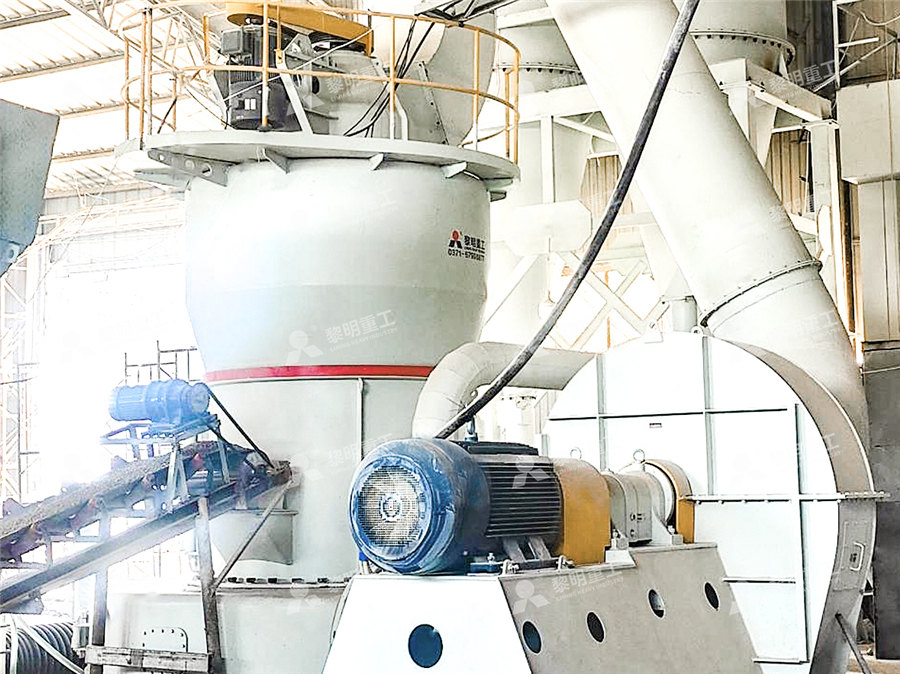

Semicoking coal grinding equipment

.jpg)

SemiCoke Dryer Machine Zoneding Mining Machine

Semicoke plays a significant role in the industrial sector due to its distinctive characteristics, including high fixed carbon content, elevated electrical resistivity, and excellent chemical reactivity Additionally, it features low ash, aluminum, sulfur, and phosphorus contentSemicoke is a product of lowtemperature pyrolysis by lowrank coal, with a composition similar to that of anthracite for pulverized coal injection (PCI) Herein, we investigated the differences Impacts of Blending Semicoke in PCI Coal on Grinding Efficiency 2019年1月1日 This chapter explains the technological principles behind semisoft coking coal utilization from the viewpoint of the mechanism of carbonization and reviews the development The development of cokemaking technology based on the 2023年7月17日 Coal briquettes are made by compressing coal dust and a binder, while formed coke is produced by carbonizing and consolidating semicoke Formed coke has higher fixed carbon content, lower moisture, and Clean Preparation of Formed Coke from Semicoke by

.jpg)

Semi Coke SpringerLink

2024年1月1日 Powdery semi coke can be used as blast furnace injection fuel, sintering fuel, and boiler fuel, as well as lean agent for coking and coal blending, and raw material of Semi coke is the solid products, obtained from lowrank bituminous coal, lignite, or peat by carbonization at low temperature (500–750 C) in a retort furnace In general, semi coke is also a Semi Coke Springer2023年11月6日 Intelligent coal gangue separation equipment has the advantages of fast speed, high precision, strong modularity, and integration scalability It also has the advantages of low operation cost and energy A review of intelligent coal gangue separation 2018年10月1日 Through optimizing the structure of coal blending system, the accuracy and stability of coal blending process control system can be improved, the coal blending error can Structure optimization of coal blending equipment in coking

.jpg)

