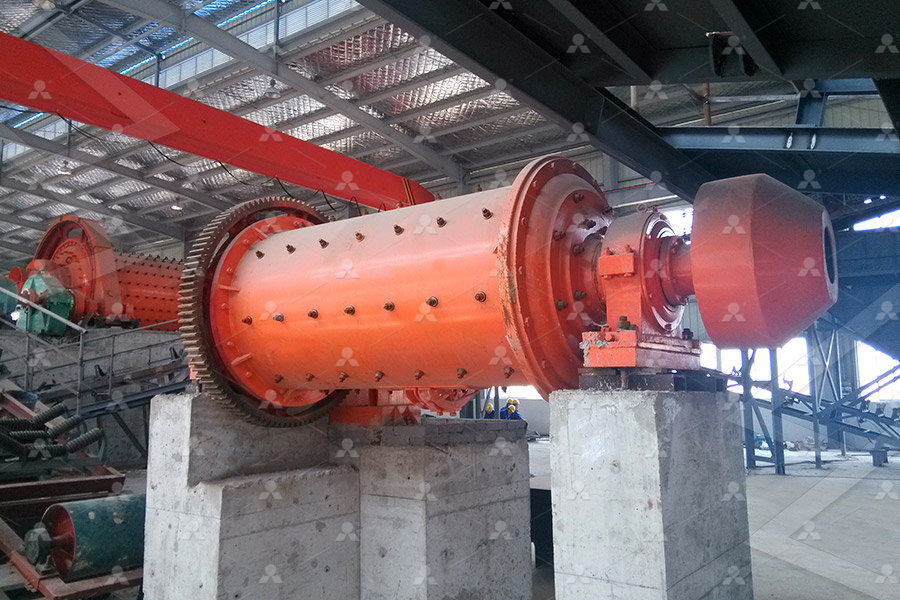

Guangxi Liugang steel slag processing

Asian Steel Group Co, Limited I ASIAN STEEL GROUP CO, LIMITED

According to reports, Zhongjin Metal Company, a subsidiary of the Liuzhou Iron Steel Group, announced to start the stainless steel slag treatment project in Yulin city, Guangxi Province Since late 2023, the company has been carrying out technological transformation of the steelmaking system, dismantling the existing 600t mixediron furnace and building a new set of Guangxi Liugang Zhongjin Stainless Steel Co Ltd2018年8月1日 In China, the most common treatment approaches are similar to the aging treatment method used in Japan and mainly include selfdisintegrated steel slag by steam, a Steel slag in China: Treatment, recycling, and management2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1] China's crude steel output in 2021 was Comprehensive utilization of steel slag: A review ScienceDirect

广西柳州钢铁集团有限公司

企业概况 广西柳州钢铁集团有限公司(简称“柳钢”),一艘紧跟钢铁工业发展潮流,向海行进的钢铁巨轮。This research is financially supported by the Guangxi key Laboratory of Road Structure and Materials Fund: Study on Mechanical Properties and Road performance of Steel Slag concrete Investigation on the Mechanical Properties and Microscopic Guangxi Iron and Steel Group Co Ltd (广西钢铁集团有限公司 (柳州钢铁股份防城港基地)), also known as Wuhan Iron and Steel Liugang (Group) Joint Co, Ltd, is a blast furnacebasic Guangxi Iron and Steel Group Co Ltd Global Energy MonitorSteel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can Steel slag in China: Treatment, recycling, and management

China’s Liugang building first stainless plant in Guangxi

2019年1月15日 Guangxi Liuzhou Iron Steel Group Co (Liugang), the largest integrated carbon steel mill in Southwest China, has officially expanded into the stainless sector with a ground 企业概况 广西柳州钢铁集团有限公司(简称“柳钢”),一艘紧跟钢铁工业发展潮流,向海行进的钢铁巨轮。广西柳州钢铁集团有限公司Ecofertec Slag Processing and Metal Recovery Plant ECOFERTEC is designing customized steel slag processing and metal recovery plants for each projectspecific purposes The newest technology ECOFERTEC slag processing plant Steel Slag Processing — EcofertecLocation: Qisha Industrial Park, Fangchenggang City, Guangxi Zhuang Autonomous Region Coordinates (): 21, 108 (exact); Background The production capacity of Liuzhou Iron and Steel Co, Ltd is gradually moving from Liuzhou to the Fangchenggang base in Guangxi Iron and Steel Group Co Ltd Global Energy Monitor

