Limestone Crusher Smelting Waste Slag Crushing

.jpg)

11192 Crushed Stone Processing and Pulverized Mineral Processing

Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl, marble, shell, 2013年3月1日 This research study was conducted to evaluate the effect of quantity of steel slag on the mechanical properties of blended mixes with crushed limestone aggregates, which Evaluation of steel slag and crushed limestone mixtures as 2003年3月1日 The durability performance of both steel slag and crushed limestone aggregate concretes was evaluated by assessing water permeability, pulse velocity, dimensional stability Comparison of properties of steel slag and crushed limestone A crusher in the lab was used to make the steel slag in the same size like crushed limestone Different test were used to evaluate the physical, mechanical and chemical properties of the COMPARATIVE STUDY OF USING STEEL SLAG AGGREGATE AND

Limestone impact on properties, microstructure and CO

2024年10月10日 Utilizing industrial and urban solid wastes is crucial for developing lowcarbon cements This study proposes a novel method to integrate recycled glass and blast furnace durability of steel slag cement concrete is better than the same for crushed limestone aggregate Therefore, a thorough evaluation is necessary before using any waste material as aggregate EFFECT OF USING STEEL SLAG AGGREGATE ON MECHANICAL The following lists the inputs and outputs for limestone and other crushed rock mining and processing Key inputs and outputs are: Inputs Electricity Fuels Water Outputs Dust Waste Limestone and Crushed Rock Department of Energy‘slag’ generally refers to ground, granulated, iron blast furnace slag – with the descriptors to be explained and developed in this technical note In a general sense, the term ‘slag’ refers to a Ground Slag Properties, Characterisation and Uses

Limestone Crushing Process JXSC Mineral

The limestone crushing process involves several stages, each with specific machinery and equipment The typical limestone crushing process is Primary Crushing > Secondary Molten slag is carried outside and poured into a dump The general term slag may be a byproduct or coproduct of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced [1] Slag is mainly a Slag WikipediaStay tuned for more exciting posts about crushing equipment! What Is A Limestone Crusher And What Are Its Uses? A limestone crusher is essentially a heavily built machine designed to reduce large rocks and stones, such as Limestone Crusher: What Is It How Does It Work?Slag Crushing Machine is a robust industrial apparatus designed to break down and process slag, a byproduct of metal smelting, into it efficiently reduces bulky slag materials, enhancing the recycling process and minimizing waste Slag Crushing Machine Prices, Manufacturers Sellers

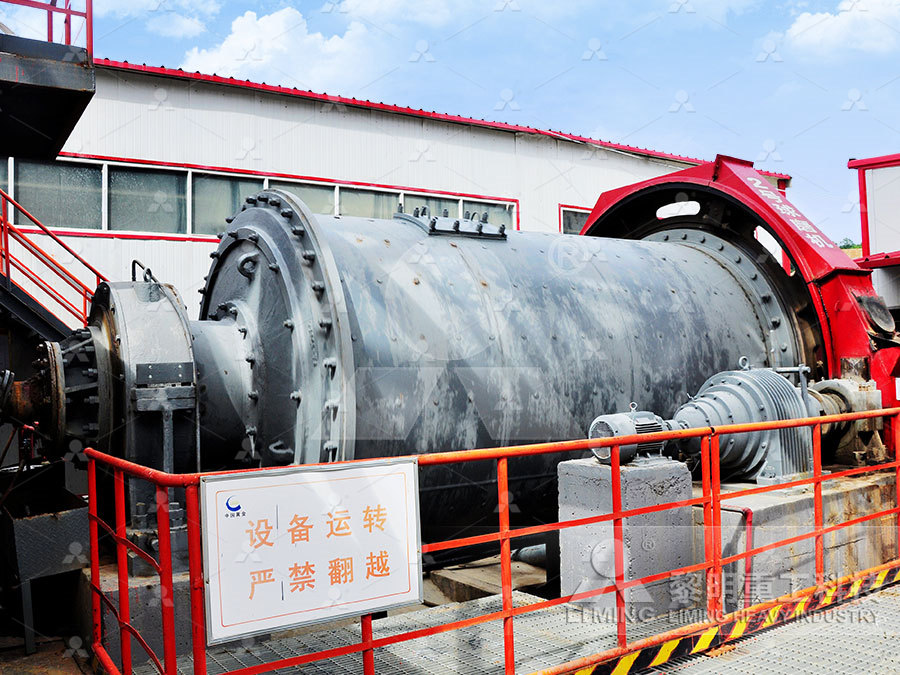

Slag Crushing Plant CM Mining Machinery

2022年12月15日 Slag is actually a byproduct generated during manufacturing of pig iron and steelSteel slag could be the discharged waste in steelmaking process and it truly is an industrial solid waste Slag crushing plant is widely used for crushing especially slag, stone, refractory material, glass, coal many other products 2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding process2024年2月2日 The brick slag crushing and sand making has good development prospects If you want to invest in brick slag crushing plants, crusher equipment is the key Currently, there are two main types of equipment available for brick slag crushing: fixed crushers and mobile crushers 1 Fixed brick slag crushing plantConstruction Brick Slag Crushing And Recycling Plant2023年11月10日 Impact crusher PF1315 is a crushing equipment that uses impact energy to line can be used for aggregate and artificial sand making operations of hard limestone, granite, basalt, river pebbles, smelting slag and other hydropower projects, construction waste crushing and other mobile stone operations People Also Impact crusher PF1315 Aggregate Rock Crushing Equipment