Impact of grinding media shape on the dissociation characteristics

This suggests that leveraging hexagonal prisms as the grinding media is capable of efficiently and selectively grinding coking coal middlings while protecting clean coal from overgrinding 2016年7月1日 In India, there is a limited resource of prime coking coal, because of which these lowgrade high ash semicoking coals may be used for the coke making after beneficiation The objective of the present investigation was to study the beneficiation of semicoking coal using allflux separator that uses the principle of liquid–solid fluidization for separating the particlesStatistical modelling and optimization study for beneficiation of 2006年5月8日 MARKETS Semisoft coking coal to lift: AME THE huge price differential between semisoft coking coal and hard coal has driven demand resurgence for the lower priced coal, with North Asia steel companies indicating they intend to increase their semisoft coking coal purchases at the expense of hard coking coal, according to Sydneybased economic Semisoft coking coal to lift: AME MiningMonthly2020年8月21日 Hard coking coals like anthracite have better coking properties than semisoft coking coals, allowing them to garner a higher price Australian HCC is regarded as the industry benchmark While PCI coal is not often What You Should Know About Metallurgical Coal

Impact of grinding media shape on the dissociation

To enhance the utilization rate of coking coal resources, researchers have conducted deep studies on the reseparation of coking coal middlings, which focus on deep dissociation and advanced flotation techniques [3, 4]Due to the gangue that coexists with coal typically having finely embedded particle sizes and complex dissemination characteristics, the flotation 2024年7月22日 country With a surplus of semisoft coking coal in South Africa, this research sought to look into this kind of abundant coal to enhance its property as a reductant for blast furnace applications For this reason, a study was conducted on two Southern African coals, Grootegeluk (semisoft coking coal) and Moatize (higher quality coal)Upgrading SemiSoft Coking Coal by Hydrothermal Treatment: Round Sheet Semi Coke O2 Coking Gas Ethylene Glycol 425wt% NaOH Medium Temperatiure Tar Coal Ammonium Sulfate Sulfuric Acid (925%) Crude Benzene Tar Washing Oil Sulfur Cream PDS + Extract Caustic Soda Plant (EAC IND 3) VCM Plant (EAC IND 2) Acetylene Plant (EAC IND 3) Poly Vinyl Chloride (PVC) Calcium Carbide Plant SemiCoke Plant (EAC BRIEF PROCESS DESCRIPTION OF COAL TO PVC PROJECTcountry With a surplus of semisoft coking coal in South Africa, this research sought to look into this kind of abundant coal to enhance its property as a reductant for blast furnace applications For this reason, a study was conducted on two Southern African coals, Grootegeluk (semisoft coking coal) and Moatize (higher quality coal)Upgrading SemiSoft Coking Coal by Hydrothermal Treatment:

Different Types of Coal Introduction underground COAL

These properties do not affect the way coal is mined, but they do affect the value of the product and there are different grades of coking coal, from "hard" coking coals (the best grade), through "medium" to "soft" coking coals, and even "semihard" and "semisoft"2023年6月10日 Lump semi coke can be used as reducing agent in ferroalloys, calcium carbide, and other industries It can also be used as gasification coke and civil smokeless fuel Powdery semi coke can be used as blast furnace injection fuel, sintering fuel, and boiler fuel, as well as lean agent for coking and coal blending, and raw material of briquette/cokeSemi Coke SpringerLink2021年5月11日 Based on utility, coals are classified into coking type and noncoking type Further, coking coals are subdivided into four groups: prime coking coal, medium coking coal, semicoking coal, and weakly coking coal Prime coking coals when subjected to the carbonization process at high temperature produce coke of metallurgical standardsMineral Beneficiation and Processing of Coal SpringerLink2013年4月1日 The use of coal in the steel industry, similarly as in the whole national economy, is often preceded by its pretreatment Coal is mined in the form of big solids, but, being in such a form, it (PDF) Modeling of the process of coal grinding

