Slag micro powder fineness

.jpg)

Influence of fineness on the cementitious properties of steel slag

Figure 2shows the exothermic rates during the hydration of the three steel slags with different finenesses The exothermic process of steel slag is very similar to that of cement which can be divided into five stages: (1) short rapid exothermic stage at which the first exothermic peak forms; (2) dormant period at which the 展开2020年11月1日 Meanwhile the microstructure of slag powders has been quantified by using shape index, roundness coefficient, flat degree, angularity and surface roughness In the Analysis and multiobjective optimization of slag powder process2013年9月1日 Increasing fineness improves the early activity of steel slag The activity of the superfine steel slag is much lower than that of cement The superfine steel slag makes far Cementitious properties of superfine steel slag ScienceDirect2023年8月1日 In this work, steel slag (SS), blast furnace slag (BFS), ultrafine SS (USS) and ultrafine BFS (UBFS), with fineness of 407, 450, 748 and 760 m 2 /kg respectively, were Effect of fineness on the hydration and microstructure of

Preparation and Performance of UltraFine High

2023年12月11日 The composite micronized powder is prepared by using blast furnace slag (BFS), waterquenched manganese slag (WQMS), manganese tailing slag (MTS) and desulfurization gypsum (DG) and grinding aid (GA) 2022年11月11日 In this paper, steel slag ultrafine powder (SSUP) was prepared in the laboratory through mechanical activation combined with grinding aids Furthermore, the grinding time was optimized The particle size, specific Laboratory Preparation and Performance 2022年10月1日 In this work, the hydration, microstructure, and macroscopic performances of the samples containing ground steel slags were investigated The results show that most pastes Influence of steel slag fineness on the hydration of cementsteel 2020年9月28日 In this paper, the hydration process and microstructure of alkaliactivated materials with steel slag as a cementitious material and fine aggregate were studied The phase composition and micromorphology of hydration Hydration and Microstructure of Steel Slag as

Study on the Properties of HighPerformance Ground Iron and

2020年11月16日 Ground iron and steel slag with excellent performance was prepared using the uniform test design The influence of the fineness and content of steel slag powder on the Slag powder is a process with characters of multivariables, strongly coupling and nonlinearity The material layer thickness plays an important role in the process It can reflect the dynamic Analysis and multiobjective optimization of slag powder process2021年7月11日 Six different recycled micro powders were prepared by grinding the construction wastes that composed of concrete, tile, brick, and concrete Experimental researches on their physical and chemical properties, particle size distribution, chemical composition and strength activity index were investigated and compared with the characteristics of cement, slag powder Characteristics of Recycled Micro Powder Produced Using Construction 2024年8月7日 In this paper, steel slag powder was used to replace part of the cement in road concrete, and group tests were carried out on coarse aggregates with different water–cement (W/C) ratios, different steel slag parameters, and Preparation and Performance Testing of Steel Slag

Effect of fineness on the pozzolanic reaction kinetics of slag in

2021年3月1日 It was found that the slag fineness has little influence on the pozzolanic reaction kinetic parameters described above Efficiency of high energy over conventional milling of granulated blast furnace slag powder to improve mechanical performance of slag cement paste Powder Technol, 308 (2017), pp 37462024年11月1日 The fine aggregate met the requirements for medium sand, with a fineness modulus of 271, an apparent density of 314 g/cm³, and a bulk density of 168 g/cm³ The amorphous substance content in electric furnace slag micropowder is reduced, with the material predominantly comprising four phases: (MgO) 0239 (FeO) Effect of electric furnace steel slag powder on the strength of 2020年10月10日 The impact of the slag fineness and replacement level on the early cement hydration and the latter from Xray powder diffraction (XRD; D2 Phaser, Bruker) No free CaO or free MgO could be detected in the diffractogram of the NFM Effects of SCMs particles on the compressive strength of microstructurally designed The impact of slag fineness on the reactivity of blended cements with 2020年9月28日 Due to the low hydration activity and poor volume stability, extensive steel slag utilization is restricted In this paper, the hydration process and microstructure of alkaliactivated materials with steel slag as a cementitious material and fine aggregate were studied The phase composition and micromorphology of hydration products were measured using XRD, NMR Hydration and Microstructure of Steel Slag as Cementitious

