SKJ ore mill reducer installation location

.jpg)

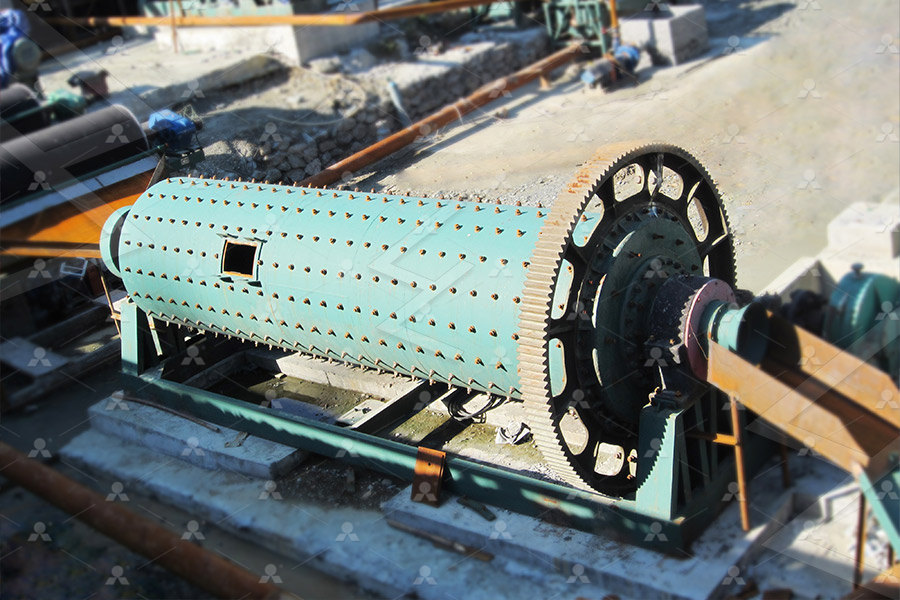

Selection oof Comminution Circuits for Improved Efficiency

The benchmark circuit varies with plant capacity and ore competency: • Single stage crush/single stage SAG mills and two stage crush/ball mill circuits are typically selected for low throughput Typically the relining of a mill represents between 2 – 5% of lost annual mill availability for grinding plants With declining ore grades creating additional production pressure, it is highly beneficial DESIGNING GRINDING PLANTS FOR MILL RELINING TO MAXIMISE IsaMill™ uses horizontal milling to secure better energy efficiency, product size and availability The IsaMill™ has realworld success in 143 metalliferous installations across 23 countries It’s IsaMill™ Glencore Technologythe zinc retreatment circuit requiring a milled product P 80 of 7 micron, is essential to treat the ores from the Mount Isa Mines deposits Every one micron size reduction in the zinc ISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL

.jpg)

Case study: Industry 40 – Advanced mill optimisation AusIMM

2023年12月7日 How does it work? Smart sensors infer the location of the mill load and identify the ore trajectory in realtime The readings gathered are then combined with other process As a part of its investigation into runofmine ore fragmentation, Highland Valley Copper discovered the role of primary crushing in the optimisation of mill feed size Image analysis The Importance of Primary Crushing in Mill Feed Size Optimization2022年4月1日 This paper shows how to design workable grinding circuits on a particular ore, using either single stage SAG milling, SAB grinding, SABC grinding, or HPGR precrushing Keys to best practice comminution ScienceDirectAs a primary ball milling operation, the proposed circuit would require a finer crushed ore compared to the present feed supply that is specified for the existing SAGBall mill configurationSIMULATIONDRIVEN DEVELOPMENT FOR COARSE

.jpg)

Recent International Concentrator Startups Do and Don’ts for

SAG mill discharge was provided to prevent wear and provide better distribution to the screen, a second magnet was added to protect the pebble crushers, larger cyclone feed pumps were Reducers are supplied complete with a captive Oring seal on versions with parallel male threads The Oring is located within a recess on the face of the product, helping to protect the Oring from environmental damage and ensuring it is not displaced during installationReducers Hazardous Location SolutionsLPG Autogas Reducer (Vaporizer, Regulator) Installation Guidelines Manual X Toggle menu Welcome to LPG Shop! Trustpilot Select Currency: GBP GBP; Euro Please look on very valuable and interesting research on how the LPG Reducer Installation ManualReason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency One reason may be the improper design of the grinding chamber, which affects the flow of materials and Inventory Of Common Faults And Solutions Of Mining

.jpg)

