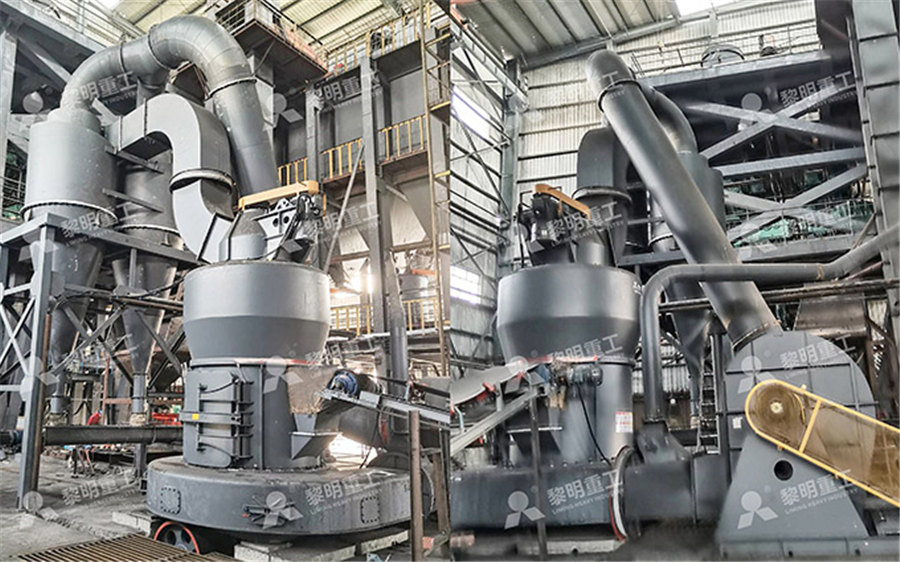

Raw coal vertical grinding Raymond mill

Raymond® Bowl Mill Coperion

The Raymond® Bowl Mill is considered the finest vertical roller mill available for pulverizing coal Each bowl mill system is designed to achieve the best solution for the processing application The mill, feeder, classifier, fan, cyclone, dust The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and Raymond Bowl Mill designed and built for flexibility QlarThe Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies limestone, clay, minerals and manufactured materialsRaymond Roller Mill airswept vertical ringrollThe raymond mill machine features a compact vertical structure, occupying minimal space while boasting a robust system It seamlessly transitions from raw material processing to powder production, culminating in final packaging, Raymond Mills High Quality Vertical Mill Manufacturer

Raymond Mill Raymond Mill Working Principle

Different from ball mills and other grinding mills, the Raymond Mill adopts a compact vertical structure And in its grinding system, the host, the powder concentrator and other auxiliary devices are connected closely• Hot air temperature and flow path through the grinding zones have been designed carefully so that it dries out coal without affecting the throughput ball race mill can handle moisture up to 15% • Mill can handle high ash abrasive Raymond mill Schenck Process Holding GmbHRaymond Mill is beneficial for energy saving and environmental protection It has high processing capacity, high separation efficiency and low energy consumption High Grinding EfficiencyRaymond Mill: Working Principle Parts Powder The Raymond® Vertical Mill is a highspeed air swept swing hammer mill used to pulverize materials in the extreme fineness range The principle of integral air classification, originally developed by Raymond®, has been applied with Raymond® Vertical Mill Coperion

Raymond® Roller Mills Coperion

The Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others2021年7月26日 When the humidity of the raw coal is below 15%, the CLIRIK coal pulverizer is used to grind the raw coal into 200 meshes Fine powder, while eliminating the need for drying and saving energy The drying capacity of the Coal PulverizerRaymond MillNEWSClirikHLM vertical grinding mill and vertical roller mill is a highefficiency energysaving advanced pulverizing equipment integrating drying, pulverizing, grading and conveying, which has been researched and developed by Guilin Hongcheng Company for more than 20 years Hongcheng HLM vertical grinding mill has the advantages of high grinding efficiency, low power HLM Vertical Grinding Mill Vertical Roller MillBellian Mining Machinery offers different types of Vertical Mills to suit various applications, including Vertical Raw Mills, Vertical Cement Mills, Vertical Grinding Mills, and Vertical Coal Mills Each type is designed to meet specific requirements and Vertical Roller Mill, Vertical Raw Mill, Vertical Cement Mill

