HOME→Calcium carbide mud medium speed mill positive pressure direct blowing coal mill structure diagram

Calcium carbide mud medium speed mill positive pressure direct blowing coal mill structure diagram

Modeling of a medium speed coal mill ScienceDirect

2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China They are designed and manufactured by the German company Babcock This kind of 2017年6月1日 Positivepressure, directfired pulverizing systems with mediumspeed mills are widely used in coalfired power plants in China; these systems are typical threeinput, three Optimization control of a pulverizing system on the basis of the 2022年2月1日 The aim of this paper is to: (i) propose a new type of calcium carbide production method and analyze the relationship between the input and output energy transfer and loss, Energy and exergy analysis of a new calcium carbideMediumspeed coal mills are widely used in thermal power plants and play an irreplaceable role in the pulverizing process This paper focuses on a positive pressure direct firing type of medium A Modeling and Optimizing Method for Electricity Current

.jpg)

Program Design and Calculation Example of Direct Fired

In this paper, based on the direct fired systems with medium speed mill, a common computing program of coal pulverizing system is written by Visual C++ 60 The program can In the pulverizing system of a coalfired power plant, the positive pressure direct blowing system of the cooled primary fan in the medium speed coal mill is adopted Each boiler is equipped $LUIRURDO0LOO IOPsciencemedium, provided the original work is properly cited Eur J Org Chem 2020 ,4339–4346 4339 ©2020TheAuthorsPublishedbyWileyVCHVerlagGmbHCoKGaA,Weinheim in good yields at Direct Exploitation of the Ethynyl Moiety in Calcium Carbide Two new models for predicting the reaction kinetics for the formation of calcium carbide (CaC2) from coalderived coke and calcium oxide (CaO), or lime, are proposed and compared to four A rotary kiln process for making calcium carbide

