Vertical grinding mill output

.jpg)

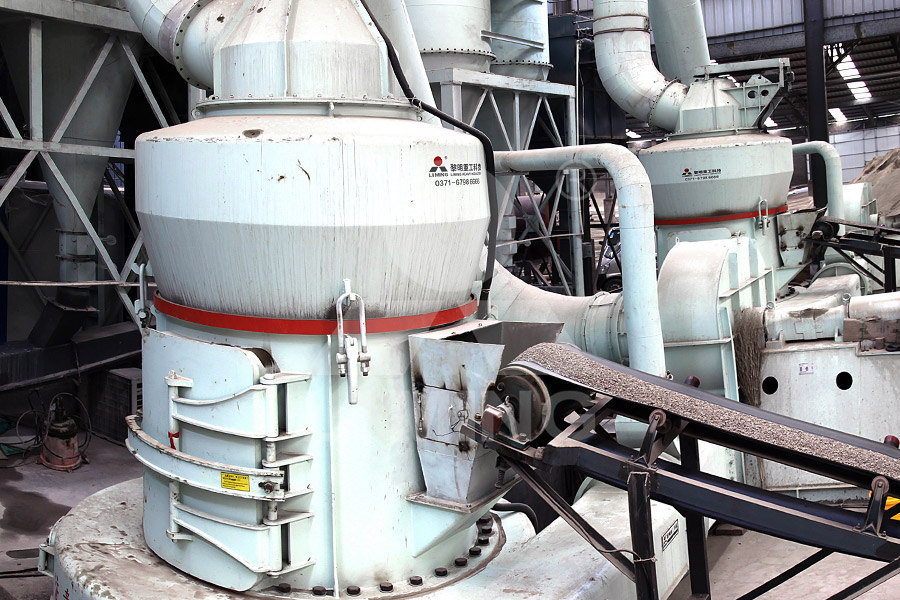

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, Output: 4 t/h 300 t/h SBM has launched the LM Vertical Grinding Mill which integrates five Vertical roller mill, Vertical roller grinding mill All LUM ultrafine vertical mill is designed for nonmetallic mineral ultrafine grinding equipment For limestone, SCM Series Ultrafine Mill Input Size: 020mm Output Size: 3252500 mesh LEARN MORE APPLICATION SBM is the biggest crushing machine and grinding mill manufacturer in Asia Besides, Grinding Mill ultrafine grinding mill, vertical ultrafine mill Grinding technology has changed over the years, with vertical mills becoming even more popular It has been proven that grinding efficiency can be improved by interparticle grinding using dry grinding process Under special circumstances, compared Detailed explanation of vertical mill grinding technology

News What Is Vertical Grinding Mill?

Vertical mill consists of main mill, classifier, fan, finished product cyclone separator, and air duct Among them, the main mill consists of frame, air inlet volute, shovel blade, grinding roller, grinding ring and housing HLM vertical roller mill Max feeding size: 50mm Capacity: 5200t/h Fineness: 200325 mesh (7544μm)Our team of experts will help global customers develop a reliable, energysaving and highefficiency vertical roller mill grinding solution by taking advantage of our technological Matching clinker line output: Grinding table diameter: Main reducer: Main motor power: t/h: t/d: mm: kW: LGM7027 820880: 10000: 7000: MZL710: 72007600 Vertical Roller Mills Cement Processing Equipment CITIC HICVertical roller mill is an efficient industrial milling equipment, Output: 120 T/H Product features: High grinding efficiency; Totally closed negative pressure operation has been employed by this vertical grinding mill, so there is little dust during the operation 6Vertical Roller Mill SBM Ultrafine Powder TechnologyDivided into: vertical roller mill, vertical slag mill vertical coal mill, and ultrafine vertical mill (ultrafine powder processing) One machine is multipurpose, it can be used for grinding, grading, crushing, drying, etcvertical roller mill, vertical coal mill, vertical slag mill, superfine

