Fly ash absorbs water quickly

.jpg)

Transformation of nonwater sorbing fly ash to a water sorbing

2020年10月29日 A novel and ecofriendly fly ash water absorbent (FAWA) was synthesized by grafting the partially neutralized polyacrylic acid (PAA) chain on to the surface of fly ash (FA) 2019年9月26日 This experimental study further investigated the feasibility of using the local FA to replace cement at weight ratios ranging from 40% to 70% to produce high volume fly ash (HVFA) concrete The(PDF) Water absorption of high volume fly ash Fly ash (FA), a hazardous byproduct of coal combustion in power plants, poses significant environmental and health risks due to improper disposal and utilization This study introduces Facile and sustainable upcycling of fly ash into multifunctional Fly ash or more specifically, flyashbased sorbents, may be used for the removal of NO 2 from flue gas It is known that NO 2 is adsorbed on a molecular sieve (zeolite) and mesoporous Coal fly ash: an emerging material for water remediation

.jpg)

State of the art review on physiochemical and engineering

The adsorption of VOC from the air and the heavy metals from waste water employing fly ash nanofiber membrane needs further investigation for its better understanding2020年2月4日 This work investigates the sorption properties of fly ash zeolites synthesized with different methods using CO2CO2 sorption and regeneration properties of fly ash 2022年2月27日 Fly ash showed prominent adsorption capacity for pollutants in water especially when it was activated or applied in composites In addition to direct pollutant binding in soils, Applications of fly ash for pollutant adsorption in water SpringerModified fly ash can adsorb VOCs, NOx and SO 2 emissions in the air and can also remove some heavy metals and other organic/inorganic pollutants (eg, phosphorous, fluoride, boron, phenolic compounds, pesticides and dyes) from Application of Fly Ash as an Adsorbent for Removal of

.jpg)

Selfcleaning superhydrophobic fly ash geopolymer

2023年1月2日 This paper presents the fabrication of a superhydrophobic and selfcleaning surface on a fly ash geopolymer as a method to prevent moisture intake2023年9月8日 Cement quickly absorbs water and goes through a hydration reaction when it comes into touch with calcium sulfate whiskers and water Fly ash originated from coal mines and was finally reused in coal mines, which embodied the concept of resource recyclingEnhancement mechanism of Insitu selfgrowing calcium sulfate on fly 2007年4月1日 Disposal of high amount of flyash from thermal power plants absorbs huge amount of water, energy and land area by ash ponds Therefore, flyash management would remain a great concern of the centuryWater Holding Capacities of Fly Ashes: Effect of Size FractionationFacile and sustainable upcycling of fly ash into multifunctional durable It is worth noting that raw FA is inherently hydrophilic and readily absorbs water upon contact Fig 5 a presents the digital images of water and cotton fabric, the water droplets are quickly absorbed by the material upon contact, resulting in aqueous dye Facile and sustainable upcycling of fly ash into multifunctional

Water absorption in fly ash concrete ResearchGate

2015年1月1日 Download Citation Water absorption in fly ash concrete Fly ash is used as Partial replacement of cement by 30%, 40%, 50%, and 60% and polypropylene fibers are used in 02%, 2020年10月29日 The fly ash water absorbent (FAWA) exhibited high waterabsorbing capacity (WAC) of 310 g/g at par with commercially available superabsorbent hydrogel (SAH) The Transformation of nonwater sorbing fly ash to a water sorbing 2024年3月19日 Fly ash is a greyishblack powdery substance easily available and produced as a side product of burning any organic substance A huge amount of fly ash is generated worldwide, and today’s world faces a severe problem of its disposal Owing to its various applications, researchers began utilizing fly ash as a catalyst to solve environmental problems Emerging applications of waste fly ash for remediation of 2 天之前 Fig 10 shows the FTIR spectrum of untreated fly ash, 5 wt% and 10 wt% carbonated fly ash along with the 5 wt% fly ash with inclusion of both natural surfactants FS and NS In raw fly ash, peak 1074 cm −1 corresponds to SiOSi asymmetric stretching and peak at 794 cm −1 is associated with the absorbance due to symmetric of SiOSi bond [45] Sustainable biomass derived natural surfactant of soybean seeds in fly

