What is a small openair industrial grinding mill manufacturer

Air Classifying Mill ACM Air Classifier Mill

RIECO’s Air classifier Mill (ACM) is an air classifying mill with integrated grinding, classifying, conveying, and collecting operations for achieving ultrafine grinding (up to 2 micron*) depending upon the nature of the productThe Mikro ACM® Air Classifying Mill is an air swept mechanical impact mill with a dynamic air classifier designed to grind an extensive range of materials down to a D97 of 20 microns The Air Classifying MillAn air classifier mill, also known as an air classifying mill, uses airflow to separate particles by size The mill consists of a grinding chamber, a classifying wheel, and a fan The raw material to be ground is fed into the grinding chamber, which is Air Classifier Mills for Precise Particle Sizing AtritorPrater Air Classifying Mills (CLM) offers the combination of twostage closed circuit grinding with internal air classification Their unique capabilities out perform singlepass mills when handling difficult to grind products or those requiring a Air Classifying Mill for Particle Size Reduction Prater

MICRONIZER JET MILL Sturtevant Inc

Utilizing a unique fluid energy grinding system to generate particleonparticle impact, the Micronizer grinds and classifies powders to micron and submicron sizes in a single opera Jet Milling is an efficient way to mill or micronize various ceramics, polymers, and other friable materials Abrasive and temperaturesensitive products can be finely ground with minimum Jet Milling Material Milling AVEKAThe Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others Raymond Roller Mill airswept vertical ringrollWilliams Patent Crusher designs and manufactures highquality industrial roller mills that dry, classify, and consistently deliver a uniform grind for almost any material Our primary goal is to provide the best value for our customers and Industrial Roller Mills Williams Crusher

.jpg)

HIGmill high intensity grinding mill Metso

Metso HIGmill™ is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind MIKRO ACM® AIR CLASSIFYING MILL The Mikro ACM® Air Classifying Mill is an air swept mechanical impact mill with a dynamic air classifier designed to grind an extensive range of materials down to a D97 of 20 microns The Mikro ACM® Air Classifying Mill is available in a range of sizes and can be supplied for laboratory use or large Air Classifying MillFind your air classifier mill easily amongst the 26 products from the leading brands (NETZSCH, Hosokawa, EIRICH, Main applications • Grinding mills designed for mediumsmall productions (20÷1000 Kg/hour) of: foodstuffs, Air classifier mill, Air classifier grinding mill All China Grinding Mill wholesale Select 2024 high quality Grinding Mill products in best price from certified Chinese Mining Machine manufacturers, China Crusher suppliers, wholesalers and factory on MadeinChinaGrinding Mill MadeinChina

.jpg)

Mills: What are they? How are Mills used? Advantages IQS

A grinding mill circuit includes the feed system, mill, classifier, separator, and product collector Closed circuit grinding mills return large particles for remilling while open circuit grinding mills do not feedback in a loop Chapter 4: What are the various types of milling?The Metso Outotec® Open Ended Discharge Grinding Mill Fives designs fittoprocess solutions From very large to small mill size Air swept mill or a birotator mill Fitted with Compare this product Remove from comparison tool by manufacturer Fritsch GmbH mills; Hosokawa mills;Large mill, Large grinding mill All industrial manufacturersHammer Mill DFZC Bühler is a leading manufacturer of food processing and animal feed processing equipment he allows however the processing of more consequent batches than FNG0000 or BLX This mobile grinding unit is used for small industrial productions As The Metso Outotec® Open Ended Discharge Grinding Mill Impact mill, Impact grinding mill All industrial manufacturers2017年2月13日 DRY GRINDING BALL MILL Complete laboratory testing service, mill and air classifier engineering and proven equipment make possible a single source for your complete drygrinding mill installation Units available with air swept design and centrifugal classifiers or with elevators and mechanical type air classifiers All sizes and capacities of Ball Mills 911Metallurgist

