Pulverizing processing Preparation work

How to Process Coal into Pulverized Coal in 5 Steps?

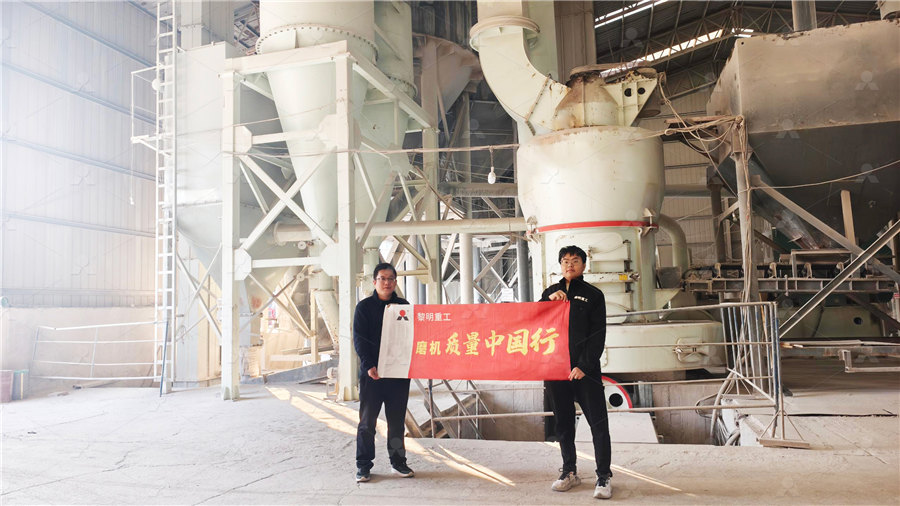

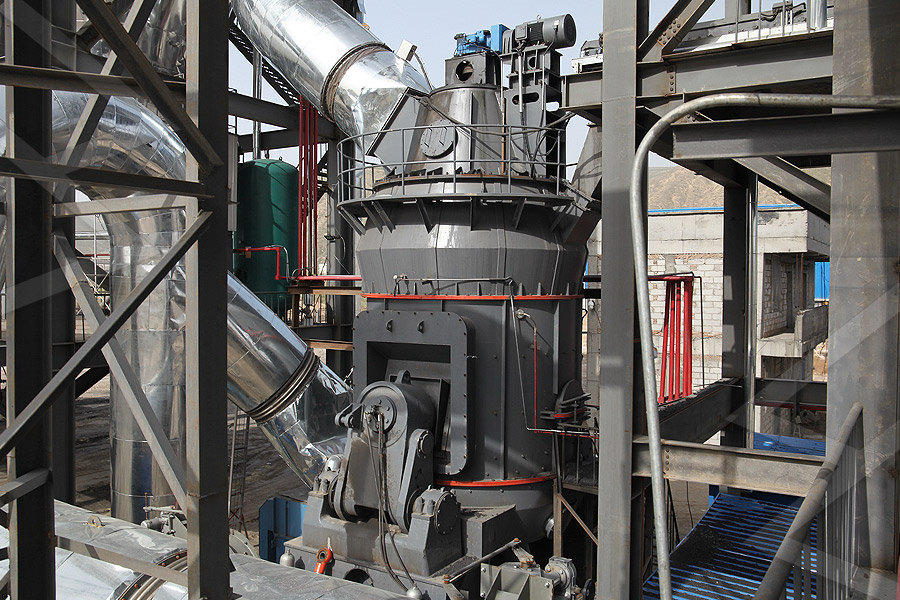

2024年1月11日 The process of pulverizing coal involves several steps Each of these is essential to effectively and safely produce a fine powder that burns easily FTM Machinery, in this post, explains how to process coal into Pulverization refers to the process in which metal hydride alloy particles crack and disintegrate into smaller particles due to repeated adsorption and desorption of hydrogen atoms, induced Pulverization an overview ScienceDirect Topics2019年10月31日 Pulverization may be classified into rough, medium, small crushing, coarse, fine, and ultrafine grinding Thinky Corporation has developed a rotation and revolution nano Pulverization 2: Pulverization method and pulverizer THINKY MIXERAbstract: A pulverized coal processing system for producing coal powder used in aluminum alloy smelting process was introduced The explosibility of the coal used in the system was Coal Pulverization System: Explosion Prevention and Process Control

