HOME→High phosphorus grinding calcite ore powder processing technology to improve iron and reduce impurities

High phosphorus grinding calcite ore powder processing technology to improve iron and reduce impurities

Review on High Phosphorous in Iron Ore: Problem and Way Out

2024年5月28日 In today’s scenario, ultrafine grinding followed by froth flotation seems to be the most feasible solution for the beneficiation of high phosphorous iron ore in which the 2024年5月30日 A twostep method of gasbased direct reduction and magnetic separation was thus proposed to recover iron and reduce phosphorus The results showed that the powdery Iron recovery and dephosphorization behaviors from high Highphosphorus oolitic hematite is a potential iron ore resource China and Europe have 4窶・ billion tons and more than 14 billion tons of iron reserves, respectively1窶・) Corresponding Gasification and Migration of Phosphorus from Highphosphorus 2021年3月24日 Obtaining highquality concentrates with high iron content and low content of impurities from lowgrade iron ores requires the maximum possible liberation of valuable minerals and a high accuracy Mineral and Technological Features of

Iron recovery and dephosphorization behaviors from highphosphorus

2024年5月30日 With the depletion of highquality iron ore resources, highphosphorus oolitic hematite (HPOH) has attracted great attention due to its large reserve and relatively high iron content However, HPOH is very difficult to be used in ironmaking process due to its special structure A twostep method of gasbased direct reduction and magnetic separation was thus 2016年5月24日 The results show that under the proper conditions, a final metallic iron powder assaying over 91% Fe and 025% P was obtained with iron recovery of 90% and phosphorus removal rate of 9179% using Synchronous Upgrading Iron and Phosphorus 2022年2月22日 Deep dephosphorization of high‑phosphorus oolitic iron ore (HPOIO) is extremely difficult because of its refractory characteristics A new approach for simultaneous iron recovery and Effect of calcium compounds on direct reduction and phosphorus 2019年6月21日 Increasing Iron and Reducing Phosphorus Grades of MagneticRoasted HighPhosphorus Oolitic Iron Ore by LowIntensity Magnetic Separation–Reverse FlotationIncreasing Iron and Reducing Phosphorus Grades of MagneticRoasted High

Microwave Assisted Liberation of High Phosphorus Oolitic Iron Ore

2014年1月1日 Deposits of highphosphorus iron ores are widely spread worldwide, but the use of these deposits in industry is limited owing to the high phosphorus content, which affects the cost of the iron 2017年5月22日 Unlike previous dephosphorization studies, the present work complies with a concept to recover phosphorus within the utilization of highphosphorus oolitic iron ores to prepare FeP alloy for highphosphorus steel production Simultaneous enrichment of iron and phosphorus can be achieved by directly alloying the highphosphorus oolitic iron ore at high reduction Simultaneous Recovery of Iron and Phosphorus from a HighPhosphorus 2019年6月21日 Highphosphorus oolitic iron ore, treated by suspended flash magnetic roasting, contained 4273% iron (mainly present as magnetite) and 093% phosphorus (present as collophane) Lowintensity magnetic separation (LIMS) was combined with reverse flotation to increase the iron and reduce the phosphorus contents of the roasted product The results Increasing Iron and Reducing Phosphorus Grades of MagneticRoasted High 2022年10月1日 Deep dephosphorization of high‑phosphorus oolitic iron ore (HPOIO) is extremely difficult because of its refractory characteristics A new approach for simultaneous iron recovery and A new iron recovery and dephosphorization approach from high

.jpg)

Smelting Potential of HIsmelt Technology for HighPhosphorus Iron Ore

2011年3月20日 HIsmelt is an energysaving and emissionreducing technology as compared to the blast furnaces (BF) This paper analyzed the preponderances of smelting highphosphorus iron ore and ilmenite by 2022年8月20日 Steelmaking by basic oxygen furnace is an important method for steel production During the converter steelmaking process, the lance supplies oxygen to oxidize and eliminate the carbon content in the liquid steel (Li, 2005; Trung et al, 2011)The gas of CO is generated in large quantities and it takes a certain amount of metallic and nonmetallic A novel and clean utilization of converter sludge by coreduction 2024年8月1日 Highphosphorus iron ore is abundant in the United States, Canada, France, Egypt, Australia, and China However, it is not widely used due to the high impurity content (Baioumy et al, 2017, Schwid et al, 2020, Donskoi et al, 2022)With the depletion of highgrade iron ores, efficient utilization of lowgrade iron ores is of great strategic significance to ensure Migration behavior of iron and phosphorus during gasbased 2023年1月1日 Deep dephosphorization of high‑phosphorus oolitic iron ore (HPOIO) is extremely difficult because of its refractory characteristics A new approach for simultaneous iron recovery and dephosphorization from HPOIO by oxidation roasting – gasbased reduction (ORGR) and magnetic separation process was developed The underlying mechanism was investigated A new iron recovery and dephosphorization approach from high

