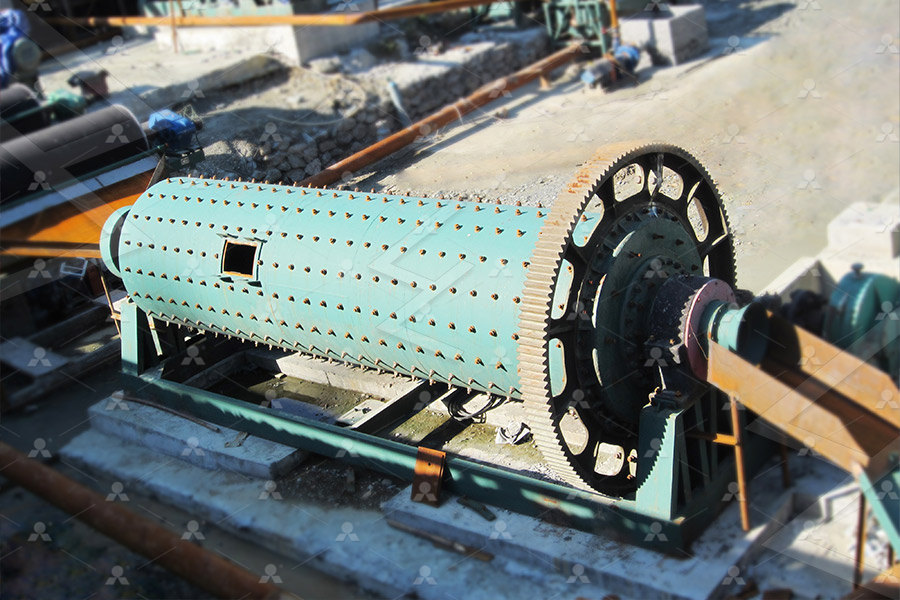

How to produce ore grinding machine

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined and processed to extract iron for various industrial applications This article provides a comprehensive overview of the iron ore 2023年7月20日 Ultrafine grinding process is a kind of mechanical grinding, in which the commonly used devices include ball grinder, tower grinder (vertical roller grinder), stirred Ultrafine Grinding Process SpringerLink2024年8月15日 Mineral processing, also known as ore dressing or mineral beneficiation, typically consists of four key unit operations: comminution, sizing, concentration, and dewatering 1 Comminution involves both crushing and Mineral Processing Plants: What You Need to Know2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the Ore Grinding SpringerLink

Mineral Processing Equipment for Mining Industry

2024年8月7日 Mineral processing involves key stages to extract valuable minerals from ores, including crushing to reduce ore size for further processing, grinding to further refine particle size and liberate minerals, classification to 2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersGrinding Mills — Types, Working Principle ApplicationsGrinding can be achieved by several mechanisms, including: impact or compression due to sudden forces applied almost normally to the particle surface; chipping or attrition due to Grinding Mill an overview ScienceDirect Topicsmineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more Mineral processing Metallurgy, Crushing Grinding

Fine grinding: How mill type affects particle shape characteristics

2017年9月1日 The objective of this work is to assess the influence of fine grinding in ball mills and stirred mills on valuable mineral liberation and particle shape characteristics of UG2 ore, a 2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder Crushers are widely used in ore crushing, aggregate Types of Crushers: Choosing the Right One for Each 2023年8月2日 Precision grinding can produce smooth surfaces that are often required to function many components properly The three main types of precision grinding machines are surface grinders, cylindrical grinders, and The Details of Accurate Grinding: A Practical Guide2024年1月23日 Initial Investment: Grinding machines, especially those used for precision applications, are costly Highend machines with advanced features like CNC systems are even more expensive Basic Grinding Machines: Entrylevel What is Grinding: Definition, Process, Types

.jpg)

Intro to Grinding Methods, Machines and Tools

2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Die Grinder for more information and some recommended models Angle grinders are also abrasive hand tools Unlike die grinders, We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface finish We will also discuss the various industries that use surface grinding, the benefits of using surface grinding in these industries, and how to choose the right grinding wheel for a specific applicationThe Ultimate Guide to Surface Grinding: Techniques, Applications, 2021年7月3日 Creep feed grinding is a slow, onepass operation that makes a deep cut of up to one inch in steel materials at low table speeds between 05 and 1 ipm It is not suitable for conventional grinding machines, but for those which are compatible with it, it offers high productivity and cost effectivenessMachining 101: What is Grinding? Modern Machine ShopWhat is a Grinding Machine? A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformationWhat Is Grinding Machine? Definition, and Types The

