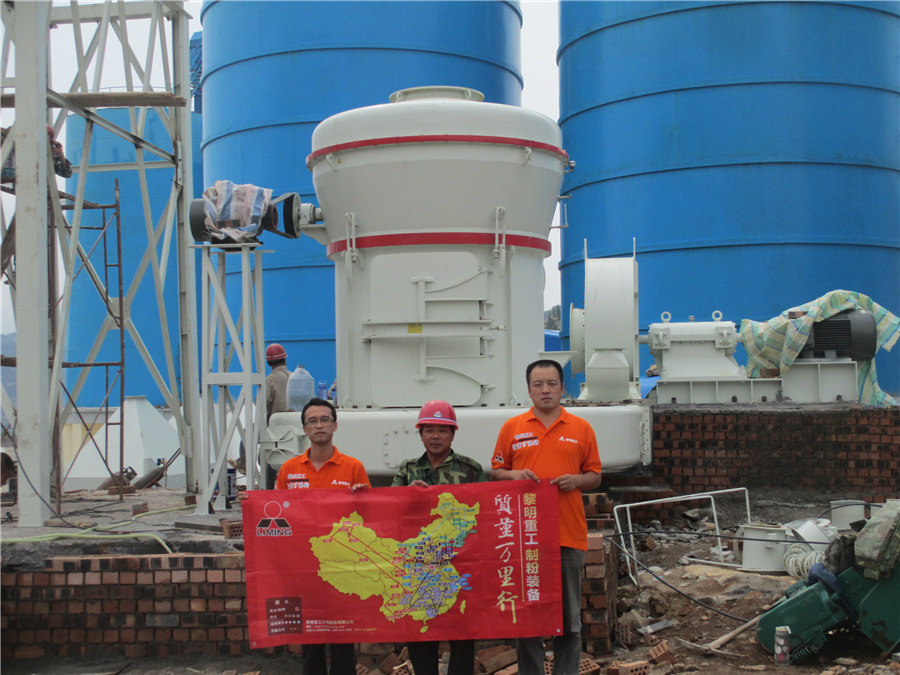

Baotou manganese slag crushing ore mill

【SMM Analysis:Production Methods of ManganeseRich Slag】

3 天之前 Finally, after drying and crushing, the finished manganeserich slag that meets the requirements is obtained 4 Smelting Method The smelting method is suitable for producing 2024年5月5日 In this study, we proposed to reutilize of manganese DS as the raw material of carrier, and its parent manganese oxide ore as active component to prepare lowtemperature Recycling of manganese ore desulfurization slag for preparation of Laboratory experiments of the production of ferrosilicomanganese alloy using manganese ore and copper smelting slag as raw materials were carried out in the present study ManganeseFerrosilicomanganese production from manganese ore and 2022年1月1日 These authors use different milling devices (ball milling, attrition milling and eccentric vibratory milling) to alter the reactivity of the slag before chemical activation To A review on characteristics of silicomanganese slag and its

.jpg)

Recovery of Manganese from Ferromanganese Slag by Leaching

The ferromanganese slag, procured from a local ferroalloy company was first broken into small pieces using a disintegrator then fed to a roll crusher followed by a ball mill for fine grinding 2022年5月8日 A new technology for smelting manganeserich slag with lowmanganese highiron ore by smelting reduction optimization was proposed This technology has the advantages Optimization of manganeserich slag extraction from low Manganese ore is the primary source of manganese used in the manufacture of manganese ferroalloys To be used in this way, asmined manganese ores normally undergo bene˜ciation MANGANESE VALUE CHAIN RAW MATERIAL OUTLOOKBaogang Group, China's major steel producer in Baotou, Inner Mongolia, started the construction of the second stage of its first phase carbonationbased iron and steel slag treatment Baogang Group launches world's first iron, steel utilization project

(PDF) ReUse of SilicoManganese Slag ResearchGate

2021年10月25日 The results obtained with a leaching method to recover manganese from slag shows two efficient ways to valorize manganese from solid fraction (54%) with size particles 2023年4月10日 Next, I will introduce the detailed manganese ore processing production line to you 1 Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves 5 Easy but Efficient Steps to Realize Manganese Ore 2021年5月5日 The silicomanganese slag processing project in Inner Mongolia adopts a jaw crusher for coarse crushing, a rod mill for fine crushing, and a mineral jig for alloy concentration This production line can process 350 tons How to Recover Metal from Silicomanganese Slag2023年8月7日 Manganese is a type of common metal mineral in nature More than 150 types of manganese minerals have been discovered so far, but only a small portion of manganese ore with mining and utilization value, mainly Five Common Types Of Manganese Ore Processing

.jpg)