Compressive Strength and Water Absorption Characteristics of Fly Ash

2018年7月15日 From the Fig 2, it can be observed that the compressive strengths of fly ash replaced cement mortar bricks increase with an increase in fly ash content, whereas in wood ash replaced bricks, the compressive strength decreases as the percentage of wood ash increases, but with reference to the control cement bricks, all fly ash replaced bricks achieved reasonable 2023年3月1日 C618: Class C fly ash contains more than 10% lime an d Class F fly ash contains less than 10% lim e Fly ash can also be divided into LT (low temperature) and HT categories depending on how th e (PDF) Exploring the Viability of Fly Ash Bricks as an Alternative 2020年6月11日 UliaszBochenczyk, A Application of Fly Ash From Hard Coal Combustion in Water Boilers for CO 2 Sequestration via Mineral Carbonation Rocz Ochr Sr (2008)The potential of FBC fly ashes to reduce CO 2 emissions2017年12月8日 Compressibility parameters (Cv, Cα and Cc) decrease with the addition of 10% fly ash to peat and the reason for the reduction is fly ash absorbs water from peat and undergo reactions producing Effect of fly ash on the compressibility behavior of peat: An

.jpg)

EFFECT OF FLY ASH ON WATER DEMAND AND STRENGTH OF A

2020年8月13日 The columns, beams and slabs were tested with pundit machine and the average readings recorded as shown in Figs 15, a sample of column, beam and slab of the first floor, second floor, third 2009年9月1日 Biofuel combustion ash can be successfully utilized to produce building materials [4] Due to of its chemical, physical, and morphological properties, biofuel fly ash, as a pozzolanic additive (PDF) Characterisation and use of biomass fly ash in 2022年6月10日 Municipal solid waste incineration fly ash (FA) can represent a sustainable supply of supplementary material to the construction industries if it is pretreated to remove hazardous substances such as chloride, sulfate, and heavy metals In this paper, the phenomenology associated with a water washing multicycle treatment of FA is investigated, MSWI Fly Ash Multiple Washing: Kinetics of Dissolution in Water, 2019年6月5日 At 160 mm, the ash "B" absorbs about 22 t imes more water than the ash "A", and at a flow rate of Nowadays, the most frequently applied are mixtures of fly ash and water, (PDF) The influence of the type of fly ash on selected physical

Effects of fly ash properties on carbonation efficiency in CO2

2019年6月1日 Coal fly ash, a byproduct of coal combustion power plants, has been considered a promising material for CO 2 sequestration, because of its high alkalinity and particularly large volume production worldwide [20, 21]In 2010, the global generation of coal fly ash was approximately 780 Mt [22]As a hazards waste, fly ash without proper disposal can pollute 2024年4月10日 The fly ash collected from the thermal power plants is usually obtained from burning bituminous and anthracite coals which have high ash content (30–40%) and low calcium content (1–5% Large CO2 reduction and enhanced thermal performance of agro 2020年7月13日 The leaching of Cr(VI) from lignite fly ash was investigated by means of experimental standards and theoretical simulations Two lignite fly ash samples with different calcium oxide concentration were examined Acid extraction of fly ash and batch leaching tests were performed at various liquid (water) to solid (fly ash) ratios (L/S) for the estimation of Cr(VI) Leached from Lignite Fly Ash—Assessment of Groundwater • On further addition of fly ash of about 15% and 20% to the soil sample, which does not improve the properties of the soil • The silt sized particles is increased when fly ash is added to the soil sample which absorbs the water more than before and thus decrease in liquid limitSoil Stabilization by Using Fly Ash IOSR Journals