.jpg)

Precision Metal Grinding Metal Cutting Corporation

2020年6月14日 There are different types of grinding machines, as well as many different scenarios where precision metal grinding can be used But in general, grinding produces a rougher finish, while honing can produce a finish as smooth as Ra 1 µin (003 μm) However, 2017年6月9日 Various Sizes of Surface Grinding Machines The surface grinding concept is the same no matter the size of the part to be ground However, (ECC) combines electrochemical erosion and grinding to produce a burrfree, shiny surface Principles of Precision Surface Grinding ServicesGrinding Machine A grinding is metal cutting operation which is performed by means of a rotating abrasive wheel that acts as a tool; These are mostly used to finish workpieces which must show a high surface quality, accuracy of shape and dimension Mostly, it is finishing operation because it removes material in very small size of chips 025 – 05 mmGrinding Machine Definition,Working,Parts,OperationTypes2023年6月21日 Proper Grinding Machine Maintenance is Critical to Ensure Safe Grinding Wheel Usage ANSI B71 states: An employer shall maintain grinding equipment in a condition that will not create a hazard for an employeeThe employer shall instruct an employee to report defective equipment to an employee supervisorGrinding Machine Maintenance Norton Abrasives US and

5 Grinding Considerations for Improving Surface

2021年8月20日 Machine Condition Grinding machinerelated factors can affect the workpiece surface finish These include: Wheel/hub assembly balance: If the grinding wheel assembly is not balanced to an acceptable level, it can result in 2023年10月27日 The mined titanium ore first goes through a crushing and grinding process to produce powders with uniform particle sizes When crushing, use a jaw crusher for coarse crushing, and then use a cone crusher for fine How to Process Titanium Ore (A Stepbystep Guide)2022年11月28日 The grinding wheel extends into the hole for grinding At this time, the outer circle is used as the positioning reference to ensure that the inner circle and the outer circle are concentric Centerless internal grinding is usually used to grind the inner raceway of the bearing ring on the special grinding machine for the bearing ringWhat is Grinding Process How It Works Different Types of Grinding2023年5月30日 A grinding machine’s electric motor provides rotational motion power to the grinding wheel via a belt and pulley system So, when we turn on the electric motor, it rotates at a specific angular velocity (10015000 RPM, depending on the grinding machine), and the grinding wheel begins to turn as well, and we carry out the operationGrinding Machines Overview, Working, Types, and Uses EDUCBA

Thread Machining: Process, Methods, Cutting Guide WayKen

2023年2月10日 The singleline grinding wheel has a pitch accuracy with grades 5 ~ 6 It also has a surface roughness of R125~008 μm Singleline grinding is ideal for making a precision screw, worm, thread gauge, shovel grinding hob, and small batch threading The multiline grinding is divided into cutin and longitudinal grinding methods3 Estimation of the power consumption of a grinding mill 31 STEP 3 : Estimate the power consumption of a grinding mill for a particular application The Bond 3rd theory of comminution is estimating the power required to mill a particular ore thanks to the following formula [Chopey] :Grinding power : step by step calculation PowderProcessThis article speaks about different types of grinding machines, parts, and their working A workshop can have a single grinding machine or multiple grinding machines based on the surface finish requirements of the workpiece This is normally the last operation performed on an item to achieve high precision Our Videos Refer YouTubeGrinding Machine: Definition, Types, Parts, Working Operations2013年1月1日 Superb grinding machines now produce optical quality finishes due to developments in process control and machine design It is the same for extremely high removal ratesPrinciples of Modern Grinding Technology ResearchGate

.jpg)

Illite Ore Industrial Grinding Mill Machine SBM Ultrafine

2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation requirements and meet Surface grinding is a automotive, medical, and electronics, where precision and flatness are critical The process is commonly used to finish machine parts, such as bearing surfaces, gears, and mold components, to ensure a precise fit and optimal performance One of the main advantages of surface grinding is its ability to produce flat Surface Grinding EngineeringTechnology2020年6月29日 Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines Grinding machines have advanced in design, Chapter 17: Grinding Methods and Machines2023年10月19日 The calcined expanded vermiculite should immediately enter the cooling machine or be cooled naturally The FTM Machinery cooling machine can cool the clinker coming out of the rotary kiln to below 200°C, maintaining Vermiculite: What Is It and How to Process It? Fote