Slag Crushing Plant Track Mounted Mobile Slag Crusher Machine

This project helps a customer complete a slag crusher plant with an output of 100t/h Limestone Crushing Plant; Granite Crushing Plant; Projects Menu Toggle 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; 200t/h River 2015年6月16日 Sizing a crusher can be done reliably calculated thanks to the Impact/Crushing Work Index and the testwork research done by Fred Chester Bond and his 1952 paper According to Bond’s Third Theory of Comminution, the work/energy input is proportional to the new crack tip length created during particle breakage and equivalent to the work represented by the product Bond Impact Crushing Work Index Procedure and Table of Crushability Steel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipmentSteel Slag Processing SHANGHAI SANME MINING MACHINERY 2024年1月11日 Equipment Configuration Of Limestone SandMaking Plant The equipment for the limestone sand production line mainly includes a vibrating feeder, jaw crusher, sand making machine, circular vibrating screen, sand Limestone Crushing And SandMaking Plant

Review on the innovative uses of steel slag for waste minimization

2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Crushing Limestone to a 1¼" Product A RM 120X crushes limestone in Brazil feeding 2 ft x 2 ft blast rock producing a 1¼" spec product We can crush hard limestone with an impact crusher Occationally, limestone can be very hard Crushing Limestone Impact Jaw Crushers2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industriesAt present, there are two types of stone crushing machines commonly used: mobile stone crushers and stationary stone crusher equipment Stationary crushers include jaw crushers, impact crushers, hammer crushers, Rock Crusher Eastman Rock Crusher

Steel Slag Processing Plant Equipment Selection Eastman Rock Crusher

2023年12月27日 Steel slag uniformly enters the jaw crusher through a vibrating feeder for coarse crushing treatment After coarse crushing, the steel slag enters the vibrating screen for screening into materials of different particle sizes If it does not meet the particle size requirements, the materials will return to the crusher machine for crushing2024年6月28日 Wide application: Suitable for both dry and wet crushing, for materials with up to 15% moisture Onetime forming: Eliminates the need for primary and secondary crushing, reducing costs by approximately 40% Large feed opening: Handles feed sizes up to 1000 mm, making it ideal for coarse crushing Nonclogging: Designed to ensure smooth flow of high What Crusher Should You Choose for Primary Crushing?2023年8月1日 In this study, the energy and exergy of the organic Rankine cycle driven by steel slag waste heat and solar energy were analyzed for various system configurations In the system design, the technology of crushing waste heat pressurized hot smothering technology of steel slag rolls was considered Subsequently, a regenerator was integrated into this system The heat Energy and exergy analysis of waste heat recovery from SpringerDownload scientific diagram Particle size distribution of raw materials including limestone powder, tailing A, tailings B, and cement from publication: Effect of Incorporating Waste Limestone Particle size distribution of raw materials including limestone

Crusher,Mobile crusher,Crusher Machine YIFAN Mining Crushing

CJ jaw crusher is the latest research and development of limestone, sandstone, coke, coal gangue, raw coal, gypsum, slag, coke Yifan Machinery stone crushing equipment Large than small jaw crusher jaw crusher broken than the larger, higher yields lower cost advantage, welcomed the consultationAIMIX offers stone crusher Indonesia for the processing of rocks, pebbles, and limestone, and secondly for mining, smelting, building materials, road, railroad, water, and chemical industries, etc Additionally, we can also provide you with a special stonecrushing plant for the processing of construction waste, which can be cleverly reusedStone Crusher Indonesia Crushing Pebbles, Basalt, CobblestoneElectric furnace slag is a solid waste discharged from the process of metal smelting by electric furnace, and its main components are oxides such as calcium, iron, copper, silicon, magnesium, aluminum, manganese, and phosphorus The common ones are steelmaking electric slag and coppersmelting electric slag At present, environmental protection isWhat kind of crusher is needed to process electric furnace slag?Limestone generally adopts dry crushing process For metallurgical and construction use limestone, only the ore needs to be crushed and screened If you want to further produce fine powder limestone products, use a jaw Limestone Crushing Solution Eastman Rock Crusher

.jpg)

