What is the name of the machine for grinding sulfur powder

.jpg)

Sulfur Grinding Classifying Process Superfine sulfur

Ultrafine pulverisation of sulfur is usually achieved by grinding sulfur particles/blocks in grinding mill During the sulfur grinding and collection process, due to the nature of sulfur itself, the sulfur powder may be subject to friction, The Rotoform S8 has been specifically developed for the pastillation of sulphur It is designed for small to midsize capacity requirements and is the world’s most widely used process for the production of premium quality sulphur pastillesRotoform S8 IPCO2019年8月23日 Mined sulfur is mostly from salt domes or bedded deposits The vast majority is produced as a byproduct of oil refining and natural gas processing Sulfur mining uses three different mining techniques: conventional Sulfur Processing Equipment, Process Flow, CasesFrom precrushers for the comminution of coarse materials to jet and ball mills for ultrafine grinding: Hosokawa Alpine offers mills for a wide range of fineness levels The mill type that is best suited to your application depends not only on Grinding Hosokawa Alpine

Grinding Mills and Pulverizers Selection Guide: Types,

There are several types of grinding mills and pulverizers available to industrial buyers These types include, The tumbling reservoir of a ball, tube, roller, media, or vertical mill uses the impact and friction of the feed material, often 2020年4月6日 IPCO Drum granulation is a fully automated sulphur granulation process based on rotating drum technology These sulphur drum granulators are the highest capacity units available and produce formed sulphur to SUDIC Sulphur Processing – IPCO Drum Granulation Energy Powder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction A mill or grinder uses a mechanical action to break the material and reduce it to the required size This may encompass a Grinding Milling Powder ProcessSolutionsPowder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction A mill or grinder uses a mechanical action to break the material and reduce it to the required size This may encompass a Grinding Milling Powder ProcessSolutions

Grinding and Polishing Guide Buehler

2021年11月15日 Figure 33 PlanarMet 300 Planar Grinder A Planar grinding machine, like the PlanarMet 300 planar grinding machine shown in Figure 33, utilizes a fixed abrasive stone for rapid sample grinding This type of • Ball Mills or BallMedium Mills grind through impact of a grinding media such as balls, rods, etc • Vibratory or Shaker Mills use high speed vibrations and grinding media to combine multiple grinding forces to reduce materials to fine powders These mills can include grinding forces and media like balls, beads and grinding mediaPrinciples of Sample Preparation by Grinding or Comminution2021年11月27日 The powder grinding mill is the equipment used to grind and process materials such as ore The finished products granularity of the grinding machine has a wide range, the largest diameter of particles can reach 30 mesh, the general diameter of particles is up to 0033 millimeters (425 mesh)What is Powder Grinding Mill? JXSC Machine2023年9月5日 Powder metallurgy involves creating powder and manufacturing products Powder metallurgy is primarily a metallurgical process, as the name suggests The products created using powder metallurgy often extend beyond the realm of materials and metallurgy, encompassing multiple fields, such as materials and metallurgy, machinery and mechanicsPowder Metallurgy: A Comprehensive Guide for Beginners

.jpg)

Grinding Machine: Definition, Parts, Working Principle, Operation

2021年5月5日 Grinding Machine Application: The following application of Grinding Machine are: The Grinding Machine is used in various industries for grinding The first and foremost industry where this machine is used in Manufacturing Industry The Grinding Machine is used for finishing the cylindrical and flat surfaces2022年11月25日 What is Powder Metallurgy? Powder Metallurgy (PM) is a metal solidification technique that involves compacting metal powders into a die and heating it to temperatures just below their melting point to fuse by sintering to create a rigid 3D component Powder Metallurgy Manufacturing processes like casting and metal working use molten and solid forms as raw What is Powder metallurgy Powder metallurgy types application2024年9月16日 KRUPS Silent Vortex Electric Grinder: True to its name, this spice grinder was quieter than most of the competitors It didn’t grind spices very evenly, though, because of its high blade The blade was also fairly loose, so a lot of dust fell through into the baseThe 4 Best Spice Grinders of 2024, Tested Reviewed Serious To provide better powder grinding and classifier machines for more customers all of the world, creating more value for them Skip to content : [ protected] Tel: +86 ; Actively promote the future development of ultrafine powder, focusing on crushing,grinding,classifying and modification process of ultrafine powderEPIC Powder Grinding and Classifier Machine Supplier

.jpg)