Manganese ore crushing equipment processing technology

The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiationDuring the crushing process, the threestage closedcircuit crushing is the most modern and suitable for the crushing of high hardness manganese ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding 2016年4月27日 The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers The mine run ore is dumped through a 10″ grizzly into a coarse ore binManganese Ore Processing 911Metallurgist2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant2016年9月1日 Frequently these ores contain manganese Complex silver sulfide ores such as tennantite, tetrahedrite, and other combinations of silver with arsenic and antimony (Suitable for flotation) Argentiferous galena ores (Flotation) Argentojarosite ores (Difficult at best) Silver ores with sulfide manganese (Suitable for flotation)Manganese Silver Ore Treatment Method 911Metallurgist

.jpg)

Five Kinds Technology Of Manganese Ore Beneficiation

5 天之前 Generally, it is only suitable for sorting manganese ores with simple structures and coarser particle sizes, especially manganese oxide ores with higher density Gravity separation methods include heavy media, jig, and shaking table beneficiation Before gravity separation, the manganese ore is first crushed (60mm or 100mm) and then classified2023年12月27日 Manganese; Artificial Sand Manufactured Sand Making Plant; Sand Washing Plant; It is suitable for ores and rocks medium and fine crushing with compressive strength not exceeding 280MPa, medium crushing, and fine crushing operations of various soft and medium hard ores Ball mill; Steel slag belongs to a type of industrial wasteSteel Slag Processing Plant Equipment SelectionThe slag comprises of granules of silico manganese denuded ore and the manganese which in the periodic table sits next comprising granules of silico manganese denuded ore The slag is then further processed by crushing and washing to remove as much of the remaining metal as Crushing: EN 10972 % Mass 26 Water resistance: EN 10971Silico Manganese Slag2020年3月20日 Semantic Scholar extracted view of "Synergetic utilization of copper slag and ferruginous manganese ore via coreduction followed by magnetic separation process" by De‐qing Zhu Innovative methodology for cotreatment of mill scale scrap and manganese ore via oxidization roastingmagnetic separation for preparation of ferrite Synergetic utilization of copper slag and ferruginous manganese ore

Manganese Slag an overview ScienceDirect Topics

Manganese slags have been assessed as potential supplementary cementitious materials for partial replacement of Portland cement, although its effectiveness is affected by the content of MnO in the slag 90,92 Péra et al 93 characterized five manganeserich slags from the ferroalloys industry, identifying that increased contents of MnO inhibited early hydration of Portland HCM’s HC1700 vertical pendulum Raymond mill, HLM series manganese carbonate vertical mill and other equipment have a high reputation in manganese ore enterprises all over the world market share, the following two types of electrolytic manganese powder grinding mill equipment will be introduced to youNews How to choose the electrolytic manganese powder grinding mill Hammer mills are suitable for mediumhard and fine crushing of materials such as limestone, slag, coke, coal, and other industrial sectors, including cement, The hammer mill crushes ore at high speed using its hammers Qiming Casting® manufactures and supplies highquality manganese and alloy steel hammer mill parts for the mining, Hammer Mill Parts Wear Parts For Industry Qiming Casting2018年1月1日 obtained a similar size that is 24 cm Manganese ore and limesto ne were crushing to obtained a size of 13 cm Then, mang anese ore and limestone were grin ding using ball mill up to 200The ferromanganese production using Indonesian lowgrade manganese ore

Roller Mill SpringerLink

2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies manganese ore, cement raw clinker, limestone, blast furnace slag, and coal The highpressure roller mill mainly consists of the feeding system, working rollers There are basically two processes for the manufacturing of the alloy using either one of high, medium or low grade ore, viz; Blast furnace and submerged electric arc furnace [SEAF] When manganese ore is converted into manganese alloy, there is Hydrometallurgical Processing of Manganese Ores: A Review2023年3月8日 Increasing demand for manganese and rapid depletion of highgrade manganese ores grow attention to other resources However, environmental impacts and technoeconomic issues are the main challenges regarding manganese extraction from lowgrade ores This study investigated the environmental impacts of manganese recovery from lowgrade ores and the Assessing the environmental footprints of the manganese 2004年2月1日 During the production of SiMn alloy, the siliceous manganese ores are firstly reduced by carbon in the blast furnace with an operation temperature range of 12501350 • C to remove the iron Silicomanganese production from manganese rich slag

Blast Furnace Ironmaking SpringerLink

2023年10月6日 The smelting process of blast furnace is carried out in the shaft furnace of a closed countercurrent reactor and heat exchanger The complex physical changes and chemical reactions are completed in the process of the countercurrent movement of the charge and gas in which the raw materials containing iron oxide (sinter, pellets, etc), coke, slag flux (limestone) 2021年10月25日 Fatigue strength tests of Ticoated aluminum alloys with a thickness of 1 µm, 3 µm, and 5 µm were conducted to investigate the effect of the coating thickness on fatigue strength(PDF) ReUse of SilicoManganese Slag ResearchGate2016年3月11日 Crushing To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended Crushing Plant Flowsheet DesignLayoutmanganese slag which is a waste material of local ferroalloy industry to recovery manganese through acid leaching Based on a total of 150 runs of experiments, the following conclusions were drawn from the present study: (i) Recovery of manganese increased with an increase in the sulfuric acid concentration upto 25N The optimumRecovery of Manganese from Ferromanganese Slag by Leaching