Thermally assisted liberation of high phosphorus oolitic iron ore

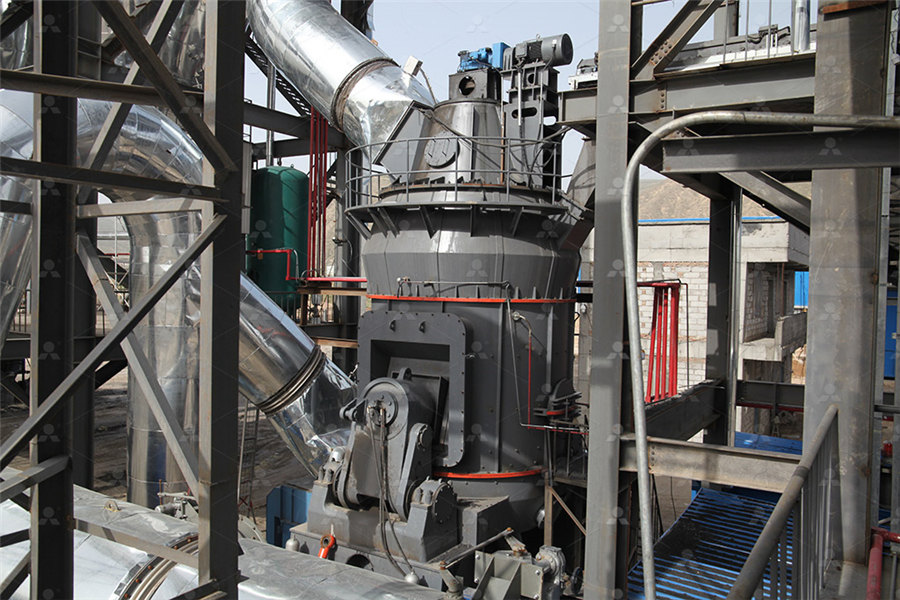

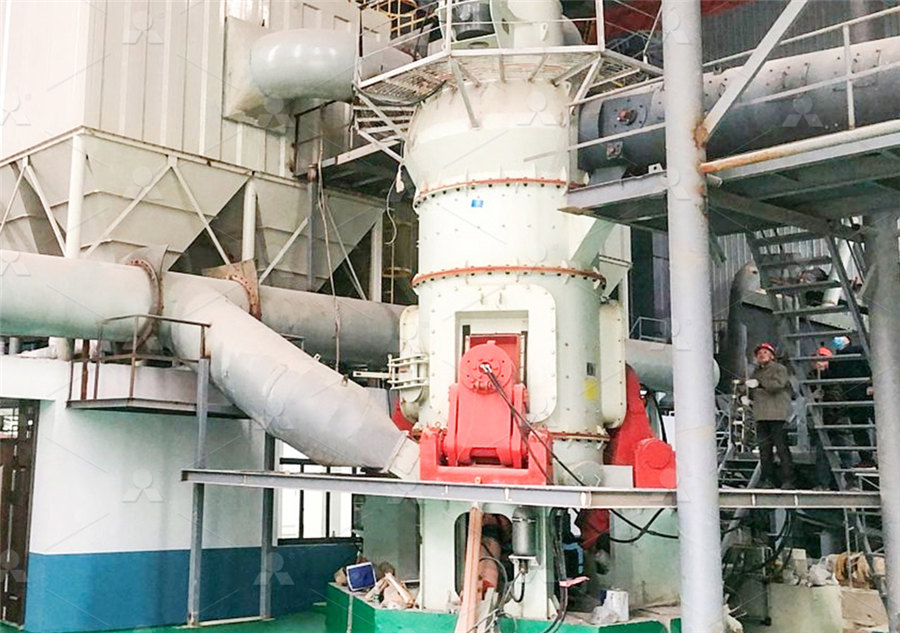

2015年1月31日 With the present rates of iron ore consumption, currently unusable, highphosphorus iron ore deposits are likely to be the iron ores of the future as highergrade iron ore reserves are depletedThe CLRM Enhanced Roller Mill adjusts for calcite powder from 80 to 500 mesh, ideal for materials under Mohs 6 It is energy efficient Grinding and Processing Calcite processing mainly includes three steps: crushing, The spiral sand washing machine can clean and separate the soil and impurities in the sand and stone, with high sealingCalcite Mastery: From Hardness to Powder Processing TechniquesIron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctiveIron processing Definition, History, Steps, Uses, Facts2016年9月1日 Due to the fact that the technology of processing magnetite ores of the Peschanskoe deposit at the enterprise of the subsurface user is configured to receive only iron concentrate, the development REMOVING IMPURITIES FROM IRON ORES: METHODS AND

.jpg)

Green and efficient separation of iron and phosphorus from high

2023年8月1日 With the increasing consumption of highquality iron ore, realizing the efficient utilization of refractory iron ore resources is of strategic significance for the sustainable development of the iron and steel industry (Qin et al, 2023, Sahu et al, 2023, Yuan et al, 2019)Among refractory iron ores, highphosphorus oolitic iron ore (HPOIO) has attracted 2011年5月1日 In order to effectively remove the phosphorus from high phosphorus iron ores, while reduce the amount of acid and the iron losses, ZHANG Shengfu, WEN Liangying, BAI Chenguang, et al Monitoring of Raceway in BF Using Digital Image Processing Technology [J] Journal of Iron and Steel Research, 2006, 18(3) : 56 (in Chinese)Removal of Phosphorus From High Phosphorus Iron Ores by 2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove