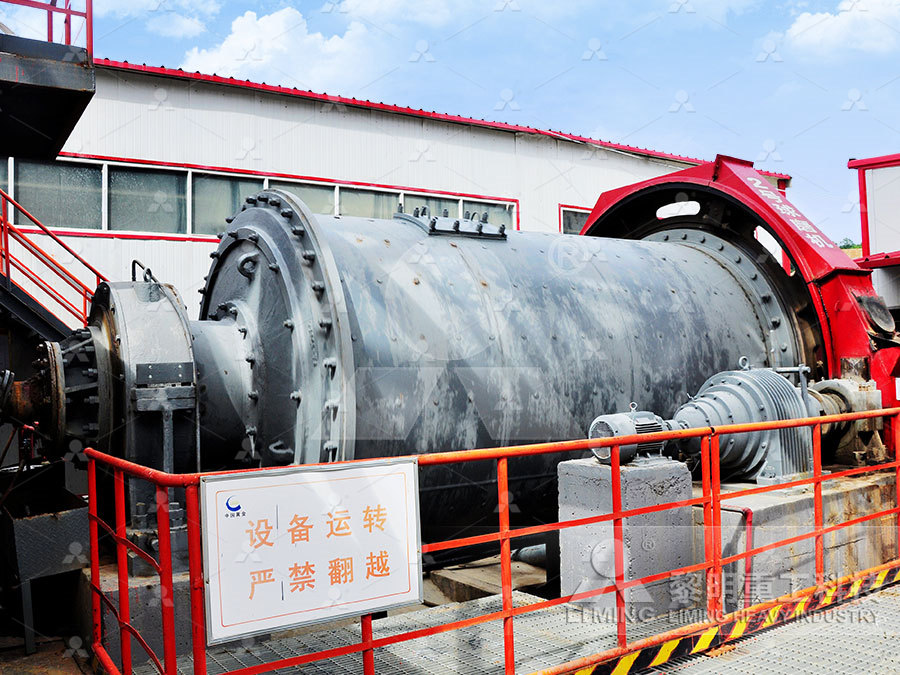

Cement brick mechanical crushing equipment

Rebel Crusher For Sale Rebel Concrete Crusher RR

2021年12月7日 The Rebel Crusher is the perfect compact mobile crushing screening machine Crush rock, limestone, brick, concrete, asphalt Made in Zhengzhou Wanjun Machinery Equipment Co, Ltd was established in 2019, the company has RD, sales, manufacturing and aftersales integrated services, the company's main products: large, medium and small unburned brick machine, cement brick machine, hollow brick machine, eighthole disc, jaw crusher, vertical shaft sand making machine Zhengzhou Wanjun Mechanical Equipment Co, LtdZhengzhou shuangsheng Machinery Manufacturing Co, Ltd has been committed to producing and selling supporting equipment, such as brick making machines, fully automatic hydraulic brick making machines, crushing sand making Zhengzhou shuangsheng Machinery Manufacturing AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher The hammer crusher is a kind of crushing machine which uses impact energy to crush materials It is mainly Cement Crusher Crushers for Cement Plant AGICO

Mobile Concrete Crushers: 90385 TPH RUBBLE MASTER

Mobile concrete crushers for processing concrete building slabs, bridgedeck, sidewalk, curbing, pipe, and high PSI runway concrete Turn your concrete into cash with a mobile concrete crusher Highquality aggregates for a high PMSA ® is the leading and largest manufacturer of a full range of highquality concrete brick, block and paver making machinery on the continent We offer startup manually operated machines producing 4,800 bricks per shift, to fullyautomated machines producing 283 269 bricks per 9hour shiftBrick Block and PaverMaking Machinery, Brick Machine PMSAVess produces highquality block making machines, brick making machines, concrete batching plants and crushing and screening plants designed for longterm use vess tries to provide highquality machines with a reasonable price and the machines have 2 years of guarantee as wellBlock and Brick making machines and Concrete batching plants The Tigerbite 425 crushes between 68 tonnes per hour, or 36 tonnes of mixed concrete, crushing 40mm down to dust How does the Tigerbite 425 Mini Crusher save you money? The Tigerbite 425 enables on site recycling of bricks and concrete, reducing the need for skips and transport costs associated with waste removalTigerbite Mini Crushers Tigerbite 425

