Expected investment for iron oxide powder making plant to operate

.jpg)

Iron Oxide Manufacturing Plant Report 2024: Setup Cost

IMARC Group’s report, titled “ Iron Oxide Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue, ” provides a complete roadmap for setting up an iron oxide manufacturing plantThe iron powder project report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed Iron Powder Manufacturing Project Report 2024 Plant Cost2024年9月25日 IMARC Group’s report, titled “Iron III Oxide Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost Iron III Oxide Manufacturing Plant Setup: Detailed Project Report 2023年11月20日 IMARC Group’s report titled “Iron Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost Iron Powder Manufacturing Plant Project Report 2024: Cost

.jpg)

NIIR Project Consultancy Services:Iron Powder Manufacturing

The scope of the report includes assessing market potential, negotiating with collaborators, investment decision making, corporate diversification planning etc in a very planned manner The scope of the report includes assessing market potential, negotiating with collaborators, investment decision making, corporate diversification planning etc in a very planned manner Synthetic Iron Oxide Manufacturing Plant, Detailed Project The overwhelming application of Iron (III) oxide is as the feedstock of the steel and iron industries, eg the production of iron, steel, and many alloys Black iron oxide has the highest tint Investment Opportunities in Iron oxideIron powder particles' high surface areatovolume ratio offers dual benefits: it enhances reactivity, making the powder suitable for catalytic applications and improving its sinterability Flowability What Is Iron Powder? Linde AMT

.jpg)

Iron Oxide Market Size, Share, Growth Forecast, 2032

The strategic integration of iron oxide in construction and paint applications aligns with industry trends, driving its prominence in the global market landscape The global Iron Oxide market is 2024年3月20日 Electrochemical production of iron metal can support a decarbonized process for steelmaking Here, we report a lowtemperature, electrochemical cell that consumes lowcost Electrochemical chloriron process for iron production from iron 2024年3月20日 Electrochemical production of iron metal can support a decarbonized process for steelmaking Here, we report a lowtemperature, electrochemical cell that consumes lowcost and abundant iron oxide, salt, Electrochemical chloriron process for iron production 2024年4月26日 The intense heat generated by the combustion of coke reduces the iron oxides in the ore to metallic iron The limestone or dolomite reacts with impurities, forming a slag that floats on top of the molten iron The molten iron, Iron Ore Processing: From Extraction to Manufacturing

.jpg)

Electrochemical ChlorIron Process for Iron

2023年2月22日 Process parameters and sensitivities of the batch chloriron cell (A) Relationship between ηFe and J for Fe plated in a batch cell divided by Nafion 115 ηFe >85 % was sustained for current 2002年7月30日 The lowered SI of pellets at higher gangue contents has also been reported by several other researchers Basda and Arol (2002) reported a decrease in the SI from 30 per cent to 40 per cent at 125 Coating of iron oxide pellets for direct reduction ResearchGateThe global iron oxide market size is estimated to be valued at around USD 2,6294 million in 2023 Sales of iron oxide are projected to increase at a healthy CAGR of 41% from 2023 to 2033 The market is expected to top a valuation of USD 3,9297 million by 2033Iron Oxide Market Size, Demand Forecast to 2033 FMI2010年1月1日 Further processing of these iron oxide powders could enable the production of iron powder for various applications in powder metallurgy For this purpose, a new process route with an ecofriendly Elaboration of iron powder from mill scale ResearchGate

.jpg)

(PDF) Iron Ore Sintering: Process ResearchGate

2017年2月16日 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents and solid fuel (coke)2024年9月4日 These systems allow operators to manually control the application of powder, making them suitable for projects that involve intricate designs or low production volumes A manual powder coating plant typically includes a powder coat applicator, a powder coating booth, and a curing ovenIron Phosphate for Powder Coating2024年2月24日 The hydrogen used to convert the iron oxide into iron powder can be extracted again This is done by adding hot water vapour to the iron powder When the water (H 2 O) reacts with the iron molecules (Fe), its oxygen content (O 2) is bound in the iron oxide (Fe 2 O 3), while the hydrogen (H 2) can be captured and used in industry, etcWelcome to the new Iron Age: iron can generate eternal energy2023年11月8日 Iron oxide nanoparticles (IONPs) are defined as “Nanozymes” due to their inherent enzymelike activities and catalytic properties that are comparable to those of different(PDF) Iron Oxide Nanoparticles: Green Synthesis and