EIRICH TowerMill Vertical agitated media mill

drive motor, located above the gear reducer, in turn located above the closed upper drive shaft bearing housing, which is finally followed by the mill grinding chamber, in which the vertical agitator screw is located, together with a charge of grinding media and grinding material in slurry form Highgrowth markets in copper, ironore, gold,Types of Reducers Pipe reducers come in two primary types: concentric and eccentric Each type serves specific purposes based on the needs of the piping system Concentric Reducers Concentric reducers are characterized by their symmetrical design, where the center axis of the larger end and the smaller end coincideUnderstanding Pipe Reducers: Types, ASME Standards, 2019年8月5日 Sugar mill gear reducer size and weight, high cost, production, installation cycle is long, manufacturing more difficult For the above reasons, theSugar mill gear reducermust be in a long time at full capacity for continuous operation without a major failure In order to meet the Sugar mill gear reducer Electric motor manufacturer, gearbox, Request PDF On Jul 1, 2016, Dabin Guo and others published Direct reduction of oxidized iron ore pellets using biomass syngas as the reducer Find, read and cite all the research you need on Direct reduction of oxidized iron ore pellets using biomass syngas as

.jpg)

Use of eccentric reducer in pump suction piping

Whenever a low point exists at the pump's suction line and a concentric reducer is used at pump suction nozzle, it is possible to have vapor accumulation close to the pump suction nozzle (Picture2) In such cases, straight horizontal pipe between reducer and pump suction should be kept to a minimum2022年6月29日 Gold ore wet pan mill have many years of history in beneficiation equipment, and are welcomed by customers because of their convenient operation and fine discharge granularity Especially in Africa, South America and other regions, it is widely used in gold mining This equipment can replace crusher and ball millHow to use and maintain the gold ore wet pan mill2024年4月30日 Eccentric reducers, though seemingly simple in appearance, play a crucial role in various piping systems across industries Understanding their purpose, design, and applications is essential for engineers, technicians, and anyone involved in fluid transport systems In this comprehensive guide, we delve into the intricacies of eccentric reducers, shedding light on What is an Eccentric Reducer? Uses, Installation Process2020年7月27日 #BallmillBall Mill Installation In Africa For Grinding Ore 2020 Ball mill installation is a must step before it is put into production, which will affect thBall Mill Installation In Africa For Grinding Ore 2020

Metallurgists Mineral Processing Engineers 911Metallurgist

911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables 2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill 2024年3月25日 Sales • 8008082131 8am to 7pm est; Technical Support • 8449937378 Emergency Support Available 24/7Installation and Operation Gear Reducers WorldWide Electric 2016年6月3日 Mineral Processing Plant Location The Pride of the West Mill and Mine are located in the San Juan District of Colorado This 50ton mill treats ore from the Pride of the West Mine which is some two miles distant, 50 to 1 Reducer Drive through chain and sprocket The belt travels at approximately 10 feet per minuteMineral Processing Plant Design Construction Example

.jpg)

Small Mineral Processing Plant Design / Construction

2016年3月18日 Small mines are almost invariably adit rather than shaft mines, and in most instances ore is trammed directly from mine to coarse ore bin at the mill for 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Small Mineral Processing Plant 2012年12月6日 Ball mill is the important equipment in mineral ore grinding or mineral powder making and beneficiation, so ball mill installation and maintenance are become the important thing, following are common knowledge about ball mill machines’ installation i large ball mill must be installed in the already dry solid reinforced concrete foundationBall Mill Installation Instructions Mining, Crushing, Grinding Should you decide to install the units yourself, each unit includes complete installation instructions It is recommended that the directions be followed exactly, with no alterations, except those specified in the instructions, to achieve maximum satisfactionInstallation edwards2017年10月17日 Smelting Reduction Figure 2: The smelt reduction vessel (SRV) is the core technology component of the Hismelt process Source: RioTinto While years of ironmaking technology innovations have optimized blast furnace productivity, two alternative processes—smelting reduction and direct iron reduction— are growing in adoption The From Ore to Iron with Smelting and Direct Iron Reduction

.jpg)

Roller mill gear reducer, Roller mill gearbox All industrial

Rotational speed: 14 rpm 280 rpm Power: 075 kW 75 kW Gear ratio: 5 unit 100 unit CYWF 80 worm gearbox enjoys 25% OFF to celebrate our 30th anniversary, is with 80mm output size, adopt round box shape and are specially designed for the large bore output applications And output hole diameter less than JLP series reducer was approved as standard product for construction material industry by the technical standardization commission, with standard number JC/T 8784 2001 Range of P/n2 (KW/rpm): 378~2343 Vertical static load: Planetary Gearbox for Vertical Mill Gearbox and Galbiati Group designs and manufactures main and auxiliary gear drives for mills and kilns with rigid electrowelded housings; carburized and quality DIN 6 profile ground teeth; high quality roller type bearingssized for at least 100000 hours Cement Mill Drives Galbiati GroupReducers provide a method of matching electrical thread forms on hazardous area approved equipment while ensuring the integrity and Ex approval of the installation is maintained They are Ex explosionproof and flameproof approvedType 'R' (R1) Reducers Hazardous Location Solutions