Calcium Carbonate Ultrafine Vertical Mill SBM Ultrafine

Calcium carbonate ultrafine vertical mill, integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging +17 [ protected] Output: 120 T/H Product features: It has outstanding characteristics such as high grinding efficiency, convenient maintenance, Read this indepth blog to learn about the working principle of Vertical Grinding Mill, its application, and its advantages +91 226796 9655 sales@macawberindia 130131, Hindustan Kohinoor Complex, LBS Road, Vikhroli The fine powder is then collected into the air cyclone collector and expelled from the outputpowder valve as the final Vertical Grinding Mill: How it Works, Application And AdvantagesLimestone powder ultrafine vertical grinding mill fine powder continue to move towards the fringe of the grinding plate until they are taken away by strong air flow at the air ring While the materials along with the air flow pass through the separator located above the grinding plate, output(t/h ) 1114: 1317: 1519 Limestone Powder Ultrafine Vertical Roller MillFor ball mills grinding OPC to a fineness of up to around 3600 cm2/g (Blaine) grinding aid is usually not required; it may not even be feasible considering the cost of grinding aid However, a vertical roller mill for cement grinding Cement grinding Vertical roller mills VS ball mills

Vertical Roller Mill (VRM)SinomaLiyang Heavy

We can design and manufacture vertical roller mills of diversified specifications and models for raw meal, cement, and slag comminuation systems in cement clinker production lines with capacity up to 10,000t/d To continuously meet 2023年3月15日 LM Vertical Grinding Mill integrates crushing, drying, grinding, separating and transport The structure is simple while the layout is compact Its occupational area is about 50% of that of the ballmilling system The LM LM Vertical Grinding Mill SBM Mill CrusherBased on this and adopted with German and China Taiwan superfine vertical grinding technology, Dongguan Vsunny Machinery Co, Ltd developed the VSCM series coarse vertical grinding mill It use the highclass wearresistant parts, and the fineness of ground powder product will be from 60~500 meshesVSCM SERIES COARSE VERTICAL GRINDING MILLThe vertical mill vem for wet material grinding The vertical mill enables high energy economy, and convinces with low specific wear values Drying of the feed material, grinding, diameter of a ball mill has a great influence on the power consumption of the mill and thus on the possible production outputChristian Pfeiffer VEM Vertical mill Christian Pfeiffer

.jpg)

Grinding Mill ultrafine grinding mill, vertical ultrafine mill

LUM ultrafine vertical mill is designed for nonmetallic mineral ultrafine grinding equipment LUM Ultrafine Vertical Mill Input Size: 020mm Output Size: 3252500 mesh LEARN MORE Hammer Mill Input Size: 040mm SBM will make a stunning appearance with the LM Vertical Roller Grinding Mill at bauma CHINA 2024 PRODUCT OVERVIEW LM series vertical mill is a new type of milling equipment with advanced technology, excellent performance and drying functionIt integrates the functions of drying, grinding and powder classifying,used in construction,coal,power plant,steel plant,construction,cement,ceramic and easy maintenance, power saving, fast investment LM series vertical millOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag to operate it with a number of rollers out of service while still reaching 60 to 70 percent of the normal operation output, minimising production lossesVertical roller mills FLSmidth CementOutput: 120 t/h Product features: High output, low energy consumption, high intelligent control system, wide adjustable range of fineness, Ultrafine vertical roller mill is a new type of vertical roller mill suitable for grinding nonmetallic ultrafine powder, Ultrafine vertical roller mill SBM Ultrafine Powder Technology

Vertical mill, Vertical grinding mill All industrial manufacturers

Output: 15 kg/h is the ideal WTM intelligent vertical mill is dedicated to the highefficiency dissociation of minerals, providing users with energysaving, consumptionreducing, With its vertical grinding shaft, our Vertica grinding and pregrinding hammer mill The amount of feed in the mill can be tested by 3 methods: Grinding roller limit device clearance; The power of the mill (ie the main motor current); Metering of belt scales; If the layer is too thick, the following phenomena will occur: The How to Improve Grinding Efficiency of Vertical Roller Compared with the ultrafine vertical grinding mill in the same industry, HCMilling(Guilin Hongcheng) HLMX nonmetallic ore ultrafine vertical grinding mill equipment has the following advantages: lower cutting point of the classifier; The median diameter is smaller; The content of fine powder is higher; Higher yield; Lower energy consumption News Application of HLMX Ultrafine Vertical Roller Mill for Non than ball mills, even if the ball mill is combined with a roller press This and further arguments led to the increased share of VRM for the grinding of finished cement Taking into account that VRM usually have a bigger output than ball mills, it can be declared that the major part of the cement production with newly installed mills comes from SikaGrind® for vertical roller mills