Enhancing the Compressive Strength of the Fly Ash Brick by Fibre

2019年8月11日 Compressive strength test results of 10 R proportion e 10 C Proportion: In 10 R proportion, the materials used to cast the bricks are flyash 50%, quarry dust 30% and Ordinary Portland Cement (OPC 2017年5月1日 Coalderived fly ash carbons (chars) have a structure that is dependent upon the rank of the feed coal Lowrank coals will produce a char with no signs of melting, bituminous coals (in general Coalderived unburned carbons in fly ash: A review2024年2月21日 Fly ash (FA) contents and waterbinder ratio (w/b) are the important factors influencing the mechanical characteristics of cementbased materials, meanwhile the porous structure of material plays a vital role The compressive strength and water permeability of cementbased samples with highvolume FA contents (0%, 30%, 40%) and different w/b (03, Strength, Permeability and Multiscale Pore Characteristics of 2018年1月1日 Fly ash is a potential source of highly reactive feedstock for carbon dioxide (CO 2) mineral carbonationIn this chapter, the importance, advantages, and challenges of using fly ash as a feedstock for CO 2 mineralization are introduced The physicochemical properties of fly ash and their effects on carbonation performance, as well as the property changes after Carbon dioxide sequestration by direct mineralization of fly ash

Flowable Fly Ash Transportation Research Board

1 Flowable fly ash can be used as a fill material in place of compacted soils or granular materials In addition, it can be placed directly into water or wet conditions and it can be placed by pumping or conventional methods 2 Dry fly ash obtained directly from readymix hoppers has been used, but fly ash conditioned with water to control2022年2月20日 The research on fly ash for membrane fabrication was initiated in 2006 and only very recently, publications in this topic have started to steadily increase as depicted in Fig 2In view of the extensive research that is being carried out on fly ashbased membranes, this article aims to provide the readers an overview of fly ash membrane fabrication and its application in Process intensification through waste fly ash conversion and 2020年4月8日 Traditionally fly ash is thought to be glassy, spherical particle originating from pulverized coal combustion (PCC) at temperature up to 1700 °C However, nowadays fluidized bed combustion (FBC) technology is spreading quickly around the world as it is an efficient and environmentally friendly method FBC is also able to utilize mixtures of lowgrade solid fuels Utilization of Fly Ashes from Fluidized Bed Combustion: A Review 2018年5月20日 Fly ash has a significant influence on the pore solution to mitigate ASR Firstly, fly ash reduces the alkalinity of pore solution by alkali binding Diamond [105] measured the alkali concentration (Na + and K +) in pore solution of OPC paste and fly ash blended paste (30% fly ash +70% OPC)Review ScienceDirect

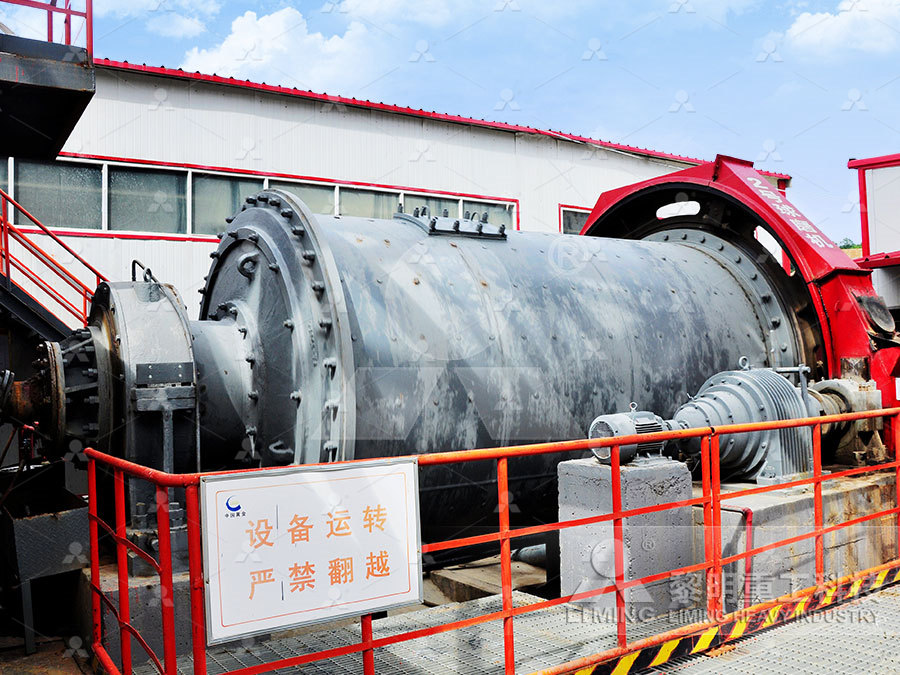

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Application of Fly Ash as an Adsorbent for Removal of Air and Water

