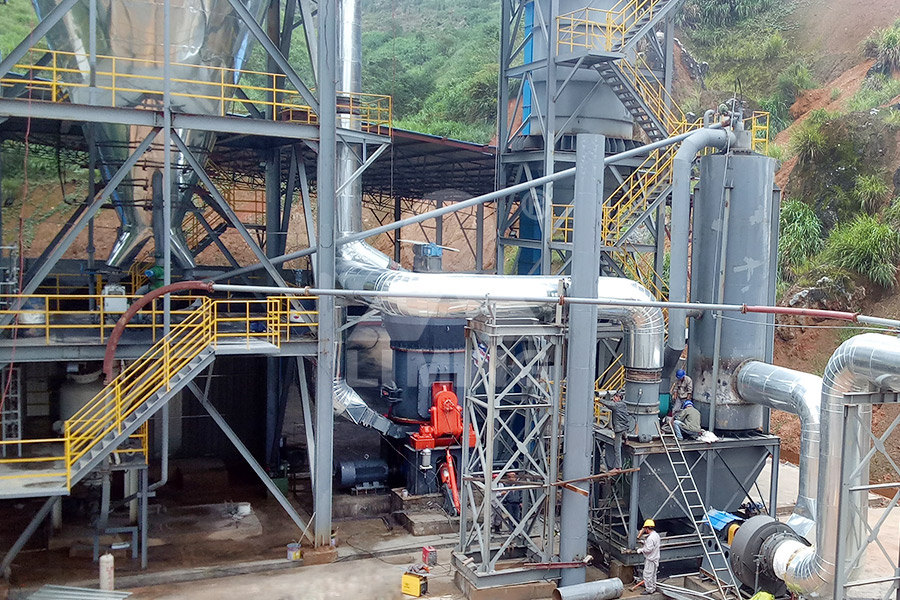

150,000 tons of slag micro powder vertical mill production

.jpg)

GGBS Production LineHenan Zhengzhou Mining

We ZK company is the professional slag powder production line supplier We can provide both ball mill and vertical mill production process, while providing 'turnkey' service from civil engineering to commissioning2020年11月1日 Slag powder is produced in the closed vertical mill where complex physical and chemical change happens, leading to the difficulty of modeling by mechanism Generalized Analysis and multiobjective optimization of slag powder processThe production method is capable of realizing sharing of most of equipment while realizing recovery and reutilization of resource by using the same vertical mill to respectively grind steelProduction method for grinding steeliron slag powder, mineral What equipment does annual output 150,000 tons of slag vertical mill production line have? Slag vertical mill is the preferred equipment for the production of slag powder, which produces What equipment does annual output 150,000 tons of slag vertical

What Is The Market Prospect Of Steel Slag Vertical

Recently, the steel slag powder production line with the largest production capacity in China was completed and put into operation in Shagang Group The total investment of this project is about 170 million yuan, and it is estimated Steel slag is one of the main solid wastes in steel plants, with considerable discharge The recycling of steel slag has become the focus of social attention The micropowder processing scheme using steel slag vertical roller mill can Introduction To The Way Of Steel Slag Recycling The 2020年7月1日 For slag powder process, operational stability of the vertical mill (indexed by the material layer thickness) is the primary concern for production safety and longterm benefitsAnalysis and multiobjective optimization of slag Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical mill Home Product Case About Liming Vertical roller mills are mainly ㎡ Production Basevertical roller mill, vertical coal mill, vertical slag mill, superfine

The difference between CLUM ultrafine vertical mill and HGM micro

2022年1月13日 HGM micro powder mill HGM micro powder mill is an industrial grinding equipment specialized in processing and manufacturing fine powder and ultrafine powder The product fineness can be adjusted between 3002500 mesh according to the needs, and the product fineness can reach D97≤5um at one timeCapacity: 0430 t/h Feeding size: 15 mm Output Size: 1503000 mesh Brief Introduction: Our Shanxi customers will build a highend superfine calcium carbonate production line with an annual output of 150,000 tons, which will become a production line with a certain scale in Shanxi Province after construction and productionCalcium carbonate grinding powder production line 150,000 T/YDownload Citation The Vertical Mill Slag MicroPowders' Particle Size Distribution and Microstructure Analysis Vertical mill grinding system is one of the important cement grinding equipments The Vertical Mill Slag MicroPowders' Particle SizeThe GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder Integrating crushing, transporting, grinding and drying, the steel slag vertical mill is a kind of ideal equipment for grinding steel slag The models of CHAENG’s GRMS steel slag vertical mill are complete, include GRMSS33 31 Steel Slag Vertical Mill

.jpg)

