Which type of 3mm coal sample ore grinding machine is easy to use

Small Pulverizer Laboratory Pulverizer JXSC Machine

2018年2月9日 Small pulverizer is a minilab grinding machine for crush the ore/material samples into powder, which has been widely used in the laboratory of the mining, chemistry industries2024年10月28日 The sealed pulveriser gets an "automatic dust proof" and a "pot antiloose" device, which provide the machine advantages of low noise, no dust, and easy operation The Laboratory 3mz100 Sample Pulverizer for Sample Ore GrindingPulverizers efficiently reduce aggregate, mineral or coal sample particle sizes using grinding plates, hammermills, or centrifugal impact Grinding Mills include Ball Mills, Mortar Grinders, Crushers, Pulverizers Mills Gilson CoGilson laboratory coke and coal testing equipment are widely used for sample preparation, particle sizing, and hardness determinations of samples Hardness and grindability testers, Coal Testing Equipment Gilson Co

Ore Sampling Methods: Good Proper 911Metallurgist

2017年2月21日 In samplingmills the shakingtray is generally used on account of the ease with which the rate of feed can be inspected, and the great facility with which such feeders can be 2024年8月7日 Key types include Jaw Crushers, which handle large rocks and ores through compressive force; Cone Crushers, which provide finer output for hard materials; and Impact Mineral Processing Equipment for Mining Industry2021年8月13日 There are two types of selfgrinding processes: dry grinding and wet grinding Concentrators mostly use wet grinding In order to solve the problem of hardtogrind particles Grinding and grading equipment in beneficiation JXSC Mining2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding Ore Grinding SpringerLink

.jpg)

Helping to reduce mining industry carbon emissions: A stepby

2022年3月30日 High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO 2 emissions by up to 345 megatonnes/year, or 435% when compared In this blog, let’s explore what are the 4 types of grinding machines and get comprehensive guidance to assist in selecting the most suitable machine for your needs 1 Surface Grinding 4 Types of Grinding Machine and How to Choose Yours2017年2月21日 In samplingmills the shakingtray is generally used on account of the ease with which the rate of feed can be inspected, and the great facility with which such feeders can be cleaned after each lot of ore has been run For finegrinding machines, the coffeemill type still successfully holds its own against most of the newer devices, although Ore Sampling Methods: Good Proper 911MetallurgistThe latest Xometry product updates, news, and trends in manufacturingXometry Resources

Grinding Mills — Types, Working Principle

2018年8月17日 Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles Rod mills can accept feed up to approximately 50 mm (2 in) and Laboratory Sealed Disk Crusher and Vertical pulverizer can be used for intermittent and continuous fine grinding of hardbrittle and mediumhard materials in the field of mining and metallurgy, glass industry, ceramics industry, research institute and institutions of higher leaning for making samples instead of grinding samples manuallyThey are suitable to be operated Coal Mineral Ore Grinding Machine Laboratory Disc Mill 2016年2月29日 It is considered that a good ore sample from a given lithological type within a deposit will produce constant results However, in some deposits, well defined zones formed by remobilization may overprint the lithological horizons resulting in important differences in gold particle size and its distributionGold Extraction Recovery Processes 911Metallurgist2023年8月31日 The laboratory double roller crusher is for crushing nonmetallic materials such as coal, ore, and rock, which is suitable for intermediate and fine crushing of raw materials in the laboratory; This machine uses two rollers to rotate relative to each other to crush the material entering the crushing chamber, then enters the receiving hopper through the gap between the 3 Types Of Laboratory Crushers For Sample Ore Preparation

.jpg)