Air impact pulverization–precise classification process to support

2017年8月1日 Ultraclean coal with 140% ash content is prepared through precise classification The pulverization effect mainly comes from airflow kinetic energy transformation 13 行 These models use various process parameters such as the current, inlet pressure, pressure difference, inlet/outlet temperatures along with the vibration signal as the inputs Coal Pulverizers an overview ScienceDirect Topics2024年1月1日 Pulverized coal injection of blast furnace ironmaking is a smelting technology where pulverized coal is directly blown into the blast furnace hearth from the tuyere to replace Pulverized Coal Injection of Blast Furnace Ironmaking2021年11月4日 This study presents the development and application of an attrition test machine that enables an investigation of the factors that influence pulverizing efficiency The attrition tester simulates grinding conditions in real Technique to Investigate Pulverizing and Abrasive

.jpg)

Sample Preparation for Fire Assay 911Metallurgist

2016年11月18日 The samplegrinders, resembling coffee mills, sold by makers of mining machinery, are more widely used Such machines are adopted at large smelting or sampling works, where great numbers of samples are crushed daily In smaller works or offices the buckboard (Fig 93) is most suitable2015年9月30日 What is xray fluorescence and why is XRF sample preparation is important for correct XRF analysis This is a little introduction to some of our instruments; from left to right we have the XMET7000 series these hand held XRF Sample Preparation Methods/ProcedurePULVERIZING MACHINE WITH TRADITIONAL PROCESSING TECHNIQUE IN NIGERIA Y Yerima1; *S E Uwadiae2; and EMTuru3 Department of Chemical Engineering, Igbinedion University, Okada1,2 Department of Chemistry, KSCOE, Gidan Waya, kafanchan Email: mailyerima@yahoo1,3 and suwadiae@yahoo2 ABSTRACTComparative Performance Evaluation of Intermediate Ginger Pulverizing 2009年1月1日 There is a rich and long history of magnetite ore processing in Western countries, Site preparation and improvements 2 098 103 2 083 927 1 885 881 1 862 409 In this work, the purpose was Processing of Magnetite Iron Ores–Comparing Grinding Options

What is pulverizer and how does it work Huibang Machine

2021年5月19日 How Pulverizer Work Pulverizers process materials in batches or continuously by accepting incoming material, often on a conveyor, rotating it and pressing a crushing into it, then sending it out They may also cool, heat, or aerate material as it exits2021年11月4日 The operating costs of breaking coal particles into fine powder, to achieve optimum combustion for the boilers in a power plant, are made up of power input to carry on an energy intensive comminution mechanism and to overcome friction losses within pulverising machines The operating costs also include the cost of the replacement of the processing Technique to Investigate Pulverizing and Abrasive Performance further laboratory sample preparation techniques Laboratory or analytical samples must be processed into a form which allows for extraction or digestion ultimately for an analytical instrument or chemical testing Sample processing involves reducing the material size to ensure samples for homogeneity and extraction into a suitablePrinciples of Sample Preparation by Grinding or Comminution2022年9月22日 Land preparation is a necessary activity that cannot be avoided, thus if it is to be carried out, it must be done correctly and effectively Farmwella continually hosts a bootcamp to train farmers on how to set up their farms, including land preparation In this bootcamp, we will walk farmers through realistic and practical actions they can take to set up a profitable farmLand Preparation; Methods, Steps, and Factors to Consider

Molinos pulverizadores de laboratorio RETSCH

High throughput: Streamlined sample preparation with fast, efficient pulverizing Expert Support: Benefit from RETSCH’s expertise, assisting you in selecting the perfect mill for your application and providing ongoing support Have a look at our company video for Video credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and hardness of feed must be considered; Output size ranges; Mills can handle dry or wet input, or both; Mills operate in batches or continuouslyGrinding Mills and Pulverizers Selection Guide: Types, Features Animal feed processing plays a vital role in the farming industry This complex and sophisticated system encompasses several steps and technologies From the selection of raw materials to the processing of the final product, each link in the feed processing flow carries important functions and responsibilitiesAnimal Feed Processing Techniques and EquipmentAll forces used in the pulverizing process are transmitted to the foundation via the gear reducer and loading elements The pendulum movement of the roller wheels provides a freedom for wheels to move in a radial direction, which results in no radial loading against the mill housing during the pulverizing processPulverizer Wikipedia