Direct Exploitation of the Ethynyl Moiety in Calcium Carbide

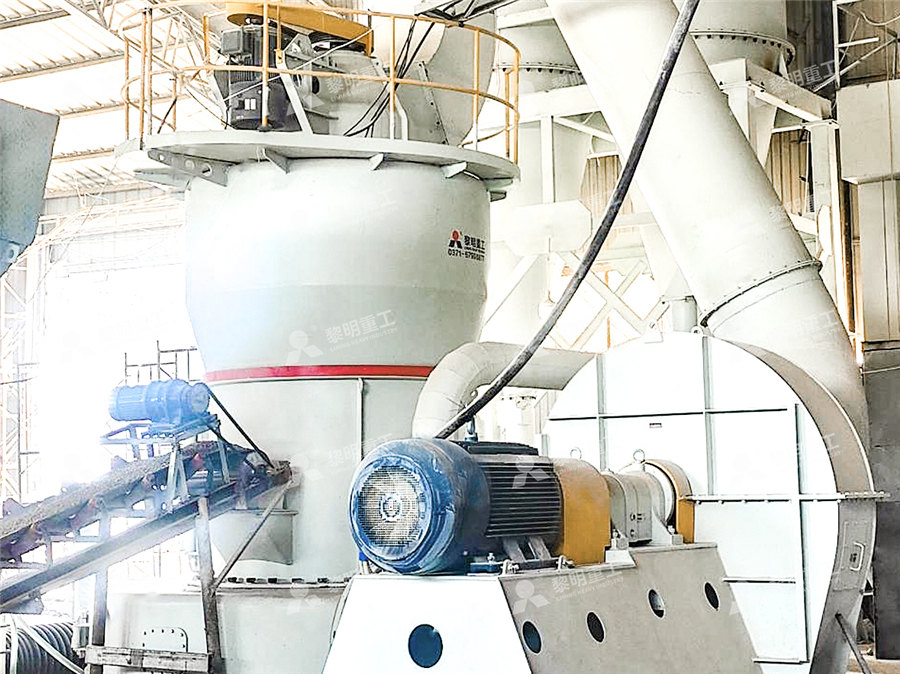

2020年5月29日 Ball milling of calcium carbide (CaC 2) enables the reaction of its ethynyl moiety with organic electrophiles This was realized simply by comilling CaC 2 with organic 2017年8月1日 China's energy structure (coal resources are rich, Shin et al established a dynamic model with two kinds of coal particles and a differential coal mill pressure; however, In this study, MPS180HPII medium speed coal mill is used as the research objectModeling of a medium speed coal mill ScienceDirect2021年8月1日 Fault analysis and optimization technology of HP bowl type medium speed coal mill August 2021; Journal of Physics Conference The boiler pulverizing system is of positive pressure direct bl Fault analysis and optimization technology of HP bowl type medium speed MTM trapezium mill is a new type of industrial mill designed on the basis of Raymond mill, creating a new mark post in the grinding mill industry The MTM Medium Speed Trapezium Mill is the world's leading industrial mill Feed particle size: 0 MTM Series Medium Speed Trapezium Mill

HP Series Medium Speed Bowl Mill

HPSeriesMediumSpeedBowlMill 703 Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online HP Series Medium Speed Bowl Mill is used to grind, dry and separate raw coal into qualified fineness for combustion in steam boilers It consists of a grinding bowl, grinding rollers, spring loading device and other components2022年2月1日 Although the energy consumption of producing calcium carbide by ETM is very high (~4000 kWh/tCaC 2), limited by the level of technological development, ETM is the only way to produce calcium carbide on a large scale for a long time [13]In order to reduce the energy consumption and pollutant emissions, many energy saving measures are adopted, such as Energy and exergy analysis of a new calcium carbide2022年5月1日 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coalbased CaC 2CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are generated annually in China, among which only a Recycling and utilization of calcium carbide slag ScienceDirect2024年10月29日 The production of one ton of calcium carbide results in the generation of about 12 tons of calcium carbide slag (CCS) [23] CCS can be utilised as a raw material for the production of cement, modified for use as a waterproofing material, Preparation and Performance Assessment of Calcium Carbide

Development of calcium coke for CaC2 production using calcium carbide

2020年9月21日 A type of calcium coke was developed for use in the oxythermal process of calcium carbide production The calcium coke was prepared by the copyrolysis of coking coal and calcium carbide slag, which is a solid waste generated from the chloralkali industry The characteristics of the calcium cokes under different conditions were analyzed experimentally CaC 2 Structure Let's look at the calcium carbide structure (image will be uploaded soon) Production of Calcium Carbide Calcium carbide is industrially produced in an electric arc furnace with a mixture of coke and lime, approximately at 2,200 °C (3,990 °F)Calcium Carbide – Structure, Production, Uses and FAQs Vedantu2016年2月1日 Electronm icroscopy images:AC) shallown anospheres that were prepared by using the AlCl 3 6H 2 O/CaC 2 system;DF) Carbon nanoonions that wereprepared by using the CuCl 2 2H 2 O/CaC 2 system (PDF) Calcium Carbide: A Unique Reagent for Organic2017年6月1日 The coal mill is assumed to be a lumped parameter object, and a calculation method based on the static heat balance of the coal mill calculates all heat input into or output from the coal mill quantitatively; however, a model of the coal mill has yet to be established on this basis (Feng et al, 1997, Ganapathy (2002), Magdalinović (1989))Optimization control of a pulverizing system on the basis of the

.jpg)

The structure of MPS mediumspeed coal mill system

Download scientific diagram The structure of MPS mediumspeed coal mill system from publication: Modeling of Coal Mill System Used for Fault Simulation Monitoring and diagnosis of coal mill 2023年10月19日 Industrial solid wastes red mud and calcium carbide slag are used to prepare lightweight aggregate ceramsite by coldbonded pelletizing technology in this study The effects of mixing water and curing method on the physical properties of ceramsite were investigated, including natural curing (in air at 20 °C), sealed curing, water curing, hot air oven curing, Investigation of various curing methods on the properties of red mud 2012年2月1日 Macrocellular porous silicon carbide foams were produced using a polycarbosilane preceramic polymer and a chemical blowing agent (azodicarbonamide)Silicon CarbideBased Foams From Direct Blowing of Polycarbosilane2022年11月21日 An important aspect in the case of AAM binders containing red mud is the leaching experiment An et al [169], in their work on RM and calcium carbide residue, performed this test after 28 days of curing The results presented by them showed that toxic heavy metal levels are below the acceptable limit, which proves their safety for the environmentStrength development and microstructure of sustainable