Mobile Hammer Crusher PC800X600 Hammer Mill for Rock Brick, Limestone

The Hammer Crusher as one of the most popular stonecrushing equipment in the world, it is ideally suitable for primary and secondary crushing The Hammer Crusher is widely used in mining, smelting, building materials, roads, railways, water conservancy, chemical industry and many other departments, meanwhile all kinds of materialsWe always 2023年2月14日 Discover the latest technologies and best practices in the limestone crushing industry to increase efficiency and improve the quality of the final product 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; 100t/h Slag Mobile Crushing Plant; Blog; About; Contact Us +86 Optimized Limestone Crushing Process for Increased Efficiency2019年11月4日 The compressive strength of limestone is generally around 150 MPa, which belongs to soft rock The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energysaving performanceLimestone Rock Crushing Flow Price JXSC MachineThere slag crusher jaw crusher, impact crusher, cone crusher, mobile crusher There slag mill ball mill, Raymond mill, vertical mill, jet mill and so on Kefid machinery is a professional production crusher and milling machine manufacturers, and its products have been exported to the world more than 180 countries and regionsSteel Slag Crusher and Grinding Mill Mining, Crushing,

The SPL Waste Management Challenge in Primary Aluminum

2021年3月16日 By Alton Tabereaux, Contributing Editor Spent potlining (SPL) disposal is one of the largest environmental waste management challenges confronting worldwide primary aluminum smelters due to its toxicity The International Aluminium Institute (IAI) asserts that 16 million tons of SPL were generated from primary aluminum production in 2019,1 making it the 2003年3月1日 Up to now, the main methods of using steel slag were used as sinter material, hot metal dephosphorizing agent, waste water treatment materials, reclamation of waste steel, concrete admixtures, CO2 Comparison of properties of steel slag and crushed limestone aggregate Slag Crusher offered is used for crushing stag that is produced during smelting process through different processed applied in production Slag in metals is present as form of undesired impurities at time of smelting which float to top in form of protective crust of oxides on top of metal being smelted, thus protecting liquid metal under itISC Machines Pvt Ltd Slag Crusher IndiaMART2023年3月27日 Limestone crushing is an essential part of the mining and construction industry Cone crusher parts are used for this purpose, and they come in various sizes and configurations to match different applications Do’s Don’ts Of Limestone Rock Crushing Mellott

Using SteelSmelting Slag as a Raw Material Component in the

Using SteelSmelting Slag as a Raw Material Component in the Production of Asphalt Concrete Dmitry Kuznetsov1*, Marina Vysotskaya1, and Albert Burgonutdinov2 1Belgorod State Technological University VG Shukhov, Kostukova str, 46, , Belgorod, Russia 2 Perm National Research Polytechnic University, Komsomolsky Prospect, 29, , Perm, Russia2024年10月9日 Slag, a byproduct of metal smelting processes, is produced in large quantities by steel mills, foundries, and other metalworking industries While once considered waste, slag is now recognized as a valuable resource due to its potential applications in construction, road building, and other industries Stationary recycling crusher plants for slag play a crucial role in Stationary Recycling Crusher Plants for SlagOur Location Plot No 8, Sudarshan Nagar 100 Ft Road, Near Hanuman Mandir Amritsar, Pb IndiaSlag Crusher Plant Manufacturer India Slag Crusher Machine2024年3月12日 Steel slag (SS), a waste product of steel manufacturing, After the initial crushing by a jaw crusher, the steel slag is reduced to a size smaller than 60 mm replacing traditional limestone to improve smelting efficiency and recover a large amount of metal iron and other useful elementsSteel Slag Recycling: The Definitive Processing Solution

Rock Crushers Pulverizers Williams Crusher

Once in the crusher, the material is broken down using a breaker plate and grinding chamber The reduced rock exits the crusher via a conveyor belt or is discharged into a hopper In some applications, primary crushing alone can suffice However, primary crushing is often followed by secondary crushing and tertiary crushing2020年2月10日 There are mainly three steps of crushing, washing and screening in the artificial sand manufacturing process The crusher machines of the crushing step may employ use jaw crusher, impact crusher, cone crushing, hammer crusher, sand maker The artificial sand size different, the crushing equipment is differentArtificial Sand Manufacturing Process Eastman Rock CrusherLimestone Crusher for Efficient Limestone Crushing Plant Limestone is a versatile nonmetallic mineral with widespread applications in construction, agriculture, environmental protection and more As the primary raw material for cement production, reliable limestone supplies are critical for sustainable infrastructure development globallyLimestone Crusher for Efficient Limestone Crushing PlantThe Williams Reversible Nuggetizer® Crusher (US Patent No 3,667,694) is a rugged primary, singlestage impact crusher capable of a broad range of crushing applications including cement, rock, limestone, coal, concrete, and other mineralsThese mills are also often used for various types of automotive and metal scrap Reversible Nuggetizer Rock Crusher Features:Cement Limestone Rock Crusher Reversible Nuggetizer Crusher

.jpg)

Crushing in Mineral Processing 911Metallurgist

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface