Primary air pressure record of coal mill in thermal power plant

.jpg)

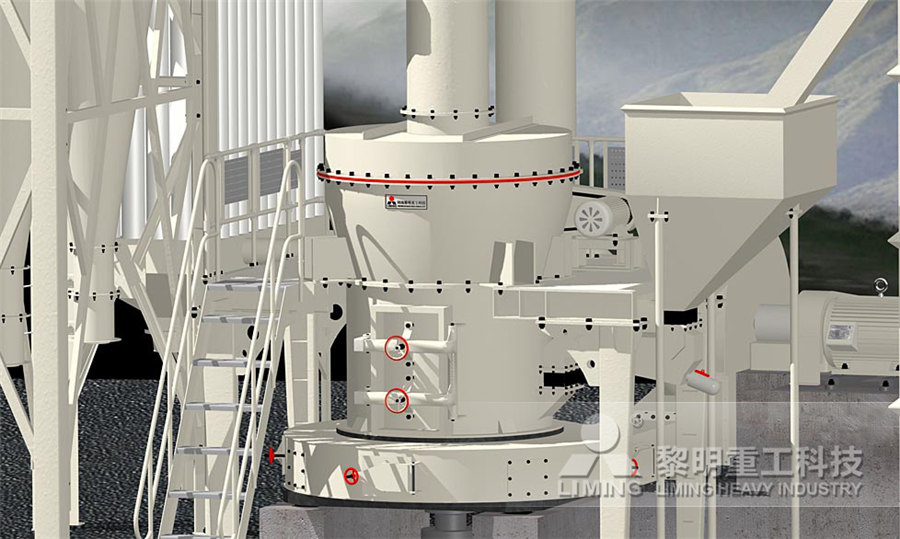

Modeling and Control of Coal Mill

Coal mill is an important component of the thermal power plant It is used to grind and dry the moisturized raw coal and transport the pulverized coal – air mixture to the boiler Poor dynamic performance of coal mill will lead to decrease in the overall efficiency of the power plant, slow 2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants It describes how pulverized coal is dried, ground, circulated, and classified within the mill to produce a fine powder that is then transported to Coal mill pulverizer in thermal power plants PPT2016年8月1日 Based on the potential for significant powersavings, the present study develops a strategy for enhancing coalfired power plant efficiency by decreasing primary air fan power A powersaving control strategy for reducing the total pressure 2007年7月1日 Reduced hot air temperature from APH outlet results in lowering of secondary air injection temperature and coal–air mixture temperature at the mill The objective of this paper Effect of air ingress on the energy performance of coal fired

Improving performance of primary air fansin thermal power plants

2014年9月2日 This paper describes various technoeconomical energy conservation measures for reducing the carbon emission by improving the performance of Primary Air fans in coal 2016年1月1日 Optimising the pressure at PA fan discharge, control of excess air, pressure drop across air preheater (APH) and mills and maintaining the optimum primary air pressure at millsCarbon emission reduction by improving performance 2015年11月15日 For a reference power plant, the exergy of the coal feed is calculated to be 108 times the lower heating value The actual thermal efficiency is 455% The irreversibilities Thermal efficiency of coalfired power plants: From theoretical to Pulverised Coal, Primary Air, Mill Differential Pressure, Fitness Function, Raw Coal 1 INTRODUCTION In coal fired power plants, pulverised coal (PF) flow from coal mills is to be Pulverised Coal Flow measurement in Thermal Power Plant

.jpg)

One approach to temperature distribution control in thermal

2020年3月2日 Research has shown that the temperature distribution inside the boiler of such power plant can be controlled by adjusting firing, through coal redistribution among the mills estimate the pulverised coal flow using real time onsite plant data 2 COAL MILL MODELLING In thermal power plant, pulverization of coal is carried out by coal mill Raw coal is moved from the storage to the mill by conveyor mechanism The type of coal mill envisaged for our model is bowl mill which is shown in Fig1Pulverised Coal Flow measurement in Thermal Power Plant2012年10月12日 12 Primary air fans Primary air fans (PA) are high pressure fans used to supply the air for the transportation of coal directly from the pulverizer to the furnace These fans provide a positive pressure upstream of Fans in thermal power plants PPT Free DownloadIntroduction The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder into a predetermined size in order to increase the surface area of the coal If Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