Guangxi LiuGong Group Co, Ltd

Guangxi LiuGong Group Co, Ltd was founded in 1958, is a largescale equipment manufacturing stateowned enterprise formed by stateowned assets authorized management, the core enterprise is Guangxi LiuGong Machinery CoLtd The core enterprise is Guangxi LiuGong Machinery Company Limited LiuGong Group adheres to the mission of "Sincerely providing 2024年3月12日 Leading Technology: We have advanced steel slag processing technology and equipment that can efficiently and environmentally recycle steel slag Rich Experience: With over 40 years of experience in steel slag processing and machinery manufacturing, we have provided professional solutions and services to numerous clients in the fieldSteel Slag Recycling: The Definitive Processing SolutionThe main challenge of the steel industry for the next decade is the steel production transformation process, starting in Europe The CO 2 intensive blast furnace/basic oxygen furnace (BOF) route will be substituted by a combination of Direct Reduced Iron (DRI), based on natural gas, later on “green” hydrogen, with an Electric Arc Furnace (EAF) or a Submerged Arc Furnace (SAF), The steel production transformation process in Europe: New slag 2021年11月23日 [Vale and Liugang signed Memorandum of understanding on developing steelmaking decarbonization solution] on January 13, 2022, Vale signed a memorandum of understanding with Guangxi Liuzhou Iron and Steel Group Co, Ltd ("Liuzhou Iron and Steel Group") According to this memorandum of understanding, the two sides agreed to seek Vale and Liuzhou Iron and Steel Group sign Memorandum of

Metal slag processing // REMONDIS´ Lippe Plant

LEGRAN’s metal slag processing not only benefits steelworks and other metal processors, it also protects the environment In other words: it is vital as it helps curb climate change Every gram of metal that is recovered and returned to production cycles reduces energy consumption and environmental pollution2020年9月28日 Due to the low hydration activity and poor volume stability, extensive steel slag utilization is restricted In this paper, the hydration process and microstructure of alkaliactivated materials with steel slag as a cementitious material and fine aggregate were studied The phase composition and micromorphology of hydration products were measured using XRD, NMR Hydration and Microstructure of Steel Slag as CementitiousSlag processing and valorization concepts, BOF slags, LD slag, stainless steel slag, Ferro alloy, FeCr, NF slags, copper slag, lead slag Navigation aufklappen/zuklappen Home; Services; Projects; Slag Processing Metal recovery; The motivation for slag processing in most cases is the recovery of metal, Slag Processing CALA Mineral Processing Consulting and Steel structure production projects: Guangxi Financial Plaza, Nanning Qingxiu Wanda Plaza, Wanda Mao Sales Center, Guangxi Nanning Santang MercedesBenz 4S Store Maintenance Center, Guangxi Baise Guangyin Aluminum Co, Ltd, AnheuserBusch InBev Beer (Nanning) Co, Ltd Beer production project of 300,000 tons, Beihai Chengde Nickel Industry Co, Ltd (Nickel Guangxi Fengyuan Steel Structure Co, LtdLight Steel

Basics of slag production Article on the slag industry from Global Slag

2011年10月27日 Slags from the Iron and Steel Industry Background With world steel production now well over a billion tonnes per year, the slag that arises from some of the processes involved is a major resource Traditionally it has been used mainly as an aggregate but for some types there are other applications, such as a raw material for cement or as a 2005年5月31日 Request PDF Steel Slag — Its Production, Processing, Characteristics, and Cementitious Properties Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen Steel Slag — Its Production, Processing, Characteristics, and LGMC (Guangxi Ligong Machinery Co, Ltd), is a company that specialized in not only construction machinery, but also more than 2,000,000 machine parts, which can be used in allterrain Learn More the whole siteAbout – Guangxi Ligong Machinery Co,Ltd2021年12月21日 Guangxi Liugang Zhongjin Stainless Steel Co, Ltd, Deputy Director of Production Safety Manufacturing DepartmentZeng Yao said in an interview: base and introduce more than 30 various stainless steel deep processing enterprises to do Larger and stronger stainless steel precision and deep processing industry chainLiugang Zhongjin stainless steel products will achieve full

