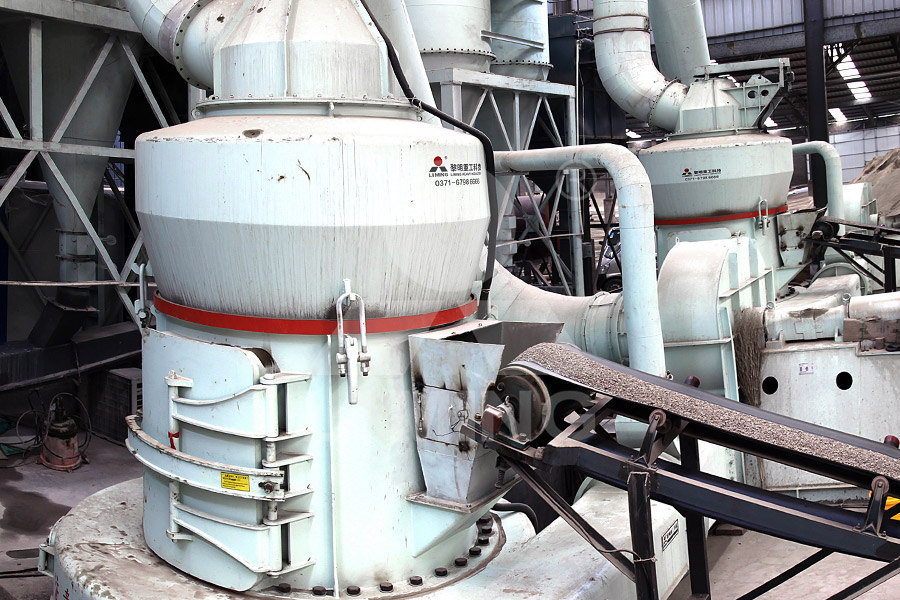

Single bar quicklime mill

.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materialsQuicklime milling is generally divided into four types: coarse powder processing (03mm), fine powder processing (20 mesh400 mesh), ultrafine powder processing (400 mesh1250 mesh) quicklime processing plant, quicklime grinding machine, quicklime HAZEMAG’s Hammer Mills HNM are used for fine crushing or mill drying of mediumhard to soft materials such as: Anhydrite, quicklime, lignite, dolomite, electronic scrap, gypsum, glass, Hammer Mill HNM HAZEMAGQuicklime lumps are ground and classified in Pfeiffer MPS vertical roller mills The fineness of the white fine limes can be set within wide limits (006 to 01 mm) In downstream Pfeiffer lime Quicklime preparation Gebr Pfeiffer

.jpg)

Quicklime Singleton Birch

Microlime is a fine, white calcium oxide powder that is made by pulverising and air classifying quicklime It is typically used in flue gas systems, for aerated concrete block manufacture, Quicklime or Calcium Oxide (CaO), is an alkaline and crystalline solid utilized in several environmental and industrial applications Graymont can supply various types of quicklime in Quicklime GraymontThe process heats the limestone from ambient temperature to 900°C, which is the point where the carbon dioxide is driven off, leaving calcium oxide, also known as quicklime Modern kilns are Vertical Shaft Kilns HWISARRALLE's Rolling Mills stand as a pinnacle for the seamless production of plain round bars, offering an unparalleled range of diameter references, customer length specifications, and SBQ Mills >A Universe of Engineering

Lime/quicklime for metallurgy – how producing and briquetting

2023年2月4日 Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime The standard quicklime feed system from Carmeuse Systems is designed as a compact ”slakerina box” system This modular chemical feed system provides an integrated solution for Standard Quicklime Feed System in a Box Carmeuse SystemsThe quality of quicklime is affected by several factors related to the limestone feed and the calcination process These include the chemical composition and crystalline structure of the limestone, as well as operating conditions in the kiln Factors Affecting The Quality of Quicklime2014年2月1日 Based on the product being rolled these mills are called, merchant bar mill, bar and rod mill, bar and light section mill, rebar (reinforcement bar) mill, light merchant mill, special bar quality (SBQ) A single shift of the Main Features of a Modern Bar and Light Section Mill

.jpg)

Hammer mill HUM HAZEMAG

HAZEMAG’s Hammer Mills HUM are employed for the fine crushing and/or drying grinding of mediumhard to soft materials such as: Anhydrite, quicklime, lignite, dolomite, electronic scrap, gypsum, glass, potash, limestone, chinaclay, diatomite, chalk, phosphates, salts, The high moisture and viscosity characteristics of oily cold rolling mill (CRM) sludge led to limitations in its recycling In this paper, the results of using quicklime as a conditioning agent to improve the dewaterability of the oily CRM sludge cake were reported Quicklime was selected as the best conditioning agent through conditioning–dewatering experiments because it could Enhancing the Dewaterability of Oily Cold Rolling Mill Sludge The quality of the quicklime is largely dependent on the efficiency of the grinding process, which is where the vertical mill comes into play The vertical mill, also known as the vertical roller mill, has emerged as a leading piece of equipment for the production of quicklime due to its advanced technology and operational excellence 2Vertical mill: The preferred equipment for quicklime productionHAZEMAG’s Hammer Mills HNM are used for fine crushing or mill drying of mediumhard to soft materials such as: Anhydrite, quicklime, lignite, dolomite, electronic scrap, gypsum, glass, potash, limestone, diatomite, chalk, phosphates, salts and clayHammer Mill HNM HAZEMAG

