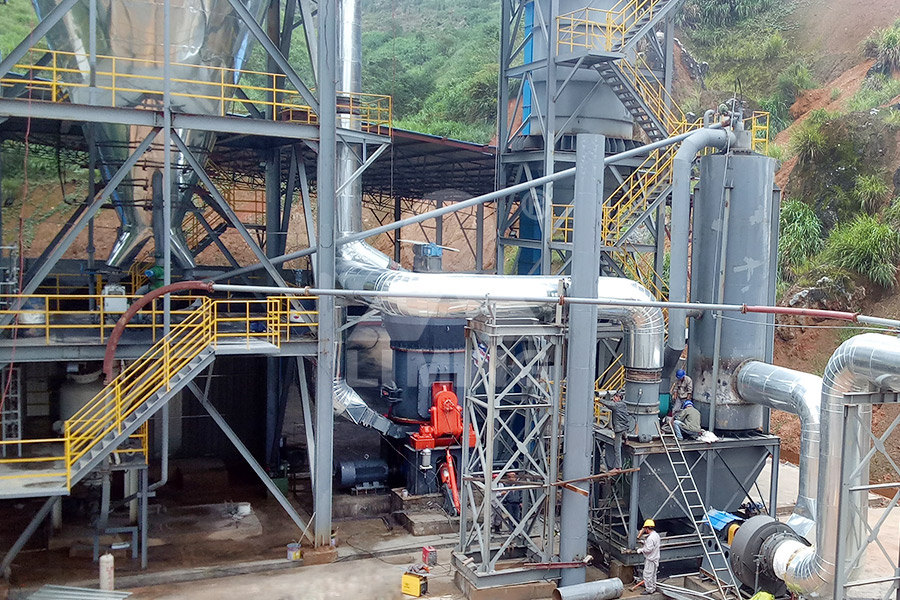

Fly ash powder process flow

CFB石灰石脱硫剂制备96.jpg)

Review A review on fly ash highvalue synthesis utilization and its

2024年3月1日 Gong et al (2023) proposed a novel process for the extraction of alumina from high alumina fly ash using an improved hydrochemical process, in which the low alkali 2024年7月1日 To improve the mechanical properties of aluminum foams prepared by powder metallurgy, lowcost solid waste fly ash (FA) was selected as the reinforcement phase, and the Reinforcement effect of fly ash with different morphologies on 2023年3月15日 A new type of inorganic fiberfly ash continuous fiber was innovatively developed in this study to alleviate the problems of low comprehensive utilization rate and lacking of high Preparation and microstructure analysis of fly ash continuous fiber2021年7月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides Fly Ash properties, characterization, and applications: a review

.jpg)

Fly AshLinear Low Density Polyethylene Composites for

4 天之前 21 Materials The matrix utilized was the linear lowdensity polyethylene R36A050U grade by Greenage Industries (Ahmedabad, India) The specific polymer is characterized by a 2011年1月1日 The fly ash, also known as pulverised fuel ash, is produced from burning pulverized coal in electric power generating plants During combustion, mineral impurities in Fly Ash SpringerLink2024年11月26日 The application of incineration fly ash (IFA) sintering technology has brought a large amount of secondary fly ash (SFA) rich in heavy metals and chlorides, and its treatment Innovative Technology for Secondary Fly Ash Full Resource 2016年11月1日 This paper presents the pozzolanic properties, mechanical properties, chemical and mineral composition of fly ash obtained in the combustion process in a power plant Nikola Tesla A (PPNT A)(PDF) Laboratory testing of fly ash ResearchGate

.jpg)

Preparation, properties and applications of fly ashbased porous

2022年7月20日 In this review, the processes for obtaining fly ashbased porous geopolymers are divided into two categories: bulktype (direct foaming, sacrificial template, additive MANUFACTURING PROCESS: Fly ash (70%)Lime (10%) Gypsum (5%) and sand(15%) are manually feed into a pan mixer where water is added to the required proportion for homogeneous mixing The proportion of raw material may vary FLOW SHEET DIAGRAM Fly PROJECT PROFILE ON FLY ASH BRICKSAlso Read: How Mattress Is Made in Factories Manufacturing Process Explained Fly Ash Brick Manufacturing Process Fly ash brick manufacturing involves the following steps: 1 Mixing the Raw Materials The raw materials, How Are Bricks Made Fly Ash Bricks Manufacturing 2022年12月1日 Methods of sampling fly ash: 2021: Japan: JIS A 6201: Fly ash for use in concrete: 2015: United Kingdom: BS EN 4501: Fly ash for concrete Definition, specifications and conformity criteria: 2012: BS EN 4502: Fly ash for concrete Conformity evaluation: 2005: PD CEN/TR 15840: Evaluation of conformity of fly ash for concrete Guidelines for Fly ash for sustainable construction: A review of fly ash concrete