.jpg)

Brick equipment for sale Machinery Partner

New equipment for processing Brick Brick crushers, screeners, conveyors, and more to complete your entire production line Browse a wide range of equipment, including brick crushers, and get ever Enhance your refractory manufacturing with our cuttingedge equipment designed for producing refractory bricks, blocks, and panels From advanced forming machines and precision molds to efficient mixers, dosing systems, automatic Home Titan MachineryIn short, a plant chemist must not only concern himself with the ultimate cement quality a kiln feed will deliver but must also design the mix to possess good burnability and coatability properties in the kiln This subject is discussed in Kiln Refractory Requirement , properties Factors Characteristics of cement brick machine for sale 1 Reasonable design We adopt automatic shuttle board system, conveying materials, splitting materials, compulsory materials placing system, head synchronization and frame synchronization system, can achieve automatic and cycling production, productivity is high, can produce a large quantity of bricks, and quality is Cement Brick Machine For Sale Aimix Group Construction Equipment

Cement Crusher Crushers for Cement Plant AGICO

Jaw Crusher Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crusher is a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric 2024年6月28日 The results demonstrate that the crushing efficiencies of ore crushing particles, raw material crushing particles, and cement crushing particles can respectively reach 807%, 7015%, and 8027% Energy Efficiency Measurement of Mechanical Crushing Based on Need professional equipment, tools or supplies for your next job or build? Kennards Hire has you covered! With more than 70 years of experience we offer fast and reliable rentals, Australia wide Call 135 135 or click here to find out more about our diverse equipment range!Kennards Hire Hire or Rent Equipment, Tools SuppliesIn the mechanical stress category, brick crushing is the most common problem (Figure 378) The main reasons for brick crushing are: 1) installation problems such as too many shims, gaps, and misalignment, 2) excessive shell ovality, 3) kiln misalignment (doglegs) as shown in Figure 3714, and 4) improperly designed brick retainersEverything you need to know about Refractories in Cement Manufacturing

Small Mobile Crushers, Screeners, Shredders Komplet America

Efficiency: Komplet America equipment is designed to optimize productivity and minimize waste, ultimately boosting your bottom line Sustainability: We are committed to environmental responsibility Our equipment’s compact design and efficient operation contribute to reduced carbon footprint and resource consumptionStage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inchesHow Cement is Made Cement Manufacturing ProcessCement is often referred to as Portland cement, a generic term used for nearly all cement It is the mixture from which many types of concrete are made and is called such due to its resemblance to a type of building stone quarried in the early part of the 19th century This stone came from the Isle of Portland, located off the southern coast of EnglandWhat Equipment is Used for Cement Manufacturing?The rotary kiln design is important for cement manufacturing Refractory brick is a kind of rotary kiln With the continuous progress of the cement industry, rotary kiln, as the core cement equipment of cement they can be respectively classified as chemical damage, mechanical stress damage, and thermal stress damage In most cases Rotary Kiln Design: Cement Rotary Kiln Refractory Bricks Rotary

The Science of Brick Installation

H Brick Height (Lining Thickness) L Brick Length HOT FACE Flame Side COLD FACE Kiln Shell Side H Brick Height (Lining Thickness) 1 Tighten bricks with a hydraulic jack Maximum jack pressure shouldn’t exceed 3540 N/mm2 (~1/2 brick cold crushing strength) During jacking, a rubber hammer should be used to knock bricks into place 22021年2月23日 The design mix for cement sand brick was used in accordance with BS EN 9982 [] and the mixtures were designed according to the British Standard requirement []Generally, the ratio of cement and sand in sand cement brick is 1:6Density, Compressive Strength and Water Absorption SpringerBrick sample no Fly ash (gm) Cement (gm) Sand (gm) Gypsum (gm) 1 119 35 88 31 2 131 35 82 24 3 143 35 76 16 4 155 35 70 8 Table 3: Mixing proportion of raw materials and brick sample in (%) for fly ash Lime proportion Brick sample no Fly ash (%) Lime (%) Sand (%) Gypsum (%) 1 50 10 28 12 2 55 10 26 9EXPERIMENTAL INVESTIGATION ON MECHANICAL PROPERTIES OF FLY ASH, CEMENT RUBBLE MASTER's mobile impact crushers can be configured to meet any spec so you can tackle more jobs with a single machine Meet Your Spec Highquality recycled concrete aggregates with excellent gradation for densegraded Mobile Concrete Crushers: 90385 TPH RUBBLE MASTER