.jpg)

Guangxi Liuzhou Iron and Steel Group gxzf

A Guangxi Liuzhou Iron and Steel Group workshop [Photo by Li Weiguo/] Over 60 years of development, Guangxi Liuzhou Iron and Steel Group has become the largest iron and steel complex in South and Southwest China It is also one of China's top 500 enterprises and one of the world's top 50 steel enterprises2014年2月19日 Slags are byproducts of the metallurgical industry It is of importance to recycle materials and recover heat from metallurgical slags to reduce the energy consumption and environmental impact of steel industry China is the largest iron and steelmaking slag producer in the world, and intensive efforts have been made during last decades for slag valorisation, Current Development of Slag Valorisation in China3 Steelmaking Slag Processing Technology The iron/steel slag processing flow is schematically shown in Fig 2 Steelmaking slag is subjected to the following four processes: ① solidify and cooling of the hot molten slag, ② crushing and magnetic separation treatment of the slag to recover the metal iron,Processing and Reusing Technologies for Steelmaking SlagSteel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace This paper reviews the production, processing, and characteristics of steel slag, and its use as a cementing component in different cementing systems The chemical composition and cooling of molten steel slag have a great Steel Slag—Its Production, Processing, Characteristics, and

Slag Recycling and Metal Recovery MEKA

As a result of growing environmental awareness, steel slag is now highly regarded as a recycled material that can reduce environmental impact due to its resourceconservation and energysaving properties MEKA is designing and manufacturing customized steel slag processing and metal recovery plants for each projectspecific purposesABOUT US ABOUT LIUGONG For the past six decades, LiuGong has learned, adapted and grown into an established name in machinery Started in 1958, LiuGong brought the first modernized wheel loader to China in 1966, eventually expanding to 19 different product lines today Attention to quality aAbout Us LGMEA2015年3月17日 Steel slag is a byproduct of the steel industry Understanding of the chemical, mineralogical, and morphological properties of steel slag are necessary for its use in sustainable practicesSteel Slag; Chemistry, Mineralogy and Morphology2024年11月6日 Liugang Zhongjin produces first stainless steel CRC, Kallanish reports Cookie userfriendly coverage of the steel and related markets and industry that delivers the essential information quickly while delivering on most occasions just the right amount of betweenthelines comment and interpretation for a near real time Liugang Zhongjin produces first stainless steel CRC

Liugang Will Hold Fangchenggang Iron and Steel Base

2020年8月17日 Guangxi iron and steel group is the investor of Fangchenggang iron and steel base, aiming to set up a ten million tons iron and steel project, it first set up by WISCO Group and Guangxi SASAC in 2005 The continuation of Fangchenggang base start formally after Liugang group taking over the Guangxi Liuzhou Iron and Steel Group Co, Ltd2019年6月18日 The Cr present in stainless steel slag, charg e chrome slag and vanadium slag usu ally exists as Cr 2 O 3 However , there is a possibility that it is oxidized to hazardous(PDF) Metallurgical Processing Strategies for Metals Recovery Guangxi Wuzhou Jinhai Stainless Steel Co, Ltd Stainless steel Oxygen production steelmakingThe group has been committed to the development of the stainless steel business for 20 years It is a stainless steel group enterprise with the entire industrial chain of inspection, oxygen production, steelmaking, hot rolling, pickling, cold rolling and pipe makingGuangxi Wuzhou Jinhai Stainless Steel Co, Ltd Stainless steel 2020年12月8日 LiuGong Group and seven strategic investors signed capital increase, share expansion, and equity transfer agreements totaling 3192 billion CNY of Guangxi Liugong Machinery Group Co Ltd (“LiuGong Machinery”) An employee stock ownership plan was also implemented, which raised another 223 million CNY in capital from 1,274 key employeesLiuGong Group Signs Strategic Investor Agreements for Mixed