.jpg)

ENHANCING ASPHALT CEMENT PROPERTIES USING GEOPOLYMER BASED ON FLY ASH

BASED ON FLY ASH AND GLASS POWDER Hamid, Abdulrahman1,4, Baaj, Hassan2, ElHakim, challenging process for glass manufacturers (Polley, et al, 1998; Shi Zheng, 2007; Vafaei Allahverdi, lower density, and lower flow compared to limestone and ordinary Portland cement Ghasemi and Marandi (2013) investigated the efficiency of using crumb2021年8月23日 All synthesized glasses were ground to powder with a comparable specific surface area of 4,200±50 cm 2 g1 on the Blaine scale to eliminate the influence of fineness of glasses on their pozzolanic reactivity and, in consequence, on the properties of Portlandfly ash cements composed with these glasses Because the consumption of energy during grinding Effect of Chemical Composition and Network of Fly Ash Glass on 2016年11月1日 PDF Fly ash is one of the most common waste materials created by burning of coal It is composed of smaller particles, Mixtures are ma de in order to examine the process of (PDF) Laboratory testing of fly ash ResearchGate2019年1月3日 This noflow condition means that fine dry fly ash isn’t making it to the silo or through the silo to the outlet (where it’s loaded on trucks for transport) There are two main reasons why noflow conditions happen: arching and ratholing Due to the cohesive strength of fine dry fly ash, the material is a great source of frictionOvercoming Challenges with Fly Ash Handling ProcessBarron

Anhydro Spin Flash Drying SPX FLOW

Developed and pioneered by SPX FLOW Danmark, Anhydro Spin Flash® drying technology is a patented process, widely adopted by industrial customers all over the world Anhydro Spin Flash® plant Feed Air inlet Air outlet Powder outlet SPX FLOW, Inc (NYSE:FLOW) is a leading manufacturer of innovative flow technologies,Keywords: Manufacturing Company, Fly Ash Powder, characteristics, Building construction material, Thermal Conductivity Conduction of heat is flow of heat which occurs due to exchange of energy from one molecule to another without appreciable motion of molecules In any heating process, heat is flowing outwards from heat generation point THERMAL CONDUCTIVITY CHARACTERIZATION OF FLY ASH: A 2024年1月19日 The fly ash powder, with a density of 212 g/cm 3, was generated during the burning of sugarcane bagasse Hybrid composites preparation Hybrid composites based on polypropylene (PP) matrix and reinforced with different amounts of powdered wood chips (PWC) and/or fly ash (FA) particles were fabricated through a melt compounding processSynergistic reinforcing effect of fly ash and powdered wood chips 2023年6月15日 Fly ash can replace part of cement as a relatively cheap cement admixture, thereby reducing the cost of building materials During use, fly ash can also reduce the slurrying time and cement content of concrete, and improve Fly Ash Properties, Source, Advantages, Uses

Preparation, properties and applications of fly ashbased porous

2022年7月20日 The process flow chart for the direct foaming method (Optical and SEM image from unpublished data of our research group, with H 2 O 2 as blowing agent plus surfactant) In addition to aluminum powder, zinc powder can also be used, leading to fly ashbased foams 2019年6月20日 Abstract The production of amorphous mesoporous silica nanoparticles can be achieved using sodium silicate (Na2SiO3) solutions prepared from South African coal fly ash waste The first part of this study Preparation of Sodium Silicate Solutions and Silica2023年1月9日 Fly ash is a kind of active mineral fine powder resource The research shows that different fineness of fly ash has different effects on silicate hydration products SBM manufactures different types of grinding equipment for fly ash grinding process They can grind fly ash into different fineness for different applications 1, used in concreteHow to Process Fly Ash and What Is It Used for2023年12月7日 This study investigates the alterations in the ratios of components such as class C fly ash (FA), blast furnace slag (BFS), and waste stone powder (WSP) types of limestone powder (LP) used in the production of geopolymer concrete These components are meticulously examined concerning the physical and mechanical attributes of geopolymer concrete Using The Effects of Fly Ash, Blast Furnace Slag, and Limestone Powder