.jpg)

Mechanical properties and water absorption of cement

2020年11月1日 Afterwards, the recycled brick aggregates were prepared after mechanical crushing and sieving, and the obtained recycled brick aggregates were further ground into WBP by grinding equipment In addition, various fineness levels of WBP could be obtained by adjusting the grinding equipment and the grinding durationThe equipment required is very simple: Just a gutter around the coolers, from which the water runs into the individual cooler tubes The amount of water is controlled by the clinker temperature, and it has been established that 1 % water on clinker basis reduces the clinker temperature by about 15 – 20°C, which is close to the theoretical maximumCLINKER COOLING COOLER SYSTEMS INFINITY FOR CEMENT EQUIPMENTExperimental Investigations of Cement Clay Interlocking Brick Masonry Structures Strengthened with CFRP and CementSand Mortar Abstract: Many masonry structures are constructed with cement clay Compressive strength of cement bricks: (a) 300 kg/m 3 cement 2012年7月1日 This paper aims to fabricate and optimize ecosustainable cement brick using different sizes of clay brick waste (CBW) The prime input factors of mixtures were clay brick powder (CBP) as a binder Physicomechanical properties of solid cement bricks containing

.jpg)

Types of Crushers: What You Need to Know Machinery Partner

ARK 2416 jaw crusher in action Gyratory crushers Run of mine material is transferred into a gyratory crusher’s upperlevel hopper The walls of the gyratory crusher’s hopper are lined with “Vshaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a coneHenan HuanSheng Mechanical Equipment Co, the chief engineer of the domestic machinery industry renowned crushing, the sand industry experts, has designed and developed several generations Block Machine, Brick Machine, Interlocking Brick Machine, Paving Brick Machine, Concrete Block Machine, Cement Block Machine, Concrete Mixer, Curb Henan Huansheng Mechanical Equipment Co, Ltd2024年3月5日 Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader Find Crusher Aggregate Equipment from KINGLINK, METSO, POWERSCREEN, Seller: Northeast Crusher Aggregate Equipment For SaleWelcome to Doubell Brick Machines your portal to brickmaking equipment for the largest range of brick sizes and styles The website offers machinery pricing as well as brickmaking help guides to assist you on your business journey Brick Machines Doubell Brick Machines

Water absorption of solid cement bricks: (a) 300kg/m3

Experimental Investigations of Cement Clay Interlocking Brick Masonry Structures Strengthened with CFRP and CementSand Mortar Abstract: Many masonry structures are constructed with cement clay 2019年7月19日 In homogenized microcrack crushing, as shown in Fig 1, the cement concrete pavement is crushed by special mechanical equipment that produces a lowvelocity impactBefore homogenized microcrack crushing, it is necessary to investigate the pavement conditions and classify them according to the deterioration stateInvestigation on the fracture mechanism of homogenized micro 2023年12月27日 The steel slag waste after various mechanical equipment processes will be reused in multiple industries, Brick factories and cement plants will need the iron powder and purchase it The crushing processing and reuse of steel slag are profitable and have a protective effect on the environment, Steel Slag Processing Plant Equipment SelectionAs a cement plants supplier, AGICO is able to manufacture hammer crusher, Jaw crushers are a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric power, Simple mechanical structure, compact and light; 4 High reliability, low maintenance fee, Cement Crusher Crushers for Cement Plant AGICO Cement Equipment

.jpg)