Grinding machine Wikipedia

Rotating abrasive wheel on a bench grinder Pedalpowered grinding machine, Russia, 1902 A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grindingIt is a type of material removal using an abrasive wheel as the cutting tool [1] Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear Food powder mixing Explore this informative page to gain insights into the world of food powder mixing Whether you're a smallscale business owner looking for practical mixing solutions or part of a largescale production facility aiming to maintain highquality standards, this resource offers valuable guidancePowder Mixing: The Ultimate Engineering Guide for Bulk Solids To complete the cycle, products made from metal powder can be recycled and made into new powder How Metal Powder Is Made Your manufacturer’s powder metal supplier follows careful steps to make a product that provides How Metal Powder Is Made: Step 1 of the Powder 2024年10月22日 The grinding machine has various components, and these are as follows: Grinding Wheel: This tool carries out the grinding process It has abrasive grains and cuts the workpiece Machine Bed: The machine bed supports the grinder parts and absorbs the vibrations during the grinding process Wheel Head: It has a grinding wheel and also manages the What is a Grinding Machine : Components, Types, and Uses

.jpg)

Grinding Mills Common Types 911Metallurgist

2016年11月7日 As the name implies, in the batch mills, Fig 14a, the charge of powder to be ground is loaded into the mill in a batch and, after the grinding process is completed, is removed in a batch Clearly such a mode of operation can only be applied to mills of small or moderate sizes; say to mills of up to about 7 ft diameter by about 7 ft long2024年4月19日 Grinding Wheel: The grinding wheel is one of the most critical components of a grinder machine It is typically made of abrasive materials like aluminum oxide or silicon carbide The grinding wheel rotates at a high speed, creating the cutting action needed to remove material from the workpieceThe Grind: Understanding The Processes Of Grinding MachinesHere’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas 1 Surface Grinders: A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table 2 Cylindrical Grinders: A cylindrical grinder is used for shaping the outside of a workpiece 3What Is Grinding Machine? Definition, and Types MechdailyThe primary cocoa processing equipment includes roasting machines, peeling and grinding machines, pressing machines, and powder making machines The roasting machine is used to roast the cocoa beans at a specific temperature range of An overview of advanced cocoa processing machinery

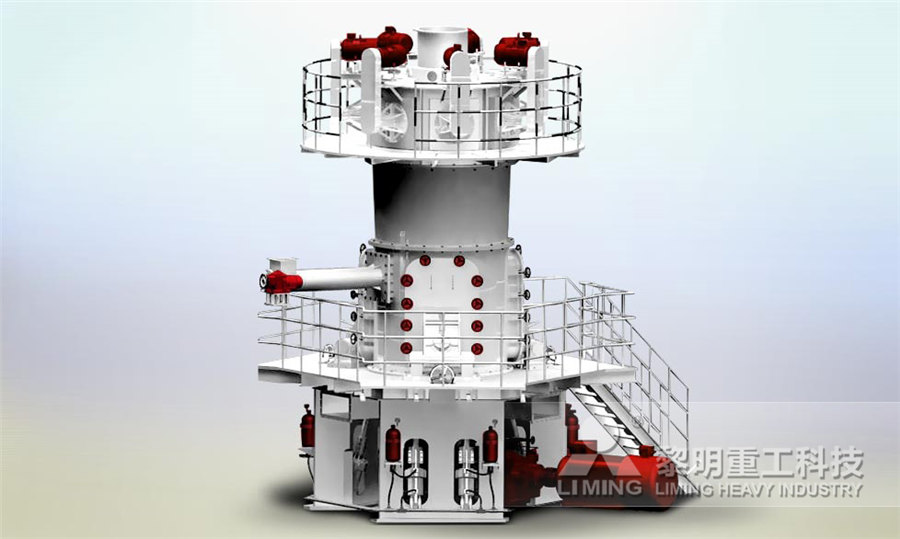

Powder Grinding Machine

1)if your project on powder processing needs to import a powder grinding machine, then Yinda will be your best choice to manufacture your powder grinding machine orders 2)Yinda is one of the leading powder grinding machine suppliers and all of our powder grinding machines can meet ISO/CE/GMP standards, and we will provide a competitive price based on your project2021年1月1日 The investigation of the mixtures processed by SLPS with different mixing ratios of metallic grinding swarf and PM powder shows a significant reduction in the number of pores in International Journal of Machine Tools and Manufacture 2010; 50 (12): 10771087 [19] Klocke, F, Barth, S, Mattfeld, P, High Performance Potential of the Recycling of Grinding Sludge by various Powder 2019年10月31日 “Pulverization” (comminution, crushing, grinding) is the process of applying an external force to a (solid) material of a certain size to destroy it and reduce it into pieces that are smaller than the original size (*7) Powder Terms Pocket Book, Association of Powder Process Industry and Engineering, JapanPulverization 1: Definition and purpose | THINKY USAThe most common machine coolants used today belong to one of two categories based on their oil content: Oil‑Based Machine Coolants ‑ including straight oils and soluble oils Chemical Machine Coolants ‑ including synthetics and semi Types of Machine Coolant Carbide Processors