Mineralogical Study of Beneficiated and

2019年10月29日 Coking/metallurgical coal is one of the essential raw materials for steel industries The metallurgical coal in India contains high ash content (mineral matters), is rich in inertinite, and 2024年3月19日 Abstract The hot strength and mechanical strength of metallurgical coke are the critical parameters for efficient blast furnace operation Therefore, producing the desired qualities of coke like coke strength after reaction, coke reactivity index, and coke M10/M40 is essential for optimizing the cost and productivity of hot metal Hence, the intrinsic property of coal is LowCost Ironmaking: Metallurgical Coal Prospective2023年10月8日 The selection of coal crushing equipment mainly depends on the input size of raw coal, the moisture of the coal, and the production scale (output) of the plant Of course, the output size and the final use of coal also need to be considered, such as 025 mm for gas furnaces, 825 mm for steam locomotives, 625 mm for industrial furnaces, and 025 mm for 6 Types of Coal Crusher: Which Is Best for Crushing My Coal?of microwave pyrolysis of coal in a char bed,11) a method for the manufacture of metallurgical blast furnace coke from a mixture of heavy coking coal and non or weakly coking coal by means of rapid microwave heating rate (25 kW, 30°C/minute),18) and more recently coke making from a high volatile bituminous coal within 10 minutes2) ShudaiInfluence of Additives on Cokemaking from a Semisoft Coking Coal

MODELING OF THE PROCESS OF COAL GRINDING

lurgy, pulverized coals combusted in different types of power plants, coking coals, etc THE MODEL OF GRINDING PRODUCT GRAIN SIZE DISTRIBUTION The effect of the grinding process depends on a very large number of parameters These include quantities related to the material being comminuted, the grinding equipment, the method of supplying energy Download scientific diagram Influence of the coal bulk density and share of semisoft coking coal on the coke total pore volume V TOTAL from publication: StampCharged CokeMaking Technology Influence of the coal bulk density and share of semisoft coking coal 2015年11月26日 Coproduction of DRI Powder and Semicoke from Siderite Ore and Low Rank Coal by Excessive Coalbased Direct Reduction in Rotary Kiln November 2015 ISIJ International 56(1)(PDF) Coproduction of DRI Powder and Semicoke from Siderite Keywords: coking, noncoking coals, coke small, economic efficiency 1 Introduction In Romania, the mining resources of coking coal are small and cannot guarantee the requirements metallurgical industry Of all the coal mines, only some contain coking coal, these being coal mines from Lupeni, Uricani and Barbateni [2]EXPERIMENTAL RESEARCH REGARDING DECREASING OF FABRICATION

Non Coking Coal for Iron Production – IspatGuru

2017年2月14日 At that time, thermal coals were readily available and had a much lower cost than hard coking and semisoft coking coals As understanding of the impact of coal quality on BF performance increased the demand for lower volatile coals has increased over the last 5 yearsSemi coke is the solid products, obtained from lowrank bituminous coal, lignite, or peat by carbonization at low temperature (500–750 C) in a retort furnace In general, semi coke is also a byproduct or intermediate product of the conversion of coal into liquid and gaseous fuels (Fig 1) Properties The main component is carbon, which can beSemi Coke Springer2016年6月1日 In India, there is a limited resource of prime coking coal, because of which these lowgrade high ash semicoking coals may be used for the coke making after beneficiationStatistical modelling and optimization study for beneficiation of 2013年9月3日 The stamped charging of coals, developed in Europe and adopted in China and India, allows the use of high volatile poor coking coals, soft and semi soft coals as well as inerts like petroleum coke (PDF) A review on stamped charging of coals

.jpg)

Technological Advancements and Prospects for NearZero

2024年9月15日 This review examines the technological bottlenecks, potential solutions, and future development directions in the treatment and resource utilization of semicoking wastewater (SCOW) in China By comprehensively investigating the semicoking industry and analyzing wastewater treatment research hotspots and existing projects, this study systematically 2022年4月5日 Noncoking coals are used in the cement, direct reduction, and smelting of iron ore, chemical, paper, etc industries India is one of the countries with rich noncoking resources in the world Most of the Indian coal is formed during natural disasters like floods (drift origin) The major problem with Indian origin is the high ash content Prediction of Washability Characteristics of Noncoking and Semicoking 2012年8月22日 However, it is to assume that this will be in the range of 500 plants, not including socalled primitive ovens, that means smaller coking plants without any technical equipment for operation Three principles will still characterize prospective projects for new coking plants: improvement of economics of coke production as well as optimization of the coke qualityEnvironmental Control and Emission Reduction for Coking PlantsThe advantages has been described of using a semiindustrial oven at a cokechemical plant Such oven in particular makes it possible to select the most rational conditions for preparation of the coal blend (humidity, degree of grinding, bulk density), to find the optimal composition of the experimental blend using gas and weakly coking coal, toJournal of Coal Chemistry, 2019, No

