste the zero slag process Total Materia

Element Distribution and Migration Behavior in the

2021年12月8日 1 School of Environmental and Municipal Engineering, Qingdao University of Technology, Qingdao, China; 2 Shanghai Engineering Research Center of Solid Waste Treatment and Resource Recovery, Shanghai Jiao 2021年3月16日 By Alton Tabereaux, Contributing Editor Spent potlining (SPL) disposal is one of the largest environmental waste management challenges confronting worldwide primary aluminum smelters due to its toxicity The The SPL Waste Management Challenge in Primary 2017年8月1日 On the basis of analysis of limestone decomposing and slagging mechanism, the changing of surplus heat was studied using limestone instead of lime as the slagging agent during steelmaking process The Research Process on Converter Steelmaking Process by Using Limestone2007年1月1日 The main byproduct of this smelting process is "slags" rich in iron oxide, formed by the reaction between iron oxide and silica; other contaminants in ore often include slag in the process Examination of smelting and smithing slags formed in bloomery

.jpg)

Smelting Reduction Processes SpringerLink

2020年3月3日 Process description: The AusIron process is a bath smelting process which directly processes ferrousbearing feed materials to produce molten iron The process, as shown in Fig 811 , is based on top submerged lance technology where coal, ferrous feed, flux and oxygen are injected directly into the smelter slag bath2023年8月1日 The treatment process for valuables' recovery includes grinding the asreceived copper slag to the desired liberation size The ground copper slag is then subjected to froth flotation, wherein various reagents are added to facilitate the flotation of valuable constituents and the simultaneous removal of undesirable impuritiesA comprehensive review on the recovery of copper values from copper slag2012年5月23日 Recently, Park and Park investigated the vitrification of red mud using gold tailing and waste limestone to make glass ball by slag atomizing technique (SAT), which is a process where air jets are (PDF) A new approach to the recycling of gold mine tailings 2021年7月15日 A potential industrial wastewaste cotreatment process was proposed and verified for the recovery of the valuable metals Co, Ni, and Cu from copper smelting slag by utilizing high temperature SO 2 offgas Sulfation roasting followed by water leaching under designed thermodynamic conditions was conducted to facilitate the selective formation of Co, A potential industrial waste–waste cotreatment process of

Lime, an essential component in the steel industry

Formation of slag: calcium oxide is used in slag formation which, among other things, accumulates the waste materials that are produced in the steel making process Moreover, it protects the metal from the elements in the atmosphere, such as nitrogen and hydrogen, it is also an insulator allowing the high temperatures reached in the process to be maintained (1,600 Electric furnace slag is a solid waste discharged from the process of metal smelting by electric furnace, and its main components are oxides such as calcium, iron, copper, silicon, magnesium, aluminum, manganese, and phosphorus The common ones are steelmaking electric slag and coppersmelting electric slag At present, environmental protection isWhat kind of crusher is needed to process electric furnace slag?