Powder Grinding Pulverizer Machine for Sale HB Refine

HB Refine is a single source for you to find best industrial pulverizer machine for your applications As a industryleading pulverizer machine manufacturer, HB Refine has professional technical knowledge and rich grinding experience to provide standard equipment and custombuilt machines with high quality and reliable at competitive price2024年1月23日 Basic Grinding Machines: Entrylevel grinding machines, suitable for smallscale operations or less complex tasks, typically range from $5,000 to $20,000 MidRange Grinding Machines: These machines, offering What is Grinding: Definition, Process, Typesgrinding available Range Information: » Supplied as machine only or complete milling system » Large range – from lab to production » 3 hp to 125 hp » Grinding media options include turbine and screen, pinned disc, and rib track The Kek Universal Mill is designed for highperformance fine grinding, versatility and safety Available with Powder Processing Equipment Systems QlarJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

Sulfur Grinding Classifying Process Superfine sulfur powder

Ultrafine pulverisation of sulfur is usually achieved by grinding sulfur particles/blocks in grinding mill During the sulfur grinding and collection process, due to the nature of sulfur itself, the sulfur powder may be subject to friction, static electricity, thermal ignition, resulting in adhesion of the sulfur powder due to electrostatic adsorption, and may cause an explosion in a confined 2024年10月23日 A grinding machine is also called a grinder, which is a type of tool used to machine components It offers versatility and precision when it comes to manufacturing metal components A grinding machine has an abrasive wheel that allows for finishing the workpieces and achieving the desired surface quality and accuracy in terms of dimensions21 Types of Grinding MachinesEngineering ressources for design and operation of solids and powder milling Menu Current page : Menu Menu Welcome to Solids Milling Engineering Guide Milling / Grinding / Comminution / Size reduction Milling Process Technologies A free online Engineering Guide to the a very common milling machine found in process Powder Milling and Grinding An Engineering Guide2020年6月29日 Next, mount the wheel on the grinding machine and dress Then remove the wheel and rebalance it Remount the wheel and dress slightly a second time Shifting weights on the wheel mount will balance the wheels The wheel is installed on a balancing arbor and placed on a balancing fixtureChapter 16: Grinding Wheels and Operations American Machinist

.jpg)

What Is Grinding Machine? Definition, and Types The

What is a Grinding Machine? A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformation2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to Quartz Processing Mastering the Art of Stone to Powder pulverizers are essential machines for grinding, crushing, and reducing dry materials into fine powders They are used in various industries such as pharmaceuticals, food processing, cosmetics, and many more If you are Guide To Powder Pulverizers TodayMachine2018年4月28日 Grinding is a staple sizereduction process to produce food powders in which the powdered form is chemically and microbiologically stable and convenient to use as end products or intermediate products The moisture Effect of Moisture Content on the Grinding Process

Grinding for food powder production ScienceDirect

2013年1月1日 Grinding technology and equipment was described according to the nature and characteristics of the food material Illustration was shown with the grinding of cereals and tubers for flour production, of spices, fruits and vegetables for powder production The limiting factors of powder production by grinding (water and sugar content, caking 2023年10月13日 Principles of particle reduction The most common method for obtaining a homogeneous sample is grinding of comminution Grinding samples has many benefits for sample preparation since it increases homogeneity, increases surface area and decreases particle size which can improve extraction efficiencyPrinciples of Sample Preparation by Grinding or ComminutionThis peanut powder grinding machine is a kind of specialpurpose peanut powder making machine It is the right peanut powdering machine to produce highquality peanut powder as ingredients for rice dumplings, cookies, etc Model MF1 Power 3KW Voltage 380V/50HZ Capacity 200600kg/h DimensionPeanut Powder Grinding Machine2021年1月16日 Your Single Disc Surface Grinding Machine will look like a horizontal spindle surface grinding machine albeit smaller in size since it does not need a reciprocating or circular table The grinding action in your machine takes place by the abrasive particles on the face of the grinding wheel You will be able to give the feed (depth of cut) by moving the wheel headSurface Grinder Types of Grinders How They Work Fine

Solids and powder milling Size reduction

1 Principles of milling bulk solids Milling is the action of reducing the size of particles thanks to a mechanical action The mechanical action is submitting the particles to a stress, under the stress, some cracks will appear and subsequently the particle will be broken in different parts2024年4月19日 Different types of lab grinder machines Lab grinder machines are an essential tool in many scientific and research laboratories These machines are used to grind, homogenize, and mix samples for various applications, such as DNA extraction, cell disruption, and sample preparation for analysisThe Ultimate Guide To Choosing The Right Lab Grinder Machinesmall maize grinding machine Packaging Once the maize flour is milled to perfection, it is packaged using automated packaging machines Proper packaging ensures the preservation of quality, hygiene, and convenience for distribution and consumption Choosing a reliable corn machinery manufacturerTypes of Commercial Maize Milling Machines