Indian Traditional Foods: Preparation, Processing and Nutrition

2019年10月19日 Studies on preparation of curry leaf (Murraya koenigii L) chutney powder Journal of Food Service, 14(3), 175–187 Google Scholar Banerji, A, Anthanarayan, L, Lele, S (2017) Rheological and nutritional studied of amaranth enriched chapatti (Indian flat bread) Journal of Food Processing and Preservation, 42(1), 1–8High throughput: Streamlined sample preparation with fast, efficient pulverizing Expert Support: Benefit from RETSCH’s expertise, assisting you in selecting the perfect mill for your application and providing ongoing support Have a look at our company video for Retsch : Retsch : 제품 : Pulverizer Mills2021年5月11日 The modernday coal processing plants can be categorized into four different circuits, depending upon the size of the coal particles to be treated: (a) coarse coal processing circuit treating particles coarser than 10 mm, (b) small coal circuit for washing particles in the size range of 110 mm, (c) fine coal circuit for cleaning particles in size range of 015–1 mm, and Mineral Beneficiation and Processing of Coal SpringerLinkThe processing of enset is traditionally a role for women, who act as a reservoir of knowledge about the techniques involved, but the tasks involved are laborintensive and tedious (Hunduma Ashenafi, 2011) The preparation of enset for processing is a Assessment and evaluation of Enset Processing Technologies

Pulverization 2: Pulverization method and pulverizer

2019年10月31日 Materials for which the rotation and revolution nanopulverizer has difficulty or no possibility of processing Based on the results of previous experiments, it has been found that Thinky’s rotation and revolution nanopulverizer has difficulty processing the following materials: – Elastic materials (resin, rubber, natural materials, etc)2016年1月1日 Mining processing plants widely use electric mechanic complexes with heavyload drive synchronous engines Starting orepulverizing mill drives may significantly affect the electric equipment (PDF) Forming mining processing plant orepulverizing milldrive Pulverization is the operation of reducing a solid material to powder for industrial or pharmaceutical processing or use It is the mechanical reduction of coarse pieces into smaller particles between 100 and 50 μm in size Pulverization or fine grinding has many advantages: homogeneous mixtures, and improvement of tolerability of preparations, extraction processes Pulverization FPS Food Pharma Systems2016年8月29日 This chapter describes the existing and emerging cassava processing technologies and utilization of cassava flour and starch Fresh cassava roots are subjected to size reduction operations like Cassava Flour and Starch: Processing Technology and Utilization

]@S0{UDKK%G24F3JGHC.jpg)

Laboratory Pulverizer Grinding Machine Sample

It is commonly used for sample preparation in XRF fluorescence spectrometer analysis The laboratory pulverizer is widely used in industries such as cement, steel and metallurgy, geological minerals, nonferrous metals, power plants, The work is almost the same but the way is slightly different Each and every machine has different intensity on which it works, it takes different amount of electricity and power Some need more and some need quite less depending upon the quality and nature of the raw materialsWhat Is Pulverizer and Its Main Uses In the Food Industry?Pulverizing bowl: also called pulverising mill grinding bowl, pulverizer grinding bowl It is a grinder that grinds coarse material into fine powder Qingdao Decent Group is a Chinese factory that provides fire assay equipment for mineral laboratories, laboratory sample preparation equipment, and designs and manufactures mobile container laboratoriesPulverizing Bowls Pulverizers Qingdao Decent GroupRecently some more works have also been done on the quality of surimi manufactured from freshwater fishes like silver carp [23, 24] Chowdhury et al, 2009a, Common carp [25] , LabeoSurimi powder: Processing technology and potential application

.jpg)

Cashew Nut Processing United Diversity

Cashew Nut Processing Intermediate Technology Development Group 2 Processing overview Traditionally, extraction of the kernel from the shell of the cashew nut has been a manual operation The nut is roasted which makes the shell brittle 2 Asphalt Pulverizing Pulverizing is similar to milling, in that a huge machine drives along the roadway, ripping up existing asphalt Unlike milling, pulverization is the first stage in reusing asphalt to repave the same area Pulverization leaves several inches of groundup asphalt where old asphalt paving used to be3 Asphalt Processes to Know: Milling, Pulverizing and StabilizationHigh precision and flexibility in pulverizing The operator has full control over the pulverizing process and can adjust all relevant machine parameters and process steps The rotation speed of the grinding vessel is continuously adjustable between 600 and 1500 rpm The temperature is constantly monitored and kept constant at target temperatureHerzog: HPMP Combined mill and pellet press2023年6月1日 In this work, considering the abovementioned advantages proved by previous works, we have developed a new pulverizing approach that integrated the SC, HD, and JM technologies into the preparation of Sm(CoFeCuZr) z sintered magnet We first used SC method to increase the degree of undercooling and uniformity of element distribution, which can help Combination strategy for highperformance Sm(CoFeCuZr) z