How Does a Raw Mill Work in a Cement Industry

2024年2月23日 The operation of the cement raw mill is a critical step in cement production By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process Therefore, the efficient operation of the cement raw mill directly impacts the production efficiency and quality Wide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etc Strong production ability: AGICO CEMENT has a large production capacity and rich experience to produce any cement equipment required in cement plantCement Mill Cement Ball Mill Vertical Cement Mill Factory PriceAlso, Raymond Mill has the characteristics of low energy consumption and a good grinding effect and is widely used in metallurgy, building materials, the chemical industry, mining, and other fields Working Principle Raymond roller mill is mainly composed of main machine, analyzer, blower, finished cyclone separator, pipeline device, motor, etcRaymond Mills High Quality Vertical Mill ManufacturerRaymond mill or raymond grinder, raymond grinding mill adopts advanced grinding technology to crush and finely grind raw materials into required powder products It is a powder grinding machine widely used in mining, metallurgy, building materials, coal and nonferrous metal industries It is mainly used for finely grinding various ores, Raymond Mill JXSC Machinery

Raymond mill, Raymond grinding mill All industrial

Raymond mill, also called Raymond grinding mill vertical for coal grinding Contact Raymond mill Final grain size: 75 µm Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates HOW TO SOURCE PRODUCTS Exhibit with us FAQ Brand list;2023年12月7日 Raymond grinding mill is prominently employed in the mining industry for ore grinding, enabling the refinement of raw materials for subsequent metal extraction In cement production, it plays a pivotal role in grinding materials like limestone and clay to produce the essential components of cementHow Does The Raymond Roller Mill Work Raymond Grinding Mill Performance Advantages of Raymond Mill 1Small Occupational Area Saving Costs on Foundation Building Different from ball mills and other grinding mills, the Raymond Mill adopts a compact vertical structure And in its grinding system, the host, the powder concentrator and other auxiliary devices are connected closelyRaymond Mill Raymond Mill Working Principle Zenith CrusherOur main products include ultrafine vertical roller mill, ultrafine grinding mill, Raymond Grinding Mill for Coal Powder Making Plant Material: coal Fineness: 80400mesh Capacity: 12 t/h see More >> Raw material: custic calcined SBM Ultrafine Powder Technology Industrial

Raymond mill Schenck Process Holding GmbH

Get constant throughput of pulverized coal with capacities from 10 to 40 metric tons/hour bull; Lowmaintenance design a) Higher available grinding mass b) Arrangement is such that most of the coal particles gets ground by rubbing of 2022年10月3日 Vertical Raw Mill is a main equipment that is used in grinding or refining raw materials at PT Semen Baturaja (Persero) Tbk using a tire roller that can produce raw meal with the standard (PDF) ANALISA KINERJA ALAT VERTICAL RAW MILL PABRIK II PT 2024年3月22日 During the operation of the Raymond roller mill, materials to be crushed are introduced into the machine via the feed hopper located on the side of the machine shell The grinding roller device, suspended beneath the host’s star rack, is relied upon for the milling process As materials are fed into the mill, they undergo a dual motion: revolving around the How Does a Raymond Roller Mill Work Raymond Grinding Mill Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceVertical roller mills FLSmidth Cement

.jpg)

ATOX® Coal Mill FLSmidth Cement

A compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate Shanghai Clirik supply different types Grinding Mills, such as Raymond Mill, Ultrafine Mill, Vertical Roller Mill, Coarse powder mill, and so Vertical Grinding Mill Fineness: 30325mesh Capacity: 150t/h Raw materials: quartz stone Fineness: 08 mm Capacity: 345 t/h Raw materials: coal, salt, chalk, gypsum, blocks, limestone, glasses Raymond Mill, Ultrafine Mill, Vertical Roller Mill, Coarse powder mill Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVReeThe Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY

.jpg)

OK™ Raw and Cement Mill

The OK™ Mill was originally designed for cement grinding In 2017 we released the OK™ vertical roller mill for raw materials grinding The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and applicationVertical Coal Mill is specially used for ultrafine grinding of raw coal and bituminous coal materials in cement, power plants, iron and steel plants and other fields The GRMC coal vertical mill produced by CHAENG adopts special structural design and production process, which is energysaving and environmentally friendlycoal grinding machine CHAENGThe mining industry is a critical sector of the global economy, providing essential raw materials for industrial production, including coal, iron, and goldWhat is a Coal Grinding MillFactor 3: The humidity of raw material Raymond mill is suitable for processing the material that with humidity below 6% if the raw materials have humidity then they will stick to the inside of the fine Raymond mill after grinding, which will cause blockage during transportation Factor 4: The composition of raw materialFour factors Affecting the Grinding Efficiency of Raymond Mill

