Process card flow of limestone powder production line

Limestone Quarrying and Processing: A LifeCycle Inventory

Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by processes in the production of lime are: (1) quarrying raw limestone; (2) preparing limestone for the kilns by crushing and sizing; (3) calcining limestone; (4) processing the lime further by 1117 Lime Manufacturing US EPAProcess flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by A LifeCycle Inventory of Limestone Dimension Stone Quarrying 2023年2月15日 The whole lime production line includes: mining, crushing, screening and calcinating First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are Lime Production Process and Required Equipment

.jpg)

PROCESS FLOW DIAGRAM FOR LIMESTONE

Download scientific diagram PROCESS FLOW DIAGRAM FOR LIMESTONE QUARRYING OPERATIONS (NATURAL STONE COUNCIL, 2008) from publication: Metallic Commodities – Carbonate Ores Carbonates process in the shaft kiln The final goal of this collaborative research activity is to design a shaft kiln that takes into account the impacts of raw materials and fuels Cimprogetti’s analytical LIME MANUFACTURING Analyse to excel CimprogettiSection 2 provides a detailed description of the production process for lime, with discussions of individual lime products, limestone inputs, and costs of production Section 3 describes the Lime Production: Industry ProfileThe process flow of the limestone grinding production line mainly includes the following steps: Crushing: The initial step is to run large chunks of limestone through a crusher, reducing them Limestone Grinding Mill Plant TAYMACHINERY

.jpg)

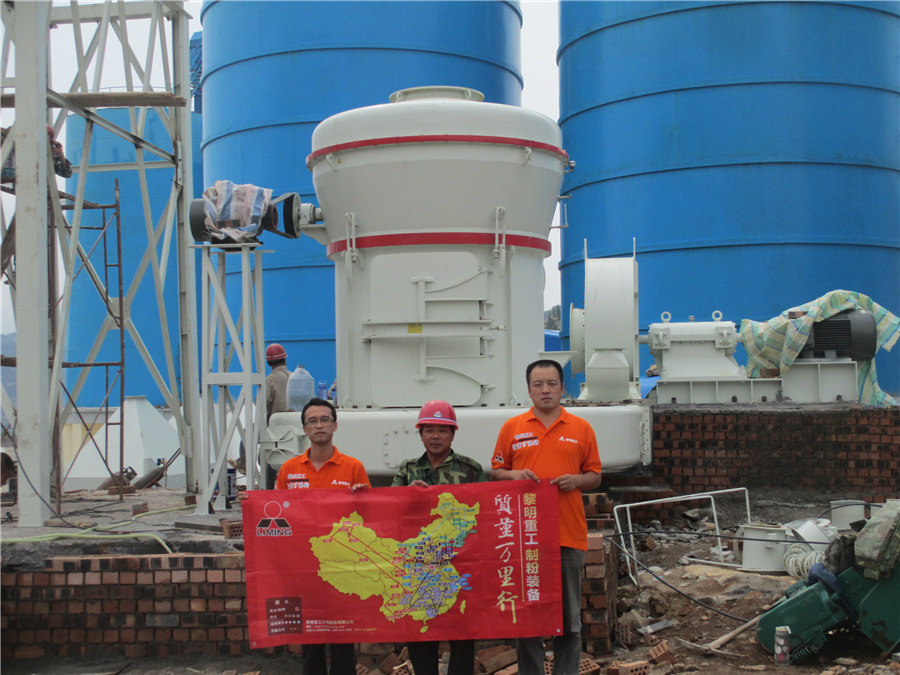

Limestone Mill High Efficiency, Large Capacity, 200

Calcium carbonate can be directly processed into aggregated rock and burnt into unslaked lime There are two types of lime: unslaked lime and slaked lime Unslaked lime is lumpy, its main content is CaO, pure unslaked lime is white, Client Limestone processing plant Gericke Continuous pneumatic dense phase PTA system with Technology twin pressure vessel (transmitter) arrangement, each one holding 650 litres with Pneumatic Dense Phase conveying system for a Limestone PLant2024年4月17日 Limestone powder granulator is a specialized machine used to compress limestone powder into small, uniform pellets These pellets are often used in various industries, such as construction, agriculture, and water treatment The process of making limestone pellets is relatively simple and can be done with the help of a limestone powder granulatorlimestone pellets granulating production line CMPP2024年2月23日 The limestone powder making process and its versatile applications highlight the importance of this finely ground material across multiple industries From construction to agriculture, environmental remediation, and Introduction of limestone powder making process

.jpg)

