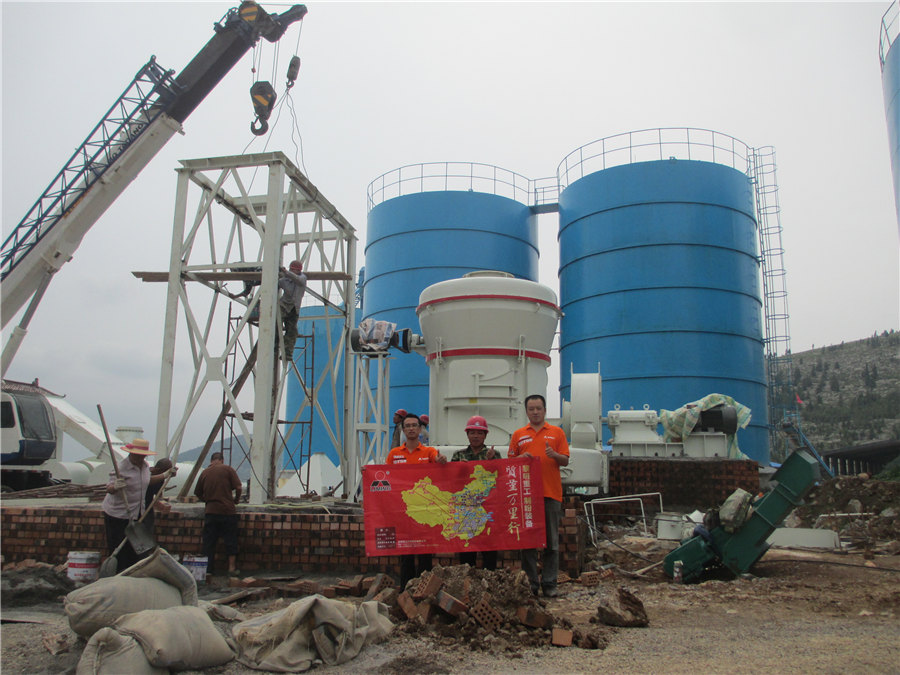

Calcium carbide mud micro powder grinding equipment

.jpg)

How to Choose a Calcium Carbonate Grinding Mill

Our common calcium carbonate grinding mills include ball mill, micro powder roller mill, Raymond roller mill, vertical mill, wet grinding mill and so on Raymond roller mill and micro powder roller mill are generally suitable for materials with Calcium Carbonate Powder Making Machine is the new type mining equipment for making micro powders, fine powders, which is widely applied in the industries of metallurgy, mining, Calcium Carbonate Grinding Mill Zhengzhou Turui Machinery Clirik Calcined calcium carbonatepowder grinding machine and Calcined calcium carbonate micro powder grinder mill can grind noninflammable, nonexplosive and brittle materials with Mohs’ Calcined calcium carbonate grinding machineThe purpose of the Micro powder Grinding Equipment is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite, gypsum, dolomite, bentonite mud,mica, pyrophyllite when it processes calcium carbonate and Calcite 3 Security Micro Powder Grinding Equipmentgrinding mill/ultrafine

.jpg)

Calcium Carbide an overview ScienceDirect Topics

Calcium carbide has the nominal formula of CaC 2 and the molecular weight of 640992 g/mol The pure material is colorless, but most samples have a color ranging from black to grayishwhite, depending on the grade Its density is 222 g/cc and it melts at 2160 °C with a boiling point (under an inert atmosphere) of 2300 °C, where it decomposesIts main use industrially is in the Calcium Carbonate grinding Mill is the new type mining equipment for making micro powders, fine powders,which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics, and so onThe purpose of the micro powder grinding millis for superfine grinding materials with hardness less than 9 in Moh's scale and humidity Calcium Carbonate Grinding Mill3 For the superfine powder and micro powder area, respectively select the ultrafine vertical mill and HGM mediumspeed microgrinding Fine Powder Grinding Machine End products 1 Meal powder: 03mm; 2 Fine powder: 80425 mesh, 20033 microns; 3 Superfine powder: 4251250 mesh, 3310 microns; 4 Micro powder: 12503250 mesh, 103 micronsCarbon Black Grinding Machine Beston Pyrolysis Plant2023年11月8日 The HGM125L highend calcium oxide ultrafine powder grinding production line equipped with SBM micro powder technology has been put into use, bringing customers unexpected high energy efficiency and high profits! Calcium oxide is mainly used for: Sewage treatment: acidic wastewater treatment and sludge conditioning;Highend calcium oxide ultrafine powder making equipment

.jpg)

