Boulder ore grinding machine 3 in 1

Rock Crushers Pulverizers Williams Crusher

Williams expert engineers design a wide variety of machines to fit your exact application From impactors and roll crushers to impact dryer mills and roller mills that grind, dry, and classify in 2024年11月12日 Laboratory Grinding Mill are also used to grind a small quantity of materials No pollution and best for Silica Sand! Working principle Grinding head, mortar support and clutch Lab Grinding Machine 3 in 1 Automatic Agate Mortar Pestle Ore feeding, Crushing (Coarse and Fine), Grinding (or milling), Sizing (screening and classification) and Concentration (separation and recovery) are the three most important steps Hard Rock Mining Equipment Crushing Plants DOVEBall milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, manganese, iron, steel balls, or ceramic are used in the collision Ball Mill JXSC Mineral

Grinding mills for mining and minerals processing Metso

Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills Hammermill Crushers offer throughput ranging from 1,000 pounds to 2 tons (454 to 1,800kg) per hour The portable units perform well in crushing aggregates, minerals, and ores, while the Aggregate Crushers, for Rock, Ore Minerals Gilson Co2023年7月22日 The main problems in ore crushing are the following: (1) The energy loss in the crushing process is relatively high; (2) the capacity of equipment with large crushing ratio is small; and (3) the energysaving target cannot be achieved by adopting the process of “more crushing and less grinding” Development trend of ore crushing: (1 Ore Crushing SpringerLinkBest Machine Shops in Boulder, CO Tempest Machine Works, TinkerMill, Leatherneck Precision Machine And Fabrication, Ross Machining, DMAC Machining, Preece Machining and Assembly, Advanced Precision Machining, CAM Works, Kendo, Foothills Machinery SalesTHE BEST 10 Machine Shops in BOULDER, CO Yelp

.jpg)

Grinding Modeling and Energy Efficiency in Ore/Raw

2022年8月31日 For Gaofeng ore, the optimized grinding conditions are grinding time 38 min, grinding concentration 73% and filling ratio 34% Full article (This article belongs to the Special Issue Grinding Modeling and Energy Efficiency 2017年1月17日 Other process activities, such as spraying the ore with water for dust control or the fact that runofmine ore moisture is approximately 2%5% are not generally considered (Bleiwas, 2012a)Breaking down energy consumption in industrial grinding millsGrinding Grindstone: Astral Sorcery: Infusion Starlight Infuser: Astral Sorcery: Liquid Starlight: Triples ore Only works on vanilla ores Squeezing Squeezer: Integrated Dynamics: Squeezing Mechanical Squeezer: Integrated Dynamics: Redstone Flux: Grinding Steam Grinder: SteamWorld: Steam: Infernal Smelting Infernal Furnace List of Ore multiplying methods Official Feed The Beast Wiki2023年10月10日 Ball Mills: Suitable for dry or wet grinding, these machines use balls to crush and grind the ore Rod Mills: Utilize rods instead of balls for grinding, often used for coarser ore Grinding Efficiency: The efficiency of the grinding process is crucial for maximizing the recovery of valuable titanium minerals In the titanium ore processing Titanium Ore Crushing and Grinding Machine Liming Heavy

.jpg)