.jpg)

CoalFired Thermal Power Plant ScienceDirect Topics

A coalfired power plant (Fig 2) operates by burning coal to generate heat, which is then used to produce steam in a boilerThe highpressure steam drives turbines connected to generators, converting the kinetic energy into electricity Coalfired power plants have long been prominent in electricity generation due to the abundant availability of coal reserves3 Total Mill outlet air flow (including seal air) t/h 7104 6843 4443 2262 4 Mill outlet temp °C 65 65 65 65 5 Mill outlet coal moisture % 1875 1875 1875 1875 6 Mill inlet Primary air flow t/h 676 657 421 257 7 Mill inlet Primary air temp °C 324 313 321 301 * BMCR – Boiler Maximum Continuous Rating 5 4 3 2 7104 6843Pulveriser Mill Performance Analysis Optimisation in Super1834 by increasing steam pressure to145 psig [9] Presently the efficiency of a coal based power plant is of the order of 40% Process description of a coalfired power plant In a coalfired power coal is burnt to produce electricity In a coalfired plant, pulverisers are used to mill the coal to a fine powder for burning in the combustion Auxiliary Power Analysis of a Coalbased Thermal Power Plant2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic

.jpg)

Modeling and Control of Coal Mill

mill differential pressure of the primary air, and the amount of coal suspended in the air During normal operation = Mass of pulverized coal carried by primary air (kg) = Mass flow of dry raw coal out of the mill In the thermal power plant, the outlet temperature is maintained at 年6月3日 Working Principle of a Thermal Plant The working fluid is water and steam This is called feed water and steam cycle The ideal Thermodynamic Cycle to which the operation of a Thermal Power Station closely resembles is the RANKINE CYCLE In a steam boiler, the water is heated up by burning the fuel in the air in the furnace, and the function of the boiler is to give Thermal Power Plants: Components Working Principle2021年2月25日 In China’s primary energy consumption system, the proportion of raw coal has remained above 70% for a long time, and the raw coal consumption for power generation has exceeded 50% of the domestic coal consumption [1]Of the total emissions released by coalfired power plants in China, CO 2, SO 2, and NO X account for more than 40%, 40%, and 35%, Thermodynamic analysis of coalfired power plant based on Firing high moisture highly reactive subbituminous coals exposes your plant to risks of: • Unsafe working conditions, possible threat to worker safety • Damage repair cost (Primary air inlet ducts, PA fans, mill internals, feeders, etc) • Derates, forced outage, shut downMill Inerting and Pulverizer/Mill Explosion Mitigation

.jpg)

Carbon emission reduction by improving performance

2016年1月1日 This paper describes various technoeconomical energy conservation measures for reducing the carbon emission by improving the performance of primary air (PA) fans in coal fired thermal power Coal Mill in Thermal Power Plant Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free This document discusses coal pulverizers/mills which are critical components that convert the stored Coal Mill in Thermal Power PlantCoalfired plants are the most widely used power plant today They involve the combustion of coal producing high pressure (typically 2400–3500 psig, ~165–240 bar) and high temperature (>500ºC) steam which is used to drive a turbine at synchronous speed (3000 rpm in countries such as the UK with a 50 Hz supply frequency, 3600 rpm in Instrumentation and control in coalfired power plant ICSCAbstract: In a pulverized coalfired (PCF) thermal power plant (TPP), mixture of coal, air and gas is supplied into the furnace volume via the mill duct system and coal/air distribution should NUMERICAL AND EXPERIMENTAL INVESTIGATION OF A PULVERIZED COAL MILL