Efficient destruction of hexachlorobenzene by calcium carbide through

2017年1月1日 As shown in Fig 1, CaO and NaOH show negligible MCD capability for HCB with their dechlorination degree being only about 38% and 69%, respectively, after 12 h millingIn contrast, CaH 2 and CaC 2 show excellent dechlorination performance with their dechlorination degree being about 839% and 925%, respectively The dechlorination performance of the co 2024年1月5日 A mixture of calcium carbide residue and coal fly ash with a Ca/(SiO2 + Al2O3) ratio of 15 resulted in the highest compressive strength at long curing periods in both pastes and mortarsEvaluation of calcium carbide residue and fly ash as sustainable 2023年10月1日 Storing CO 2 in building materials is an effective way to utilizing CO 2 and mitigating climate change This study presents a new approach connecting the decarbonization of the coaltochemical industry with the production of CO 2 cured building materials This approach uses calcium carbide residue (CCR), a byproduct of the CaC 2toacetylene process, as an Carbon dioxide cured building materials as an approach to 2024年8月9日 Currently, the current focus of mud treatment research primarily centers on addressing issues such as oil drilling waste fluid, road and bridge waste mud, and the utilization of activated sludge resources [3], [4], [5]Treatment methodologies encompass a range of approaches including land tillage, chemical flocculation for solidliquid separation [6], [7], [8], Study on mechanical properties and microstructure of metakaolin

SHPHGLXP VSHHGFRDOPLOO ResearchGate

However, the faults of medium speed coal mill in power plant operation are also more prominent, The boiler pulverizing system is of positive pressure direct blowing type2024年10月15日 Carbide slag (CS) is a typical alkaline solid waste with Ca(OH) 2 as its main component, exhibiting a high capacity for CO 2 mineralization Currently, the methods for CS mineralization of CO 2 include direct and indirect mineralization which the initial pH of the reaction system plays a crucial role in the mineralization process In this study, we explored the effects Optimizing carbonation reaction parameters of calcium carbide 2017年8月1日 @article{Gao2017ModelingOA, title={Modeling of a medium speed coal mill}, author={Yaokui Gao and Deliang Zeng and Jizhen Liu}, journal={Powder Technology}, year={2017}, volume ={318 running in sliding pressure condition with a large load variation is constructed by means of the mechanism analysis and data fusion methods The Modeling of a medium speed coal mill Semantic Scholar2024年10月25日 Carbide residue is generated during the production of acetylene through calcium carbide hydrolysis, and it mainly consists of Ca(OH) 2, as indicated in Fig 4 The content of Ca(OH) 2 in carbide slag is 7013 % (calculated from the weight loss observed between 341 °C and 520 °C using TGA)Performances enhancing of supersulfated cement (SSC) using

Study on Preparation and Performance of Calcium Carbide Slag

2020年8月1日 Request PDF Study on Preparation and Performance of Calcium Carbide Slag Foam for Coal Mine Disaster Reduction and CO2 Storage In the process of coal mining, coal spontaneous combustion in the 2019年7月30日 Ground calcium carbide residue (GCCR) in dry condition had white and gray color and the color was changed to dark when it was in wet condition Another property of GCCR was water solubility The use of calcium carbide residue (CCR) facilitated hydration reaction and provided relatively high 7 days strengthEvaluation of compressive strength and resistance of chloride 2020年9月1日 Calcium carbide can be obtained by cyclic technology using lime (calcium carbonate and calcium oxide) and various sources constructing closed carbonneutral cycles is provided by atomeconomical Calcium Carbide: Versatile Synthetic Applications, Green Methodology 2017年5月1日 Download Citation Modeling of a medium speed coal mill This paper presents a coal mill model that considers the effect of coal moisture on its accuracy This mathematical model is derived Modeling of a medium speed coal mill ResearchGate