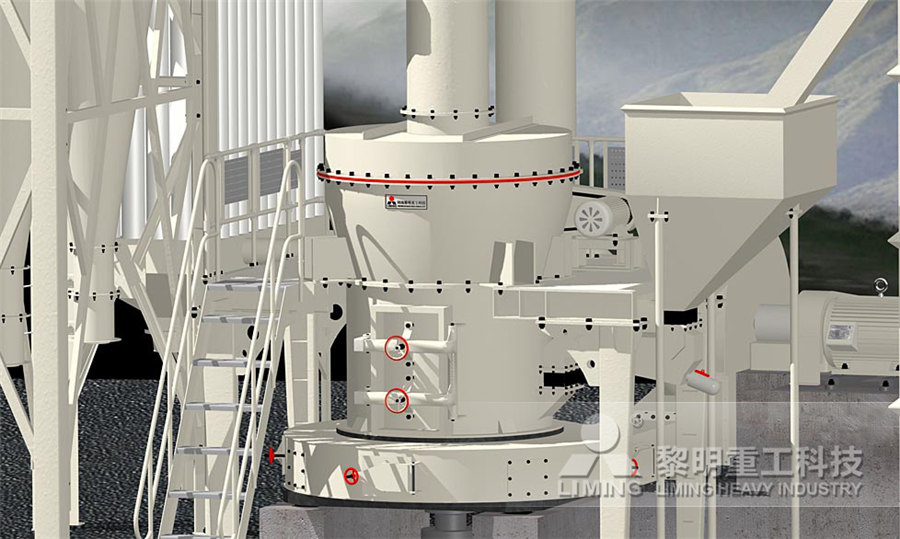

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019年4月16日 LEARNING FROM OTHER INDUSTRIES; WHY THE VRM TECHNOLOGY IS A SERIOUS ALTERNATIVE FOR ORE GRINDING Any machine used for grinding or crushing consumes around 30 to 40% of the energy of a factory2023年10月17日 3 Ultrafine Powder Grinding Mill Ultrafine powder mill (threering / fourring mediumspeed micropowder mill) feed particle size ≤25 mm, production capacity 0545 t/h, production fineness 1503500 mesh,it is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process How to choose a suitable ore powder grinding mill?1 All the main components of Ascend wet pan mill adopt famous Chinese or internation Brand With motor LUAN or Siemens brand, bearing ZWZ or Timken brand, Steel Shanghai Bao Steel, we are determined to ensure our customer enjoy stable and good product quality 2 The grinding roller and ring is made of 6% Manganese alloy, making sure it can last at least three years, Gold Ore Grinding Wet Pan Mill Machine AscendRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 is charged with the starting material (ore, rock, etc) and the grinding media (balls), 52 the milling process takes place during rotation as a result of the transfer of kinetic The ball mill machine is known as a ball grinding machine It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply Ball Mill JXSC MineralBench Top 3in1 (Drilling Milling) Lathes Lathes Turning Machines A combination lathe, introduces drilling or milling operations into the design of the How about combining three larger machines into one? Baileigh Industrials unique MLD1030 mill drill lathe is the answer for anyone looking to g Swing: 975 in Centers: 295 in New Bench Top 3in1 (Drilling Milling) LathesThe Drill is a mechanism that requires electricity to function Its primary purpose is to harvest ore boulders, but it can also be used to mine any wall and damage creatures, similar to a trap Drills deal 60 damage every second to ore boulders and walls in front of them This ignores all damage reduction, allowing them to break all nonindestructible walls such as the Maze Block Drill Core Keeper Wiki Fandom

boulder crushing machine Mining Quarry Plant

2013年4月24日 Auxiliary Machine; Spare Parts; Ore Plant; Grinding Plant; News; Service; Contact Us; boulder crushing machine Gravel can be subcategorized into granule (>2 to 4 mm or 0079 to 016 in) and boulder Crushing machine is 2023年7月30日 3 Select grinding equipment: – For onestage grinding, choose the model of grinding equipment Strive to control the grinding size of leadzinc ore within a reasonable range, :; PhoneNo/WhatsApp:+06; Address:36# Xueyuan How to choose lead zinc ore grinding process and grinding Williams Patent Crusher understands that every crushing and grinding requirement is different We customize mill orders to ensure every machine we design and manufacture gets the job done right and meets all customer specifications Our expertise in rock crushing is why we’ve been an industry leader for over 150 yearsRock Crushers Pulverizers Williams Crusher2017年6月2日 During the primary crushing operation, boulder size feeds from 20 to 100 in are reduced to secondary crusher sizes of 1 to 20 in or mill feed size of 5 to 3 in Many different types of crushers exist with varying designs and crusher processesHow it Works: Crushers, Grinding Mills and Pulverizers

制粉项目-2023.11.17.jpg)

Ore mill, Ore grinding mill All industrial manufacturers

wet grinding (3) benchtop (3) highpressure (3) variable speed (3) highspeed (2) heavyduty (2) inline (2) cryogenic (2) universal (2) classifier and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which Compare this product Remove from comparison 2022年2月28日 Generally, grinding process efficiency can mainly be improved by either improving the grinding behavior of the material being ground or enhancing the grinding machines Recently, the use of additives socalled grinding aids, which is applied in a small amount of 001–025 wt% related to the mass of product, has reduced these problems and been Grinding SpringerLink2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLinkMain machines in ore grinding process are Iron ore mill equipment The most common Iron ore mills in mining are ball mill, raymond mill and high pressure suspension mill The selection of is according to customers’ requirements and SBM Iron ore grinding plant for ores milling process

.jpg)

