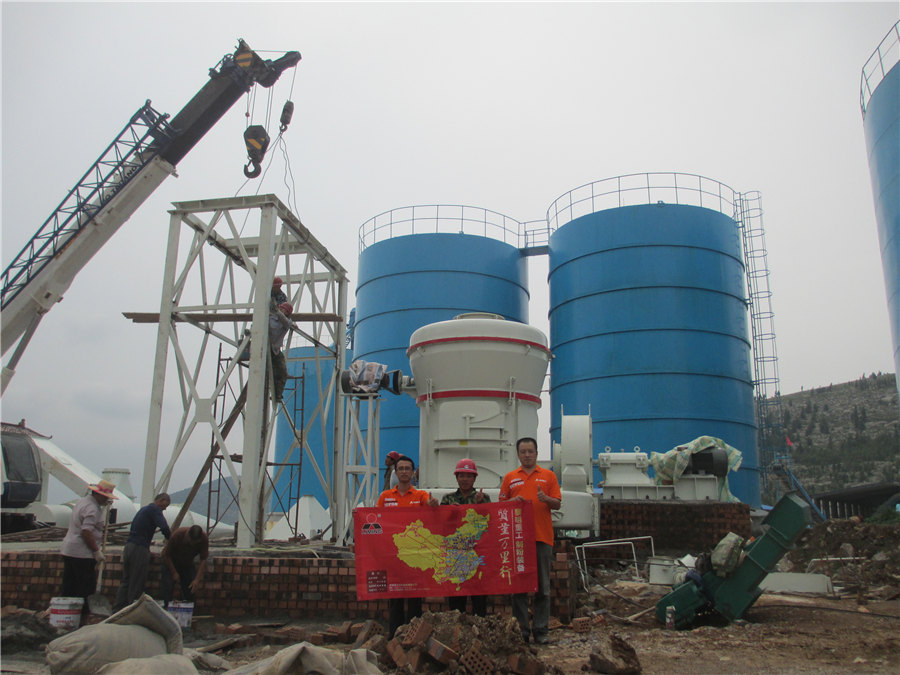

State investment limestone crusher smelting waste slag field

Recent research progress on recycling metallurgical waste slag and

2024年11月1日 In recent years, a novel method for treating impurity elements in waste slag, known as electric field strengthening treatment, has emerged as an effective means to 2023年11月20日 Mineral process wastes, such as metallurgical slags nowadays, are of significant metals and materials resources in the circular economy The usability of ironmaking slag is well established; however, steel A Review on Environmental Concerns and 2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating Sustainable Approaches for LD Slag Waste 2023年3月6日 It comprehensively reviewed the current state of the art for using smelting slags as sustainable adsorbents for water and wastewater The study revealed that ferrous slags are more effectiveRecycled Smelter Slags for In Situ and Ex Situ Water

Life cycle assessment of melting reduction treatment for iron and

2022年11月1日 By melting reduction modification technology, it effectively extracts the iron element existing in the waste slag to form high valueadded iron and steel products2020年10月15日 Enhancing the development and deployment of treating waste from the steelmaking process will be environment friendly and resourcesaving Capturing CO 2 by steel slag (SS) via mineralization is regarded to be an Cotreatment of Waste From Steelmaking Processes: 2023年5月15日 This paper summarized the comprehensive utilization status of steel slag in building materials, agriculture, wastewater treatment, marine engineering, ceramics, and CO 2 Comprehensive utilization of steel slag: A review ScienceDirect2024年6月12日 Blast furnace slag (BFS) and steel slag (SS), as industrial solid wastes produced in the process of steelmaking, account for 80%–90% of the total smelting slag BFS accounts Recycling of iron and steel slag for carbon reduction and low

.jpg)