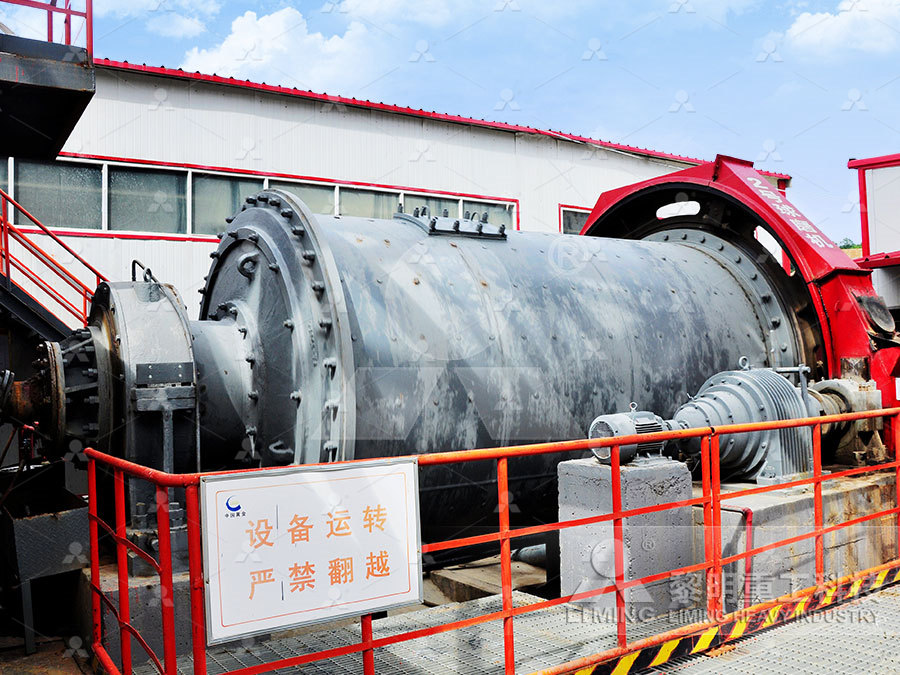

Comparison of Three Different Processes for Slag Micropowder

The slag micropowder is produced by a ball mill, the fineness adjustment is more flexible, and the particle shape and gradation of the slag micropowder are better In the case of the same specific surface area, the quality of the ball mill product is better than that of the vertical mill, and the corresponding strength is also good, but the power consumption is higher when the ball mill is 2023年5月15日 On this basis, steel slag and slag composite micro powder (SSCM) technology was proposed, which realized the high added value and utilization rate of steel slag in industrial applications Influence of steel slag fineness on the hydration of cementsteel slag composite pastes J Build Eng (2022)Comprehensive utilization of steel slag: A review ScienceDirect2022年2月26日 The 1000 mesh blast furnace slag powder is suitable for three ring medium speed micro powder mill Three ring medium speed micro grinding is a kind of ultrafine grinding equipment Its processing fineness is between 4003000 mesh, the power consumption is about 22220kw, and the hourly production can reach more than 50 tonsWhat is Blast Furnace Slag and How to Process It?2024年2月14日 With the rising costs of highactivity materials like slag (Han et al 2017), the focus has shifted to economically viable alternatives such as steel slag (SS) and ceramic powder (CP) SS, a byproduct of the iron and steel industry, contributes significantly to China's annual production (Francisca and Glatstein 2020 ; Cui et al 2021 ), offering a sustainable resourceSustainable assessment and synergism of ceramic powder and steel slag

The Effect of Fineness on the Hydration Activity Index

2019年9月15日 To improve the properties of ground granulated blast furnace slag (GGBS) and utilize ground granulated blast furnace slag efficiently, this study investigates the effect of fineness on the DOI: 101016/jjobe2022 Corpus ID: ; Influence of steel slag fineness on the hydration of cementsteel slag composite pastes @article{Pang2022InfluenceOS, title={Influence of steel slag fineness on the hydration of cementsteel slag composite pastes}, author={Lan Pang and Shucong Liao and Dengquan Wang and Mingzhe An}, journal={Journal of Building Influence of steel slag fineness on the hydration of cementsteel slag 2022年10月1日 Shi et al [50] also investigated the activity index of steel slag powder with different fineness (D50 = 133 μm, 811 μm, 510 μm, and 252 μm, respectively) and reported that finer steel slag has higher activity indexes (28 d On this basis, steel slag and slag composite micro powder Influence of steel slag fineness on the hydration of cementsteel slag 2020年2月26日 The present investigation is mainly focused on the effect of copper slag (CS) on micro, macro, and flexural characteristics of geopolymer The fineness modulus of sand and CS were found as 261 (PDF) Effect of Copper Slag on Micro, Macro, and Flexural

