What to do if the speed of calcite micro powder mill is slow

.jpg)

Dry Fine Grinding of Calcite Powder by Stirred Mill

2013年4月11日 In this study, the effects of various operating parameters, such as grinding time (min), stirrer speed (rpm), feed quantity (% of ball weight), and ball filling ratio (%) on fine grinding of calcite powder (CaCO 3) (d 50 = 3404 µm) were studied using a laboratory vertical stirred 2010年4月1日 Milling speed is one of the most important milling parameters that controls the milling process because it provides the mill with the energy required for (1) powder particles Powder Milling an overview ScienceDirect TopicsThis study focused on ultrafine grinding of calcite powder (CaCO 3) using a vertical stirred ball mill The influences of various operating parameters such as stirrer speed (rpm), ball filling Optimization of Wet Grinding Parameters of Calcite Ore in Stirred 2022年3月1日 Influences of different grinding aids on dry fine grinding of calcite using a laboratorytype ball mill were investigated Tested grinding aids had affected the flowability Analysis of grinding aid performance effects on dry fine milling of

Evaluation of the best suitable purification method to purity

Calcite mineral ores are very common in Rathnapura District in Sri Lanka, especially in Balangoda – Kalthota region Several types of physical and chemical methods were evaluated to find out 2021年4月21日 In batch grinding, these mechanisms can be caused by powder caking in the mill bottom, and the grinding efficiency can be reduced Powder caking (heavy) was observed at The Influence of Stirred Mill Orientation on Calcite Grinding2014年3月1日 For a given fineness, a lower specific energy is needed using a low stirrer speed Solid concentration affects grinding kinetics but improves energy efficiency Viscosity is a key Grinding of calcite suspensions in a stirred media mill: Effect of 2018年9月24日 One of the most energyintensive processes for producing submicron range calcite is stirred media mill In the present work, numerous operating parameters such as solid Effect of Operating Parameters on the Breakage Process of Calcite

.jpg)

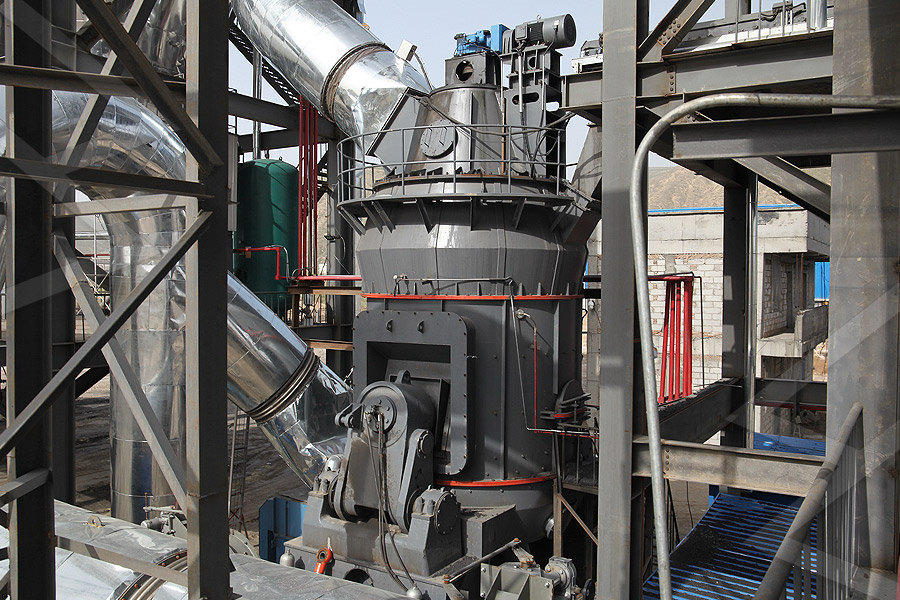

Calcite Hardness Grinding Mill,Raymond Mill,Ball Mill,Ultrafine Mill

Calcite processing mainly includes three steps: crushing, sand making and grinding It has a Mohs hardness of only 3 and is relatively easy to break Calcite feedstock with a size of less than 2019年8月29日 Therefore, to avoid the overqualification of ball mill, the grinding mill is a better choice in the calcite powder production Raymond mill, the threering and mediumspeed micro powder miller and HGM German series mill or How to Make Fine Calcite Powder? Fote Machinery SBM micro powder grinding mill is a highly efficient industrial grinding mill, its finished products: 3253000 mesh; it's capacity: 0245t/h +17 [ protected] airflow with crushed materials are brought to classifier Micro Powder Grinding MillIt is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, Micro Powder Grinding Mill