Exploring the Different Types of Grinding Machines

2019年11月1日 Surface Grinding Machine A third type of grinding machine is a surface grinding machine Surface grinding machines are unique because they feature an adjustable head The head on a surface grinding machine can be lowered down to the workpiece Once lowered, the head can then rotate back and forth under the machine’s grinding wheel2002年4月1日 Grindability of coal is a central characteristic of coal which is closely related to pulverizer performance and mill capacity (ACARP, 1998) and is defined as ease of grinding of coal which is, in An assessment of grindability index of coal ResearchGate2015年5月24日 The use of a laboratory pulverizer is a must before sending any soil or test sample for XRF, titration, ICP or other assay method; you need to pulverize or fine grind a dry representative portion of the rock sample using what is commonly called in the laboratory language of sample preparation a laboratory pulverizerAny of these term are part of the Laboratory Pulverizers 911MetallurgistRelated Products 1) Laboratory grinding millerclick for more details 2) laboratory intelligent conical ball millwith automatic discharging Company Profile Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional Laboratory Mine Sample Pulverizer Grinding Mill Machine for Coal Ore

Coal Sample Preparation Strategy using the TENCAN GQM series

2024年6月10日 Therefore, a Semiautogenous milling strategy was taken advantage of for the grinding activity that involved five (5) different coal samples and the optimum product stream in the particle size 2017年9月1日 With the continual depletion of high grade simple ore bodies, more complex, finely disseminated ore bodies are being processed, which has led to an increase in the prevalence of fine grinding (Sinnott et al, 2006)This has been evident in the platinum group element (PGE) industry in South Africa, where the Bushveld Complex hosts 70% of global Fine grinding: How mill type affects particle shape characteristics 2022年2月28日 Generally, grinding process efficiency can mainly be improved by either improving the grinding behavior of the material being ground or enhancing the grinding machines Recently, the use of additives socalled grinding aids, which is applied in a small amount of 001–025 wt% related to the mass of product, has reduced these problems and been Grinding SpringerLink2018年8月8日 One of the most effective methods of grinding Portland cement is the use of an electromagnetic mill, which has proven its advantage in creating clinkerless binders [2], regulating the kinetics of (PDF) Grinding Kinetics Adjustment of Copper Ore Grinding in

.jpg)

What is Grinding: Definition, Types, Uses, and Working Process

2024年7月10日 Grinding Machines: These machines perform flat, cylindrical, or centerless grinding operations They feature motordriven wheels that remove material from surfaces Common types include bench grinders, hand grinders, pedestal grinders, portable grinders, flexible shaft grinders, and precision grinders, each suited for specific applications and 2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911Metallurgist2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral Processing2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGate2015年4月9日 Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grindingGrinding Mills and Their Types – IspatGuru2019年4月16日 These mills have found widespread use in cement grinding operations as well in the grinding of coal for power plants In these operations the VRM is recognised as being more energy efficient than (PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more Mineral processing Metallurgy, Crushing Grinding