How to Process Fly Ash and What Is It Used for? Fote Machinery

2023年5月27日 If the content of fine powder with particle size ≤ 0044mm in the raw material is low, grind the fly ash with a ball mill, and then screen it with a powder separator Ftmmachinery can design a reasonable grinding process according to the specific conditions of fly ash and provide corresponding equipment2017年6月27日 Coarse ash particles, referred to as bottom ash or slag, fall to the bottom of the combustion chamber, while the lighter fine ash particles, termed fly ash, remain suspended in the flue gas Prior to exhausting the flue gas, fly ash is removed by particulate emission control devices, such as electrostatic precipitators or filter fabric baghouses (see Figure 11)Chapter 1 Fly Ash An Engineering Material Fly Ash Facts for In this present investigation, geopolymer specimens were prepared by fly ash powder and various concentrations of NaOH solution maintained at 10 molar (M), 12 molar (M) and 14 molar (M) along with Na2SiO3 solution followed by artificial curing at 60 °C up to 50 h Na2SiO3 solutiontoNaOH solution ratio and liquidtosolid mass ratio are maintained at 1 and 03, respectively Synthesis, Characterization and Properties of Fly Ash BasedThis fly ash powder causes various effects on the environment, such as air, water pollution Large land area is also required for the dumping and disposal of fly ash, and it is highly unsustainable for the environment Process flow sheet of geopolymer specimen preparationSynthesis and Characterization of Fly Ash and GBFS Based

Process Flow MEPCO

Process Flow The AAC block manufacturing process involves the following steps: Raw material preparation The key ingredient to manufacture AAC blocks is fly ash or pond ash Fly ash is mixed with water to form fly ash slurry After thorough mixing, slurry containing fly ash (or sand), lime powder, cement, 2023年10月9日 Another way to activate FA is by adding chemicals from powder, ball mill, limestone, and water with doses of 10 to 33% fly ash The process workability and flow capacity of SCC [55]Use and effect of fly ash in concrete: A literature Summary:The fly ash processing system is composed of dryer, elevator, silo, grinding mill, fan, powder concentrator, dust collector, pipeline device, etc How to Process Fly Ash and What Is It Used for Fly ash is the fine ash collected from How to Process Fly Ash and What Is It Used for2015年3月1日 Copper based composites with SiC and Fly ash as reinforcement is prepared by powder metallurgy process During processing of composites the compaction pressure is maintained as 400MPa for all Influence of Process Parameters on Cu–Fly Ash Composite by Powder

Flow battery electrolyte from carbon black incineration fly ash:

2021年9月1日 The elemental analysis of different fly ash samples has been performed by dissolving the fly ash samples in a mixture of sulfuric and nitric acid With the help of microwave, the solid fly ash samples were dissolved and the solutions after filtration were collected for elemental analysis Mass balance of the process has been included in Fig S1Powder Feed Rate 1,000 kg/hr Powder Moisture into Dryer 140% Powder Moisture from Dryer 80% Required Evaporative Capacity (kg/hr) 650 RECIRCULATING FLASH DRYER PROCESS FLOW 7 8 3 4 6 2 1 1 Feed Hopper 2 Steam Heat Exchanger 3 Dryer Cyclone 4 Dryer Dust Filter Unit 5 Dryer Recirculating Fan 6 Dryer Exhaust Fan 7 Cooler CycloneCONTROLLING FLASH DRYERS2024年4月26日 Abundant tuff mineral resources offer a promising solution to the shortage of fly ash (FA) and silica fume (SF) resources as emerging supplementary cementitious materials However, a lack of clarity on its hydration mechanism has hindered its practical engineering application In this study, high SiO2content tuff powder (TP) was examined to assess the Replacing Fly Ash or Silica Fume with Tuff Powder for Concrete 2018年8月1日 This work evaluated the change of airflow and kinematic characteristics of fly ash particles in the separation process of fly ash using rotary triboelectrostatic separator CFD software Fluent 145 provided the flow field, fly ash particles and carbon particles information on the premise of overcoming the inconvenience of observationResearch on flow field and kinematic characteristics of fly ash

