Ore mill seal ring

Solutions for the mining, mineral processing and cement

SKF provides a large variety of customized seals for machines in the mining, mineral processing and cement industries, covering hydraulic seal kits with piston, rod and wiper seals, rotary Vertical grinding roller in the ore powder or coal powder inside the mill, it is difficult to seal, demanding, is also very important, both to prevent oil spills, but also to prevent dust intoHP coal mill oil sealSHANGHAI POF SEALS SOLUTIONS CO, LTDIn order to secure the stable operation of steel production equipment, JTEKT produces optimal oil seals that contribute to ensuring a favorable working environment where the equipment Oil Seal For Steel Production Equipment 株式会社ジェイテクトOrings are found everywhere within mining applications They are used to seal mating joints and prevent fluids from leaking out Orings are typically made of elastomeric materials resistant to Mining Sealing Solutions ESP International

Seal Systems for Mining Minerals Manufacturing

The specially engineered, fully interchangeable ear drive Oring seal head extends the functionality of the 5600 series product line for standard ANSI and large boreTrelleborg has been providing mill lining systems since 1920 The focus is on working with our customers to provide incremental improvement to enhance mill availability, increasing efficiency and reducing energy consumption Full lining Mill Lining Systems FluidHandling TrelleborgASG has the expertise to provide a custom solution to fit any industrial sealing requirement perfectly, from precision Orings to complex assemblies Many of the solutions we have STEEL MILL METAL PROCESSING High Quality Sealing Rings Heavyduty rotary seals, engineeredmolded parts and highperformance static seals, keep the mining truck operating efficiently They prevent contamination by mud, dirt and water, protecting components from abrasion and keeping Sealing Solutions for Mining Equipment Trelleborg

R)8OC`6F[ZIB.jpg)

Merkel Seals and Sealing Systems for the Metal Processing Industry

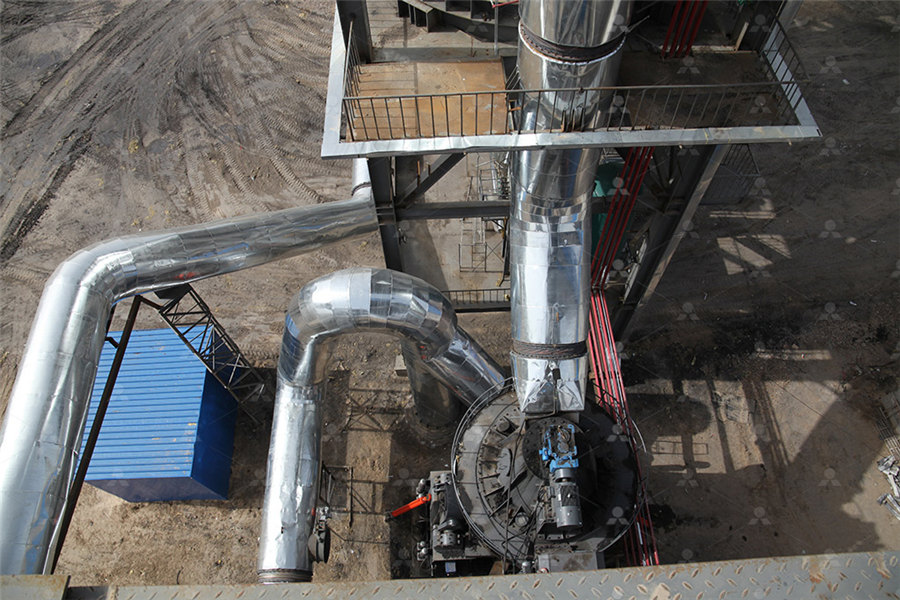

sealing elements using Finite Element Analysis and other modern design tools Our product range includes wipers, rod and piston seals, Simmerrings, swivel joint seals, guide and wear Upgrade your SAG mill feed chute seal M 1023 100012ENG V2 Product datasheet A proper seal makes all the difference in the way your SAG mill performs A relatively minor wear part, the feed chute seal affects performance, lifecycle and safety with your SAG mill – and the stakes are high should it happen to failProduct datasheet Upgrade your SAG mill feed chute seal2015年3月15日 For the grinding tests, a Loesche mill LM45 (table diameter 045 m) is used (Fig 2a) This pilot scale mill is a special development for ore grinding, which is reflected by several features The mill has four rollers, which are able to stress the particle bed with grinding pressures of up to 5000 kN/m 2Research of iron ore grinding in a verticalrollermillseal leaks leading to water ingression are intermittent and are therefore hard to detect A large Australian gold mine was experiencing problems with detection of seal failures on their large SAG Mill at the mine The seal failures resulted in large amounts of water and process ore being ingressed into the lubrication systemDetecting SAG Mill Seal Failures Pall Corporation