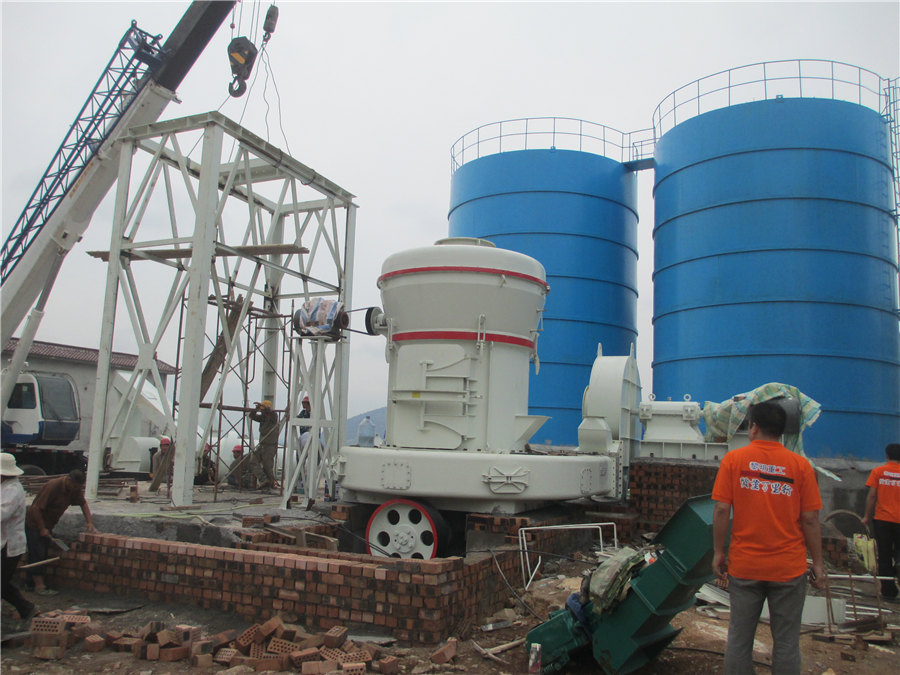

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Vertical mill, Vertical grinding mill All industrial manufacturers

Grinding in a complete closed system, no dust, low noise, clean and environmentally friendly Fluidized Bed Opposed Air Jet Mill: After the compressed air is filtered and dried, it is sprayed into the grinding chamber A grinding mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processes ensuring efficient and rapid size reduction for laboratory and industrial applications Cutting MillsGrinding Mills for reliable size reduction tasks RETSCH2015年10月23日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a EnergyEfficient Technologies in Cement Grinding IntechOpenRotational speed: 10,000, 12,000, 14,000 rpm The cyclone mill TWISTER is designed for sample homogenization of food and feedstuff for subsequent NIR analysis The form of rotor and grinding chamber has been optimized to Cyclone mill, Cyclone grinding mill All industrial

.jpg)

Ultrafine mill, Ultrafine grinding mill All industrial manufacturers

Rotational speed: 120 rpm 240 rpm Output: 400 kg/h 30,000 kg/h Machine length: 13,900, 14,700 mm inhales air within the grinding mill and, in turn, the airflow with crushed materials are brought to the classifier whose highspeed impeller will screen the airflow: the unqualified particle size will fall and return 2023年5月15日 We should be able to achieve the necessary particle size distribution using the grinding mill we select Energy Efficiency A grinding mill’s energy use represents a considerable running expense, thus choosing one What is Limestone Grinding Mill SBM Mill Crusher2024年4月28日 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead of falling freelyGrinding at or close to critical speed of the mill yields a poorer grinding efficiency The ball mills are mostly operated at 6575% of the critical speed to What is a Ball Mill Explained: InDepth Guide JXSCThe industrial vertical grinding mill system has simple process flow, compact layout, and small building area It covers an area of ??about 70% of the ball mill system, and the building space is about 60% of the ball mill system It can be arranged in the open air, which directly reduces the investment cost of the enterpriseIndustrial Vertical Grinding Mill

Grinding Mills Common Types 911Metallurgist

2016年11月7日 For the preparation of small quantities of powder many types of mill are available but, even so, the ball mill is frequently used For the grinding of the largest quantities of material however, the ball, tube or rod mill is used almost exclusively, since these are the only types of mill which possess throughput capacity of the required magnitudeProduction of industrial and professional stone mills for industrial mills Industrial production processes are increasingly required to meet a wide variety of requests from customers and thus from final consumers, who are now demanding different food products to suit today’s major changes in lifestyle The BioStoneMill industrial and professional electric stone mill is able to Industrial Electric Stone Grinding Mill Manufacturer BioStoneMillPowderizer®: Airswept impact mill with integral classifier; grinds to lowmicron range with tightest particle size distribution Simpactor®: Centrifugal, pintype impact mill; reduces lowto mediumdensity materials to 50200 mesh Air Classifiers:Air streams separate fine and coarse particles with mechanical rejector for product quality MICRONIZER JET MILL Sturtevant IncOur ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsBall Mill Grinding William Boulton

Ball mill, Ball grinding mill All industrial manufacturers

air classifier mill DYNAIR Output: 1 t/h A compact benchtop grinding mill with powerful and shear crushing capabilities IQ MILL2070 makes the sample grinding Find a nearby distributor or reseller Contact the manufacturer to get a quote or a price Examine product characteristics and technical specifications for major brands Hammer Mill DFZC Bühler is a leading manufacturer of food processing and animal feed processing equipment talc grinding mill, micagrinder mill, Final grain size: 200 µm Rotational speed: 70 rpm Machine length: 120 cm Ball Bill, Cement mill, Cement grinding mill All industrial Air Classifying Mill Manufacturer 935; kemai@kemaiy Home; About Us; Products Highquality Air Classifying Mill Manufacturer for Precision Grinding Industrial Dust Collection S Series Mobile Impact/Hammer CrusherAir Classifying Mill Manufacturer Kemai2016年10月12日 Open Circuit Grinding Open circuit grinding consists of one or more grinding mills, either parallel or in series, that discharges a final ground product without classification equipment and no return of coarse discharge Closed Circuit Grinding VS Open Circuit Grinding