Effects and mechanism of superplasticizers and precursor

2022年10月3日 To promote the application of green geopolymer materials, the effects and mechanism of commercial superplasticizers on the fresh properties of onepart geopolymers prepared from fly ash (FA), slag powder (Slag) and anhydrous sodium silicate powder were studied, including flowability, rheological properties and particles packing propertiesstate The shrinkage limit of the soil with varying percentage of Fly Ash is given in table 4 and fig 4 Table 4: Shrinkage limit for Red soil + Fly ash (5%, 15%, 20%) Fig 4: Shrinkage limit (soil + Fly ash) Sl No Specimen [soil% fly ash%] Plastic limit % 100 + 0 2203 2 95 + 5 2179 3 85 + 15 2414 4 80 + 20 4479Soil Stabilization by Using Fly Ash IOSR Journals2019年7月15日 The charged fly ash particles entering a highvoltage static separation chamber are deflected by an electric field force to separate the ash particles and carbon particles At the same time, a reverseblowing airflow is applied in the direction opposite to the flow of electrified fly ash particles during the separation processSeparation of unburned carbon from coal fly ash: A review2023年3月15日 A new type of inorganic fiberfly ash continuous fiber was innovatively developed in this study to alleviate the problems of low comprehensive utilization rate and lacking of highvalue utilization means of industrial solid waste fly ash The melt flow temperature and macromechanical properties of different samples were studied The results showed that with the Preparation and microstructure analysis of fly ash continuous fiber

R)8OC`6F[ZIB.jpg)

Sintering Process and Characteristics of GlassCeramics from Coal Fly Ash

Request PDF On Jan 1, 2020, Li Zeng and others published Sintering Process and Characteristics of GlassCeramics from Coal Fly Ash Find, read and cite all the research you need on ResearchGate2021年11月19日 Fly ashmixed polymeric media for abrasive flow machining process November 2021; The raw coal fly ash powder was taken from machine process are satisfied by fly ash media and the Fly ashmixed polymeric media for abrasive flow machining process2020年6月30日 A specially developed ultrasonic measurement apparatus (UMA) was used to in situ monitor the setting process of fly ash blended cement paste Combined with the results of Vicat Needle tests, isothermal calorimetric measurement, XRD analysis, SEM morphology and compressive test, the influence of curing temperature (20, 40, 60, and 90 °C) and fly ash Early Hydration and Setting Process of Fly Ashblended Cement Flooding or Uncontrolled Flow Another fly ash challenge is that the fine particle sizes (fine powder) can turn to fluid due to the presence of in a hightemperature process This process is called pyrolysis and is used for wastewater treatment In addition, fly ash may be used in the stabilisation process of contaminated soil or hazardous Fly Ash Handling: Challenges and Solutions When Conveying

Fabrication of Fly AshBased Refractory Brick Through Powder

2022年10月1日 Tianyuan Wang et al proposed a triplelayer microstructure for alumina fly ashbased ceramic where three unique layers of material were fabricated with 20, 30, and 40% fly ash The triplelayer microstructure of the ceramic was sintered at 1400 °C exhibited excellent physical properties such as the bulk density of 229 g/cm 3 and rupture modulus of 11674 MPa2019年12月1日 There has been an increasing attempt for fly ash utilization in different sectors Loya and Rawani [5] identified top areas for the quantity of fly ash utilization as 4419% in cement and concrete sectors, 1525% of ash in roads, embankments and ash dyke raising, followed by 1249% in reclamation of low lying areas and land filling, 884% in mine filling, 761% in bricks, Physical, chemical, and geotechnical properties of coal fly ash: With much fly ash still being diverted to landfills and existing landfills filled with fly ash that could potentially be used in concrete, there is still an important opportunity to further increase fly ash contents in concretes The aforementioned survey conducted by Obla et al [2]Best Practices Guide for HighVolume Fly Ash Concretes:2020年1月11日 In this paper, the effect on thermal behavior and compounds mineralogy of replacing different percentages of fly ash with compact particles was studied A total of 30% of fly ash was replaced with mass powder glass (PG), 70% with mass natural aggregates (S), and 85% with mass PG and S According to this study, the obtained fly ash based geopolymer exhibits XRD and TGDTA Study of New Alkali Activated Materials Based on Fly Ash

.jpg)

Comparison of Glass Powder and Fly Ash Effect on the Fresh

2019年10月13日 CEM I 425 R type Ordinary Portland cement was used as well as class F fly ash and glass powder as mineral additive materials in the production of mortar samples Physical and chemical properties of cement, fly ash and glass powder are given in table 1 Additionally, SEM images analysis of fly ash and glass powder are given in figure 1