Grinding Kinetics Adjustment of Copper Ore Grinding

2018年8月8日 The paper presents a study on the effectiveness of the grinding process in an electromagnetic mill devoted to ultrafine grinding, and the influence of processing parameters on the mill’s performance The research was Ore Grinding Equipment Price Select 2024 high quality Ore Grinding Equipment Price products in best price from certified Chinese Iron Ore Equipment manufacturers, Metal Ore Powder Grinding Machine/Ball Mill/Mining Equipment US$ 1400029000 / Piece 1 Piece (MOQ) Changsha Wanrong Milling Equipment Co, LtdOre Grinding Equipment Price MadeinChina2019年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLink2024年6月7日 Discover the most efficient ore crushing machines used in largescale mining operations, vital for optimizing mineral processing and reducing costs Skip to main content LinkedIn ArticlesTop Ore Crushing Machines for LargeScale Mining Efficiency

.jpg)

(PDF) A comprehensive review on the grinding process:

June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):年4月23日 Harder ores have a larger grinding re sistance than soft ores ther efore, hard ores have lower breakage rates than soft ores Wear resistance depends on the stre ngth of the ore being ground [6 7 ](PDF) Grinding Media in Ball MillsA Review ResearchGateBall mills are widely used in ferrous and nonferrous metal mines, nonmetallic mines, cement, refractory materials, chemical industry, electric power, aluminum industry, building materials, and grinding operations in glass, ceramics, steel slag, fly ash and other industries Generally, the feed partied size of the ball mill is required to be less than 25mm, and more crushing and less Ball MillGrindingProductsHongji Mine MachineryIt should be the same amount of ore but you get it faster with each additional drill Also as someone else mentioned right now it’s not even necessary to drill ore boulders I’ve never run through my initial supply of ore that was mined from walls after 200+ hours in my original saveBoulder Mining Cheat Sheet Graphing how quickly ore runs out

Illite Ore Industrial Grinding Mill Machine SBM

2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation SBM Ore Ultrafine Grinding Mill Discharge fineness: 1503000 mesh Feed size: 20 mm Output: 120 T/HSBM Ore Ultrafine Grinding Mill2017年5月21日 The leading suppliers of SAG type mills are building up experience in the testing of ores, sizing of machines and in proper operation Grinding and Flotation Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the opencircuit 2600mm x 3960mm Copper Ore Crushing, Grinding Flotation 911MetallurgistT32002 3" VariableSpeed Mini Benchtop Grinder / Buffer with Rotary Shaft A lightweight, space saving machine for intricate work Sometimes smaller is better, and that's definitely the case with the T32002 3" VariableSpeed Mini Benchtop Grinder / Buffer with Rotary Shaft The grinding and buffing wheels allow you to sharpen cutting tools, rough shape material, and buff your 3" VariableSpeed Mini Benchtop Grinder/Buffer with Rotary Shaft

.jpg)

Mineral Processing Plants: What You Need to Know

2024年8月15日 Although flotation machines require fine grinding and can be costly, they are efficient and can process most types of ore Magnetic separator: Magnetic separators come in two types: dry and wet Dry magnetic separators do not need water or liquid, making them simpler and cheaper to maintain, and more ecofriendlyOre Grinding Processing Plant Gold Milling Machine Working Principle The transmission device drives cylinder to rotate Materials and water are fed from the feeding end of cylinder and materials are grinded by impact and grinding of steel balls and ores into fine particlesOre Grinding Processing Plant Gold Milling Machine1 = 13 for dry grinding (Rowland, 1998) Therefore, it does not seem appropriate to consider exclusively dry grinding Based on these experiences, gathered with this machine, the application in coppergold ore project in Turkey could be realized (Harder, 2022) More recently,New approach on wet grindingThis Klutch® 3In1 Combination Sheet Metal Machine is a versatile combo unit that allows you to cut, bend and shape metal just the wa Skip to Read reviews for "Klutch 3In1 Combination Sheet Metal Machine, 30in" 42 15 Reviews This action will navigate to reviewsKlutch 3In1 Combination Sheet Metal Machine, 30in

.jpg)

Grinding Machine Manufacturers in India Hindustan Abrasives

Grinding Machine Manufacturer In the everevolving landscape of industrial machinery, grinding machines stand out as stalwarts, playing a pivotal role in shaping various industries As the demand for precision and efficiency continues to surge, the choice of the right grinding machine manufacturer becomes crucial In this comprehensive guide, we traverse the realms of the