Ceramic mill, Ceramic grinding system All industrial manufacturers

Motor power: 30 kW 250 kW Machine length: 1,650 mm 3,900 mm Machine width: 900 mm 3,700 mm trouble, etc Also this mill is fabricated with special hardenedsteel of vessel, disc, shaft cover, separation rotor, etc with hardened Cr alloy steel, SUS 420J2 This DS Horizontal Mill is fullydeveloped Grinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill show Grinding Mills 911Metallurgistclosed system, no dust, low noise, clean and environmentally friendly Working Principle Fluidized Bed Opposed Air Jet Mill: After the as the FNG, he allows however the processing of more consequent batches than FNG0000 or BLX This mobile grinding unit is used for small industrial Contact the manufacturer to get a quote or a Laboratory mill, Laboratory grinding mill All industrial manufacturersRotational speed: 5,000 rpm 25,000 rpm Motor power: 100 W Machine length: 300 mm batches, timeconsuming cleaning and the often small sample quantities The Tube Mill 100 control Pharma Solution package, consisting of the Tube Mill 100 control batch millBatch mill, Batch grinding mill All industrial manufacturers

.jpg)

Industrial Grinding Machine Manufacturers, Suppliers, Dealers

This industrial device is essential for grinding and cutting tasks of specific types like surface grinding, cylindrical grinding, and cutter grinding Manufacturing Process In various manufacturing processes, grinding machines are used to improve the accuracy and performance of highquality components of various productsGrinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 71 Introduction Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterGrinding Mill an overview ScienceDirect TopicsThe rod mill generally uses a wet overflow type and can be used as a firstlevel opencircuit mill Compare this product Remove from comparison tool grinding mill, pyrophyllite grinding mill, ceyssatite grinding mill, a laboratorygrade ball mill designed to obtain small particle size samples for testing standardsStone mill, Stone grinding mill All industrial manufacturers2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Find, read and cite all the research you Grinding in Ball Mills: Modeling and Process Control

.jpg)

A Definitive Guide to Rolling Mills: All You Need to

2023年5月31日 Definition of a Rolling Mill Generally, a rolling mill refers to a machine used in metalworking works or projects to shape metal materials by passing them through a pair of rolls Similarly, these machines’ main objective Fluid Air mills' versatile design, combined with a removable containment option, a laboratorygrade ball mill designed to obtain small particle size samples for testing standards This unit is suitable for grinding small amount of the Laboratory mill, Laboratory grinding mill All Zhengyuan is China powder grinding mill manufacturer, offer jet mill, impact mill, ball mill, roller mill, plastic pulverizers We also provide accessories for powder grinding equipment, like air classifier, dust collector and rotary feeder We offer fine grinders for different uses, such as for grinding large quantities of material, superfine grinder mills for grinding sample material and Ball Mill Jet Mill Powder Grinding Mill Impact Mill Manufacturer 2017年6月9日 The mica was ground in the 10inchdiameter, opencircuit plant at a feed rate of 50 pounds per hour; the mica feed slurry contained 20 percent solids, and minus 14 plus 28mesh Ottawa sand was the grinding medium In the opencircuit grinding plant, a premixed, dispersed slurry of mica and water was fed to the attrition grinder by means of a Attrition Grinding Mill Design 911Metallurgist

.jpg)

Grinding Characteristics of Wheat in Industrial Mills

PDF On Jan 16, 2013, Gheorghe Voicu and others published Grinding Characteristics of Wheat in Industrial Mills Find, read and cite all the research you need on ResearchGateGrinding Mill Design Process Selection According to the china ball mill ore sample provided by the customer, the parameters of ore crushing and grinding are measured Through the simulation of JKSimMet computer software, the best SAG mill and Ball mill specifications and parameters are settled Strength Finite element analysis is commonly used to calculate the strength of the Industrial Ball Grinding Mill Machine Supplier/Manufacturer CICGrinding in a complete closed system, no dust, low noise, clean and environmentally friendly Fluidized Bed Opposed Air Jet Mill: After the The rod mill generally uses a wet overflow type and can be used as a firstlevel opencircuit mill 37, 55, 75, 132 kW grinding – continuous for fine grinding of industrial minerals Centrifugal mill, Centrifugal grinding mill All industrial manufacturers2023年6月12日 We specialize in ball mills and ball mill lid replacements, among other services We can design and build ball mills that suit your needs, whether you need a small batch mill or a largescale production mill We can also provide you with the necessary accessories, such as liners, grinding media, bearings, gears, and moreWhat is a Ball Mill?

Coarse powder mill, Coarse powder grinding mill All industrial

Final grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L welded mechanic, it is intended for the small installations of grinding in laboratory