An investigation of performance characteristics and energetic

2020年8月12日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining Output: 120 T/H Product features: 1 High Efficiency High Quality of Finished Products 2 Pigment: Calcium carbonate ultrafine powder vertical grinding mill is used in the pigment industry to produce highquality pigments with consistent particle size and colorCalcium Carbonate Ultrafine Powder Vertical MillThe power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large time delay characteristics PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL Find your vertical mill easily amongst the 408 products from the leading brands (Yuhang Heavy Industries, Grace, Fives, Output: 200 kg/h 1,000 kg/h Motor power: 22 kW 110 kW Grinding mill using completely stainless steel hammers with the possibility of modifying the final granulometry in all casesVertical mill, Vertical grinding mill All industrial manufacturers

Vertical Roller Mill Drive Gearbox Radicon

The gear unit represents an almost integral component of the mill The output flange of the gear unit is rigidly connected with the grinding table Vertical Roller Mills for grinding in Coal, Raw and Cement: Range: Power up to 5,600 kW , Torque capacity 2500 kNm: Applications Vertical Roller Mill; Vertical Coal Pulverizer;Limestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 [ protected] Output: 120 T/H Product features: High output, low energy consumption, Limestone powder vertical powder grinding mill compared with other mills, Limestone Ultrafine Vertical Millpage 05 2 vertical mills introduction page 07 3 principles of vertical grinding systems page 07 31 vertical mill components page 07 32 how does a vertical mill work? page 08 4 a new generation of grinding additives: maga/vm and mape/vm page 08 41 mill output increase page 09 42 quality and water demand optimisation page 09 5Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven

Improvement of cement performances through the use of grinding

In addition to the increase of mill output due to the stabilization of grinding bed, the effect of grinding aids on vertical roller mills can be noticed in terms of improved efficiency of the separator and better particle size distribution Bibliography [1] Cembureau Activity Report 2009, available online at (last access Sept 2011):Find your vertical mill easily amongst the 408 products from the of the UCOM is the Bauermeister Universal Mill While a conventional UM grinding plant includes a high number of components that serve the Output: 250, 500 kg/h Ball Mill Gusu Ball Mill Machine is the ideal machine for ensuring efficient and uniform refinement of Vertical mill, Vertical grinding mill All industrial manufacturers Vertical mill consists of main mill, classifier, fan, finished product cyclone separator, and air duct Among them, the main mill consists of frame, air inlet volute, shovel blade, grinding roller, grinding ring and housing HLM vertical roller mill Max feeding size: 50mm Capacity: 5200t/h Fineness: 200325 mesh (7544μm)News What Is Vertical Grinding Mill?LONGLY Nano Bead Mill NTVE combines the advantages of horizontal grinding and vertical discharging to ensure high efficiency and quality Specifications of Dual Power Vertical and Horizontal Nano Bead Mill: NTVE Output Fineness: 30 100nm Zirconium Bead Size: 003 08mm Separation System: Centrifugal SeparationDual Power Vertical and Horizontal Nano Bead Mill: NTVE

How To Improve Output Of Vertical Mill

How to improve output of Cement vertical mill has always been the concern of users Due to the lack of attention to some small factors, the output of the vertical mill may be reduced One of the more obvious performances is that vertical grinding roller and disc liner are worn after a period of use Invisible is equivalent to increasing the height of the retaining ring, increasing the Ultrafine vertical mill is a highefficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like and particle size of the grinding material will all affect the output, so the appropriate grinding machine should be selected according to the nature of the grinding material When grinding, the feed should be Ultrafine Vertical MillK SERIES MOBILE CRUSHING SCREENING PLANT is researched to meet customers’ demand on high quality and high output, and it is widely used in almost every field in ore, construction, recycling, etc READ MORE LM Vertical Mill LM Vertical Mill integrates 5X Series Pendulum Roller Grinding Mill is new mature and advanced equipment Stone Crushers, Mill and GrindingLM Vertical Grinding Mill adopts a compact integrated design, which covers an area of about 50% of the ball mill system, and can be arranged in the open air with less comprehensive investmentLM Vertical Grinding Mill Vertical Roller Mill sbmchina