.jpg)

Raymond Mills Raymond Roller Mill Grinding Mill AGICO

What Is Raymond Mill Raymond mill is also called Raymond roller mill It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball millThis kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc Under normal conditions, these materials’ AGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System Cement vertical mill, also called roller mill, is another raw mill commonly used in cement pared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw MillFactory stock of coal powder grinding machine Our inventory is very sufficient, after your consultation, the sales manager will recommend the appropriate Raymond mill model to you according to your needs, welcome to contact usRaymond Mill Superfine Charcoal Powder Grinding MachineWhat Is Cement Vertical Mill The cement vertical mill is a type of grinding equipment that merges fine crushing, drying, grinding, and powder separating into a single, which simplifies the production process and has many irreplaceable advantages, such as high grinding efficiency, large feeding size, low power consumption (2030% less power than a cement ball mill), large Cement Vertical Mill Vertical Grinding Mill Vertical Mill

.jpg)

SBM Ultrafine Powder Technology Industrial Grinding Mill,

Our main products include ultrafine vertical roller mill, ultrafine grinding mill, Raymond Grinding Mill for Coal Powder Making Plant Material: coal Fineness: 80400mesh Capacity: 12 t/h see More >> Raw material: custic calcined magnesia; Equipment: Raymond Mill Working Principle In the Raymond mill, a Raymond mill spring with a pressure of 10001500 kg is fastened to the grinding roll hanger After starting work, the grinding roller rotates around the main shaft and rolls close to the grinding ring under the action of the Raymond mill spring and centrifugal forceRaymond Roller Grinding Mill Vertical Roller Grinding Mill Coal mill is the main equipment in the pulverized coal preparation processBecause calcining topgrade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized coal preparation system is one Cement Mill Cement Grinding Machine AGICO Cement Grinding MillAGICO Cement provides vertical cement mill, vertical roller mill used for cement manufacturing, powerful grinding and homogenization, customdesign cement mill, onschedule delivery Skip to content +86 Vertical Cement Mill, Vertical Roller Mill Buy

Vertical roller mill for raw Application p rocess materials

Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimationProcess introduction The GRMR raw material vertical mill of CHAENG is a kind of new high efficiency, coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any Vertical roller mill, Vertical roller grinding mill All Coal mill hot air inlet temperatures should never be more than 600 ° F and the outlet temperature should not exceed 200°F on Raymond coal mills If the flow of raw coal to the coal mill is interrupted for any reason (for example: plugging, failure of the coal feeder, etc), the outlet temperature of the coal mill can quickly climb to coal feeders and coal mill CapabuildRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by Raw mill Cement Plant

What is the process flow of vertical mill to produce pulverized coal?

Mill connection: the circulating fan is connected to the explosionproof bag dust collector and the inert gas supplement pipe: the inert gas supplement pipe is connected to a heat source system that supplements the low oxygen content heat source gas to the pulverized coal vertical mill to control the low oxygen in the extracorporeal circulation system The limiting oxygen content The MPS ZGM coal mill is a type of coal mill that operates at a speed of 50300r/min This equipment is used to prepare and process auxiliary materials for blast furnace ironmaking It provides suitable coal powder for the blast furnace ironmaking systemMPS ZGM Coal MillGrinding Equipment YingYong MachineryThe Raymond Vertical Mill is designed to pulverize materials into the extreme fineness range, with particle sizes as small as 510 microns It uses a principle of integral air classification to efficiently produce finely ground materials The mill is available in 18inch and 35inch sizes and can process a variety of materials including minerals, chemicals, and manufactured products It Raymond Vertical Mill Technical Datasheet PDF Mill (Grinding Large pieces of coal are crushed by the crusher to the feed fineness of the mill ( 80% below 20mm) The second stage: Milling The crushed small lump coal is sent to the silo by the hoist, and then sent to our grinding mill chamber for grinding evenly and Coal powder plant, Coal grinding mill, Coal mill, Coal vertical mill

.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, MPS 5000 B mill for raw material grinding, Turkey Tracim, Turkey MPS 5300 B mill for cement raw material grinding, CDI Hail Cement, Saudi Arabia