广西柳工农业机械股份有限公司官网

广西柳工农业机械股份有限公司成立于2016年2月,经营范围包括:农业机械及农机配件、机械产品及配件、喷灌设备研发、制造、销售、安装及售后服务;农业机械设备、机械设备租赁;农业机械、机械产品的技术研发、咨询、转让、服务及试验;技术管理咨询;场地租赁;工业自动化控制 Tailored services designed to embrace the entire slag management process, including safe and efficient slag pot carrying, cooling and maintenance Enabling further slag processing by excavating, removing and transporting slag from lagoons Pot Carrying TippingSlag Management Services Harsco Environmental(processing of steel slag into cement), and Guangxi Chengde International Trade Co (raw material purchasing and product distribution) The Chengde Group is itself a joint venture of the Guangxi Beibu Gulf International Port Group and Foshan Chengde Stainless Steel Co Beihai is one of four ports with a planned handlingChina chemical safety case study: Metals pollution from a steel Carbon dioxide sequestration using steel slag—modeling and experimental investigation Smitha Gopinath, Anurag Mehra, in Carbon Dioxide Sequestration in Cementitious Construction Materials, 2018 41 Introduction Steel slag is an industrial waste that is generated during the production of steel In the production of steel, oxides of metal impurities in the iron combine Steel Slag an overview ScienceDirect Topics

.jpg)

Chemical, Mineralogical, and Morphological Properties

2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes in Highland, Indiana, was the source plant for the BOF slag Multiserv Ltd, Harsco Corporation, which performs slag processing operations 2023年11月17日 The growth of electric arc furnace (EAF) steelmaking in North America has occurred mainly in the past 40 years due to low electricity prices, an abundance of steel scrap (especially near large population centers), and the Electric Arc Furnace Steelmaking and Slag Formation, 2018年8月1日 In addition, simple processing facilities will lead to steel slag after treatment cannot be used effetely, their disposal will pollute the farmland Therefore, steel slag is a serious problem in China, both in terms of quantity and discharge, as Steel slag in China: Treatment, recycling, and management2023年12月27日 It is suitable for processing large steel slag materials (feed particle size ≤ 1200mm) It uses the principle of squeeze crushing, combined with a deep Vshaped and dead zonefree crushing chamber There is no need to worry about material blockageSteel Slag Processing Plant Equipment Selection

.jpg)

스테인레스 스틸 산업의 최근 중요한 동향 뜨거운

2023年5月29日 Guangxi Liugang Zhongjin Stainless Steel Co, Ltd는 Zhongjin Company의 오래된 지역의 안전, 에너지 절약, 탄소 감소 및 환경 보호 기술 변환 프로젝트를 위한 제강 시스템 프로젝트를 건설할 계획입니다 이 프로젝트는 광시 Yulin의 Bobai Longtan 산업 단지에 있습니다2019年5月23日 Jin Q, Xu JY, Gao WB (2005) New technology of steel slag processing and its application as the second resource at baosteel Baosteel Technology 3:12–15 Google Scholar Zeng J, Li LS, Su SH et al (2006) The study about magnetic separation of LD slag China Resources Comprehensive Utilization 9:33–35 Google Scholar Comprehensive Utilization Technology of Steel SlagLiugang steel slag leaching toxicity test is qualified On the basis of the above research, Liugang steel slag is a kind of fertilizer raw material which is mainly Si, Ca and contains trace Mn, P, Fe, and other elements The content of metal elements in steel slag is highResearch Progress on Application of Steel Slag in AgricultureSteel Slag Processing line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipmentSteel Slag Processing Gongyi Jingying Machinery

Core CultureGuangxi Wuzhou Jinhai Stainless Steel Co, Ltd

Core CultureGuangxi Wuzhou Jinhai Stainless Steel Co, Ltd Stainless steel Oxygen production steelmakingThe group has been committed to the development of the stainless steel business for 20 years It is a stainless steel group enterprise with the entire industrial chain of inspection, oxygen production, steelmaking, hot rolling, pickling, cold rolling and pipe making