Limestone prehomogenization process flow chart

.jpg)

Limestone Quarrying and Processing: A LifeCycle Inventory

Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by 2022年8月23日 The plant processes 65 MT/h of clay, 260 MT/h of limestone and 125 MT/h of gypsum to produce 220 MT/h (175 million MT/year) of cement Cement Manufacturing Cement Manufacturing – Process Modeling and TechnoEconomic Download scientific diagram PROCESS FLOW DIAGRAM FOR LIMESTONE QUARRYING OPERATIONS (NATURAL STONE COUNCIL, 2008) from publication: Metallic Commodities PROCESS FLOW DIAGRAM FOR LIMESTONE QUARRYING In this study, a flue gas emission from a cement manufacturing process 40% of the CO 2 comes from fossil fuel combustion in the kiln process, about 50% is due to decarbonation ofTypical cement manufacturing process flow diagram [4]

.jpg)

Manufacturing process flow 1 Quarrying and Crushing Messebo

The prededusted gas is vented out and sent to some recirculated as separation air and some to the Electrostatic precipitator for further clean up and sent to the environment then after The Let us say there are five different raw materials, A, B, C, D and E According to the blending strategy, let us assume A, B and C are proportioned and blended in the PreBlending HOMOGENIZATION STRATEGY IN THE CEMENT INDUSTRY PEC through the wet process The most common way to manufacture Portland cement is through a dry process The first step is to quarry the principal raw materials, mainly limestone, clay, and Chapter 4 Cement Manufacturing and Process ControlPrehomogenization is the proportional mix of the different types of clay, limestones, or any other required material 5 Raw material storage Each of the raw materials is transported separately Cement Production: How Cement Is Manufactured CEMEX UK

Creating a Process Flow Chart: A StepbyStep Guide

If you're looking for a way to visualize your business processes and increase efficiency, process flow charts are a great tool to use These process diagrams show the steps of a process and help you identify areas where improvements from the coolers is returned to the kilns, a process that saves fuel and increases burning efficiency After the clinker is cooled, it is ground and mixed with small amounts of gypsum and limestone The cement is now ready for use in construction projects The flow sheet of cement manufacturing is given in Fig 41 Kiln feed is subjected to Chapter 4 Cement Manufacturing and Process ControlDecision flow chart: These flow charts play a vital role in the decisionmaking process, answering simple questions to arrive at a final decision Swimlane flow chart: Swimlane flow charts allow you to visualize who’s responsible for each part of a process or project, whether that’s an individual or a Process flow charts: Types, uses and benefits The WorkstreamDownload scientific diagram Flow diagram and system boundaries of limestone quarrying operations of the Plant A from publication: Assessment of Environmental Impacts of Limestone Quarrying Flow diagram and system boundaries of limestone

.jpg)

Cement Manufacturing Process: Know Extraction, Processing

2024年9月10日 Cement is an essential building material used in construction The Cement manufacturing process involves the extraction and preparation of raw materials, such as Limestone, clay, shale, iron ore, and Gypsum These materials are crushed, ground, and blended to form a raw meal, which is then heated in a kiln at high temperaturesprocess The proper choice oef quipment and perating o strategy play an equally important role in promoting homogenization Limestone is the most important raw material in the manufacture of cement as it provides the main ingredient CaO It is blended with other raw materials such as clay, marl, shale to prepareHOMOGENIZATION STRATEGY IN THE CEMENT INDUSTRYPrehomogenization In past cases, where the main component of the cement raw material (usually limestone), showed con siderable fluctuations in the CaC03content, and as long as relatively low quantities of raw materials were processed in cement plants, selective quarrying was applied, to reduce to some extent fluctuations in the limestone’s chemistryPrehomogenization INFINITY FOR CEMENT EQUIPMENTRaw material prehomogenization is the process of blending raw materials like limestone, clay, and iron ore in such a way that the chemical composition remains consistent throughout the batch This step is crucial in cement production as raw materials sourced from different quarries or suppliers often have varying chemical compositionsRaw Material PreHomogenization: Ensuring Consistent Cement

.jpg)

Cement Manufacturing Process: Step 1: Extraction of Raw Scribd

Cement Flow Chart Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free The cement manufacturing process involves 3 main steps: 1) Extraction of raw materials like limestone, chalk, and clay from quarries These materials are crushed and stored 2) The raw materials are ground into a fine powder and heated to 1,500°C in a kiln to Download scientific diagram Process flow sheet of the fluid milk model Full homogenization is used CIP = cleaninginplace from publication: Computer simulation of energy use, greenhouse gas Process flow sheet of the fluid milk model Full 2016年12月13日 4 DETERMINATION OF PREHOMOGENIZATION FACTOR 03092012 Capacity t/h Stacker speed (%) 50 55 60 210 333 366 398 215 325 357 328 217 322 354 385 220 318 350 380 CALCULATIONS Determination Prehomogenization factor PDF SlideShare2024年3月20日 The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a Understanding the Steel Making Process: A Flow