impurities The eighth chapter of this book deals with mining and beneficiation of phosphate ore The principle and operating conditions of important Mining and Beneficiation of Phosphate Ore IntechOpen2023年1月1日 Deep dephosphorization of high‑phosphorus oolitic iron ore (HPOIO) is extremely difficult because of its refractory characteristics A new approach for simultaneous iron recovery and dephosphorization from HPOIO by oxidation roasting–gasbased reduction (ORGR) and magnetic separation process was developedThe underlying mechanism was investigated A new iron recovery and dephosphorization approach from high

Simultaneous Recovery of Iron and Phosphorus from

2017年5月22日 When highphosphorus iron ore concentrates activated by ball milling were processed by acid leaching, iron ore concentrates containing 5603 mass pct iron and 021 mass pct phosphorus with an iron 2015年9月1日 Phosphorus and silica minerals are the main finely disseminated impurities in the iron oxide ores, especially in some specific iron deposits in Sweden, Brazil, India, Iran, and MexicoProcesses for phosphorus removal from iron ore A 2016年3月31日 In this paper, an effective method was developed to remove phosphorus and upgrade iron from high phosphorus oolitic hematite ore by high temperature flash reduction—a wet magnetic separation process A thermodynamic analysis of iron and phosphorus mineral reactions and experiments with FeP separation process were performed, and the mechanism Synchronous Upgrading Iron and Phosphorus Removal from High Phosphorus 2021年10月24日 In this study, direct reductionmagnetic separation process was applied to enrich phosphorus and iron to prepare FeP crude alloy from a high phosphorus oolitic hematite ore (HPOH) The results show that at lower temperatures and with absence of any of additives, Fe cannot be effectively recovered because of the oolitic structure is not destroyed In contrast, Synchronous enrichment of phosphorus and iron from a highphosphorus