Calcite Hardness Grinding Mill,Raymond Mill,Ball Mill,Ultrafine Mill

The HGM Micro Powder Grinding Mill offers a wide range of product fineness, adjustable from 300 to 2500 mesh It has a large output range of 05 to 30 tons per hour, catering to various production needsCurseForge App Read more about Installation issues, troubleshooting guides, FAQs and app related errors Authors support Read more about Reward Program, moderation,Support: CurseForge support2017年7月7日 Pin mill configuration In a pin mill, the particle size is controlled by three parameters: Feed rate, rotor speed and airflow Varying these parameters will have the following effects: Increasing the feed rate will result in a coarser particle size while reducing the feed rate will have the opposite effectTop 5 productspecific milling technologies used in industrial Brief introduction Micro powder roller mill is also known as ultrafine powder grinding mill It is a new type of powder processing equipment, mainly used for crushing and processing nonmetallic minerals such as calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite and other nonmetallic minerals with Mohs hardness less than 5 and water Micro Powder Roller Mill for Getting Ultrafine Powder DASWELL

.jpg)

(PDF) Calcite Microcrystals in the Pineal Gland of the Human

2002年10月1日 A new form of biomineralization has been studied in the pineal gland of the human brain It consists of small crystals that are less than 20 microm in length and that are completely distinct from 2008年2月1日 XRD patterns of calcite ground in the P4 mill for increasing time with indication of main peaks of aragonite (*), quartz (#) and ferrite (airon) contaminant) (a); corresponding phase percentages (PDF) XRD line profile analysis of calcite powders produced by 2024年3月5日 Micro Milling involves using advanced CNC machines, meticulously calibrated tools, and cuttingedge technology to create intricate components with unparalleled precision Maintaining your interest in this topic, I assure you that micromilling differs from your runofthemill machining techniqueWhat is Micro Milling? Everything you need to know Worthy 1 Clean the mill Clean the inside and outside of the parts of the mill, including the machine body, grinding ring, grinding roller, motor, belt, gear connection, etc, and all the places that can be cleaned should be cleaned The purpose of this Calcium Carbonate Ultrafine Grinding Mill

.jpg)

Effects of Mill Speed and Air Classifier Speed on

2021年6月29日 The aim of this work was to observe the impact of the milling technique employed by the DESI 11 disintegrator on the properties of fly ash This type of mill is a highspeed pin mill with two Los procesos de desalinización con ósmosis inversa se caracterizan por eliminar en gran medida los minerales y sales del agua de alimentación, produciendo un agua no estable que puede causar Remineralization of permeate water by calcite bed 2014年2月20日 of micrometric calcite needles serve to establish a transfer func tion linking gray levels (GL; lightness) to the mass of coccoliths or to any fine calcite particle isolated in digital imagesOptical measurements to determine the thickness of calcite Influencing Factor of Rotational Speed of Stone Powder Mill Date: 02:18:35 Now on the market, there are a variety of Stone Powder MillsDifferent Stone Powder Mills and materials have different Rotational Speeds Operators of equipment should be familiar with processing efficiency of Stone Powder MillInfluencing Factor of Rotational Speed of Stone Powder Mill

Powder Milling an overview ScienceDirect Topics

2010年4月1日 Controlling the powdermilling process Prof Dr M Sherif ElEskandarany, in Mechanical Alloying (Third Edition), 2020 Abstract As was pointed out in the last two chapters, powdermilling process, using ball or rod mills, aims to produce a highquality end product that can be composites and nanocomposites, and nanocrystalline powder particles of intermetallic HGM series ultrafine powder mill (threering / fourring mediumspeed micropowder mill) is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process ball mill grinding and powder selection, greatly reducing production costsUltra Fine Powder MillCoarse powder grinding mill is engaging in crushing various rocks and stones into coarse powder and small particles, such as calcite, etc +17 [ protected] language >Shibang Industry Technology Group The three ring medium speed micro powder mill can grind the material to an ultrafine particle size of more than 3000 mesh Coarse Powder Grinding Mill SBM Ultrafine Powder TechnologyMicro powder roller mill As the name suggests, the micro powder roller mill mainly crushes the material by rolling and grinding the multilayer ring rollers It is mainly used to produce ultrafine powder of 845μm Our common micro powder roller How to Choose a Calcium Carbonate Grinding Mill DASWELL