Fans for Power Plant: ID, FD, Primary Air and More AS Engineers

2024年8月16日 This fan ensures that the boiler operates at its best, supporting overall power plant efficiency 3 Primary Air Fan The Primary Air Fan has a specific role in the power plant: it provides the initial air needed to transport and dry the pulverized coal before it enters the furnace This fan is crucial for preparing the coal for combustion2022年5月1日 The overall efficiency of a TPP depends on the way in which the equipment is operated and controlled Rejuvenation of controllers for TPP is necessary to improve the performance of the plant and to minimize the consumption of fuel, steam, thermal energy, waste heats etc Heat rate is one of TPP efficiency which converts a fuel into heat and into electricity Improvement in efficiency of thermal power plant using primary air flow carries the fine coal to the burners, and the coarse coal falls back into the grinding zone of the pulverizer Fig 1 shows the main component in the milling system and the position of typical arrangment The mill design in the power plant is a vertical bowl The mill rotated on his axis at minimum speed 35rpm by aAnalysis of the Coal Milling Operations to the Boiler ParametersCoal Mills in thermal power plant Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online This document discusses coal pulverization in power plants It covers various topics related to coal pulverizers including: Types of coal and reasons for pulverizing coal like improved efficiency and combustion controlCoal Mills in Thermal Power Plant PDF Mill (Grinding) Scribd

.jpg)

Energy Balance of a CoalFired Power Plant in Condensing Operation

2013年6月1日 Coal feeder is the main equipment in steam power plant which serves to adjust the flow rate of coal coming into the mill to be crushed Disturbance in one of the coal feeder makes Pulverizer/Mill Pulverised Coal, Primary Air, Mill Differential Pressure, Fitness Function, Raw Coal 1 INTRODUCTION In coal fired power plants, pulverised coal (PF) flow from coal mills is to be measured accurately for maximising combustion efficiency Pulverised Coal Flow measurement in Thermal Power Plant2020年1月1日 A hot primaryair pipe system is the bridge connecting an airpreheater with a coal mill in power generation stations The fl ow resistance of the system has an extremely important effect on the CFDBased Optimization of Hot PrimaryAir Pipe 2011年12月31日 Dual drums head actuations Fig3 Head and tail actuations 1 actuation drums one; 2 coupling; 3 peed reducer; 4 motor; 5 fluid coupling; 6 actuations drum twoOperation and Maintenance of Coal Handling

Derivation and validation of a coal mill model for control

2012年5月1日 Coal fired power plants are heavily used due to large and long lasting coal resources compared with oil or natural gas An important bottleneck in the operation of this particular kind of plants, however, is the coal pulverization process, which gives rise to slow takeup rates and frequent plant shutdowns (Rees Fan, 2003)In typical coal fired power plants, 2015年5月7日 4 INDEX NAME OF THE TOPIC PAGENO List of the figures i List of the tables iii Abstract iv Introduction v About Dr NTTPS vi The Process of Power Generation vii CHAPTER1GENERALLAYOUTBASICIDEA 11 Introduction 1 12 Fuel Ash Circuit 2 13 Air and Gas Circuit 2 14 Feed Water And Steam Circuit 2 15 Cooling Water Circuit 3 16 Measurement STUDY OF VARIOUS SYSTEMS IN 500MW THERMAL POWER PLANT2009年9月20日 The ball tube mill requires less mass flow rate of primary air and raw coal per MW of power produced than the bowl mill It contains larger mass of raw and pulverized coal but less grinding heat Modeling and Parameter Identification of Coal Mill2020年4月2日 Milling system in coal power plant purposely to process the raw coal to become as pulverise fuel before enter to the boiler furnace Pulverise fuel enter to the boiler furnace through pulverise Analysis of the Coal Milling Operations to the Boiler Parameters