.jpg)

Effect of limestone powder on mechanical strength, durability and

2021年3月28日 The use of limestone powder (LSP) as a cement replacement is used in abundant applications due to its low cost and wide availability Adversely, the use of LSP as a part of the precursors of alkaliactivated materials (AAMs) is still in the developing stage This scarcity of studies opened the door and encouraged the researchers for more investigations Thus, this 2021年7月1日 The addition of tailings powder improves the working performance of concrete and slightly improves the strength Due to the large amount of cement used in ultrahighperformance concrete, physical (PDF) Effect of Iron Tailings and Slag Powders on Workability and After using vertical grinding to grind nickel slag into micro powder, it is beneficial to recover nickel iron and obtain considerable economic benefits; At the same time, the screened finished micro powder is added to cement to form composite cement, which can greatly increase economic benefits and waste resource utilization, reduce the occupation of land and environmental Nickel slag powder processing solutionLIMING HEAVY Mineral powder with a fineness of 400450m2/kg can be used to prepare 425,425R slag Portland cement; mineral powder with a fineness of 450500m2/kg can be prepared with 525,525R slag Portland cementSlag Grinding Plant GGBS Plant Slag Mill, Slag Grinding Mill

Study on the Properties of HighPerformance Ground Iron and Steel Slag

2020年11月16日 Ground iron and steel slag with excellent performance was prepared using the uniform test design The influence of the fineness and content of steel slag powder on the fluidity and strength of the powder mortar was studied, the regression equations of fluidity and compression strength of different ages are derived, and the contour map is drawn Based on the fineness of steel slag enhances the late cementitious properties of the cement containing steel slag significantly Keywords Steel slag Fineness Hydration Cementitious properties Introduction Steel slag is a byproduct of the steel production Emission of steel slag accounts for about 15 % of the steel production [1]Influence of fineness on the cementitious properties of steelDownload Table Chemical composition of slag powder (wt %) from publication: Effect of alkali dosage on alkalisilica reaction in sodium hydroxide activated slag mortars Alkalisilica Chemical composition of slag powder (wt %)2022年10月1日 On this basis, steel slag and slag composite micro powder (SSCM) technology was proposed, which realized the high added value and utilization rate of steel slag in industrial applicationsInfluence of steel slag fineness on the hydration of cementsteel slag

Characteristics of Recycled Micro Powder Produced Using

Characteristics of Recycled Micro Powder Produced Using Construction Waste Jinjin Shi1,2,3(B),MiaoXu1,3, Yingbiao Wu1,2,3, and Jinyan Liu1,2 1 Cangzhou Municipal Engineering Company Limited, Cangzhou , China 2 Hebei Province Road Materials and Technology Engineering Technology Research Center, Cangzhou , China 3 Hebei Industrial 2022年10月1日 Influence of steel slag fineness on the hydration of cement Shi et al [50] also investigated the activity index of steel slag powder with different fineness (D50 = 133 μm, 811 μm, 510 μm, and 252 μm, respectively impermeability and microstructure of microexpansion steel slag cement under constraint Influence of steel slag fineness on the hydration of cementsteel slag 2019年3月1日 The reactivity of GGBS in a cementitious system depends not only on the chemical components but also on their fineness [3] The development of concrete technology has introduced the concept of ultrafine powder (defined as a powder with a particle diameter less than 10 μm), which has a specific surface area of over 500 m 2 /kg [4]Effects of ultrafine ground granulated blastfurnace slag on initial 2023年6月14日 It can be seen that the toughening effect of UHPC with steel fibre and slag micro powder is good Mechanism river sand with a fineness modulus of 247 Steel fibres with a length of 15 mm, flat type, a diameter of 022 mm, and a tensile strength of 2500 MPaExperimental Study on Axial Stress–Strain Behaviour of Steel Fibre

.jpg)