Effects of Zinc Smelting Waste Slag Treated with Root Organic Acids

2021年2月8日 Vegetation reconstruction was widely adopted for the waste slag site But the toxic elements may be made public from slag due to the organic acid secreted by plant roots, which will pollute the surrounding environment and harm human health The purpose of the study was to evaluate the harm of toxic substances released from zinc (Zn) smelting waste slag to 2020年10月16日 In view of the nonrenewable reductant resources and carbon neutralization in the process of copper slag cleaning in an electric furnace, this study proposed to use waste cooking oil as reductant to replace fossil energy Combined with the phase equilibrium theory and experimental results, the harm of excessive magnetite in the copper smelting slag to the Copper Smelting Slag Cleaning in an Electric Furnace by Using Waste 2012年1月1日 Iligan City ferronickel smelting plant is producing more than 500,000 metric tons (MT) of ferronickel slag annually which are deposited in the plant's premises since it has no economic valueCharacterization and Leaching Assessment of 2021年7月1日 The establishment of vegetation cover is an important strategy to reduce wind and water erosion at metal smelting waste slag sites However, the mobility of heavy metals in waste slagvegetation Effect of different direct revegetation strategies on the mobility of

.jpg)

(PDF) Regional variation in bloomery smelting slag of

2006年4月27日 This study highlights regional variation in the composition of ironsmelting slag produced in England prior to the medieval period and attempts to link slag composition to the type of ore smelted2023年3月16日 The term “slag” is used for different materials which result from solidification of a meltSometimes it refers to pyroclastic rocks [], sometimes to ashes, eg from waste incineration, which have undergone sintering due to partial melting [], but mostly for pyrometallurgical residues which result from the reaction of slagforming agents with gangue or impurities in the metal in Mineralogy of Metallurgical Slags SpringerLink2023年5月14日 Reusing slag and heat waste from hot slag contributes to green economy Using appropriate mixing composition, BFS and limestone mixture can be used for green cement production This works explores the potential to convert slag waste into cement clinker using heat recovered from blast furnace of iron productionBlast Furnace Slag Cement Clinker Production Using Limestone 2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimization

(PDF) Nickel Laterite Smelting Processes and Some

2019年9月3日 slag from an operational point of view, and indicated that high slag temperatures have not been a major problem because of the installation of sidewall cooling systems in ferronickel smelters [ 年11月1日 China has the largest output of steel and iron in the world (Zhang et al, 2022)In 2021, China's average annual pig iron output arrived at about 869 million ton (Stewart et al, 2021) and crude steel arrived at about 103 billion tons (Zhao et al, 2022)Meanwhile, the output of steel solid waste keeps at a high level and generally the production of one ton steel will generate Life cycle assessment of melting reduction treatment for iron and 2018年12月14日 The studies of fractional, chemical and phase compositions of aluminumcontaining slags of different origin found that slags are multicomponent systems consisting of metal and nonmetal partsTHE USE OF ALUMINUM SLAG RECYCLING 2024年11月1日 The utilization rate of SS exceeds that of LFS due to its lower basicity, although it remains considerably lower than the rates observed in developed countries in Europe and the United States, standing at approximately 30 % [4]Currently, the internal recycling of SS predominantly takes place within the smelting production process, serving purposes such as Recent research progress on recycling metallurgical waste slag

.jpg)

Removal of arsenic in acidic wastewater using Lead–Zinc smelting slag

2022年8月1日 The evolution of the chemical valence state for As, Fe, and O in the fresh LZS slag and Asbearing precipitates is shown in Fig 2di–fiii No As 3d peak was observed in the fresh LZS slag, while a strong peak of As 3d was found in the precipitates (in Fig 2di–diii), illustrating that As was effectively removed and fixated in the precipitates in the form of scorodite and its 2020年6月3日 Introduction Smelting slag is a typical hazardous waste generated in the smelting and metallurgy industry 1, 2Slag contains high concentrations of heavy metals, such as Cu, Zn, Cr and Ni, which are harmful if released into the environment 3In China, smelting slag is disposed of as an environmental priority pollutant, wherein the slag is generally stabilized with cement Highpurity recycling of hematite and Zn/Cu mixture from waste smelting 2007年1月1日 a Distribution of premodern smithing and smelting slag compositions in the system FeOSiO 2 Al 2 O 3 Data reduced by combining suitable oxides (eg FeO and MnO) and omitting minor compoundsDecisions set in slag: the human factor in African iron smelting2024年5月25日 India ranks among the foremost global producers and consumers of cement, and the cement industry contributes significantly to carbon emissions Alkaliactivated materials have gained significant attention as a sustainable alternative to Portland cement, offering the potential to mitigate carbon dioxide emissions and promote effective recycling of waste Durability of alkaliactivated fly ashslag concrete state of art