Free Process Flow Diagram Maker and Examples Canva

Create a process flow diagram online Break down complex processes into smaller steps with efficient process flows Create a process flow diagram on Canva Whiteboards and use it to visualize the big picture and your role within it With a host of creative elements and design tools, you have everything you need to take control of your workflowGrossmann’s graph theoretic algorithm [6] or Picard’s network flow method [7] The long range planning also evaluates the sequence of the extraction from the limestone quarry ie production scheduling The limestone quarry production scheduling problem Limestone Quarry Production Planning for Consistent Supply of 2023年1月5日 The operation process chart flow process chart is basically a tool for method studyTo implement the lean manufacturing concept its tools like kaizen, 6 ‘S’, SMED, OEE, VSM, and pokayoke the basic requirement is to know understand the basic process OPC FPC can help to understand the process identify the scope for improvement in each processOperation Process Chart (OPC) And Flow Process Chart (FPC)2022年8月23日 This is the ReadMe file of a SuperPro Designer example that simulates a cement manufacturing plant where cement clinker is produced by mixing clay and limestoneCement Manufacturing – Process Modeling and TechnoEconomic

.jpg)

PASTEURIZED MILK PRODUCTS Dairy Processing Handbook

Homogenization has already been discussed in Chapter 63 The purpose of homogenization is to reduce the size of the fat globules in the milk, in order to reduce or prevent creaming Homogenization may be total or partial Partial homogenization is a more economical solution, because a smaller homogenizer can be usedA Cement manufacturing Process Source:civilengineeringforumme The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1 Quarrying and Crushing 2CEMENT PRODUCTION AND QUALITY CONTROL A Cement manufacturing Process2024年3月17日 The steel making process flow chart serves as a visual representation that delineates each key stage in the transformation of raw materials into finished steel products It provides a precise roadmap that stakeholders, from industry professionals to academic researchers, can follow to understand the complexities of steel productionA Visual Guide: Steel Making Process Chart Cabaro Group2021年3月9日 In this study the process flow diagram for the cement production was simulated using Aspen HYSYS 88 software to achieve high energy optimization and optimum cement flow rate by varying the flow rate of calcium Simulation and Optimization of an Integrated Process

.jpg)

Flow diagram of the limestone scrubbing method

Download scientific diagram Flow diagram of the limestone scrubbing method from publication: Review of Design, Operating, and Financial Considerations in Flue Gas Desulfurization Systems In It notes inputs, outputs, and the tasks between them Beyond documenting operations, logical model charts go a step further to detail the longterm outcomes of the process, highlighting what it tries to accomplish and how well it meets 17 Types of Flowcharts and When To Use Them FigmaThe invention provides a stackerreclaimer for prehomogenizing limestone, which comprises a base, a stand column and a conveyor belt, wherein the base is provided with a vertical column; the top of the base is axially connected with a group of upright posts; the tops of the movable cross beam, the two groups of first connecting rods and the fixed cross beam are fixedly Stackerreclaimer for prehomogenizing limestone Google Patents2024年2月27日 Read this article to learn more about the 15 most popular types of flowcharts and discover how each one can enhance your understanding of processes, optimize workflow, and improve decisionmaking How to Make a Flowchart in 7 Simple Steps The best flowcharts are simple and clear, and effectively communicate each step of the processHow to Make a Flowchart: Beginner’s Guide ( Free Templates)

.jpg)

How is limestone processed flowchart? LinkedIn

2023年1月4日 The process of producing limestone typically starts with mining the raw material Once the raw material is acquired, it is then crushed and screened After that, Pro tip: Your flowchart should use these basic symbols as a baselineYou can add more advanced icons after outlining basic outcomes and choices Try the flowchart template to get started now Advanced symbols for flowchart pros While basic symbols highlight the main elements in your system, advanced symbols let flowcharts function in more intricate ways26 Flowchart Symbols and Meanings [+ Template] FigJamFlow Charts Related Articles How to Spot Fake News Information Gathering Business Reports Good Charts and Good Charts Workbook How to Use Gantt Charts Article • 9 min read Flow Charts Identify and Communicate Your Optimal Process Flow Charts Identify and Communicate Your Optimal ProcessCreating a process flow diagram is a structured approach to visualizing and understanding the steps and flow of a process Whether you're mapping a complex manufacturing operation or a simple business procedure, a clear and accurate PFD is invaluable Let's dive into the steps necessary to create an effective process flow diagram 1What is a Process Flow Diagram? A Complete Guide Miro

.jpg)