Sealing Solution for Birmingham Seals

BSCL Seals are present at all different stages in steel industry across the globe Start from iron ore processing till finished coils BSCL has been providing technically advanced seals solutions to meet the needs of applications in these industry BSCL involvement starts from applicationOil Seal Part Number System Global ORing and Seal’s oil seal part numbers are designed to describe the seal size, style, and material composition When searching for oil seals via our online store, you will not only be presented with your selection but Oil Seals More Global ORing and Sealtriple lip feed seal are available for each feed spout to maximize asset protection Comprehensive solution for ball mill feed ends to maximize mill availability while minimizing feed end leakages and material waste Scope of supply • Fabricated feed spout with separable lining • Sitespecific feed spout lining system • Feed seal arrangementGrinding services Ball mill feed spout MetsoThis in turn influences many subtasks in the design of an Oring seal, so that size standards make work easier in practice #5 Oring tables Two key dimensions define Orings from a geometric point of view: the diameter of the ring and the diameter of the circular crosssection (cord thickness, CS for short)ORing The Ultimate Guide Sealing Academy

Performance Pulverising Mill Bowls Chromatech

Essa traditional “ring and roller” style bowls are available in the smaller 50, 100, 125, (when used on an Essa mill) to reduce ores, minerals, metallurgical samples, ceramics, soils, aggregates, inexpensive and easily replaced polyurethane lid seal that prevents sample loss, reduces operator dust exposure and extends bowl lifeThe Essa Pulverising Mill range includes: Essa LM2 Pulverising Mill – the geochemistry industrystandard, a reliable ring mill that prepares up to 16 kg of mineral ore for analysis; Essa LM5 Pulverising Mill – used for pulverising larger sample size ores, the LM5 is particularly suited to the gold mining industry; Essa LM201 Pulverising Mill – a topoftherange vibratory mill suited to Essa Pulverising Mills FLSmidthBall Mill Trunnion Seal salonserenity Ball Mill Trunnion Seals Accinsa 28 jul 2015, the mill trunnion liner fits inside the bearing to protect it from wear caused by the ore being washed over the, part of the feed chute will be a seal between itself and the mill, trunnion bearing assembly ball mill rod mill learn moreBall mill felt sealBall mill felt seal,rod mill felt seal,no twist ball mill trunnion seals Welcome to Tables ThymeSpecial subsea retainers are also available that allow the seal ring to be fitted and removed by ROV, using a special tool that fits through the seal ring’s bore Orifice Seal Rings and Blinds Destec seal rings can be designed to incorporate orifice plates, chokes or blinds Large orifices requiring seals 200mm and above, wouldSEAL RINGS

.jpg)

芯片封装Seal ring CSDN博客

2024年5月14日 文章浏览阅读49k次,点赞8次,收藏48次。常见的seal ring会将工艺中所有的层都列出来,并标明 dark or clear,用这里的dark和clear去对照工艺制作过程中这些layer的dark或clear,如果同为dark或clear则seal ring上面有 Iron ore Limestone Coal Sintering machine Blast furnace Converter Continuous casting machines Seal inner ring Mogoil seal (MSNJ) Scale seal is combined with a seal inner ring to make the Mogoil Seal Block Mill Seal MSJ MSNJ MBNJ WRJ Oil Seal Water Seal V ring MS MSA HMSH HMSHJ XMHE MVAOil Seal For Steel Production Equipment 株式会社ジェイテクトVariously known as a Barrel Mill, a SwingMill, a Ring Mill or a Stone and Disc Mill, this highly efficient grinding machine comprises a steel vessel containing a solid steel bar (stone) and one or two steel rings, which oscillate with a rotary motion to grind materials from approximately 10 mm lumps down to powders finer than 50 micronsball mill ring2015年3月15日 The grinding parts of a Loesche mill (Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemBetween the working surfaces of track and rollers, particle bed comminution takes place A dynamic air separator (3) is located above the grinding chamber, Research of iron ore grinding in a verticalrollermill

Solutions for the mining, mineral processing and cement

SKF provides a large variety of customized seals for machines in the mining, mineral processing and cement industries, covering hydraulic seal kits with piston, rod and wiper seals, rotary seals, multilip seals and custom engineered solutions for a great variety of applications 7Iron ore Limestone Coal Sintering machine Blast furnace Converter Continuous casting machines Seal inner ring Mogoil seal (MSNJ) Scale seal is combined with a seal inner ring to make the Mogoil Seal Block Mill Seal MSJ MSNJ MBNJ WRJ Oil Seal Water Seal V ring MS MSA HMSH HMSHJ XMHE MVAOil Seal For Steel Production Equipment2020年3月1日 Fig 2 (a,b) highlights a region of the mill slide ring where cracks were detected This is the slide ring related to the fixed sliding bearing According to Silva [20], this is the region most vulnerable to damage due to the fact that there is no axial clearance between the slide ring and the bearing Fig 3 (a,b) presents a detail of the slide ring, showing part of one of the Failure analysis of a steel slide ring of a tubular ball mill used in Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH Ball mill is common used grinding plant in the for adopting new and wearproof materials to enhance crushing capacity as well as the extension of the roller and rings service life This Compare this product Remove from comparison tool roller Ore mill, Ore grinding mill All industrial manufacturers