Effect of Ash in Coal on the Performance of Coal Fired Thermal Power

2006年1月1日 This article reports the effect of ash content in raw coal on the energy performance of coal fired thermal power plants of capacity range 30–500 MWEconomizer sends water to the Boiler Boiler is the main part of any thermal power plant It is used to convert water into steam In any steam power plant water tube boiler is used It contains furnace inside the boiler shell The Coal burns into this section Drum is Thermal Power Plant : Principle, Parts, Working Mech4studyTypical plant water scheme for 2 x 500MW coal based thermal power plant Fly AshDry + Emergency HCSD, Bottom ash –wet with ash water recovery CEATETDAS02 Typical flow diagram for raw water PT plant for 2 x 500MW coal based thermal power plant CEATETDAS03 Typical flow diagram for DM plant for 2 x 500MW coal based thermal power plantSTANDARD DESIGN CRITERIA/ GUIDELINES FOR BALANCE OF PLANT 2023年7月9日 Components of Thermal Power Plant A thermal power plant generates electricity In addition to generating electricity, certain thermal power plants are designed to generate heat for industrial purposes, such as district Thermal Power Plant: Diagram, Layout, Working

Operation and Maintenance of Coal Handling System in Thermal Power Plant

2011年1月1日 The interlock and protection of belt conveyor At coal handling system in thermal power plant have interlock the equipment which can avoid equipment bad sequence startup interlock ,every equipment work according to sequence rule startup so 2035Lihua ZHAO and Yin LIN / Procedia Engineering 26 In thermal power plant each boiler uses pulverized coal as main fuel for combustion High performance bowl mil ls of bowl size 80” are used for pulverizing the coal to requiredDesign and Modify of Mill Discharge Valve Using in Thermal Power Plant 2018年5月2日 Primary air inlet pressure: kPa: 9: MILLOUTTEMP: Temperature of pulverized fuel °C: 10: PAIRFLOWDMD: Primary air flow demand: Nm 3 /h: 11: PAIRFLOWBIAS: Rees N, Fan F Modeling and control of pulverized fuel coal mills in Thermal power plant simulation and controlDetection of Malfunctions and Abnormal Working Conditions of a Coal Mill2015年1月1日 Thermal Power Plant presents practical content on coal, gas, oil, peat and biomassfueled thermal power plants, with chapters in steam power plant systems, start up and shut down, and Thermal Power Plant: Design and Operation ResearchGate

Effects of Coal Based Thermal Power Plant in India ResearchGate

2021年5月25日 This paper analysed the impact of air pollution and plant effluents due to the operation of coal based power plant in the surrounding area Thermal power plant is the huge emitter of carbon Fig 3 Variation of mass flow of raw coal and primary air flow with time 15 35 30 Mass flow rate of coal (kg/second) Primary air differential pressure (mbar) 0 25 20 15 10 wret wpc 10 5 5 0 0 0 500 1000 1500 2000 Time (seconds) 2500 3000 0 (PDF) Modeling and Control of Coal Mill AcademiaThermalbased power plants can produce electricity from coal or other fuel sources The coalfired process requires three different steps to turn energy released from burning coal to generating electricity for consumption Coal fired power plants, while producing power, require a lot of water and produce a lot of pollutants like ash and CO2 Learn how the process works as well as How Does a Coal Power Plant Work? Bright Hub Engineering2015年8月23日 Announcing a new record of 267% power conversion efficiency for silicon solar cells [18] sounds impressive to an expert, but for nonexperts, these values are deficient in comparison to reported Thermal efficiency of coalfired power plants: From theoretical to

To Improve Thermal Efficiency of 27mw Coal Fired Power Plant

Wet flue gas loss loss due to moisture in fuel due to moisture formed by combustion of H 2 in fuel 6 Radiation Unaccounted losses (Dr VK Sethi,2011) III MAJOR ENERGY SAVING POTENTIAL AREAS IN THERMAL POWER PLANT Thermal power plant is designated sector as per EC act 2001 Most thermal power plant uses 3040% of energy value of primary