Screen end mill limestone crusher

.jpg)

Limestone Aggregate Crushing JXSC Machine

Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, The limestone crushing production line is divided into three stages: coarse crushing, medium fine crushing and screening The limestone stone blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushingLimestone Crusher DingboBased on the characteristics of limestone, here are several machines recommended to you: jaw crusher, impact crusher, screening, feeding, and other supporting equipment Large pieces of limestone need to be transported into Limestone Crushing Equipment and Production LineTypical limestone crushing plant feature successive size reduction stages and intermediate screening to classify material A standard flow involves primary, secondary, and tertiary (or fines) crushing Primary crushing, the initial size Limestone Crusher for Efficient Limestone Crushing Plant

limestone crushing and screening equipment LZZG

Limestone enters the jaw crusher through the feeding device for coarse crushing, then passes through the conveyor belt, enters impact crushing, undergoes medium and fine crushing, and finally undergoes preliminary screening Those who meet the screening conditions will enter the next step of sand making machine to make sand After that, it will To make best use of the limestone, we have produced the advanced 1030 tph limestone crushing plant with screens for the worldwide customers Here is the detailed information of limestone crusher and the screensLimestone Crushing and Screening PlantSBM Industrial MEKA Crushing and Screening Technology serves all industries involved in size reduction of rock and minerals, meeting your specific requirements from single to mobile plants and complete rock processing plants, all supported by highly Crushing Screening Plants MEKAA crusher is a major investment, so it’s essential to select one with the potential to meet your needs into the future This guide covers a few of the key points to consider before making a decision But remember that your crusher is just one part of a wider process – always consider crushing in conjunction with screening and transportMASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

Rock Crushers Pulverizers Williams Crusher

Browse our catalog of limestone mills crushers Williams Patent Crusher manufactures innovative diatomaceous earth mills for grinding, drying, and classifying, reducing material to a powdery, dustlike form Our industrial When you need to separate limestone, granite, asphalt, sand, coal or concrete, Sandvik scalpers can help you do it more efficiently Sandvik tracked mobile scalpers separate the toughest feed materials with ease Each fuelefficient Mobile scalpers Sandvik’s efficient screening SRPLimestone Given its moderate softness, limestone crushing plants primarily consist of jaw crushers, impact crushers, sand making machines, vibrating screens, and more Typically, the capacity of limestone crushing plants ranges 3 Limestone Mills to Maximize Limestone Grinding Limestone Processing Line Solution Configuration: Vibrating Feeder (APG6015W) + Jaw Crusher (APJ110V) + Impact Crusher (APF1620H) + Vibrating Screen (APS3072Y3) Customer Feedback : “Since the machinery was Limestone Crusher Machine: Boost Quarrying

.jpg)

Limestone Crushing Solution Eastman Rock Crusher

Limestone generally adopts dry crushing process For metallurgical and construction use limestone, only the ore needs to be crushed and screened If you want to further produce fine powder limestone products, use a jaw I had a 100 inch Grandview electric roller screen installed in my living room at the end of July Related Essays Special Crusher And Grinding Mill For Limestone Pulse bag dust catcher is as well bare in the accomplished limestone grinding plantGrinding Screen Crusher Mills, Cone Crusher, Jaw Crushers%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resourcesMill , vibrating screens, vibrating feeders, Pulverizerbelts, conveyors and ball mills EXERCISE 61 Ball milling circuit using Austin's model Many limestone crushing plant includes limestone crusher and limestone mill or other Limestone Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

Limestone Crusher LIMING (Shanghai)