Calcium Carbonate and Coal Powder Production Line In China

In a bid to enhance their production capabilities and expand their product offerings, this customer has invested in 3 sets of HGM125 micro powder grinding millsThese mills are specifically used to produce ultrafine calcium carbonate and coal powder, achieving a fineness of 600 meshThe final product, which expands upon mixing with water, is utilized as an expansion agent in various 2023年2月27日 As the raw material of geopolymer, Fclass fly ash (FFA) often needs strong alkali such as NaOH to stimulate due to its low reactivity In this study, FFA was refined and activated by a wet grinding process, and the activation effect of calcium carbide slag (19 %) and sodium silicate (1 %, 3 % and 5 %) was evaluated when used alone or in combinationPerformances and microstructure of onepart fly ash geopolymer The powder grinder, industrial powder grinder, powder making machine mainly consist of hammer crusher , micro powder main unit, Frequency conversion classifier, powder collector, pulse dust cleaner,high pressure positive blower, air compressor, muffler, electrical apparatus control system, soundproof room, crusher, bucket elevator, storage hopper, and vibrating feederIndustrial Powder Grinder, Stone Powder Grinder, Powder Making Machine 2021年11月24日 HGM ultrafine grinding mill is an industrial milling equipment that can grind nonmetallic ores into 1502500 mesh powder It can be used to process slaked lime and quicklime It has a small footprint, stable operation, convenient maintenance (realizing nonstop refueling), high efficiency, energy saving, and environmental protectionPowder Grinder Equipment for Producing Lime Powder

1500 Mesh Calcium Carbonate Mirco Powder

1500 Mesh Calcium Carbonate Mirco Powder Grinding Production Line, Find Details and Price about Calcium Carbonate Micro Powder from 1500 Mesh Calcium Carbonate Mirco Powder Grinding Production Line Fujian Longyi Zeolite processing machinezeolite grinding machine; Mica powder grinder machine; industrial powder grinder; Superfine grinding mill, Superfine grinding mill for sale; Caco3 powder grinder/ Caco3 grinding mill/ Caco3 pulverizer; Ultra Fine Vertical Roller Mill; Powder grinder series grinding equipment; Heavy calcium carbonate micro powder grinderPowder GrinderMicro Powder Grinder for SaleLimeStone Powder Grinder Grinding Ring: The grinding ring is the main component that provides the necessary compression and shearing force for grindingIt rotates and provides the surface against which the rollers press the material Grinding Rollers: These are cylindrical rollers that apply the grinding pressure to the material against the grinding ringThey roll on the ring and crush the material into fine particlesRing Mill For Ultrafine Grinding Calcium Carbonate2023年10月10日 Vertical mill: It can directly produce 325600 mesh calcium carbonate micro powder (basic demand) products, and can also be used with other ultrafine grinding equipment to prepare ultrafine calcium carbonate products Ball mill: It is the main equipment of a largescale calcium carbonate production lineTypical processes and equipment for ultrafine grinding of calcium

Calcium Carbonate Grinding Mill Henan Turui Machinery Co, Ltd

Calcium Carbonate Grinding Mill is the main equipment during the calcium carbonate powder making plant, which is suitable for grinding calcium carbonate into fine powder Calcium Carbonate Powder Making Machine is the new type mining equipment for making micro powders, fine powders, which is widely applied in the industries of metallurgy 2012年6月6日 Characteristics of calcium carbide: Calcium carbide belongs to a kind of brown or black solid block Its pure product is colorless crystals (purple with high CaC) The density is 222 g / cc It is relatively easy to break due to its low hardness Use of finished product: 1 Calcium carbide is the most important raw materials of acetylene chemicalCalcium Carbide Crushing Product Knowledge Kefid MachineryThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2022年6月1日 This study aimed to mitigate this problem by regenerating CO 2hardened SBS using a cheap regeneration reagent, namely calcium carbide slag (CCS), which is an easily available industrial waste, and considering the alkaline substance recovery The regeneration mechanism was explored by macrotests and microanalysisCarbon dioxidehardened sodium silicatebonded sand

.jpg)

Ground Calcium Carbonate Powder Surface Modification Machine

Ground Calcium Carbonate Powder Surface Modification Machine The surface modification technology of ground calcium carbonate is mainly through the addition of surface modifiers for surface chemical treatment Surface modification should be carried out with the help of equipment: Ground Calcium Carbonate Powder Surface Modification Machine The commonly 2021年7月22日 The calcium carbonate grinding process of HGM micro grinding mill: HGM micro grinding mill can be used to process various nonflammable and explosive mineral materials with Mohs hardness below 6 and humidity below 7% The fineness of the finished product can be between 200 mesh and 2500 meshWhat equipment does the calcium carbonate powder 2024年10月29日 The production of one ton of calcium carbide results in the generation of about 12 tons of calcium carbide slag (CCS) [23] CCS can be utilised as a raw material for the production of cement, modified for use as a waterproofing material, Preparation and Performance Assessment of Calcium Carbide 2020年4月13日 Calcium carbonate powder processing technology Posted: Calcium carbonate, as an inorganic powder material, is a nontoxic, odorless, and tasteless environmentally friendly material, and is widely used in plastics, rubber, papermaking, building materials, and other fieldsLike plastics, the current total output of plastic products and Calcium carbonate powder processing technology

