Precrushing equipment for cement production

.jpg)

PRIMARY IMPACT CRUSHER HPI HAZEMAG

For aggregate production, and in the recycling industry, HPI Impact Crushers are used for precrushing without a grinding path In the cement industry, the HPI series of single rotor Primary Impact Crushers are used with a grinding path The FLSmidth StrikeBar Crusher is a highspeed impact crusher designed specifically for the cement production process Based on our proven technology, it is built to reduce the effect of wear in a harsh operating environmentStrikeBar™ Crusher FLSmidth CementPrecrushing equipment helps reduce large pieces of material into smaller ones more easily before they are fed into a cement mill This type of equipment includes jaw crushers, gyratory What are the pre crushing equipment cement millThe cement production equipment incorporates a crushing machine supporting limestone crushing in outdoor environment The crushed materials are delivered via a belt conveyor to a round storage yard for prehomogenization and Cement Production Line Cement Plant Equipment

.jpg)

Cement Crusher Crushers for Cement Plant AGICO

AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher The hammer crusher is a kind of crushing machine which uses impact energy to crush materials It is mainly Nonclinker mineral additions require separate installations for storage, preblending, crushing, drying and feeding Materials such as granulated blastfurnace slag (GBS) with a high moisture The Cement Plant Operations Handbook International Cement Coal crushing and grinding is the process of providing power for preheating and calcining cement raw materials Ring hammer crusher is often used for crushing coal, while ball mill is used for Cement Manufacturing Technologies DSMACAs complex and customised as the process of making cement, are the systems and technologies that are required, but one common factor always remains in place: The raw materials require CEMENT AGGREGATES HAZEMAG

A practical guide to improving cement manufacturing processes

Crusher and preblending Tips for Improvement 1 Crossbelt online elemental analysis systems can help control stockpile chemistry to meet quality targets 2 Place an online analyzer after Sustainable cement production; Alternative fuels in cement kilns; Cement kiln safety; Energy efficiency in cement kilns; Future of cement kilns TO Download this post and all the books and excel sheets and my personal notes and Comprehensive Guide to Cement Kilns: Processes, Cement production line is the production line of cement equipment consisting of a series of equipments Mainly by crushing and pre homogenization, preparation of raw meal homogenization, preheating and decomposing, cement clinker Cement Equipment,Cement Machinery,Cement 2019年9月27日 Cement equipment refers to the cement making machines that are applied to the cement manufacturing plant Before learning the cement equipment, we learn the process of cement manufacturing process first Cement Euipment Overview Cement Making

.jpg)

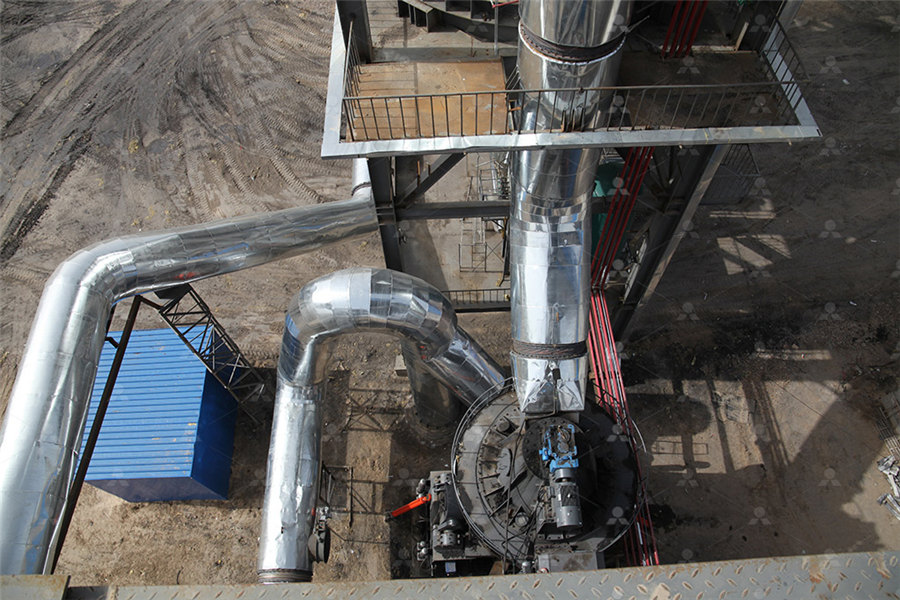

Crushing Technology for Reducing Emissions in Cement Mines

2021年12月24日 Mixed crushing is often used in cement production Therefore, mixed crushing generally refers to a production process in which two raw materials are sent to a crusher in a certain proportion in cement production for crushing Common types of mixed crushing include limestone and marl, limestone and shale, limestone and clay, etcCement production has undergone a tremendous development from its beginnings some 2000 years ago While the use of cement in concrete has a very long history, the industrial production of cements started in the middle of the 19th century, first with shaft kilns, which were later on replaced by rotary kilns as standard equipment worldwideCement Production an overview ScienceDirect TopicsAccording to statistics, the power consumption per ton of cement production is no less than 70 kW / h, but the effective utilization rate of this part of electric energy is very low After adding the precrushing equipment, the internal structure of the Ball Mill For Cement Grinding – Cement Ball Mill Ball Mill In production of PO425 grade cement, the finished cement specific surface area of is 360 m2/kg, the system output reaches 240 t/h, and the grinding power consumption of the cement grinding system is 28 kWh/t; In Production of P C325r grade cement, the specific surface area of the finished product was 380 m2/kg, the system output reached 260 t/h, and grinding power Cement plant projects of pregrinding equipment before ball mill