.jpg)

SemiCoke Dryer Machine Zoneding Mining Machine

Semicoking coal process During the semicoke drying process, a series of equipment, led by the semicoke dryer, is required to complete the drying process Our product range also includes grinding mills, crushers, conveyors, feeding machine as well as beneficiation equipment, The stamped charging of coals, developed in Europe and adopted in China and India, allows the use of high volatile poor coking coals, soft and semi soft coals as well as inerts like petroleum coke Main properties of coals taking part in the coking blend of JSW include extensive resources of low and medium volatile semisoft coking and thermal coals that are wellsuited to the PCI market These coals give high coke replacement ratios, assist in maintaining blast furnace productivity and exhibit good grinding characteristics Market—World Steel Production The International Iron and Steel Institute high energy coals Queensland for the PCI market2002年4月1日 Grindability of coal is a central characteristic of coal which is closely related to pulverizer performance and mill capacity (ACARP, 1998) and is defined as ease of grinding of coal which is, in An assessment of grindability index of coal ResearchGate

Specifications guide Metallurgical coal SP Global

coking coal globally, two for PCI coal, one for semisoft coking coal and four for metallurgical coke, for locations of loading/ delivery detailed in the table below Platts also assesses 17 individual brand relativities daily on a CFR China basis and 11 on FOB Australia basis, as well as a range of metallurgical coal4 In laboratory combustion tests, lumpy raw coal or semicoke was first coarsely broken using a jaw char at the end of the raceway, thus reducing the permeability/liquid permeability of the Impacts of Blending Semicoke in PCI coal on Grinding Efficiency They are mostly based on hydrophobicity difference8) Gui et al (2017), performed the experiment to study the liberation properties of middling coking coal9) Oliver et al, revealed that crushing increase both the liberation of mineral matter and clean coal10) Some studies conducted by the CSIRO, Australia, indicates that with the correct choice of comminution Effect of Grinding Behavior on Liberation of Coal Macerals生产焦炭的焦煤(coking coal),也称作冶金煤,属于烟煤或次烟煤。 或用多种煤炭配比混合后炼焦。焦煤在炼焦炉中隔绝氧气经过1,000°C干馏后,可挥发成分已经去除,剩余的固态物质即焦炭。 由于炼铁需要尽可能少的硫、磷雜質,所以应选择低硫低磷的焦煤。焦煤 维基百科,自由的百科全书

(PDF) Caking Ability Tests for Coal Blends in Process to Utilize the

2019年7月29日 The idea of this paper is to properly utilize Indian lowrank coking coal (semicoking coal) with the blending of highrank imported coals and to reduce the overall cost of coke making2024年1月1日 Lump semi coke can be used as reducing agent in ferroalloys, calcium carbide, and other industries It can also be used as gasification coke and civil smokeless fuel Powdery semi coke can be used as blast furnace injection fuel, sintering fuel, and boiler fuel, as well as lean agent for coking and coal blending, and raw material of briquette/cokeSemi Coke SpringerLink2024年8月1日 The phenols and ammonia–nitrogen compounds in semicoking wastewater are used to react with formaldehyde to generate phenolic resin and curing agent urotropine, so as to achieve the resourceful preparation of thermosetting phenolic resin The effects of pH value of wastewater, reaction time, reaction temperature, formaldehyde addition amount and other Preparation Conditions and Property Characterizations of Semicoking 2019年11月1日 For the topmost size interval (interval 1), integrating Eq (1) yields: m 1 (t) = m 1 (0) exp (S 1 t), where S 1 is assumed to be constant, and is determined from the slope of m 1 (t)/m 1 (0) versus t on a semilog plot This rule is known as the firstorder grinding hypothesis Firstorder models are often valid and frequently used to analyze the breakage rate of single Differences in dry and wet grinding with a high solid