Laboratory Preparation and Performance Characterization of Steel Slag

2022年11月11日 Steel slag is generally regarded as a supplementary cementitious material in cementbased materials, which is conducive to the realization of the goal of carbon peak and carbon neutralization However, the lower cementitious activity and poorer volume stability of steel slag limit its high dosage in cementbased materials In this paper, steel slag ultrafine powder 2023年6月3日 Superfine powder A powder of which not less than 90 percent by the number of the particles are less than 10 micron size When the fineness of the powder is described by means of a number, it is intended that all the particles of the powder shall pass through a sieve of which the nominal mesh aperture, in /lill, is equal to that numberPowder Fineness (Types of Powder) Pharmaguideline2022年6月14日 In order to investigate the effect and mechanism of coupled mechanical–chemical activation on the hydration activity of copper slag powder, copper slag powder with different grinding time and content was applied to prepare composite cement The hydration heat and rate of the composite cement paste were tested for 120 h The mechanical Effect of Coupled MechanicalChemical Activation on Hydration2024年8月9日 The effects of different fineness and content of LS powder on the workability, The physicalchemical properties of microlithium slag (microLS) was characterized comprehensivelyResearch on the influence of fineness and content of lithium slag

Preparation of composite microslag based on the application of

2022年3月7日 The main components of the three tailings slag are CaO, SiO 2, and Al 2 O 3 (Table 2), which are consistent with the main chemical components of limestone powder and red clay, it can be used as a mineralizer, especially the content of Fe 2 O 3And Fe 2 O 3 in lead–zinc tailings accounts for 1392% Nickel tailings contain relatively high MgO When they are 2013年10月1日 The steel slag used was ground basic oxygen furnace steel slag with the specific surface area of 453 m 2 /kg The coarse aggregates used were crushed limestone aggregates of 5–25 mm in size The fine aggregates used were natural river sands with fineness of 28 Polycarboxylic superlasticizer (PS) was used to adjust the fluidity of concreteInfluence of steel slag on mechanical properties and durability of 2023年9月22日 The use of ladle slag as a replacement for natural aggregates as coarse aggregate in concrete has gained attention in recent years due to its potential benefits in terms of sustainability and waste reduction The paper aims to investigate the influence of ladle slag as a coarse aggregate replacement on various properties of concrete, including strength, durability, Investigating the mechanical strength, durability and micro 2024年11月1日 Biricik et al reported that a Blaine fineness of 6000 cm 2 /g for SP, either adsorbed on the surface or confined within microporosities formed during ElMir A Development and characterization of ceramic waste powderslag blended geopolymer concrete designed using Taguchi method Constr Build Mater 2022;349: Optimizing mix design methods for using slag, ceramic, and glass

.jpg)

Features of Processes for Preparation and Performance of Foamed

2024年3月28日 Steel slag micronized powder, granulated blast furnace slag, and cement were used as cementitious materials to prepare a foamed lightweight soil for roadbed filling to reduce the settlement and additional stress of the foundation and to solve the environmental problems caused by the storage of large amounts of steel slag However, the instability of steel slag and 2022年1月25日 Magnesium potassium phosphate cement (MKPC) is an excellent rapid repair material for concrete, and many mineral admixtures have been applied to promote its performance This study focuses on the quantitative characterization of the physical and chemical contributions of granulated blastfurnace slag with various finenesses to the performance Hydration and Properties of Magnesium Potassium Phosphate 2022年8月26日 Effect of Limestone Powder Fineness and Substitution Ratio on the Rheological Properties of Chen et al determined that the addition of micro fly ash furnace slag on initial setting Effect of Limestone Powder Fineness and Substitution Ratio on 2024年8月9日 Modification of magnesium phosphate cement with steel slag powder and ground blast furnace slag: Mechanism of hydration and electrical conductivity Author links open overlay panel Xiangrui Meng a b, Yu Jiang c, where electrons can be stored and transmitted through their rich micro and macro pores and channels, Modification of magnesium phosphate cement with steel slag powder

Insights to compressive strength, impermeability and

2022年4月4日 Noticeably, steel slag still faces some intractable problems as construction materials on a large scale, including the potential volume instability and low hydraulic property [11], [12], [13]The fCaO and fMgO in steel slag will react with water and convert into Ca(OH) 2 and Mg(OH) 2, causing the volume expansion of steel slag [14]