The design and optimization process of ball mill to reduce particle

2020年11月16日 In this paper, ball milling parameters: weight ratio of ball to powder, size of milling balls, type of medium, volume of milling medium and rotation speed in the planetary ball milling of 2020年11月16日 In the laboratory, the common method to be used as the ball mill This work aims to design a simple horizontal ball mill Calcium carbonate material from limestone and eggshells powder was ground using the developed ball mill The balls to powder ratio (BPR) and powder type were investigated in relation to the particle sizeThe design and optimization process of ball mill to reduce particle Calcite powder has widely application However, if we want to get calcite powder, calcite micro powder mill is inevitable Today we will discuss with calcite powder applications Uses of Calcite in Construction The construction industry is the primary consumer of calcite in the form of limestone and marbleWhat are the Applicatons of Calcite powder2024年5月16日 Jaw CrusherPrimary Crusher Process: Feeding: Large chunks of calcite, as extracted from the mines, are fed into the jaw crusher Action: The jaw crusher consists of two jaws, one fixed and the other movingThe moving How To Make Calcite Powder?Calcite Powder

Effect of grinding aids on the grinding energy consumed during grinding

2010年1月31日 A series of wetgrinding experiments has been carried out on inorganic powders by a stirred ball mill to systematically investigate the grinding characteristics2022年1月13日 HGM micro powder mill HGM micro powder mill is an industrial grinding equipment specialized in processing and manufacturing fine powder and ultrafine powder The product fineness can be adjusted between 3002500 mesh according to the needs, and the product fineness can reach D97≤5um at one timeThe difference between CLUM ultrafine vertical mill and HGM micro 2004年5月1日 A new form of biomineralization in the pineal gland of the human brain has been studied It consists of small crystals that are less than 20 μm in length and that are completely distinct from the (PDF) Calcite microcrystals in the pineal gland of the human brain 2023年8月16日 Whether your plants are getting enough calcium—and what you can do about it—is directly connected to the CEC level It is also linked to the pH of your soil; Very slowgrowing plants with extensive brown and yellow discoloration and curling leaves are the signs of acute calcium deficiencyHow to Add Calcium to Soil: 9 Methods The Spruce

Evolution of calcite microcrystal morphology during experimental

2021年3月26日 B) Calcite stabilized from aragonitic coral (Series 5) composed of polyhedral crystals C) Calcite stabilized from singlecrystal aragonite (Series 6) composed of euhedral rhombic crystals D) Natural calcite from a drill core of Lower Cretaceous limestone (Series 7 and 8) composed of polyhedral crystals with some curved edges and corners2020年6月30日 In the flotation processing, methods used to change the mineral surface roughness include change the grinding method, for example, wet grinding and dry grinding [25] and grinding mill, for example, ball, rod and autogenous grinding [7, 26]Mechanical grinding could lead to great changes in the mineral surface, such as the exposure degree of crystal face, Role of surface roughness in the wettability, surface energy and 2020年8月4日 Microbialinduced calcite precipitation (MICP) is a promising new technology in the area of Civil Engineering with potential to become a costeffective, environmentally friendly and sustainable (PDF) StateoftheArt Review of MicrobialInduced 2015年4月9日 Ball mill is a versatile grinding mill and has a wide range of applications The mill can vary in size from small batch mills up to mills with outputs of hundreds of tons per hour They are the most widely used of all Grinding Mills and Their Types – IspatGuru

.jpg)

Dolomite Micro Powder Grinding Mill

Dolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment It is mainly applied to ultrafine powder processing of nonflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤92013年10月30日 2 >> EMail:joyal@crusherinc >> Http://joyalcrusher Threering Micro Powder Mill Shanghai Joyal Mining Machinery Co, Ltd Grinding Application The JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, Micro powdermill PDF Free Download SlideShare2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber of the mill 2 Grinding: Inside the grinding chamber, the bauxite ore is subjected to a series of grinding processes The grinding rollers and rings in How does HGM micro powder grinding mill process bauxite?2023年6月25日 Ball mill The calcium carbonate ball mill works by rotating a cylinder with grinding media, causing the media to fall back into the cylinder and on to the material to be ground The ball mill can be operated either wet or dry The particle size of the finished product can be adjusted by controlling the grinding time, rotating speed, size and composition of Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses

.jpg)

There’s Only One Way To Beat The Speed Of Light Forbes

2021年5月12日 Light, you have to remember, is an electromagnetic wave Sure, it also behaves as a particle, but when we’re talking about its propagation speed, it’s far more useful to think of it not only 2023年9月28日 A geopolymer has been reckoned as a rising technology with huge potential for application across the globe Dolomite refers to a material that can be used raw in producing geopolymers(PDF) Dolomite Powder in Concrete: A Review of ResearchGate2024年2月2日 If your treatment is working, it should be easy to see healthy growth in your nails But if the fungus isn't dying off, there are steps you can takeHow to Know If Toenail Fungus Is Dying and What to Do Next2023年9月27日 Nanomicro calcium carbonate has a small particle size, uniform distribution, and good dispersion performance, offering great research value and development prospectsControllable Synthesis of NanoMicro Calcium Carbonate