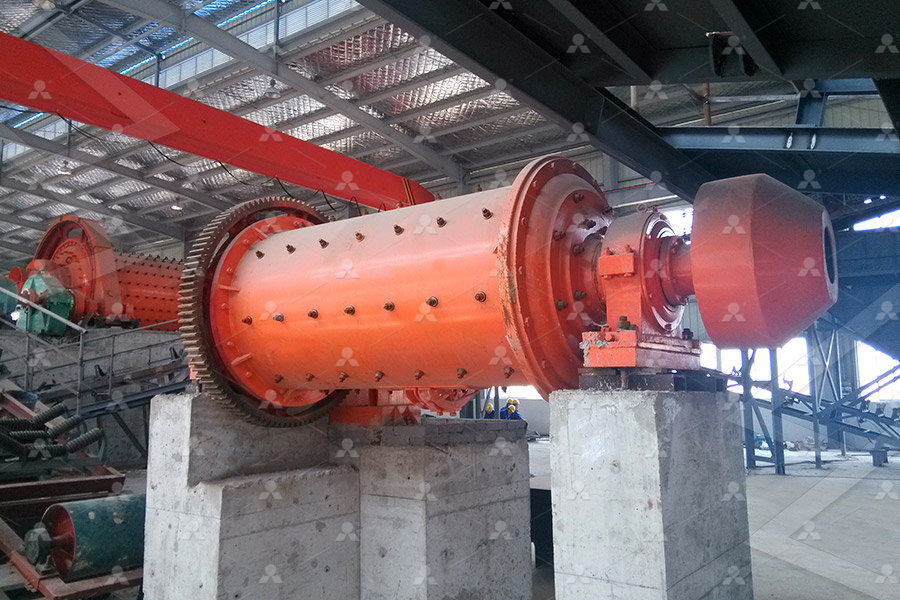

Failure analysis of a steel slide ring of a tubular ball mill used in

2020年3月1日 This work evaluated the root cause of an early failure occurring at one of the slide rings of a ball mill used in an iron ore mining plant The slide ring consists of an ASTM A516 G60 steel plate approximately 80 mm thick, welded together by three parts of its perimeterSuperior protection and easier alignment Multistage axial labyrinth cartridge seal – includes two labyrinth rings, an internal low friction Vring seal and provision for grease purging; Flinger action – the rotating labyrinth ring flings water away from the seal; Ingroove or bolton seal designs – for SKF split housings Seals can be customized for use with competitor housingsSKF Taconite SealIron ore Limestone Coal Sintering machine Blast furnace Converter Continuous casting machines Seal inner ring Mogoil seal (MSNJ) Scale seal is combined with a seal inner ring to make the Mogoil Seal Block Mill Seal MSJ MSNJ MBNJ WRJ Oil Seal Water Seal V ring MS MSA HMSH HMSHJ XMHE MVAOil Seal For Steel Production Equipment2015年7月28日 This ring is not joined to the bearing but sits on it loosely Because of the drag on the ring by the oil in the sump as the ring is revolved through it, and the lubrication of the oil between the ring and the bearing, the ring turns at a slower rate than the mill doesTrunnion Bearing Assembly Ball Mill Rod Mill 911Metallurgist

.jpg)

Ring gear drives huge grinding mill Machine Design

2000年3月1日 By this summer, a grinding mill that is bigger around than a Boeing 747 will turn chunks of copper ore into gravelsized bits for smelting and refining The largest ring gear 2015年7月28日 The Mill Trunnion Liner fits inside the bearing to protect it from wear caused by the ore being washed over the liner and through the bearing as it is fed to or discharged from the mill The difference in the trunnions at each end of the mill isn’t in the trunnions themselves The trunnion liner on the feed end of the mill may have a WORM to assist the ore into the millMill Trunnion Liner 911Metallurgist2016年2月2日 Check the ore slot feeder for obstruction or hang—ups Check the ball mill belt feeder for undue buildup of material Check oil level in ball mill lube oil tanks Also, check grease level in the mill ring gear spray lube drum Ensure that the plant air shutoff valves are open to the mill clutch and ring gear lube systemGrinding Circuit Startup and Shutdown ProcedureIncrease Mill availability to process more ore; Increase Mill operation time as a result of faster relining; Increase Life as per plant requirement; Tower II, Ring Rd, DP Block, Sector V, Bidhannagar, Kolkata, West Bengal India [ protected] +91 33 Tega DynaWear Rubber Mill Liner Manufacturer and Supplier