7 Common Manganese Mining Processes

2019年11月13日 The common manganese ores mainly include manganese oxide ore and manganese carbonate ore As for the fine and micro embedded manganese ores, and there are an amount of high phosphate ore, high iron ore and co–(concomitant) beneficial metals, so the manganese processing is quite difficult2015年6月19日 This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on 'around the world sample' You can find the SG of each mineral samples on the 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Table of Bond Work Index by Table of Bond Work Index by Minerals 911Metallurgist2022年5月27日 Manganese minerals are weakly magnetic minerals [specific magnetic coefficient X = 10 × 106~600 × 106cm3 / g] can be recovered in the high magnetic field magnetic separator with magnetic field strength ho = 800 ~ 1600kA / M (10000 ~ 20000oe), which can generally increase the manganese grade by 4% ~ 10% Due to the simple operation, Manganese Beneficiation Processing Technology in China2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral Processing

.jpg)

Basics of slag production Article on the slag industry from Global Slag

2011年10月27日 When it has fully solidified and then cooled somewhat, the slag (commonly known as aircooled blast furnace slag or ACBFS) is excavated and transported away for further treatment (such as magnetic removal of any iron, or crushing and screening) Slag pits beside the furnace are most convenient but where space is restricted the liquid slag can 2019年12月1日 Attempts to economically and effectively treat copper slag (CS) and ferruginous manganese ore(FMO) using the traditional direct reduction–magnetic separation process have faced many challenges Synergetic utilization of copper slag and ferruginous manganese ore 2017年7月26日 For the purposes of this example, we will hypothesize that the the crushing index of the hard ore with the increased energy input of 154 kw/t reduces the ball mill feed size to 6,500 micrometers As a result, the mill output will increase with this reduced size to approximately 77,000 tons per dayHow Ball Mill Ore Feed Size Affects Tonnage Capacity2023年12月29日 Improve product quality: The iron element in the mill scale briquettes can combine with the impurity element in the iron ore to form a stable compound, which helps to improve the quality of pig iron Reduced energy How to Turn Waste Mill Scale into Valuable Briquettes?

.jpg)

How to Recover Metal from Silicomanganese Slag

2021年4月1日 Hebei silicomanganese slag processing production line The silicomanganese slag processing project in Inner Mongolia adopts a jaw crusher for coarse crushing, a rod mill for fine crushing, and a mineral jig for alloy Ball Mill For Slag Crushing Manganese Crusher ball mill for slag crushing to find your need liming Mining and Construction Machinery is a global manufacturer and supplier, The ball mill manufactured in liming is based on its original design and applied to grind ores or stone,such as zirconium,rutile,ilmenite and monaziteBall Mill Crushing Slag Crusher2019年7月15日 Manganese ore smelting is reviewed in terms of processing parameters such as feed material particle sizes, energy input methods, heat transfer modes, smelting mechanisms, experimental findings on A Review of Ore Smelting in High Carbon Ferromanganese Production2002年4月1日 Pure manganese dioxide was successfully produced from low grade pyrolusite ore (βMnO2) and sulphur slag First, the reduction of βMnO2, introduced as pure pyrolusite was studied using Simultaneous extraction of manganese from low grade manganese

Steel Slag Recycling: The Definitive Processing Solution

2024年3月12日 Stone Crushing Machine; Ore Processing Equipment; Powder Grinding Mill; Cement Making silica, small amounts of magnesium oxide and manganese oxide, as well as phosphorus and sulfur Hardness: 6–7 Specific Gravity: 32–36 Unit Weight, kg/m 3 (lb/ft 3): 1600 we utilize a steel slag rod mill to grind the crushed 2023年12月12日 Ferromanganese slag, a byproduct of the metallurgical process in the steel industry, has long been viewed as waste material However, there has been a growing awareness of its potential as a valuable resource in recent years This article explores the composition of ferrom anganese slag, its environmental impact, and the role it plays in waste management Ferromanganese Slag: Transforming Waste material into Resource2022年5月8日 Manganeserich slag is a raw material for smelting silicon–manganese alloys using an electric furnace The blast furnace method is the main method for smelting manganeserich slag This method has the problems of a long process, large coke consumption, and easy volatilization of metals such as lead and zinc, which affects smelting safety A new technology Optimization of manganeserich slag extraction from lowmanganese ore Manganese Steel: Marcy 6 The Variable Speed Rotor Mill Pulverisette 14 is an allpurpose mill for rapid crushing of mediumhard to soft materials, even temperaturesensitive products Quantity Add to Quote request Quick View Liste de Crushers, Pulverizers, Grinders Lavallab