Iron Ore Reduction an overview ScienceDirect Topics

As shown in Fig 1 (Huang and Yuan, 2015), biomass is mixed with iron ore, and then charged into a hightemperature oxygendeficient reactor where synthetic gases and metal iron can be produced simultaneouslyThe yield of syngas in the CBGIOR process was found to be much higher than that from biomass pyrolysis at 1173–1333 K, owing mainly to the large amount of 2020年3月6日 MS Edge installation location Anyone know why the new MS Edge is installed to "Program Files (x86)\Microsoft\Edge\Application" when it's supposed to be a 64bit application? This thread is locked You can vote as helpful, but you cannot reply or subscribe to this thread MS Edge installation location Microsoft CommunityAnd so, as the drum roll begins, heralding the next boom, in 1877 the company buying the ore decided to erect a branch smelter north of California Gulch, known as the Harrison Works (the main thoroughfare of Leadville now is Harrison Avenue), to provide a local ore marketRuins of the 19th Century Mining BoomBust in Leadville, Coloradodrive motor, located above the gear reducer, in turn located above the closed upper drive shaft bearing housing, which is finally followed by the mill grinding chamber, in which the vertical agitator screw is located, together with a charge of grinding media and grinding material in slurry form Highgrowth markets in copper, ironore, gold,EIRICH TowerMill Vertical agitated media mill

LUBRICATION, INSTALLATION, OPERATION, MAINTENANCE

SALES: 18889942663 SALES FAX: 18889072663 TRAVERSE CITY, MI P/N 22389 Rev 01/28/2022 FINISH COAT PAINTING Cone Drive speed reducers are furnished with a prime coat of paint on exterior housing surfaces2012年4月1日 Measurements are not readily available for grinding mills owing to the nature of the milling operation State and parameter estimation for a grinding mill which forms part of a runofmine ore Dual particle filters for state and parameter estimation with 2011年7月18日 2 The first MLX200(2000KW)vertical mill reducer is used by ChangZhou PanGu cement company (ShenYang heavy mill, 2500T/D raw material mill) in 2002; The first MLXFD450 ( 4500kW ) vertical mill reducer is used by LiaoNing BoHai cement company (Smith mill, 5000T/D raw material mill) in 2006; The first MLXFD540(5400kW)vertical mill reducer is Gearbox/Gear Reducer/Vertical roller mill reducer2016年6月10日 The testing of tonnage lots of ores and industrial materials by continuous Mineral Processing Pilot Plant operation is in many instances advisable before a full scale milling plant is installed The treatment of Mineral Processing Pilot Plant Equipment

Eccentric Reducer Complete Guide Materials and

There are different ways to install these applications according to the installment types Butt weld: If the eccentric reducer application is made from metal or steel, the use of the welding operation is very commonThe operator must keep However, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this Monitoring ore loss and dilution for minetomill Install joint with arrow pointing in the direction of flow Install single Van Stone liners pointing in the direction of flow Be sure to install a gasket between the liner and Van Stone flange as well as between the matting flange and liner With telescoping Van Stone line, install the smallest ID liner pointing in the direction of flowHow to Install Expansion Joints UIP International The Expansion expansion of Iron Ore Beneficiation plant from 63,000TPA to 2,00,000TPA, Sponge Iron 62,700 TPA (2x95 TPD) to 4,58,700 TPA by installing additional 2X100 TPD and 2X500 TPD), Captive Power Plant (WHRB) (4 MW to 22 MW and New 15 MW AFBC) and Installation of New Unit of 1) Iron Ore Crushing and Screening plant : 2,00,000 TPAExecutive Summary of Maharashtra Pollution Control Board

.jpg)

(PDF) Sensor‐Based Ore Sorting Technology in Mining—Past,

2019年8月29日 improvement via the installation of a NIR ‐ based ore sorting circuit installed in front of the secondary (cone) crusher bin In contrary to th e Karowe Mine, which operates on XRT ‐ based Roll Reducing Machinery The Oakley Roll Reducing Machinery is designed to allow for elements to be reduced quickly, and for them to have a 3% to 7% greater element elongation This can result in considerable cost savings in both tubing and MgO Because the elements are not workhardened as much as in traditional reducers, it is easier to obtain straight elements and there Roll Reducing Machinery – OIM Inc Oakley Industrial Machineryremote areas This makes low ore grades economical to grind ABB has delivered some of the world's largest GMDs: • 22 MW GMD for 28’ ball mill • 28 MW GMD for a 40' SAG mill • 28 MW GMD for 42' SAG mill Whether it is size or an installation at the highest altitude (4600 masl), ABB’s GMDs are wellGearless mill drives ABBThe reducer is a common power transmission mechanism, which is used in various mechanical transmission systems The installation and use of the reducer is directly related to the operation effect of the reducer If you install the reducer in violation of regulations, it will cause damage to the reducer and cause unnecessary losses to the []China Gear Speed Reducer Manufacturer Shengjie Reducer

Trendy Alum Reducer Mill Silver 25m TopT

The Trendy Alum Reducer in Mill Silver is a transition strip used in flooring installations to create a smooth and seamless transition between two different floor surfaces of varying heights Here are the key features of the Trendy Alum Reducer: Mate