The Phase Transition and Element Distribution of Copper Smelting Slag

2023年2月22日 Sulfidation treatment of copper smelting slag In the sulfidation experiment, the particle size of the synthesized slag was controlled below 80 mesh (178 µm)The mixture of CaSO 4 and anthracite was pelletized at a pressure of 10 MPa in a Ø 4 mm pressing tool, and the weight of every pellet was roughly controlled to be 004 g Then the smelting slag and CaSO 4 2020年8月24日 The copper smelting slag recycling waste was obtained by crushing the cast slag of the Sredneuralskiy Smelter (“technical sand”) followed by flotation extraction of copper concentrate The investigations were carried out in two forest types, distinguished according to the principles of the genetic forest typology, cowberry shrub pine forest and berry pine forest with Element mobility from the copper smelting slag recycling waste 2022年5月11日 Concrete is a composite material widely used in construction Waste slag smelting (pyrometallurgical) (steel slag (SS)) is a molten liquid melt of silicates and oxides created as a byproduct of steel production It is a complex solution of silicates and oxides Steel slag recovery conserves natural resources and frees up landfill space Steel slag has been used in Electrical conductivity, microstructures, chemical compositions, 2023年5月26日 Gypsum sludge refers to a hazardous solid waste produced by the nonferrous smelting industry, and its disposal and utilization are environmentally challengingUtilization and detoxification of gypsum sludge by replacing limestone

Innovation and performance of lead smelting slagbased multi

Download Citation On Jan 1, 2024, Wenhuan Liu and others published Innovation and performance of lead smelting slagbased multisolid waste pavement concrete materials: Ratio design, mechanical 2021年3月16日 By Alton Tabereaux, Contributing Editor Spent potlining (SPL) disposal is one of the largest environmental waste management challenges confronting worldwide primary aluminum smelters due to its toxicity The The SPL Waste Management Challenge in Primary 2021年5月11日 Practically, the matte grade is adjusted by the ratio of O 2 in the blast to concentrate feed rate, assuming a constant slag composition Due to the fact that the matte grade determines the extent of oxidation of Fe and S, it also determines the extent SO 2 evolution [], and it influences the partitioning of the elements between different phasesThermodynamic Analysis of Copper Smelting, Considering the Impact Request PDF On Jul 1, 2016, Jung Ho Heo and others published Recovery of iron and removal of hazardous elements from waste copper slag via a novel aluminothermic smelting reduction (ASR) process Recovery of iron and removal of hazardous elements from waste

STUDY ON THE STRENGTH OF IRON AND STEEL SMELTING WASTE BLAST FURNACE SLAG

H Z YANG et al: STUDY ON THE STRENGTH OF IRON AND STEEL SMELTING WASTE BLAST FURNACE SLAG the coarse soil particle analysis index, the coarse particle content P5 of blast furnace slag was 97,47 Its nonuniformity coefficient Cu=2,46 and curvature coefficient Cc=0,93 This type of blast furnace slag is a poor 2018年7月12日 To our knowledge, only limited numbers of studies on the suitability of plant species for the phytostabilization of zinc smelting waste slag sites under field conditions can be found (Pierzynski et al 2002; Houben et al 2013; Siebielec et al 2018), and there is a clear need for longterm field trials evaluating the phytostabilization Suitability of four woody plant species for the phytostabilization of 2024年1月12日 LSS is a byproduct resulting from the smelting process of metallic lead, which involves hightemperature melt quenching in water, similar to other materials such as fly ash [9], steel slag [10], and GGBFS [11]The material under consideration comprises a certain quantity of amorphous calciumaluminumsilicate glassy phase, which exhibits cementitious behavior Innovation and performance of lead smelting slagbased multi 2003年3月1日 Up to now, the main methods of using steel slag were used as sinter material, hot metal dephosphorizing agent, waste water treatment materials, reclamation of waste steel, concrete admixtures, CO2 Comparison of properties of steel slag and crushed limestone aggregate