Turcon® Glyd Ring® Hydraulic Piston Seals Trelleborg

Turcon® Glyd Ring® is a doubleacting ORing energized piston seal for dynamic applications Turcon® Glyd Ring® provides low friction with no stickslip, minimal breakout force and high wear resistance Main application is actuator cylinders Installed in grooves to ISO 7425Loeschefor SIGSlip ring sealing Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses operation and maintenance of roller seals, including the sealing air system, roller maintenance, rocker arm maintenance, lever sealing maintenance, and table maintenance It also examines the condition of the SBI Nar 2 coal mill, including worn Loesche For SIG Slip Ring Sealing PDFThe Continuous Ring Mill is used for coarse or fine pulverising of large mineral samples, preparing samples for onstream analysis, dry or slurries 58 1 LID SEAL TOP DECK CRM CRM0509A0010 SEAL 59 1 CRM0500A0010 BRACKET PIVOT 510 1 CRM0F56A0010 BRACKET CLAMPING 511 1 SUPPORT ANTIRATTLE CONTINUOUS RING MILLThe Frontseal ® is an all elastomer axial seal for rotary shafts and bearings It rotates with the shaft and seals axially against a stationary counterface perpendicular to the shaft This type of seal has been used widely for several Frontseal VRings Dichta SA

.jpg)

Hydraulic Seals, Rotary Shaft Seals, ORings by

Trelleborg Sealing Solutions is a leading global supplier of sealing solutions Our range of products includes ORings, hydraulic seals, rotary shaft seals, oil seals, static seals, pneumatic seals, mechanical face seals and many more Find out 2023年9月20日 Global ORing and Seal offers over 50,000 unique oil seals with 215,000 crossreferenced part numbers for OEMs and Manufacturers To find a part you need, search for the OEM/Manufacturer part number alone, and the Oil Seals: Function Maintenance Global ORing Ball mill is a kind of grinding equipment for repulverizing primary crushed materials It is widely used in cement, construction, fertilizer, mineral processing, and other industries Ball mill grinder is used for dry or wet grinding of various ores and other grindable materials It mainly consists of a cylinder, end cover, lining plate, grinding media, and other parts5 Mustknow Ball Mill Parts And FunctionsAdd:Songjiang District, Shanghai Jing Jing Road, No 19, building 115 Zip code: Contacts:Miss Yang Tel:021| 021|HP coal mill oil sealSHANGHAI POF SEALS SOLUTIONS CO, LTD

Supply Ball Mill Seal Ring Wholesale Factory Shenyang Shilong

1 ShiLong ball mill seal ring Modle:ceramic ball mill seal ring , intermittent ball mill seal ring , over flow ball mill seal ring , lattice ball mill seal ring , wind discharge ball mill seal ring , double chamber ball mill seal ring , energysaving ball mill seal ring 2 ShiLong ball grinder mill seal ring Manufacturing Process: a drawing inspection > b wood type making > c casting KLOZURE™ Split Oil Seals are designed for easy installation around shafts, CHEVRON VRing Packing; Engineered Packing; USeals / Cups; Garlock KLOZURE® Model 26 Oil Seal, Split, MILLRIGHT BLACK, 2000 in Shaft, 2750 in Bore, 0375 in Width 245911972Split Oil Seals GarlockQuality Relaibility Performance Sealing Rings Seal rings are indispensable components in process pumps, safeguarding against leakage and ensuring seamless operations in industries from chemical processing to oil and gas production Krish Carbon leads the charge with its innovative carbon products, offering unparalleled performance and durability With meticulous Sealing Rings Krish Carbonused in combination with labyrinth seals Available for shaft diameters from 105 (135 for LX) to 2025 mm Profiles RME, RM and AX are heavy duty V — Rings that are designed primarily forlargehighspeed bearing arrangements, I E rolling mill and papermaking machine applications Additionally they can be used as secondaryRotary All Seals Inc

Silicon Carbide Seal Ring Advanced Ceramics Edgetech Industries

We provide Silicon Carbide Seal rings in the form of dynamic rings, static rings, flat rings, etc The material of the SiC Seal Ring can be reaction sintered silicon carbide (RBSiC) or pressureless sintered silicon carbide (SSiC) SSiC ceramics can work up to 1600℃, while RBSiC ceramics can only work below 1380℃ The sealing surface of