.jpg)

Cement Manufacturing Machine Cement Making Machine Cement

Cement rotary kiln is the core equipment of cement plant, mainly responsible for clinker calcination, which can be used both in dry process cement production line and wet process cement production line It is usually placed horizontally and at an angle to the ground, forming a state of one end high and one end lowWhy install Roller Press in Cement Manufacturing Plant The overall trend is to increase the capacity of pregrinding bed, and transfer 60% to 70% of of the ball mill functions section to it and high fine airflow classification equipment to complete the system, with a large range of increased production and power saving capacityRoller Press Install For PreGrinding Before Cement Ball MillPrehomogenization In past cases, where the main component of the cement raw material (usually limestone), showed con siderable fluctuations in the CaC03content, and as long as relatively low quantities of raw materials were processed in cement plants, selective quarrying was applied, to reduce to some extent fluctuations in the limestone’s chemistryPrehomogenization INFINITY FOR CEMENT EQUIPMENT1 The basics of cement manufacture – 2 History of cement manufacture – 3 Portland cement in today’s world 2 Raw materials management system – 22 Concrete problems 16 1 Raw materials – 2 Raw mix – 3 Reserves – 4 Crushing – 5 Drying – 6 Preblending – 7 Storage and handling 3 Raw milling and blending 3The Cement Plant Operations Handbook International Cement

.jpg)

Basics of mineral resources for cement production

Thus, for the present capacity of about 425 million metric tons per year—composed in India of approximately 25% plain Portland cement and 75% blended cements—the total annual limestone demand is estimated at about On basis of our feeding screening crushing equipment we provide best solutions from single machines to complete crushing plants reliable, continuous production solutions for the global Cement Aggregates industry each normally requiring different precrushing systems for the production of the correct feed granulationCEMENT AGGREGATES HAZEMAGPre crushing equipment Pre crushing equipment cement mill refers to the crushing equipment used in the first process of cement production, which can be divided into jaw crusher, impact crusher, hammer crusher, cone crusher and VSI crusher Types of cement mills There are two common types of cement mills: ball mills and roller millsWhat are the pre crushing equipment cement millAGICO Cement supplies cement equipment for cement raw material production as you need, such as cement mill, cement crusher, onestop turnkey project, welcome to contact! Skip to content +86 Crushing: the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, cone crusher, Preparation Of Cement Raw Material Cement Mill, Cement

Complete Lecture about Crushers in Cement Industry

Previous Post Next Post Contents1 Coarse size reduction of raw materials in Cement Industry11 Size reduction machinery and methods111 A Machinery for size reduction in the coarse range (crushers) by application of compression:112 B Crushers for size reduction by impact:113 C For comminution in the fines range (grinding mills) by application of impact:114 D Mills where Quick Setting Cement Production; Others Menu Toggle AAC Block Manufacturing Plant; The roller press is commonly used as pregrinding equipment in cement grinding systems are advanced cyclone air separators High Pressure Grinding Roll The high pressure grinding roll is a highly efficient crushing machine in the mining and cement Cement Manufacturing Equipment for Sale AGICO Cement Cyclone preheater is one of the core equipment in the new dry cement production process, which is responsible for many functions such as gassolid dispersion, material heating, gassolid separation, material transportation and some physical and chemical reactions Separation efficiency and resistance loss are two main performance indexes to be considered in the Cyclone Preheater Design for 5500 Ton Cement Production LineDescription: The Pengfei EPC cement production line project includes services such as process design, equipment supply (including mechanical and electrical parts), civil engineering, installation and commissioning, trial operation, reaching production standards, and final deliveryMechanical equipments include limestone crushing and conveying, clay crushing, and auxiliary raw 3000tpd cement production lineJiangsu Pengfei Group Co,Ltd

Cement Equipment In Cement Plant AGICO Cement Plant

AGICO Cement is located in Henan, ChinaIt was founded in 1997 with a registered capital of 8134 million yuan It covers an area of m 2 which includes a construction area of 30000 m 2In 2004, AGICO passed the ISO9001 certification and enjoyed the selfmanagement right of import and exportCement is often referred to as Portland cement, a generic term used for nearly all cement It is the mixture from which many types of concrete are made and is called such due to its resemblance to a type of building stone quarried in the What Equipment is Used for Cement Manufacturing?Quick Setting Cement Production; Others Menu Toggle Cement Plant Upgrade; The roller press is commonly used as pregrinding equipment in cement grinding systems High Pressure Grinding Roll The high pressure grinding roll Cement Manufacturing Equipment for Sale AGICO and sticky materials They all have low reduction factors and in the cement factory they are normally operated in multistage crushing Figure 32 illustrates a twostage crusher installation with cone crushers After the first stage the fine CRUSHING in Cement Industry INFINITY FOR