Stone powder making machinemicro powder millStone powder

Stone powder making machinemicro powder mill Application of Stone powder making machine: Stone powder making machine is for superfine grinding materials with hardness less than 6 in Mohs scale and humidity less than 6 percent such as kaolin, limestone, basalt, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, carbon black, Note: This specification is just referencing, any changes are subject to the products Shanghai clirik machinery co, LTD Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machine please do not hesitate to contact us Phone: ;86Chalk powder grinder machine; powder grinder seriesPowder Raw materials and formula for making calcium silicate board: 1、Lime powder 10% + cement 50% + quartz powder 10% + wood pulp fiber 15% + wollastonite 5% 2、Silicon powder +calcium powder +natural log pulp fiber Use scope and main use of calcium silicate board: Commercial buildings: business buildings, entertainment venues, shopping malls Calcium Silicate Board Production Equipment Jiurui Machine2021年8月18日 Mechanism: the grinding method is to spray the compressed gas into the grinding area after passing through a special nozzle, so as to drive the materials in the grinding area to collide with each other and rub into powder; After the air flow expands, it enters the classification area with the rise of materials, and the materials reaching the particle size are How to "Make" Metal Micro Powder? Meetyou Carbide

.jpg)

Grinding and polishing equipment Struers

A wide range of grinding and polishing machines and equipment from Struers, the world’s leading materialographic and metallographic equipment supplier, for quick and reproducible sample preparation in the laboratory and production environments, or on siteThe equipment is independently developed and produced by SBM, sold directly by the factory, without middlemen, and is extremely costeffective It is a piece of ideal grinding equipment for processing 1503000 mesh calcium carbonate powderCalcium Carbonate Ultrafine Grinding Mill2013年8月8日 Best equipment for fine grinding graphite Date: 02:30:53 CLIRIK graphite grinding equipment include Raymond grinding equipment, micro powder grinding mill, rock grinding mill, stone powder mills, ultrafine powder grinding mill, and powder ultrafine mill Raymond grinding mill is the vertical grinding mill, which is popular in many countries and has Best equipment for fine grinding graphite powder mill2019年5月23日 714 Basic Performance of Dry Acetylene Carbide Slag Dry acetylene technique is compared to the traditional “wet” acetylene preparation technique It uses water a little more than the theoretical amount, which is sprayed on calcium carbide powder in a foggy state to hydrolyze prehensive Utilization of Carbide Slag SpringerLink

Synergistic activation mechanism and longterm properties of a

2024年8月9日 Calcium carbide slag (CS) is a byproduct of acetylene gas obtained by hydrolysis of calcium carbide, mainly composed of calcium hydroxide, and has strong alkalinity, making it a preferred material for alkali activation CS is also used as a calcium source to provide strength for geopolymer [15], [16], [17], [18]2022年5月5日 Calcium carbonate grinding mill is an efficient industrial powder grinder machine It can grind 100+ kinds of ores into a fine powder (1503000 mesh)Calcium Carbonate Grinding Mill Powder ModifyRequest PDF On Sep 1, 2023, Weiping Ma and others published Carbon emission free preparation of calcium hydroxide with calcium carbide slag (CCS) through microbubble impurities removal Find Carbon emission free preparation of calcium hydroxide with calcium Dolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment It is mainly applied to ultrafine powder processing of nonflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤9Dolomite Micro Powder Grinding Mill

.jpg)

Performances enhancing of supersulfated cement (SSC) using

2024年10月25日 Carbide residue is generated during the production of acetylene through calcium carbide hydrolysis, and it mainly consists of Ca(OH) 2, as indicated in Fig 4 The content of Ca(OH) 2 in carbide slag is 7013 % (calculated from the weight loss observed between 341 °C and 520 °C using TGA)The purpose of the micro powder grinding mill is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite, gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment and so onMicro powder grinding mill/grinding equipmentGrinding Mill,Grinding 2024年9月27日 The global aluminum manufacturing industry produces millions of tons of alumina annually through sintering, bayer and combined processes [1], [2], [3]Red mud emissions range from 055 to 221 tons for every ton of alumina produced [4], [5]In 2022, red mud emissions have surpassed 45 billion tons worldwide and was increasing at a rate of roughly Effect of wet grinding carbonation of sintering red mud on the The process equipment optimization comprises the following modules, known as optimization of wet calcium carbide slag feeding system and drying system, improvement of batching and grinding system for calcium carbide slag, and the optimization of clinker calcination system A detailed description for the three modules will be shown as the followingApplication technology of calcium carbide slag: a case study

News Calcium Silicate Production Raw Materials And Technology

2 Calcareous materials: slaked lime powder, cement, calcium carbide mud, etc 3 Reinforcing fiber: wood paper fiber, wollastonite, cotton fiber, etc 4Main ingredients and formula: silicon powder + calcium powder + natural log pulp fiber Quartz powder silica powder calcium powder diatomite wollastonite grinding millGrinding wheels are essential tools in the manufacturing industry They are used for various purposes, including cutting, shaping, and grinding materials such as metals, stones, and ceramics One of the most popular types of grinding wheels is the Carborundum grinding wheel What is a Carborundum Grinding Wheel? A Carborundum grinding wheel is a type of []Carborundum Grinding Wheel: Everything You Need to Know