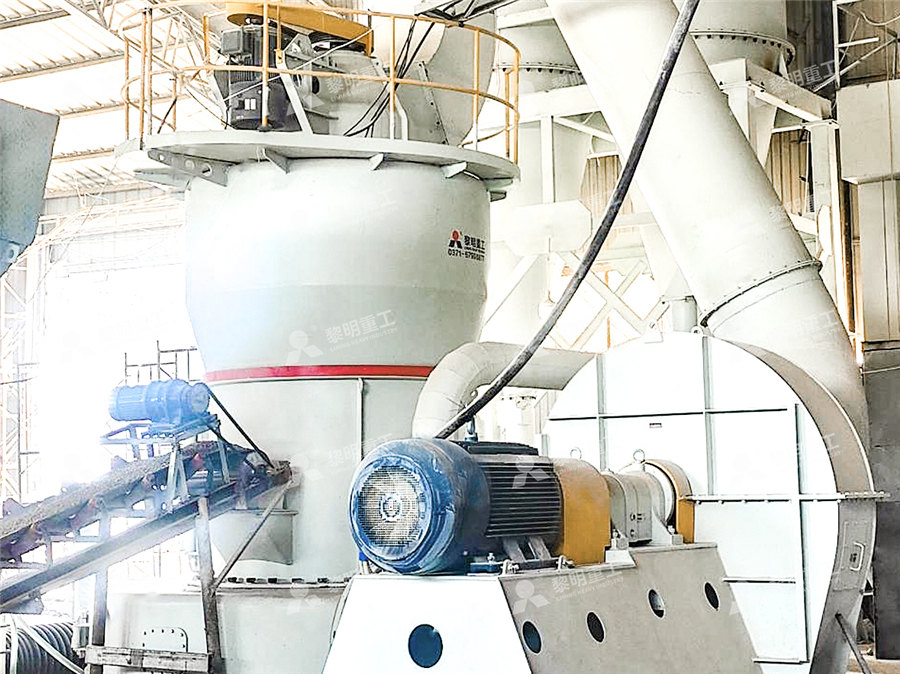

LM Vertical Mill; TGM Super Pressure Trapezium Mill; Raymond Mill; MW Series Micro Powder Mill; Limestone Crusher European Type Impact Crusher PFW1318Ⅲ, Vibrating Screen 4YZS2460 CA SE 120TPH Limestone processing in Mexic 300400TPH Iron Mining Project 350400TPH Sandstone Crushing Line 15TPH Limestone Grinding Plant Request a Roller Pulverizer For Limestone Powder,Buy Quality Roller Roller Pulverizer For Limestone Powder, Source Roller Pulverizer For Limestone Powder Products at Mine Mill, Crusher from Manufacturers and Suppliers around the World Limestone Powder Pulverizer Crusher Mills, Cone Crusher, Jaw The limestone grinding mill, also known as lime grinding, is a machine used to grind limestone into powder formLimestone remains in lumpy form after being processed through the limestone crusherBefore entering the calcination stage, limestone needs to be ground into powder form using a limestone grinding mill The main component of limestone is calcium carbonate, which Limestone Grinding Mill Solution Adjustable Powder FinenessVipeak Heavy Industry is the manufacturer of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Mill,etcWith the latest manufacturing technology, the unique structural design,we produce the high standard, qualified stone crushers and grinding mills, we provide you the detailed information of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Crusher Grinding Mill, Ball Mill // Vipeak Heavy Industry

Types of Crushers Explained: Everything You Need to

2024年4月19日 A shorthead cone crusher has a short crushing chamber and it is designed for the production of finer output sizes, generally between 6 mm and 25 mm A fine cone crusher, also known as a tertiary cone crusher, is used for 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the The Complete Guide to Primary Crushing, Secondary 2023年2月24日 Advantages of Using Limestone Crusher Machine CostEffective: Limestone crusher machines are costeffective and have a low cost of operation HighQuality End Product: Limestone crusher machines are capable of producing highquality end products that meet the required specifications Versatility: Limestone crusher machines are versatile and Limestone Crusher Machine: The Key to Construction Efficiency150200TPH Limestone Sand Making SolutionGrinding mill After being blasted, the stones will be transported to the hopper by the dump truck or loader, then flow into the vibrating feeder in order to feed the jaw crusher Grinding Limestone SAND Crusher Mills, Cone Crusher, Jaw

Hammer Mill

Hammer Mill Hammer Mill is mainly used for coarse powder production and sand production The end products can be controlled within 03mm (D90) Wide Applications; High Productivity; Easy to Maintain; Capacity: 870t/h; Max Input Size: 50mm; Min Output Size: 03mmYZS Vibrating Screen Belt Conveyer Grinder Series grinding mill machine limestone feeding size 10mm liming Crusher grinding mill machine limestone feeding size 10mm for grinding of over size Pin Mill Grinding,Pin Mill Machine Feed material = natural quarried limestone: 2 Kiln; end product Pin Mill Limestone Powder Crusher Mills, Cone Crusher, Jaw 2023年6月22日 To maximize roll life and achieve consistent endtoend performance, each pair of rolls must be parallel and tram, which means level with each other on a horizontal plane If the rolls operate out of parallel, they will grind the material fine at one end and coarse at the other and will also wear unevenly The same is true for rolls out of tramHammermill and roll crusher maintenance and operation2022年11月17日 CARA KERJA DAN BAGIANBAGIAN PENDUKUNG MESIN CRUSHER (LIMESTONE) DI PT SEMEN BATURAJA, TBK dengan adanya bantuan crusher sebelum memasuki vertikal Raw Mill end disc terluar tempat (PDF) CARA KERJA DAN BAGIANBAGIAN PENDUKUNG MESIN CRUSHER (LIMESTONE

.jpg)

Limestone Crusher, Small Mobile Crusher VYKIN Crushers

Configuration: Jaw crusher Power System: ElectricallyDriven via Onboard Genset Yanmar 40kW Generator: SELF CONTAINED, 40 kW, 50 hp Total Power (required): 24 hp, 480 v, 60 Hz Electrical Control: Yes, wireless remote standard Hydraulic Control: No hydraulics Capacity: 2030 tph Crushing material: Granite, river rock, limestone, concrete, asphalt, etc Jaw Feed Blasting, drilling, and scaling out limestone requires the right equipment When it comes to limestone material size reduction, it’s no different Williams Patent Crusher has designed and manufactured the most durable and efficient Rock Crushers Pulverizers Williams CrusherThe Williams Reversible Nuggetizer® Crusher (US Patent No 3,667,694) is a rugged primary, singlestage impact crusher capable of a broad range of crushing applications including cement, rock, limestone, coal, concrete, and other Cement Limestone Rock Crusher Reversible We make available the highend Vibrating Screens to the clients liming News chinese vibrating screen hammermill, brick: definition from answersco; chinese wooden crushing machine, morn lasercnc router,laser engraving machine,lase; Chinese coal crushing plant; hammer mill for sale limestone; impact crusher for limestone; Chinese Vibrating Screen Hammermill Crusher Mills, Cone Crusher