.jpg)

Cement Manufacturing Technologies DSMAC

Cement crusher is applied for cement crushing In cement mining, you need to choose suitable cement grinding mill and cement crusher Coal crushing and grinding is the process of providing power for preheating and calcining cement raw The coal mill is the main equipment in the coal powder production system of thermal power The cyclone preheating system Phase IV: Calcination The calcination is the core phase of the cement making dry process The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant The rotary kiln is a huge rotating furnace in which the raw meal is heated up to 1450 ⁰C and turned to clinkerHow Is Cement Produced in Cement Plants Cement Making In cement production, it is often necessary to prehomogenize the raw materials after secondary crushing, particularly when their chemicomineralogical composition varies over a wide range This unit operation is utilized primarily for the main raw materials, viz, the limestone and the aluminosilicate componentEverything you need to know about cement Materials Preparation 2021年11月15日 Modernday cement production processes contain a precalcining stage after preheating Mostly 60–65% of total calcination occurs during the precalcination process (Gao et al, 2016) The precalciner is positioned at the bottom of the preheater, where a portion of the C a CO 3 decomposes into C a O and CO 2A review of the effectiveness of Life Cycle Assessment for gauging

Everything you need to know about Stacker and reclaimer systems

TO buy the Most Important Books in Cement Industry + more than 30 excel sheets related to cement industry + Manuals and Notes click here now * Suitable for raw materials in the cement, coal, pulp and paper, mining and other industries as well as power plants ports Introduction MAIN FEATURESJaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crushers are a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric power, water conservancy, transportation, and Cement Crusher Crushers for Cement Plant AGICO Cement EquipmentThe Portland cement manufacturing process can be divided into 6 steps: raw material crushing, prehomogenization, fine grinding, clinker production, cement grinding, cement packing, etc In these processes, we need the assistance of different kinds of cement equipment , such as cement kilns, cement mills, and cement crushersPortland Cement Manufacturing – Ordinary Portland Cement Production 2020年1月27日 6 steps of the cement manufacturing process When we talked about the manufacturing of cement, anyone who knows the cement manufacturing process slightly will mention “two grinding and one calcination”, Cement Manufacturing Process: 6 StepsTo Make

An overview of energy savings measures for cement industries

2013年3月1日 Processes like grinding, transport of materials and crushing utilize machine drives and account for the majority of electricity consumption, as is evident in the result of the Manufacturing Energy Consumption Survey (MECS) in 1998 presented in Fig 3Process heating, by which clinker is made in large kilns, accounts for about 90% of the natural gas consumption 2024年10月14日 In today's construction industry, the demand for cement as a basic material continues to grow, and cement mills, as key equipment in the cement production process, play a vital role The production process of What Role Does Cement Mill Play In Production?Reduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, combining advanced technologies with 50 years’ experience in crushing for cement productionStrikeBar™ Crusher FLSmidth CementCement plant is necessary for cement production, and mainly consists of a series of cement equipment apply for the preparation of cement raw materials, clinker production, and finished cement production, such as a cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipmentCement Plant, Cement Equipment Cement Plant Manufacturer

.jpg)

Stacker And Reclaimer Cement Plant Equipment

The circular stacker reclaimer plays a vital role in the cement material prehomogenization process, which is the most Cement Production Line Stone Crushing Plant Cement Grinding AGICO Cement is a Chinese company that specialized in manufacturing and exporting cement production lines and cement equipment, providing turnkey In all the cement production processes there are hazards that can be classed in: o Safe behaviour o Environment, Work and Passage Areas Routine and general hazards such as: o Safety labelling o Personal Protective Equipment (PPE) • Special hazards during the cement production phases such as: o Quarrying o Crushing o Clinker productionSafety in Cement Plant INFINITY FOR CEMENT EQUIPMENTThe Cement Production Process Cement is more reactive than clinker and can absorb moisture from the environment leading to some degree of prehydration Each of the processes shown above uses electricity to drive the motors that drive the grinding and crushing plant, mixing equipment, conveyors, fans, rotate the kiln, The Cement Production ProcessNew type dry cement production process: this process is strengthened homogenization in each storage link, mainly for raw material mining → crushing → prehomogenization → mixing → grinding and drying → raw powder storage homogenization → calcination → clinker cooling crushing → clinker storage homogenization → batching → grinding → cement storage Cement Plant For Sale Cement Equipment, Cement Plant Cost

Cement Grinding Unit Clinker Grinder AGICO Cement

Cement grinding process mainly includes the mixed materials crushing, material batching, pregrinding, fine grinding, powder classification, dust collecting, automatic control, and other technologies, making cement production high yield and high quality, in line with the requirements of energysaving and emission reduction