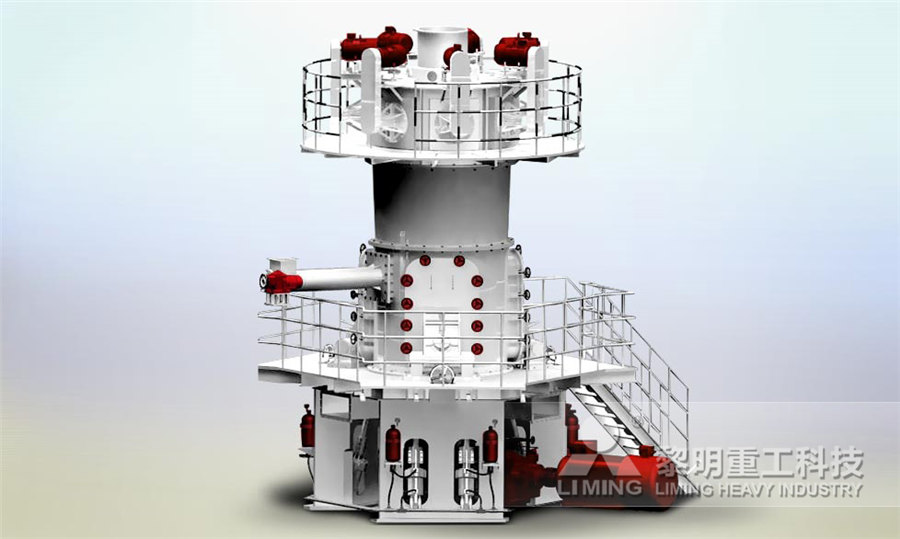

Ore Grinding Machines: Ball Mill, Rod Mil Grinding

Ore grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their 2016年6月20日 Type of the mesh The type of the mesh will have an effect on screening efficiency The most significant difference will be in special screening cases For example while screening elongated material, mesh should be of the vibrating type (rubber or harpmesh) PURPOSE OF VIBRATING SCREENS Screens are used mainly for the following purposes: Ore, Rock Aggregate Screening (Complete Guide)2017年3月4日 A simplified model (kinematic diagram) of the mechanism of the double buckling jaw crusher is shown in Fig 20 The mechanism in question is a six membered mechanism formed by attaching a binary SIZE REDUCTION BY CRUSHING METHODS ResearchGate2017年1月1日 This allows us to study whether the presence of pyroxene and olivine can deteriorate or enhance the flotation performance of sulphide ores In addition, pyroxene and olive are common gangue (PDF) Grinding Size Estimation and Beneficiation Studies Based

Particle size distribution analysis of ground coal by machine

PDF On Jan 1, 2011, C Igathinathane and others published Particle size distribution analysis of ground coal by machine vision σVolume approach Find, read and cite all the research you need 2017年3月4日 Ball mills are used for wet grinding iron ore, g old/copper ore, nickel ore and other ores, as wel l as lime/limestone for flue gas desulphurisat ion systems, coal and other raw materials Rod mill :SIZE REDUCTION BY GRINDING METHODS ResearchGate2013年5月15日 The objective of this study was to analyze dry grinding kinetics of three different solid fuels in terms of selection and breakage distribution functions values using a batch laboratory ball parisons of Dry Grinding Kinetics of Lignite, Bituminous Coal2024年4月19日 Crushers are key equipment in mining, construction and aggregate industries They break large rocks, ore, or other materials into smaller, more usable pieces This equipment reduces the material by means of compressive force, impact, attrition or shear that are specific for the type of crusher being usedTypes of Crushers Explained: Everything You Need to Know JXSC

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日 This article analyzes the problems of perfecting grinding equipment for largescale production – cement, ore, coal An improved design of a ball mill, equipped with internal energy Exchange The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batch Planetary Ball Mill PM 100 RETSCH highest fineness2024年1月23日 Initial Investment: Grinding machines, especially those used for precision applications, are costly Highend machines with advanced features like CNC systems are even more expensive Basic Grinding Machines: Entrylevel What is Grinding: Definition, Process, TypesBall mill is common used grinding plant in the industry, This machine can be can grind all kinds of ores and other materials, which Compare this product Remove from comparison tool ball grinding mill Ф2200×5500 horizontal for ore The overflow type ball mill is a new type of ball mill equipment with simple structure and selfflow Ore mill, Ore grinding mill All industrial manufacturers

Wet and dry grinding of coal in a laboratoryscale ball mill: Particle

2019年10月1日 In this study, experimental data for wet and dryground coal samples under wet and dry grinding are characterized by commonly used distribution minution: Two type of comminution devices used in this study Around 10–20 kg sample drawn from 100 kg as received coal by coningquartering method Then it is passed through 5 mm screen After screening, it is subjected to crush by two different techniques It is then sent for further characterization as mentioned above Grinding of the Effect of Grinding Behavior on Liberation of Coal Macerals J 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy budget Overall Energy Use of Fine Grinding in Mineral Processing2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911Metallurgist

(PDF) Design of a compact grinding machine ResearchGate

2021年12月1日 Aluminium samples – test samples to study th e quality of grinding Silicon carbide grit papers – to grind the test sa mples with grades P50, 100, 240 and 年10月1日 The grindability of an ore in mineral processing can be determined by the use of the Bond work index (W i)This index is determined on a laboratoryscale using a Bond ball mill and by simulating dry grinding in a closed circuit until the 250% circulating load has been obtained [14]The Bond grindability test is widely used in the minerals industry to provide data Improvement of grinding characteristics of Indian coal by