Reducing Iron Oxide with Ammonia: A Sustainable

2023年3月30日 Iron making is the biggest single cause of global warming The reduction of iron ores with carbon generates about 7% of the global carbon dioxide emissions to produce ≈185 billion tons of steel Upon combustion, the iron powder is converted to iron oxide powder, which can then be filtered out of the exhaust stream, and stored on board Later, this oxide powder can be reformed to iron powder using renewably produced hydrogen Exploring the potential of iron powder as fuel on the 2023年9月8日 solutions have been proposed for the blast furnace, for example, hig hly oxygenenriched or hydrogenrich operationBlast Furnace process optimization for sustainable Iron 2023年2月19日 You can collect rust and grind it to a fine powder if you choose to go that route 2 Make a solution containing iron (III) Add water to the iron (III) oxide source in a beaker (or another glass container of similar size) The aqueous 4 Ways to Make Iron Oxide wikiHow

.jpg)

(PDF) Energy Efficiency Improvement and Cost Saving Opportunities

2009年1月1日 In a blast furnace, iron oxides are reduced and the resulting iron is melted Iron oxides ente r the blast furnace plant in the form of raw ore, pellets o r sinter2020年6月10日 The iron oxide content of MgO grains needs to be maintained low as it forms lowmelting phases with a wide range in CaO/SiO 2 ratio Boric oxide is also a very undesirable impurity, and thus the boron content to be maintained within 002 wt% to achieve good hot strength of magnesite refractories 1446 Effect of MgO Crystallite SizeRefractories for Iron and Steel Plant SpringerLink2023年3月23日 Hydrogenbased direct reduced iron (H2DRI) is an alternative pathway for lowcarbon steel production Yet, the lack of established process and business models defining “green steel” make it Green steel: design and cost analysis of hydrogenbased direct iron O serviço do Google, oferecido sem custo financeiro, traduz instantaneamente palavras, frases e páginas da Web do português para mais de cem outros idiomasGoogle Tradutor

.jpg)

Electrochemical ChlorIron Process for Iron Production from Iron Oxide

Fig 1 Integration of the chloriron process with lowcarbon electricity, Cl 2, and electric arc furnace markets (A) Iron ore electrolysis, fed by abundant iron oxide, seawater, and zerocarbon electricity, can support further deployment of infrastructure for a netzeroemissions energy system (B) Colocation of2023年6月24日 2 Classification of iron and iron oxide nanoparticles Fe 2 O 3 is primarily used in the fields of sensors, coatings, UV radiation blocking, and coloring Fe 2 O 3 nanoparticles are also ideal for exploring nanoparticle polymorphism, magnetic transition, and structural phase transition Alpha Fe 2 O 3 is an antiferromagnetic material with hexagonal structure Green Engineering of Iron and Iron Oxides by Different Plant 2023年10月8日 Iron alloys powder refers to powder metallurgy forms of iron mixed with alloying elements like nickel, chromium, manganese, and carbon Iron powder metallurgy allows the manufacture of parts and components with controlled density, porosity, strength, magnetic and other properties by compacting and sintering ironbased powder mixesIron Alloys Powder: A Complete Guide Additive Manufacturing Iron Oxide (Fe 2 O 3) powder, CAS number , has a wide range of applications such as pigments, catalysts, and thermiteIron (III) oxide has various polymorphs, predominantly αFe 2 O 3 and γFe 2 O 3 αFe 2 O 3 has a Iron Oxide (Fe2O3) Nanopowder αFe2O3 γ