.jpg)

Limestone Ultrafine Grinding Mill

Limestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has Limestone can be used to produce Portland cement and to produce coated heavy calcium carbonate products for highend The mill production line usually includes a hammer crusher, bucket elevator, storage bin 8 32 Materials For this experiment, two 2500g samples of gravel with sizes between ½ to ¾ in were used in the size reduction using the jaw crusher A quarter of the product (approximately 500 g) after crushing was taken for the sieve analysis In the size reduction using the hammer mill, three 400g samples of limestone with sizes between ¼ to ½ in were used and all of the Lab Report on Size Reduction Using Mill and Crusherpdf1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, and the Limestone Aggregate Crushing JXSC MachineAll crusher types with 100+ years of experience crushers, on the other hand, are used in the last stage of the crushing process, especially when its required that the end product has a precise cubical from highcapacity primary crushers for large limestone quarries to specially designed machines for the crushing of materials such as Crushers All crusher types for your reduction needs Metso

.jpg)

Primary Crusher vs Secondary Crusher: Understanding Their

2023年2月28日 The primary crusher is responsible for breaking down larger rocks and stones into manageable sizes, while the secondary crusher further refines these particles into the desired product While both types of crushers are used in a variety of realworld applications, understanding their differences and when to use each type is crucial for achieving the desired Vibratory Screens by JVI > Details >Screen Equipment Designs available for capacities up to 2500 TPH Simple rugged design – Q U A Vibratory Screen> DetailsVibratory Screen Design Crusher Mills, Cone Crusher, Jaw To compensate for wear on a crusher, both rotors previously had to be welded on at great expense for up to 3 weeks To do this, the entire upper part of the crusher had to be dismantled in advance, which was timeconsuming and costly The crusher segment design from thyssenkrupp Polysius now makes it easy to replace the crusher segmentsCrushing Technologies thyssenkrupp PolysiusHammer stone crusher is mainly used for crushing materials with compressive strength less than 150Mp and humidity less than 15%, such as limestone, coal, gypsum and masonry, etcThe main working principle of hammer stone crusher is that the rotor rotates at high speed to drive the hammer, which pounds the materials and makes the materials crushed into the required Limestone Crusher Machine for Sale High Crushing Force

How Does A Vibrating Screen Work Crusher Mills

Dangoumau Ball Mill; Coal Crusher Stone Crushing Plant Project; Ball Milling Facility India; Jaw Crusher Liberia Gypsum And Limestone; COBALT CRUSHER HUB GG 20 ALLIS CARTON; Impact Rock Crushers; The electrons excite phosphor atoms along the wide end of the tube (the screen), which signal with a tiny bowl attached to your roofA Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturingLimestone Grinding Mill Plant TAYMACHINERYFor wet limestone, wet marl, clay, chalk, gypsum and similar raw materials It permits a large feed size and is capable of producing a clearly defined finished product size being preselected by the gaps of the discharge grate and therefore able to produce fedd material for ball mills, high pressure grinding mills and vertical roller millstitan® Crusher thyssenkrupp Polysius Crushing TechnologiesDominate Your Jobsite With a RUBBLE MASTER Limestone Crusher Mobile Jaw Impact Crushers watch video Crushing Blast Limestone from a Mobile Impact Crusher with onboard screen and swivel return conveyor for closedcircuit production or 90° stockpiling of Dominate the jobsite with machinery that holds up its end of the bargainCrushing Limestone Impact Jaw Crushers RUBBLE MASTER

Choosing the right primary crusher for limestone crushing Baichy

2024年7月10日 Limestone in impact crusher is constantly colliding within the crusher at high velocities to break the rock apart The impact crusher incurs higher wear costs over time, but can generally provide greater crushing results and better shapeBall Mill Trommel – Buy Grinding Mill Trommel,Ball Mill TrommelScreen This Trommel Screen is a kind of classification equipment with reliable structure, high efficiency, simple installation and easy maintenanceBall Mill Trommel Screen Crusher Mills, Cone Crusher, Jaw liming limestone crushing and screen plants Process Crusher liming limestone crushing and screen plants 21 Views The liming is the professional mining equipments manufacturer in the world, located in China,India, along with Crushing And Screening Plant Limestone Crusher Mills, Cone Crusher MTW Series European Technology Trapezium Mill Super Pressure Trapezium Grinder Mill Threerings and Mediumspeed Micropowder Grinder Pe250×400 Limestone Crusher Price; Big Crusher Jual Sillica Sand Powder Machine; eccentric shaft design for vibrating screen – Basalt CrusherEccentric Shaft Vibrating Screen Crusher Mills