RA Series Dual Stage Hammer Mill Schutte Hammermill

The RA Series Dual Stage Hammer Mill features two gravity discharge industrial hammer mills, stacked one over the other This unique design is ideal for two distinct processing goals: reducing large, bulky materials to a fine consistency, and grinding free flowing material to a ultra fine finished particle sizeHygiene [] Dwarves do not require soap to clean contaminants such as mud and blood from themselves if necessary, they will use murky pools, artificial pools of water, brooks, or a wellHowever, using soap will often generate the happy thought "recently took a soapy bath" It is possible to construct bathhouses (rooms containing pools of water, a soap stockpile, and DF2014:Soap Dwarf Fortress WikiA mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), Mill (grinding) Wikipedia2024年6月18日 Iron Bar x2 Quicklime x1 Crushed Coal x1 Advanced Smelting Level 1 15 60 2 Used in Recipes Crafting Station Item Materials Level Needed Crafting Time (mins) Labour Cost Rolling Mill x1 Steel Bar x8 Gearbox x4 Mechanics Level 4 20 360 5 Machinist Table: Steel Buoy x1 Steel Bar x4 Mechanics Level 4 1 240 05 Medium Shipyard:Steel Bar Eco English Wiki

.jpg)

RAS SERIES Schutte Hammermill

one pass through the dual stage mill, than can be achieved in multiple passes through a single hammer mill Key Features • New, easy access grates for minmal downtime • Available in 5 standard sizes • Space saving stacked design features slideout rail for ease of maintenance • Option of carbon or stainless steel plate constructionConventional top feed, bottom discharge hammer mill for processing abrasive and/or difficult to process materials The heavy duty WA Series is a gravity discharge hammer mill that features components designed for processing Industrial Hammer Mill for Abrasive Materials2024年10月9日 Quicklime vertical roller millQuicklime vertical roller mill YouTubeSchutte Hammermill stands as a leading provider of specialized solutions for mining applications, offering robust and efficient size reduction equipment tailored to the unique demands of the mining industryCrushers and Lumpbreakers for Mining Schutte Hammermill

Quicklime in Malaysia TradeIndia

We provide highgrade Quicklime Powders from reliable and authentic sources of the market These are acknowledged for purity, accurate composition and reasonable prices by our clients all across the nation The range of Quicklime Powders offered by us is known for its properties In Bulk Tanker 1M2022年12月12日 1 Introduction The oily cold rolling mill (CRM) sludge is a solid waste generated from the cold rolling steel process comprising a dense slurry of iron fines in lubricating oil and water with other impurities including heavy metal 1 The oil in CRM sludge is derived from lubricants and equipment used in the cold rolling process of steel products 2 According to Enhancing the Dewaterability of Oily Cold Rolling Mill Sludge Quicklime is used in a wide variety of applications, including the manufacture of iron and steel, the manufacture of paper and pulp, the treatment of water and flue gases and the mining industry In the basic oxygen steelmaking (BOS) process, quicklime Quicklime Preparation, Properties, and Applications with FAQsExamples: Anhydrite, quicklime, lignite, dolomite, gypsum, glass, potash Any remaining material continues to be processed until it can pass through the grate gap The grate bar gap spacing determines the Precisely balanced configuration of the hammer arms and hammer heads ensures smooth running of the complete hammer mill without Hammer Crushers – MEKA

.jpg)

COMPLETE PLANT CAPABILITY LIME SYSTEMS LTD

Each mill is capable of slaking pebble lime at a mounted ball mills suitable for quicklime slaking and regrind applications single 55kW drive installed One only 900mm diameter with a 18 EGL mill with an installed power of 150kW to fine grind mill scale is part of a metals 1 Raymond mill is used for quicklime powder making It is recommended to use Raymond mill for the processing of quicklime with an output of 1 to 9 tons and a mesh of 80 to 400 meshes CLIRIK Machinery's new Raymond mill is used as a nonmetallic mineral processing machine The fineness of quicklime produced by this mill is between 80400 meshHow to choose quicklime powder grinding mill?Single Malt Distillery Spring Mill Distillery Our Ontario at Spring Mill Distillery Shop Now Enduring Spirit The Ward Bar Hours Retail Store open daily at 12 pm Monday: 12 pm 7 pm Tuesday: 12 pm 7 pm Wednesday: 12 pm 7 John Sleeman Sons Spring Mill DistilleryThese single end bars will not warp under pressure of mounting G555B and G777 model mills and allow the operator to use the same bar on a variety of different saws The Cannon Superbar fits Stihl 12mm mounts, but must have a Cannon Granberg International Alaskan® Mill BARS CHAIN