Investigation of various curing methods on the properties of red mud

2023年10月19日 Industrial solid wastes red mud and calcium carbide slag are used to prepare lightweight aggregate ceramsite by coldbonded pelletizing technology in this study The effects of mixing water and curing method on the physical properties of ceramsite were investigated, including natural curing (in air at 20 °C), sealed curing, water curing, hot air oven curing, 2022年12月1日 China's abundant coal resources are the raw materials for the production of many important chemicals, such as calcium carbideacetylene industry [1], [2]Currently, China is the largest producer and consumer of calcium carbide in the world, and the actual output of calcium carbide reached 2888 million tons in 2020 [3], [4]As one of the important basic Carboncalcium composite conversion of calcium carbide 2022年11月1日 Download Citation Strength development and microstructure of sustainable geopolymers made from alkaliactivated ground granulated blastfurnace slag, calcium carbide residue, and red mud Red Strength development and microstructure of sustainable 2021年12月20日 This study investigates the use of calcium carbide residue (CCR) as a potential alternative to NaOH for activating coal gangue (CG) geopolymers, both of industrial waste A series of experiments were carried out to evaluate the effects of CCR content, NaOH:Na 2 SiO 3 mass ratios, liquid to solid ratio (L/(CG + CCR)), and curing time on the strength development Experimental study on calcium carbide residue as a combined

.jpg)

CALCIUM CARBIDE SPECIFICATIONS EIGA

calcium carbide to be used for the production of acetylene 2 Scope and purpose 21 Scope Calcium carbide intended for the production of acetylene 22 Purpose To provide guidance to EIGA Member Companies when they specify calcium carbide for acetylene production 3 Definitions 31 Publications terminology 311 Shall2022年5月1日 A new coal gangue(CG) activation additive was studied in this paper, carbide slag(CS) was used as an auxiliary agent on the extraction of Al 2 O 3 from coal gangue activated by Na 2 CO 3 through acid leaching The dissolution rate of Al 2 O 3 was determined by Inductively Coupled PlasmaAtomic Emission Spectrometer(ICPAES) and calculated using Aluminum extraction from activated coal gangue with carbide slag2021年11月1日 In China, the calcium carbide and methane partial oxidation methods are used to produce acetylene, with the former being predominantly used China is the largest producer and consumer of calcium carbide worldwide, with 2018 output reaching 2608 million tons, 90% of which was used to produce polyvinyl chloride, 1,4butanediol, and vinyl acetate through Life cycle assessment of acetylene production from calcium carbide 2024年8月9日 Circulating fluidized bed fly ash (CFBFA) has similar pozzolanic activity to ordinary fly ash (FA) and the important characteristic of selfhardening, which has potential value as an auxiliary cementitious material [7], [8]Red mud (RM) is an industrial solid waste discharged during the extraction of alumina in the aluminum industry, with a pH of 10–13Synergistic activation mechanism and longterm properties of a

Physicochemical Characterizations and Desulfurization Properties

2009年5月21日 To recycle industrial wastes and reduce SO2 pollutant emission in coal combustion, the mineralogical compositions, porosity structures, surface morphologies, and desulfurization properties of Keywords: calcium oxidecontaining carbon pellets; calcium carbide; coking coal; compressive strength; pyrolysis furnace 1 Introduction Calcium carbide (CaC2), produced from the reaction of coke with CaO at temperatures above 2200°C, is an important chemical required to produce acetylene as well as acetPreparation of CaOcontaining carbon pellets from coking coal 2020年12月5日 Calcium carbide slag, silica micropowder and cement were ground with a planetary ball mill, respectively The results presented in Figs 1, 2 and 3 suggest that the particle size distribution of raw materials The raw materials dried in a vacuum drying oven at 40 ℃ for 48 h and then sealed with a sealing bag for later useStudy on Preparation and Performance of Calcium Carbide Slag 2020年5月5日 Coaldominated energy consumption structure in China will be difficult to change within a short period (Lin and Zhu, 2019)Coal burning releases a great deal of SO 2Although SO 2 emissions in China have been declining year by year, the SO 2 pollution remains as an important environmental problem, highlighting the necessity of better SO 2 emission control Preparation of a new highperformance calciumbased desulfurizer using

.jpg)

Pressure loss characteristics and calculation model of calcium carbide

2019年12月17日 Pressure loss characteristics and calculation model of calcium carbide sludge flow in a pipe December 2019 Advances in Mechanical Engineering 11(12):9213