Flowchart Maker Online Diagram Software

Flowchart Maker and Online Diagram Software drawio is free online diagram software You can use it as a flowchart maker, network diagram software, to create UML online, as an ER diagram tool, to design database schema, to build BPMN online, as a circuit diagram maker, and more drawio can import vsdx, Gliffy™ and Lucidchart™ files Download scientific diagram Flow chart of the grinding and blending process from publication: Effective Optimization of the Control System for the Cement Raw Meal Mixing Process: I PID Tuning Flow chart of the grinding and blending process♦ Preblending of crushed limestone ♦ Drying – cumgrinding of raw materials ♦ Homogenization of raw meal in a blending silo ♦ Clinkerisation of the raw meal in a rotary kiln with multistage preheater and precalcinator ♦ Grinding, storage and packing ♦ M/s Ultratech Cement Limited (UTCL) 11 DETAILS OF THE PROJECTThe cyclone preheating system Phase IV: Calcination The calcination is the core phase of the cement making dry process The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant The rotary kiln is a How Is Cement Produced in Cement Plants Cement

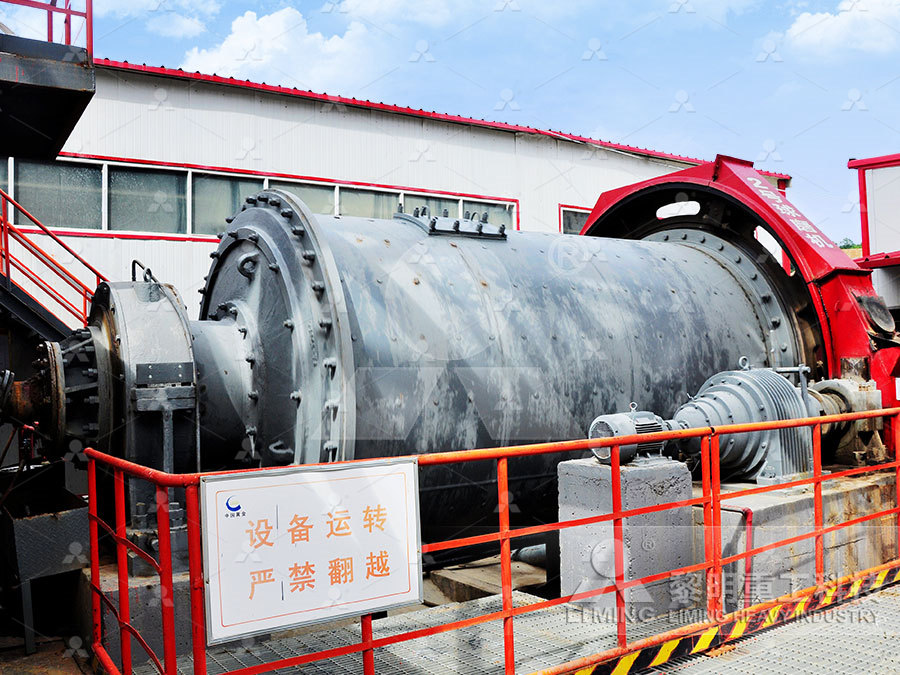

CEMENT MANUFACTURING PROCESS VisionTIR

CEMENT MANUFACTURING PROCESS Crushing Once the material has been extracted and classified, it is crushed to obtain a granulometry suitable for the grinding product and transferred to the factory by means of conveyor belts or trucks for storage in the prehomogenization park Prehomogeneization The crushed material is stored inProcess Improvement: they serve as valuable documentation for training purposes and can be used to identify areas for process improvement Communication Flow Chart Symbols and Conclusion Communication flow charts utilize symbols to represent various elements: Rectangles: Boardmix provides a variety of predesigned templates to choose munication Flow Charts: A Comprehensive Guide BoardmixWet Process Of Cement Manufacturing With Flow Chart The raw materials are calcareous materials, like limestone or chalk, and argillaceous material such as shale or clay Skip to content Civiconcepts Home; House Plans Menu Toggle The following is a cement manufacturing process flow chart,Wet Process Of Cement Manufacturing With Flow ChartDownload scientific diagram Process flow chart of compound agglomeration from publication: Effect of Ti–V Magnetite Concentrate Pellet on the Strength of Green Pellets and the Quality of Process flow chart of compound agglomeration

Effect of Prehomogenization Treatment on Microstructure,

2023年11月29日 This paper studied the microstructure, mechanical properties, and corrosion resistance of AZ61 magnesium (Mg) alloy with and without homogenization treatment before extrusion After homogenization treatment, the size of the second phase decreases, resulting in a more uniform microstructure of the extruded sample Compared to the asextruded sample, Download scientific diagram Process flow sheet for the fluid milk process Partial homogenization is assumed CIP = cleaninginplace from publication: Computer simulation of energy use Process flow sheet for the fluid milk process Partial homogenization Download scientific diagram a Flow chart for the synthesis of PCC by carbonation process, b synthesis of PCC by solution process from publication: Synthesis of precipitated calcium carbonate: a a Flow chart for the synthesis of PCC by carbonation process, b