.jpg)

Pulverised Quicklime RCI Lime

Pulverized quicklime, or quicklime powder, is produced by grinding bulk quicklime Single or multistage grinding may be required depending on the particle size requirements The final product is a fine white powder with very Ash Single Crusher Williams’ Single Crushers are also available in a 15inch (381mm) diameter dusttight version These are already well known for rugged construction, low profile, high reduction ratio, and economical cost Williams’ DustTight Ash Single Roll Crushers also have easy access to the rotor for maintenanceRoll Crushers Williams Crusher2021年8月7日 Typical forcetime profiles from breakage of single particles of 12590 mm iron ore pellets and their fragments in an impact load cell device Arrows depict presumed primary breakage point(PDF) Review and Further Validation of a Practical SingleParticle 2023年3月23日 Hydrogenbased direct reduced iron (H2DRI) is an alternative pathway for lowcarbon steel production Yet, the lack of established process and business models defining “green steel” make it Green steel: design and cost analysis of hydrogenbased direct

Simple SingleActing Mill type Steam Engine YouTube

This is my latest scratch built model engine, a simple milltype horizontal single acting steam engine with a simple spool valveAbout Me Quicklime is a calcium Screen Rotameter Flowmeter Rotary Air Compressor Industrial Eto Sterilizer Rice Packaging Machines Shredding Machine Hammer Mill Automatic Labelling Machine Diesel Forklift Aerial Work Platform Storage Rack System Epoxy Resin Mild Steel Bar Stainless Steel Sheets Stainless Steel Strips Bag Filling Machines Asphalt Q What is Quicklime? TradeIndiaUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords quicklime mill water ground per unit Prior art date Legal status (The USA Method of grinding quicklime Google PatentsThe singlestand Steckel mill is mostly used to produce small batches in an annual capacity range from 100,000 to 600,000 tons They produce transfer bar with perfect strip geometries For this purpose, SMS group uses the Camber Free Rolling technology 4high roughing millHot strip mill for steel SMS group GmbH

.jpg)

NO33 Quicklime grinding mill YouTube

Quicklime grinding mill#liming #limingmill #grindingmill #verticalmill #quicklimemill2024年5月16日 Moreover, the application of quicklime was an essential driver of fungal community change It was shown by FUNGuild functional predictions that the proportion of the pathotrophsymbiotroph type in fungi was increased by Multiyear crop rotation and quicklime application Turning limestone into quicklime industrially The next video shows a modern industrial plant for producing quicklime, calcium oxide It carries far more information than you need, and you really only need to concentrate on what happens in the kiln itself (starting just after 2 minutes) This is where the limestone is heated and quicklime is limestone, quicklime and slaked lime chemguide2023年7月20日 The high moisture and viscosity characteristics of oily cold rolling mill (CRM) sludge led to limitations in its recycling In this paper, the results of using quicklime as a conditioning agent to Oily cold rolling mill sludge conditioned by quicklime to improve

.jpg)

Standard Quicklime Feed System in a Box Carmeuse Systems

The standard quicklime feed system from Carmeuse Systems is designed as a compact ”slakerina box” system This modular chemical feed system provides an integrated solution for receiving, storing, feeding, slaking and delivering up to 2,500 lb/h of quicklime from truck to the point of application531 Mechanical Mixing Procedure Using the VacU Mixer—To a measured amount of water contained in an 800 cm3 VacUMix bowl, add 300 g of hydrated lime and hand mix for 10 s with a stiff Physical Testing of Quicklime, Hydrated Lime, and Limestone12024年6月18日 Quicklime: Items: Description: A chemical compound used in steel production General: Created at: Blast Furnace: Used at: Blast Furnace, Cement Kiln, Glassworks: Iron Bar x2 Quicklime x1 Crushed Coal x1 Advanced Smelting Level 1 15 60 2 Blast Furnace: Steel Bar x1 Slag x2 Iron Bar x2 Quicklime x1 Charcoal x2 Advanced Smelting Quicklime Eco English Wikione pass through the dual stage mill, than can be achieved in multiple passes through a single hammer mill Key Features • Available in 5 standard sizes • Space saving stacked design features slideout rail for ease of maintenance • Option of carbon or stainless steel plate construction • Multiple hammer styles and sizesRA SERIES Schutte Hammermill

.jpg)

SMARTBAR Weight Sets, Plates and Bar Les Mills US

The SMARTBAR™ weight set collection includes weight plates, single bar and bundles designed for BODYPUMP™ and to help you reach your strength and fitness goals at home or in the gym The store will not work correctly when cookies are disabled Workout bundles; Equipment Back Equipment Shop all Workout Our highquality quicklime is a crucial ingredient in sugar production B elow are some of the key uses of our quicklime products in the sugar industry: pH Adjustment The juice extracted from sugarcane during the sugar production process typically has a high acidity level, which can adversely affect the quality of the sugar producedSugar Mill RCI Lime