Limestone Powder Grinding Process ALPA Powder Equipment

2024年8月26日 In addition, the limestone powder produced by the closedcircuit process has uniform particle size and is easy to adjust, which can meet different fineness requirements 2 Example of closedcircuit production of limestone powder Raymond mill Process description:2017年11月28日 Limestone grinding mill is another key equipment for further processing the limestone The limestone grinding mill belongs to the vertical grinding mill with small footprint Limestone mill can form the independent grinding production system, thus it can efficiently and safely do the lime production process for a long timeConfiguration and Process Flow of Limestone Milling PlantGypsum Powder Production Line of this kind adopts the domestic advanced equipments such as Vertical Roller Mills and fluidized bed combustion boiler Currently the world's most technologically sophisticated desulfurization process is limestone Gypsum Powder Production Line Flow Chart Relevant facilities PEW Jaw Crusher Nimble, easy Gypsum Powder Making Production Line ManufacturerLimestone Limestone is a carbonate sedimentary rock that is often composed of the skeletal fragments of marine organisms such as coral, foraminifera, and molluscs Its major materials are the minerals calcite and aragonite, which are different crystal forms of calcium carbonate (CaCO3) A closely related rock is dolomite, which contains a high percentage of the mineral Limestone Powder Production Line Buy Limestone, mining

.jpg)

Evaluation of the Efficiency of Limestone Powder in Concrete and

2018年2月21日 The major environmental impact of concrete comes from the CO2 emissions, produced during the cement manufacturing process The main goal of this research project is to evaluate the efficiency of If you want to process it into sand and stone with concrete, that is, machinemade sand with particle size ≤ 475 mm and particle size of 1020 mm, 15 mm 30mm 12/13 stone needs to use limestone production equipment for crushing, sand making, screening and other technological processes 2 Process flow of limestone production line 01What is the technological process of limestone production line?The processing capacity of the production line is 1000t/h, 10% of the soil is removed, and the finished aggregate product is 20315mm, 18%; 1020 mm, 25%; 510 mm, 17%; 05 mm, 25% Considering the requirements of rock characteristics and product proportion, choose a twostage crushing scheme, which is jaw crusher + impact crusher combination formConfiguration and design of 1000tph limestone aggregate production 2021年10月22日 The processing capacity of the production line is 1000t/h, 10% of the soil is removed, and the finished aggregate product is 20315mm, 18%; 1020 mm, 25%; 510 mm, 17%; 05 mm, 25% Considering the requirements of rock characteristics and product proportion, choose a twostage crushing scheme, which is jaw crusher + impact crusher combination formConfiguration and design of 1000tph limestone aggregate production

The Research Process on Converter Steelmaking Process by Using Limestone

1 Content from this work may be used under the terms of the CreativeCommonsAttribution 30 licence Any further distribution of this work must maintain attribution to the author(s) and the title 2023年6月1日 As we see, powder flow is an important parameter to be evaluated before the start of any process to avoid any hindrance and losses along the production line Determining powder flow is equally important to ensure product performance and to design a hopper through which powder can flowA concise summary of powder processing methodologies for flow Configuration and process flow of limestone sand production line A limestone sand production line typically involves the crushing of limestone raw material and then processing it into various sizes of finished sand The configuration and process flow can vary depending on the desired output and the specific requirements of the application Configuration and process flow of limestone sand production lineThe fine particles of limestone powder improve the flow and spreadability of the paint Sourcing and Processing The production of limestone powder starts with mining and quarrying limestone deposits This process is done with care to ensure the quality and consistency of the final product9 important Uses of limestone powder

.jpg)

A review on use of limestone powder in cementbased materials

2018年8月30日 Limestone powder is a byproduct of the limestone quarry, and it has been used in cementbased materials for many years In 1938, Bessey [6] first reported that CaCO 3 could react with cement to form calciumcarboaluminate The formation of calciumcarboaluminate was influenced by the amount and fineness of LS, but it had little effect on the compressive The cost of a 30TH limestone powder processing grinding mill production line largely depends on the quality and brand of the equipment Highquality, wellknown brands generally come with a higher price tag but offer better performance, reliability, and aftersales serviceThe cost of a 30TH limestone powder processing grinding mill production 2022年3月14日 To further explore the effects of limestone powder (LP) on the hydration of Portland cement as well as the formation and transformation mechanism of calcium carboaluminate phases, the hydration reaction between LP and tricalcium aluminate (C3A) is thoroughly studied in this paper Due to the crucial influence of gypsum on the hydration of Effects of limestone powder on the early hydration of tricalcium 2017年1月27日 In this study, the effects of the amount of resin used for the production of polymer concrete and the workability of the concrete produced by replacing quartz aggregate powder used as filler with (PDF) Chemical and Physical Properties of Limestone Powder as

Production Manufacturing Process Flow Charts Workflow

The production process, or manufacturing process, consists of a few key components or subprocesses from production planning through quality assurance and inspection of final products Manufacturing process flow charts, or workflows, can be applied to the manufacturing process to reduce lead times, increase machine utilization and optimize first pass yieldsHow does the mining production line process improve the value of the ore itself? Reasonable selection and configuration of mining crushing production line is the top priority CM Mining Machinery crushing and grinding production solutions provide you with highyield and efficient complete solutions Process features: it has high production efficiency,Mining production line process flow CM Mining MachineryCement production process: Thermal energy demand and CO 2 emissions 30% fuel emissions thermal energy prod process emissions from calcination of limestone 60% 10% electric power consumption, indirect emissions Limestone Quarry Filter Clinker Cement Cement Mills Raw Mill Calcination Cement Constituents Crusher FanDrying Rotary Kiln PreheaterProcess characteristics of clinker and cement production SINTEF2017年12月9日 As shown in Fig 42 most of the Portland limestone and composite cements conform to the 325 and 425 strength classes, although “very high strength” 525 Portland limestone cements are also produced Most countries around the world specify similar chemical and physical requirements for the limestone that can be used, including a minimum CaCO 3 Limestone Powder SpringerLink