Beneficiation of HighPhosphorus Siderite Ore by Acid Leaching

2016年12月1日 In this study, the beneficiation of highphosphorus siderite ore by acid leaching dephosphorization, alkaline oxide reinforced carbothermic reduction and magnetic separation is investigated2024年6月17日 Highphosphorus (P) iron ore, particularly oolitic hematite, has remained unexploited due to technological and cost limitations in mining Effectively developing this ore involves not just utilizing its iron content but crucially extracting P to reduce exploitation costs Here, we applied a direct reductionmagnetic separation process to recover these valuable Direct Reduction of HighPhosphorus Oolitic Hematite: 2021年3月24日 Analysis of the current technical solutions for the processing of iron ores showed that the highgrade ores are directly exposed to metallurgical processing; by comparison, lowgrade ores, depending on the mineralogical and material composition, are directed to beneficiation including gravitational, magnetic, and flotation processes or their combination Mineral and Technological Features of Magnetite–Hematite Ores 2024年4月26日 The final stage in iron ore processing is ironmaking, where the iron ore is transformed into molten iron through a process called reduction The most common method of ironmaking is the blast furnace route In a blast furnace, iron ore, coke (carbon), and fluxes (limestone or dolomite) are loaded into the furnace from the topIron Ore Processing: From Extraction to Manufacturing

Grinding of Australian and Brazilian Iron Ore Fines for Low

2024年2月26日 Oxidised pellets have become an indispensable highquality charge for blast furnaces Nevertheless, highquality pellet feeds are becoming scarcer and scarcer To broaden the range of sources of pellet feeds and reduce the production cost of pellets, more steel mills are predicted to use coarse iron ore fines with a relatively low iron grade and low impurities for the 2018年10月4日 Developing the innovative technology for efficient utilization of highphosphate iron ore was the inevitable choice of resource strategy In this paper, exploring a new method of gasification Gasification and Migration of Phosphorus from High 2019年11月29日 With the present rates of iron ore consumption, currently unusable, highphosphorus iron ore deposits are likely to be the iron ores of the future as highergrade iron ore reserves are depletedTechnological Challenges of Phosphorus Removal in be difficult to separate Highphosphorus iron ore is a worldrecognized complex refractory iron ore 10) On account of the abovementioned difficulties, in recent years, experiments using the highphosphorus iron ore have been carried out to improve the iron grade while considering dephosphorizaGasification and Migration of Phosphorus from Gasification and Migration of Phosphorus from Highphosphorus Iron Ore

Characterisation of phosphorus and other impurities in

2019年9月17日 However, dephosphorisation may be necessary to reduce the phosphorus below the required market specification eg the Platts Iron Ore Index benchmark specified 009 wt % P at the time of writing2024年5月31日 This paper presents an industrial verification test, adding a high pressure grinding roll and magnetic separation operation after the thirdstage fine crushing operation to reduce the particle size of ball mill feed and improve the processing capacity of grinding operation The optimal process parameters of high pressure grinding roll and magnetic separation were High Pressure Grinding Roll and Magnetic Separation for Energy 2016年7月1日 High pressure roll grinding (HPRG) and ball milling were compared to investigate the influence of mechanical activation on the acid leaching dephosphorization of a highphosphorus iron ore Influence of Mechanical Activation on Acid Leaching2022年8月22日 Highphosphorus iron ore resource is considered a refractory iron ore because of its highphosphorus content and complex ore phase structure Therefore, the development of innovative technology to realize the efficient utilization of highphosphorus iron ore resources is of theoretical and practical significance Thus, a method for phosphorus removal by gasification Phosphorus reduction behavior of highphosphate iron ore

Preparation of Reduced Iron Powder from HighPhosphorus Iron Ore

Preparation of Reduced Iron Powder from HighPhosphorus Iron Ore: A PilotScale RotaryKiln Investigation Mineral Processing and Extractive Metallurgy Review ( IF 46) Pub Date : , DOI: 101080/2023年5月1日 Eggshell is a typical solid waste in the food industry (Lunge et al, 2012, Ngayakamo et al, 2020), accounting for approximately 10% of the weight of eggs (Baláž, 2018, Waheed et al, 2020)Typically, it consists of 96% CaCO 3, 1% MgCO 3, and organic matter (Attari et al, 2022, Laca et al, 2017, Liao et al, 2010)In 2018, the global eggshell production A new way to efficient utilization of eggshell waste: As green DOI: 101080/2023 Corpus ID: ; Preparation of Reduced Iron Powder from HighPhosphorus Iron Ore: A PilotScale RotaryKiln Investigation @article{You2023PreparationOR, title={Preparation of Reduced Iron Powder from HighPhosphorus Iron Ore: A PilotScale RotaryKiln Investigation}, author={Jinxiang You and Preparation of Reduced Iron Powder from HighPhosphorus Iron Ore