Construction, Working and Maintenance of Crushers for Crushing

between the crushing elements (mantle and concaves), finally exiting the crushing chamber at the bottom under the influence of gravity The crushing elements, mantle and concaves are made of high wear resistant material The crushing gap is adjusted by hydraulically lifting or lowering the main shaft by the hydraulic cylinderThe Block Mechanism Brick Machine Manufacturer Achieves Your ”Brick Industry” Dream Advantages of QT415A Multifunctional Hydraulic Block Making Machine: 1The brick making machine adopts fully automatic and intelligent operation, and workers can be employed after simple training, saving labor costs 2The new block machine adopts hydraulic braking, the Brick making machine, stone crusher, cement brick Download Table Mix proportions for solid cement bricks (kg/m 3 ) from publication: Physicomechanical properties of solid cement bricks containing recycled aggregates Recycling and reuse of Mix proportions for solid cement bricks (kg/m 3 ) ResearchGateDo you need to process sand, gravel, minerals, rock, or other aggregate products and have not yet purchased or leased crushing equipment? There’s no question—you need to work with a capable and professional material handling equipment design and engineering company dedicated to selling, renting, and installing the best new crushers for your needsTypes of Rock Crushers Quarry Crushing Equipment Kemper

.jpg)

Zhengzhou shuangsheng Machinery Manufacturing

Zhengzhou shuangsheng Machinery Manufacturing Co, Ltd, founded in 1987, is located in Zhengzhou City, Henan Province It is a company specializing in the production of block making machines, Bakingfree brick machines, Permeable China Cement Lab Equipment wholesale TBTCTM2000KN Lab Digital Display Concrete/Cement/Brick Static Hydraulic Metal/Nonmetal Compression Testing Machine testing equipment Chongqing Gold Mechanical Electrical Equipment Co, Ltd Diamond Member Audited Supplier Chongqing, China Cement Lab Equipment MadeinChinaGeorge’s experience as a mechanical engineer and his dedication to reducing the carbon footprint in construction led him to create Tabrick’s cuttingedge brickmaking machines His commitment to quality, innovation, and sustainable Brick Making Machine Manufacturer TabrickConstruction waste crushing – Transportation (steel, metal material suction) – batching autoclaved standard brick production line equipment 3 Tailing as the main raw material for autoclaved aerated concrete block, gypsum, water and aerator into cement slurry and curing by mechanical mixingAutomatic Brick Making Machine 02 uMCAD

.jpg)

SoilCement Bricks SpringerLink

2016年3月9日 Ferreira R, Gobo JC, Cunha AHN (2008) Rice husk Merger and pasture and their effects on physical and mechanical properties of soilcement bricks Eng Agric Jaboticabal 8:1–11 Google Scholar Grande FM (2003) Modular brickmaking soilcement by manual pressing with and without silica fume São Carlos, DissertationTECHNICAL NOTES on Brick Construction 9A October 2007 1850 Centennial Park Drive, Reston, Virginia 20191 gobrick 7036200010 Specifications for and Classification of Brick Abstract: This Technical Note describes the predominantconsensus standard specifications for brick and the variousSpecifications for and Classification of Brick Brick Industry Seller: CJ Equipment Inc 2021 AGROTK HPL3500 Crusher, Concrete View Details USD $15,00000 Apply for Financing Opens in a new tab Get Shipping Quotes Opens in a new tabConcrete Crusher Attachments For Sale MachineryTrader2024年6月28日 Mechanical crushing equipment holds a pivotal position in industrial production, finding widespread application in various sectors such as building materials, chemicals, metallurgy, and mining [1,2,3,4]As global awareness of energy conservation and emission reduction continues to grow, enhancing the crushing efficiency of mechanical grinding Energy Efficiency Measurement of Mechanical Crushing Based on

Hammer crusher INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 11 Overview the buying criteria for Hammer Crusher2 12Hammer crusher working principle and its application21 122Application of hammer crusher3 13 Types of Hammer Crusher4 14 Characteristics of hammer crusher41 141 Advantages of Hammer Crusher42 142 disadvantage hammer crusher5 Body construction hammer 2022年5月15日 The five watertocement ratios for this test were determined based on engineering experience: 14, 16, 18, 20, and 22 3) The cement and water were poured into the cement slurry mixer separately to prepare the cement slurry Then, the cement slurry was added into the negative pressure strengthening equipment to cover onethird of the Laboratory Investigation on Key Technological Parameters of Brick