Recent Developments on the Effects of Micro and

2024年5月1日 Limestone is commonly used in cement concrete due to its unique nature and type It has physical effects (nucleation effect and dilution effect) and chemical effects on the hydration process of cement This paper 2024年4月17日 Limestone powder granulator is a specialized machine used to compress limestone powder into small, uniform pellets These pellets are often used in various industries, such as construction, agriculture, and water treatment The process of making limestone pellets is relatively simple and can be done with the help of a limestone powder granulatorlimestone pellets granulating production line CMPPLimestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone The fine particles of limestone powder improve the flow and spreadability of the paint Sourcing and Processing The production of limestone powder starts with mining and quarrying limestone deposits This process is done with care to ensure the quality and consistency of the final product9 important Uses of limestone powder

.jpg)

Effect of particle size on powder compaction and tablet strength using

2020年1月9日 Limestone powder was also reported to be effective to inhibit AAR [12]; that is, the expansion ratios at 14 days and 28 days of mortar are both less than 010% when more than 45 wt% of limestone 2021年2月25日 Powder type of selfcompacting concrete (SCC) needs high cement content to achieve selfcompactibility, this will be undesirable in tropical climate of Sudan due to implication of high hydration heatEffects of Limestone Powder on Selfcompacting Concrete Properties2020年1月9日 Limestone can be directly processed into stones and fired into quicklime Limestone aggregate production lines are very common, with output ranging from hundreds to thousands This article uses a production line of 1000t / h as an example to describe its equipment selection and process flow Selection of main equipmentDetailed Equipment Selection and Process of 1000 Ton Limestone Lime is made from indigenous limestone or chalk rock, one of the most abundant materials in the Earth’s crust Limestone and chalk are both sedimentary rocks and are chemically known as calcium carbonate When crushed or ground, they are widely used as aggregates and building products As a raw material, calcium carbonate can also be processed []Production European Lime Association

.jpg)

Numerical modelling of multiphase FLOW and calcination process

2020年3月1日 In a calciner for cement production, limestone (CaCO 3) particles are decomposed into quicklime (CaO) and carbon dioxide (CO 2) during the calcination process The complex flow and temperature distribution caused by fuel combustion and calcination reaction of limestone are essential to calciner performance2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time(PDF) Environmental Hazards of Limestone Mining 2024年1月23日 Limestone powder in the production of concrete Limestone powder is widely used as a filler in the production of concrete in the construction industry Its fine texture allows it to fill in the gaps between aggregate particles, resulting in a denser and stronger concrete mixture9 important Uses of limestone powder ZME ( Zohdy Minerals depicts the fabrication process Figure 2 Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Figure 2 It should be Limestone Quarrying and Processing: A LifeCycle Inventory

.jpg)

Selection and process flow of limestone aggregate production line

Selection and process flow of limestone aggregate production line The selection and process flow of a limestone aggregate production line involve several steps to ensure that the resulting aggregates meet the required specifications for size, shape, and quality Here is a general outline of the process flow for a typical limestone aggregate Limestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone Therefore, the apparition of powder electrostatic charges inside it due to the triboelectric effect can increase powder cohesiveness In addition to the cohesiveness measurement performed by the GranuDrum, a GranuCharge powder electrostatic measurement allows to predict more precisely the behaviour of the powder inside the process lineElectrostatic and flowing properties of limestone and lime 2014年5月1日 At earlier period (28 days) limestone powder acts filling and accelerating effects by speeding up the hydration process of complex binder, but it will react with ordinary Portland cement to (PDF) Influence of limestone powder on hydration

Lime Production Line Active Lime Production Line Cement Plant

SOLUTION2: Lime Production Line With Vertical Kiln The vertical lime kiln is suitable for smallcapacity active lime production lines, lowcost, safe and environmentally friendly The vertical lime kiln uses the principle that the material’s own weight descends and the hot gas rises for heat exchange to burn lime We supply twin shaft lime kiln, double beam lime kiln, annular lime kiln Shear cell, crm 116 limestone powder, flow function, Characterizing powder flowability, reproducibility, Brookfield Powder Flow Tester, Jenike Shear Cell, Schulze Ring Shear Tester 10 Introduction The Brookfield Powder Flow Tester, launched in Jan 2010, was developed a Defra uarythroughBrookfield Powder Flow Tester Results of Round Robin Tests