Coal Pulverization System: Explosion Prevention and Process

80 • Measurement + Control Vol 42/3 April 2009 instmcuk instmcuk Measurement + Control Vol 42/3 April 2009 • 81 Feature: Coal Pulverization System: Explosion Prevention and Process Control Coal Pulverization System: Explosion Prevention and Process Control Abstract: A pulverized coal processing system for produc ing coal powder used in HSN Code HSN Description Bread, pastry, cakes, biscuits and other bakers wares, whether or not containing cocoa; communion wafers, empty cachets of a kind suitable for pharmaceutical use, sealing wafers, rice paper and similar products other : pastries and cakes Bread, pastry, cakes, biscuits and other bakers wares, whether or not containing Jubiliant Food Works Ltd, Hyderabad Manufacturer of Micro In another work, the authors investigated the effect of different processing methods including drying pretreatment, boiling, steaming, and microwaving on the phytochemicals—total polyphenol content, radicalscavenging activity, total flavonoid content, total condensed tannin content, and antimicrobial activity—of the edible Irish seaweed H elongataAn Overview on Effects of Processing on the Nutritional Content The Stedman Testing and Toll Processing Facility is the place to test your material in our full size equipment If it can be crushed, ground, pulverized or mixed, chances are we’ve done it We have more than 10,000 test reports to Cage Mill Crushers Industrial Pulverizing Equipment

How does a pulverizer work? LKMixer LINKER

How does grinder work? Simply speaking, into the grinding ring raceway, and is impacted, rolled and ground by the ring roller After three layers of raceway processing, the material becomes powder Ingredients usually need to be 2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica2024年9月29日 Pulverization is the process of processing large raw materials into fine particles or powders in preparation for subsequent granulation and tabletting You need to consider the hardness, moisture content, and physical properties of the raw material when selecting pulverizing equipment to ensure uniformity and flow of the final granulesTablet Pressing: Pharmaceutical Pulverizing and Granulating 2020年11月25日 For weld preparation, start with a less coarse option and increase in aggression only as necessary With heavier coatings and mill scale, the best option is usually a grinding wheel or a flap disc Flap discs are commonly used in weld preparation because they are easy to control and you can grind, finish, and blend all at once5 steps for proper weld preparation The Fabricator

.jpg)

What Is The Difference Between Grinding And Pulverizing? 4 Key

Understanding the difference between grinding and pulverizing is crucial for anyone involved in material processing These two methods, while similar in purpose, use different techniques to achieve their goals 4 Key Points Explained: Grinding vs Pulverizing 1 Mechanisms and MethodsM220 – The “Scientist Standard” for single tube processing; Midthroughput Focusedultrasonicators Close; ME220 – Compact 1 to 8 sample batch processing; ML230 – Parallel sample processing, up to 8 samples; E220evolution – High power, 1 to 8 sample batch processing; E220 – High power, 1 to 96 sample batch preparation systemDry Cryopulverization Workflow CovarisFood processing is one of the oldest industries on earth: as long as humans have produced food, we have needed methods to process it for optimized nutrition, longer storage life, and improved flavor Some of the most fundamental food processing methods can be found anywhere from an open campfire to an industrial scale processing facilityImportant Processes for Food Processing and PackagingNOPA Unlocking the Power of the Seed SOYBEAN PROCESSING 101 ISSUES OVERVIEW SOYBEAN PROCESSING FLOWCHART MAP OF PROCESSING PLANTS LOOSE, GROUND, OR PELLETED HULLS OIL DISTILLATION GRINDING NOTE: The National Oilseed Processors Association (NOPA) represents the US soybean, canola, ˜axseed, sun˜ower seed and SOYBEAN PROCESSING FLOWCHART NOPA