Nickel Slag Vertical Mill CHAENG

The output of the GRMS nickel slag vertical mill produced by Great Wall Company can reach 160t/h, and the power consumption of the system is below 38kWh/t, which can meet the annual output of 200,000 to 15 million tons of nickel slag powder production line projectThe slag vertical roller mill with powerful function and excellent performance has become a new choice for mineral powder processing The slag vertical mill integrates crushing, drying, grinding and graded conveying SMMVIK Machinery can provide a slag micro vertical mill production line with an annual output of 50000 tonsWhat mill is used for processing slag micro powder? How much does slag Caco3 Vertical Powder Grinding Mill and Modifying Machine production line in Malaysia Coarse Vertical Powder Mill Used in Dutch Agriculture Waste Tyre Pyrolysis Carbon Black Processing System Tyre Pyrolysis Carbon Black vertical roller mill clirikultrafine vertical mill, According to the display of slag powder production measured data, traditional ball mill needs power consumption 75~80kWh for per ton slag micro powder However, it needs power consumption 42~45 kWh for per ton slag micro powder if adopts advanced vertical roller mill technology, and it can be saving electricity 33~35kWh use of vertical roller mill production per GGBS Vertical Roller Mill Great Wall

.jpg)

Steel Slag Vertical Mill CHAENG

The models of CHAENG’s GRMS steel slag vertical mill are complete, including GRMSS3331、 GRMSS4641、 GRMSS5341 and so on, which can meet the needs of the steel slag production line project with an annual output of 200,0001,500,000 tonsVertical mills are generally used for grinding slag powder A vertical cement mill is also called a vertical slag mill It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grinding The vertical cement mill of AGICO CEMENT is inseparable from the following points:Slag Grinding Plant GGBS Plant Slag Mill, Slag Grinding MillFrom the coal powder preparation, heavy calcium and slag powder processing, to largescale nonmetallic mineral powder, power plant environmental desulfurization, limestone powder, building materials, chemical industry grinding engineering, professional technology covers the whole process chain of mineral processing, product processing range covers 03mm coarse CaseIndustrial Grinding Mill, Ultrafine Grinding Mill, Vertical Roller According to the display of slag powder production measured data, traditional ball mill needs power consumption 75~80kWh for per ton slag micro powder However, it needs power consumption 42~45 kWh for per ton slag micro powder if adopts advanced vertical roller mill technology, and it can be saving electricity 33~35kWh use of vertical roller mill production per Introduction of GGBS vertical roller mill Great Wall

Chalk Micro Powder Mill SBM Ultrafine Powder Technology

2021年9月30日 Chalk micro powder mill can grind nonmetallic ores into fine powder up to 6000 CLUM vertical mill (1503000 meshes), and wet stirring mill (3256000 meshes) They can grind nonmetallic ores, and the fineness can be adjusted freely according to China Shanxi annual production of 30,000 tons of anchoring agent powder project;It can not only supply all kinds of slag powder grinding equipment including ball mill, vertical roller mill, vertical roller mill slag production line AGICO Slag Mill Parameters : AGRM202: 2400: 2000: 560: 23~25: : AGRM223: 2600: 2200: 710:GGBS Production Line Slag Mill for Slag Powder Grinding2023年6月6日 Slag vertical mill selection requires rigorous numerical analysis, equipment price, scale of slag vertical mill manufacturer and aftersales capabilities are all factors that need to be considered As a slag vertical mill manufacturer with nearly 30 years of production experience, Guilin Hongcheng has rich experience in slag vertical mill parison and Analysis of Slag Vertical Mill Selection60TPH LM353N Slag Grinding Mill In Fujian, China The annual output of slag micro powder is tons, so the demand of capacity is large > Ultrafine calcite powder production project > 20t/h LM vertical coal mill site; MORE; LATEST EQUIPMENT MTW European Type Trapezium Mill60TPH LM353N Slag Grinding Mill In Fujian, ChinaLIMING

.jpg)

Slag Ultrafine Powder Processing Technology

2024年10月25日 Using the HGM series Micro Powder Grinding Mill to grind slag into ultrafine powder and mix it with silicate cement, a new type of slag silicate cement can be prepared This new type of cement can not only reasonably control the fineness of cement, but also achieve the optimal ratio of silicate cement and slag powder, thereby improving the performance of cementSlag is actually a term in a broad sense, which can generally refer to the waste slag discharged from all smelting furnaces or incinerators What is the purpose of slag grinding and what is the specific process flow of slag grinding? The News Application Of Slag Grinding Mill2021年6月22日 The calcium carbonate production line with an annual output of 300,000 tons uses a vertical grinding mill production line to crush, grind, and classify calcium carbonate +29 Gypsum Powder Manufacturing Process Using HGM Micro Powder Grinding Mill ; EXPOMINA PERÚ 2024Set Off Again With a Full Harvest ;300,000 tons of calcium carbonate powder production line 2018年4月1日 UMM Vertical Ball Mill (UVBM) was intended to be the apparatus to produce metal powder with superior characteristic in production rate while retaining good quality of metal powderDesign and Testing of UMM Vertical Ball Mill (UVBM) for

.jpg)

Slag Powder Vertical Roller Grinding Mill

2022年6月17日 With the development of the solid waste slag industry, the special dry vertical mill for the equipment of the slag micro powder industry is a new type of powder mill to increase production and reduce consumption It has high grinding efficiency, fast powder separation efficiency and fine classification accuracy It is favored by the industry and is a new type of Product Name: GGBS Production Line / Slag Mill Capacity: 36100 Million Tons Annually Grinding Systems: These include the VRM (Vertical Roller Mill) system, the Ball Mill open circuit system, the Ball Mill closed circuit system, and the Roller Press final grinding systemGGBS Production Line Slag Mill for Slag Powder Grinding2024年2月22日 As a steel slag micro powder vertical mill manufacturer, Guilin Hongcheng's HLMX steel slag micro powder vertical mill model has a great advantage in the production of steel slag micro powder If you have steel slag powder production project needs, please leave us a message to learn about the steel slag powder vertical mill model and equipment detailsCan vertical mill produce ultrafine steel slag powder?2023年3月1日 On this basis, steel slag and slag composite micro powder (SSCM) with a staggering 995 Gt/y of CO 2 steel slag production exceeds 120 million tons (Gao et al 2023)Comprehensive utilization of steel slag: A review Request PDF

Micro Powder Grinding Mill

SBM micro powder grinding mill is a highly efficient industrial grinding mill, Production Process of Micro Powder Grinding Mill The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of which can It is a twopurpose Production Line with two parts One is a steel slag production line with annual capacity of 300,000 million tons slag powder, and the other one is a GGBFS production line with annum capacity of 12 million tons GGBFS The main grinding equipment is designed with 2 GRMS vertical roller mills and 1 steel slag ball millSteel Slag Vertical Roller MillIndependent research and development of Ultrafine vertical roller mill used Adopt multihead powder separator, SBM classifier perfect solved the particle cutting point height rate of screening questions, compared with the traditional Ultrafine vertical roller mill SBM Ultrafine Powder 2021年10月5日 These artificially Penriched slags, which contain fluoride, are marketed as Rhenania phosphate in Germany, base phosphate, supra phosphate in Belgium, and thermo phosphate in Russia Slag material is also ground to a fine powder and marketed as slag meal, cinder, Thomas phosphate, and Belgian basic slagProduction, characterisation, utilisation, and beneficial soil

Vertical roller mill DARKO

The vertical mill is 30%40% more energyefficient than the ball mill Additionally, the noise level of the vertical mill is lower than that of the ball mill, approximately 2025 dB The vertical mill operates in a fully enclosed system under negative pressure, resulting in no dust and a 2011年3月17日 The invention relates to a production process of steel slag micropowder, which comprises the following steps: enabling wet steel slag powder with water content of 5% and particle size of 020mm generated after crushing and magnetic separation of steel slag to enter a mill for powder milling, conveying obtained fine powder into a vibration drying and powder Production process of steel slag micropowder Semantic Scholar(1)The specific surface area of the slag powder is 420m2 / kg; (2)The energy consumption of the slag powder system is not more than 40kWh / t; 3Technical function characteristics of slag powder technology scheme: (1)Core equipment slag vertical grinding integrates crushing, grinding, drying, conveying and powder selectionWhat is the technical scheme of the slag powder process?CHAENG GRMS slag vertical mill integrates fine crushing, grinding, drying, powder separation and conveying It has large drying capacity and low power consumption It can meet the annual output of 200,0001,500,000 tons of slag grinding plant projects The specific surface area of the finished slag powder can be up to 420~450 m²/kgSlag Vertical Roller Mill CHAENG

SBM Ultrafine Powder Technology Industrial Grinding Mill,

Our main products include ultrafine vertical roller mill, ultrafine grinding mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected] language >Shibang Industry Technology Group, Shanghai Focus on the field of micro powder grinding CLUM Series Ultrafine Vertical Roller MillA GGBS production line main includes slag feeding equipment, a bucket elevator, a dust collector, a slag vertical mill, a powder separator, a fan, a funnel, a conveyor belt, a hotblast stove, and a finished product storage facility The benefit of the key equipment vertical millSlag Grinding Plant GGBS Plant One Stop Solution CNBM Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, greatly improving the added value of finished products and application areas 2Talc Powder Ultrafine Vertical Roller MillManganese Slag Powder Plant CHAENG (Great Wall Machinery) can undertake 20 tons 15 million tons of Manganese slag powder plant EPC projectsWe can provide raw material testing , engineering design,equipment manufacturing,install,debugging,technical training,standard production,pr; Nickel Slag Grinding Plant CHAENG (Great Wall Machinery) can undertake 20 Slag Grinding Plant