.jpg)

Global Iron Oxide Powder Market Growth Projections 2031

2024年6月28日 Iron Oxide Powder Market Future Outlook and Growth Opportunities: New Jersey, United States: The Iron Oxide Powder Market is poised for remarkable growth from 2024 to 2031, with a Compound Annual 2022年9月5日 After combustion, the iron oxide powder is regenerated back to iron powder using hydrogen, ultimately derived from solar wind energy at places with a vast surplus of sustainable energy Iron powder can store energy in a very compact, cheap, safe, environmental friendly and IRON+ builds fully commercial plant on iron power Metalot2023年4月25日 In this work, a mathematical model for the straightgrate pellet induration furnace is presented The induration furnace is an equipment used for the efficient heat and mass transfer between the pellet bed and the flowing gas The model includes different physicochemical phenomenon like gassolid heat and mass transfer, drying and condensation of free surface A Mathematical Model for StraightGrate Iron Oxide Pellet If you want to get more information about natural red iron oxide, click here How to make red iron oxide powder in the DIY method To produce red iron oxide using simple DIY methods, you can follow a straightforward chemical process that uses readily available materialsMake red iron oxide powder Farayand powder

.jpg)

HIGHVELD STEEL PROSPECTUS: IRON PLANT 1

• The purchase of Iron making Plant 1 has the following distinct advantages: • The Flexibility of equipment: The newly upgraded Open Slag Bath has a proven track record of producing a range of products including ferroalloys • Open Slag Bath and preheating technology: Inherent to the design of the plant is the ability to process large amount of fine material which are problematic SECTION 1 IDENTIFICATION Product Name: Iron(III) Oxide Powder Product Number: All applicable American Elements product codes, eg FE3OX02P , FE3OX03P , FE3OX04P , FE3OX05P , FE3OX025P , FE3OX035P , FE3OX045P CAS #: Relevant identified uses of the substance: Scientific research and development Supplier details: Iron(III) Oxide Powder American Elements2014年7月17日 The ferric iron recovered from waste iron ore tailings via acid leaching followed by precipitation as ferric (hydr)oxide was used as feed stock to synthesis magnetite powder by its reductive Introducing a recycling method for iron oxide nanoadsorbent 2021年2月14日 The shaft furn ace processes must use pellets of iron oxide that was designed to operate from 1200 to 1600 °C Further processing is needed to obtain the required iron powder [8], (PDF) Design of Novel Flash Ironmaking Reactors for

Iron Oxide Direct Reduction and Iron Nitride Formation Using

2024年6月21日 Considering the properties and world trading capacity, ammonia is considered as a potential reductant for iron reduction to support green steelmaking []However, there are only four laboratorybased studies related to ammonia ironmaking that have been published to date (see Table 1) [25, 30,31,32]The basic reaction of the process will depend on the reduction 2018年1月1日 There are many types of ferrous oxides have been characterized, whereas iron (III) oxide (Fe 2 O 3), Fe(II)deficient magnetite (Fe 2 O 3 , γFe 2 O 3) and ferrousferric oxide (Fe 3 O 4) are (PDF) The Importance of Iron oxides in Natural 2008年12月17日 Walther et al [11] and Danninger et al [13] investigated the manufacturing of iron particles from iron oxide (Fe 2 O 3 ) powder, which is a byproduct of the recycling of conventional Waste Treatment in the Iron and Steel Manufacturing Industry2021年6月28日 iron oxide, was generated from the partial oxidation of hydrogen A reduction degree greater th an 90% was achieved with some excess hydrogen in a few seco nds of residence time at a temperatureDevelopment of the Flash Ironmaking Technology (FIT) for