The Ultimate Guide to Understanding Centerless Grinding

2023年9月7日 Machinists use this cylindrical grinding technology to produce long, As a result, these grinding machines are wellsuited for executing shorter job lot sizes and vast product variations Servomotor technology, on the other hand, is pivotal in modern centerless grindersProduct in approximate final shape is fed past the grinding wheel which provides the precise dimensions For lower volume manufacturing of these complex shapes, EDM machining is commonly used Simple twodimensional profiles, EDM is faster while more complex shapes using 35 axis machines run slowerMagnet Manufacturing Process How Are Magnets MadeSurface grinding is done on flat surfaces to produce a smooth finish It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth Sometimes a surface grinder is known as a flick grinder if great accuracy is not required, but a Surface grinding WikipediaDownload the Okuma Grinding Machine Guide to learn what a grinding machine is, how it works and why you need one on your shop floor One of the main benefits of grinding machines is their ability to produce smooth surface finishes They also allow for a tight toleranceGrinding Machine Guide CNC Machine Tools Okuma

.jpg)

Grinding Machine Types How it works Phillips Machine

2022年2月16日 A 5axis grinding machine is a cutter grinder commonly used to shape and sharpen milling cutters and other tool bits 5axis tool grinders can perform a broad range of grinding operations, including surface grinding, cylindrical grinding and complicated shape shaping, using a set of grinding tools2023年8月25日 Ever wondered how gears are made? The process involves multiple intricate steps to achieve precision and efficiency This article breaks down the 11 essential stages of gear processing, from ordinary turning to final measurement You'll discover how each step, like gear hobbing, shaping, and honing, contributes to producing highquality gears By the end, you'll 11 Steps of Gear Processing You Must Know MachineMFGCenterless grinding is a precise and efficient machining process used to remove material from a workpiece without the use of a grinding machine This process is ideal for cylindrical and bar grinding, resulting in an excellent surface finish and tight toleranceIn this ultimate guide, we will cover everything you need to know about centerless grinding, including its history, how it The Ultimate Guide to Centerless Grinding in Precision Machining2022年5月28日 Jig grinding is very different from cylindrical and surface precision grinding This is because it produces workpieces with more complex shapes and qualities One of the visible distinctive features of Jig grinding is a Precision Grinding: Understanding the Principle, Types,

.jpg)

The Complete Guide To Coffee Grinding The Coffee

2024年11月12日 Everything you need to know about grinding coffee beans at home As some of you may know coffee beans are technically fresh produce and as such always fall somewhere on the spectrum between fresh and 4 Turn on the machine power by turning the switch to the “ON” position Then press the green button to start the spindle 5 Move the grinding wheel down using the vertical table handwheel until it barely makes contact with the Chapter 5: Surface Grinder – Manufacturing Processes These machines are bound to produce perfectly tempered chocolate every time while also automating labourintensive tasks From grinding to mixing and moulding, machines guarantee quality and consistency They also save valuable time and effort, which makes it a nobrainerUltimate Guide to Chocolate Making Machines2024年3月22日 In the competitive landscape of machining and metal part fabrication, machine shops are continually seeking ways to enhance their offerings, reduce lead times, and increase efficiency This guide is crafted for machinists and machine shop owners looking to broaden their expertise and make strategic decisions about cylindrical grinding and superfinishing servicesThe Machinist's Guide to Cylindrical Grinding and Superfinishing:

5 Grinding Considerations for Improving Surface Finish

2021年1月26日 This new vertical turning center with measurement and robotic automation processes is able to produce vehicle ball joint ball pins in 7 seconds 25 Oct 2024 Precision Grinding machinerelated factors can affect the workpiece surface finish These include:Surface Grinding Want to learn more about surface grinding? Surface grinding is used to produce a smooth finish on flat surfaces It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smoothAchieving Excellence in Surface Grinding Universal Grinding Corporation2023年11月17日 Ensure the grinding machine is in good working condition and properly guarded Securely fasten the workpiece using appropriate workholding devices Need to find a surface grinding supplier to produce a part with a very What is Surface Grinding LEADRPOre grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their characteristics According to the different media of the mill, the grinding machines are divided into: If the medium is steel balls, it is called a ball mill;Ore Grinding Machines: Ball Mill, Rod Mil Grinding Media

Unlocking the Potential of Surface Grinding Machines

The surface grinder opens up new possibilities because it could allow you to harden the things you make and machine them to a much closer tolerance A surface grinder is an outstanding cutoff the instrument for reducing toughened shafting The material used in surface grinding is 025 to 050 mm Surface grinding is best if used for flat cutting