Comprehensive utilization of steel slag: A review ScienceDirect

2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of because when it ends up in the slag it can lead to failure of the TCLP Barium produces a deep green flame over the slag and matte, a stony appearance, and a large amount of matte Too much alkaline earths or too much zinc can “freeze” a blast furnace [2] A low silica highlime slag is a dangerous sign that the furnace is about to freezeA REVIEW OF SLAG CHEMISTRY IN LEAD RECYCLING2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of What is Blast Furnace Slag and How to Process It?2018年8月23日 The purpose of this work is to determine the regularities of reducing the losses of valuable metals with waste slag of copper smelting in the conditions of the Balkhash copper smelterDEPLETION OF WASTE SLAG OF BALKHASH COPPER

.jpg)

Clean strengthening reduction of lead and zinc from smelting waste slag

2017年2月1日 Massive emissions of smelting waste slag (SWS) cause serious harm to environment because of including toxic metal such as zinc and lead Reductionvolatilization is considered as a effective 2024年6月27日 The Multifaceted Comparison of Effects of Immobilisation of Waste Imperial Smelting Furnace (ISF) Slag in Calcium Sulfoaluminates (CSA) and a Geopolymer Binder June 2024 Materials 17(13):3163The Multifaceted Comparison of Effects of Immobilisation of Waste Industrial solid waste (ISW) is a collection of waste produced in the process of industrial manufacturing [1], [2]In recent decades, the global production of ISW has continued to increase, in China, for example, by 2020 to reach a staggering 368 billion ton [3], [4]ISW generally has the characteristics of large storage, continuous environmental pollution, rich in valuable metals, Practical experience to theoretical innovation: A model for 2023年10月1日 Lead smelting slag (LSS) usually contains high content of heavy metals (HMs) such as lead (Pb), zinc (Zn), copper (Cu), cadmium (Cd), and arsenic (As) (Liu et al, 2018)However, its complex mineral composition and distribution characteristics make the utilization efficiency of resources low at present, and disposal is usually done by open storage Synchronous stabilization of Pb, Zn, Cd, and As in lead smelting slag

.jpg)

Comprehensive Utilization Technology of Steel Slag

2019年5月23日 Wang Deyong and others proposed using the physical latent heat carried by BOF slag to directly reduce slag in smelting state, and this can save the energy needed for the second heating of slag Carbonsaturated liquid iron and additional solid carbon is used to reduce BOF slag There are two keys to this technology2022年9月25日 Iron in CSS mainly exists in the form of complex iron oxides such as iron olivine rather than magnetite or hematite, which is difficult to be recovered efficiently by traditional beneficiation methods (Li et al, 2021)In order to separate iron from CSS, it is necessary to convert the complex iron oxide into metal iron or ferric oxide, and then recover it through Extraction and separation of copper and iron from copper smelting slag 2020年6月2日 In this study, Zn/Cubearing smelting slag was recycled via an integrated acid dissolution and hematite precipitation method The slag was dissolved in nitric acid to generate an acid solution Highpurity recycling of hematite and Zn/Cu mixture from waste smelting industrialization [12−14]; metal lead smelting often needs to add limestone flux for the smelting temperature and slag lead content to reduced [15] Thus, replacing limestone with gypsum sludge and returning it to the smelting furnace as flux can utilize the calcium source in the slag, whileUtilization and detoxification of gypsum sludge by replacing limestone