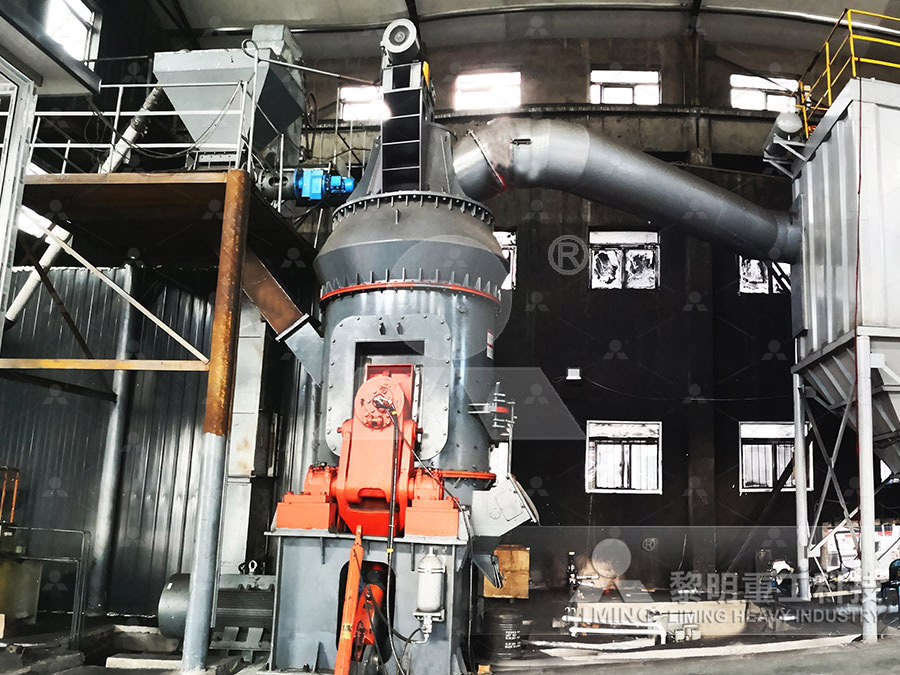

Iron Oxide Pigments Production Plant O'Neal

The plant produces 30,000 tons per year of red, yellow and black iron oxide based pigments The process technology for this facility is similar to Huntsman’s manufacturing plant in Italy Over 350 construction personnel worked 950,720 man hours with no lost time injuriesIron Oxide Market Impact of Coronavirus (Covid19) Pandemic: The covid19 pandemic has severely affected the global economy due to strict lockdowns and business shutdowns The global Synthetic Iron Oxide Pigments market is one of the major industries that ensure supply chain breaks as well as manufacturing disruptions due to these restrictionsIron Oxide Market Size, Trends and Forecast to 2030Abstract Medical applications and biotechnological advances, including magnetic resonance imaging, cell separation and detection, tissue repair, magnetic hyperthermia and drug delivery, have strongly benefited from employing iron oxide nanoparticles (IONPs) due to their remarkable properties, such as superparamagnetism, size and possibility of receiving a biocompatible Iron Oxide Nanoparticles for Biomedical Applications: A 2023年9月15日 This comprehensive guide will provide an overview of iron powder, its types, characteristics, applications, design considerations, Iron oxide pigments are produced by oxidizing iron powder Used in paints, plastics, rubber, Metal Powder Making Equipment; Other Related Link; Contact Details Shanghai, China +8621Iron Powder: Characteristics,types,Specifications Additive

.jpg)

Direct Reduction of Ferrous Oxides to form an IronRich

2015年12月1日 In this study, production of sponge iron by direct reduction of oxides and the effect of reductant on metallization were investigated In the first stage of the study, scale formed during hot rolling of slabs was reduced in a rotating furnace using solid and gas reductants Coal was used as solid reductant and hydrogen released from the combustion reaction of LNG was gaseous reduction of iron ore concentrate (MBIT) [14], also called the conveyor furnace process, which operates at 900–1300 K 2 Flash onmakrI ing Technology The Flash Ironmaking Technology (FIT) is based on the reduction of iron oxide concentrates by gas in a ash reactor This technology utilizes hydrogen or natural gas as aMaking Iron Directly From Concentrate by Gaseous Reduction