Air pollutants such as volatile organic compounds (VOCs), nitrogen oxides (NOx), and sulfur dioxide (SO2), as well as water pollutants (eg, heavy metals phosphorous, fluoride, boron, phenolic compounds, and dyes), are harmful to humans and the environment Effective control and reduction of their pollution is therefore an important topic for today’s scientists Fly ash 2010年5月8日 The amount of air entrained in the concrete controls the freezethaw durability, and the high carbon content in certain fly ash products absorbs some air entraining agents, Highcarbon fly ash materials tend to use more water and darken the concrete as well It is not recommended to use a highcarbon (greater than 5 percent) Using Fly Ash in Concrete NPCA2010年1月14日 Fly Ash (FA)a coal combustion residue of thermal power plants has been regarded as a problematic solid waste all over the world Disposal of high amount of flyash from thermal power plants absorbs huge amount of water, energy and land area by ash ponds Therefore, flyash management would remain a great concern of the centuryUse of Flyash in Agriculture: A Way to Improve Soil Fertility and its 2021年5月28日 The effect of fly ash on the slump should be considered together with concentration In a homogeneous flow the free water is relatively less The pore structure created by the large content of fly ash absorbs a lot of water; Flow Properties Analysis and Identification of a Fly

Coal fly ash: an emerging material for water remediation

Coal fly ash (CFA) is a byproduct of thermal power plant and collected from flue gases by separator Composition of CFA depends on the type of coal used and it has both crystalline and amorphous character It is considered to be an environmental pollutant and used in number of areas CFA is a useful material and widely used in cement production and as a promising 2022年12月1日 Methods of sampling fly ash: 2021: Japan: JIS A 6201: Fly ash for use in concrete: 2015: United Kingdom: BS EN 4501: Fly ash for concrete Definition, specifications and conformity criteria: 2012: BS EN 4502: Fly ash for concrete Conformity evaluation: 2005: PD CEN/TR 15840: Evaluation of conformity of fly ash for concrete Guidelines for Fly ash for sustainable construction: A review of fly ash concrete 2016年3月11日 TINJAUAN PERMEABILITAS DAN ABSORBSI BETON DENGAN MENGGUNAKAN BAHAN FLY ASHSEBAGAI CEMENTITIOUSReview The Use of Flyash as a Cementitious to Concrete Absorbtion and PermeabilityErwin Rommel1 TINJAUAN PERMEABILITAS DAN ABSORBSI BETON DENGAN MENGGUNAKAN BAHAN FLY 2023年9月22日 When discussing fly ash in concrete advantages and disadvantages, it’s worth noting that fly ash in concrete provides good use of portal cement hydration products Calcium as well as alkali hydroxide solutions, that are emitted into the porous system of the paste, mix with fly ash particles, creating a cement medium, and the heat generated by hydration of portal Use of Fly Ash in Concrete CivilJungles

The Importance of Influence Factors of the Fly Ash Cement

That means: (1) The hydration reaction of 200 mesh’s fly ash completed faster than 100 mesh’s; (2) With the same fineness, the influence of watercement ratio and content of fly ash to reaction velocity is small, and the more content of fly ash, the Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), [1] are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls: Diagram of the disposition of coal combustion wastes Fly ash is captured after coal combustion by filters (), Coal combustion products Wikipedia2023年4月17日 Volume stability improved with the incorporation of fly ash, 05–06 water binder ratio, foam stabilizer with 16% cement content, bottom ash, setting accelerator and superplasticizer with 2% cement content The amount of pores and spaces in concrete affect how quickly it absorbs waterReview on performance and sustainability of foam concrete2023年4月27日 This study looked at the effects of magnetic water and fly ash on the mechanical and durability characteristics of concrete To estimate the effect of magnetization on the properties of water, Numerous experiments on treated and untreated water, such as “pH, acidity, alkalinity, chlorides, and total solids”, have been carried out with the assistance of a neodymium rare Influence of magnetization of water on mechanical and durability

.jpg)

Influence of magnetization of water on mechanical and durability

PDF On Apr 1, 2023, T Muralidhara Rao and others published Influence of magnetization of water on mechanical and durability properties of fly ash concrete Find, read and cite all the research