What are the processes of civil coal processing

.jpg)

Coal Processing an overview ScienceDirect Topics

1982年8月9日 Coal processing refers to the practice of converting coal into various products such as coal tar, coke, and tarbased chemicals through methods like coal carbonization, coal 2021年5月11日 Coalification refers to the series of processes involved during the transformation of this organic vegetation into coal The first step in transforming vegetation into coal is the Mineral Beneficiation and Processing of Coal SpringerLink2016年2月14日 The methods of mining of coal varies from deposit to deposit This report highlights the coal mining methods, their significances, issues of concern and the stages of (PDF) COAL MINING METHODS ResearchGate2015年7月1日 Coal preparation is readily defined by five distinct unit operations: (1) size reduction, (2) size separation, (3) solid separation, (4) solid–liquid separation, and (5) waste A review of stateoftheart processing operations in coal

A review of stateoftheart processing operations in coal

2015年7月1日 Coal preparation is readily defined by five distinct unit operations: (1) size reduction, (2) size separation, (3) solid separation, (4) solid–liquid separation, and (5) waste The overall coal mining process consists of several sequential stages: (1) exploration of a potentially economic coal seam to assess minable reserves, environmental issues, marketable reserves, potential markets, and permitting Coal Mining and Processing The National Academies • Coal preparation is the removal of undesirable material from the RunofMine (ROM) coal by employing separation processes which are able to differentiate between the physical and What Is Coal Preparation? EnergygovAccording to the annual census of coal preparation plants conducted by Coal Age [], the USA operates 286 coal preparation plants in 12 statesThis number is relatively small by comparison to the worldwide fleet which is estimated to be 2,283 plants []The capacity of the plants can range from less than 200 t/h for small operations to 6,000 t/h or more for large industrial plantsCoal Preparation SpringerLink

Mineral Comminution and Separation Systems EOLSS

CIVIL ENGINEERING – Vol II Department of Geosystem Engineering, University of Tokyo, Tokyo, Japan Keywords: Mineral beneficiation, mineral processing, coal preparation, coal cleaning, comminution, mineral liberation, gravity separation, Comminution processes are generally preliminary to the separation processescountry and water for coal processing (and other purposes) is becoming scarcer and where it is available it is becoming more expensive The environmental problems associated with wet coal processing plants, specifically the disposal of slurry, is furthermore becoming more difficult and expensive to manage New plants built in the country, and evenDry Processing Versus Dense Medium Processing For Preparing Thermal CoalWhen it comes to effective coal processing, our operators at RPM Solutions bring a deep wealth of mining and machining experience to every project Call : 18002703102; info@rpmsolve; Most cleaning processes involve washing coal in order to separate coal particles from stone particles Coal can be charred, Coal Processing Coal Preparation Coal Handling RPM Solutions2020年11月24日 Coal tar is a hazardous and toxic waste, a byproduct of coal gasification processes Coal tar is a waste produced in industrial fields such as steel, power plant, and the cement industry(PDF) Characteristics Production of Coal Tar ResearchGate

(PDF) The Origin and Classification of Coal ResearchGate

2019年12月31日 The coal in the AachenSouthLimburgCampine coal field has a rank ranging from bituminous coal to anthracite (see also Chap 2 ) T able 12 lists the different coal2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica2023年6月12日 Our mission is to provide highquality coal and diesel to our customers while prioritizing safety, sustainability, and reliability Our vision is to be the leading supplier of coal and diesel, recognized for our commitment to safety, sustainability, and innovation National Coal Suppliers is a reliable South African coal supplierSouth African Coal Mining TechniquesA geologist studies the solid, liquid, and gaseous matter of the Earth as well as the processes that shape them A mining geologist is responsible for mapping out the locations of valuable minerals and will use aerial photographs, field maps, and geophysical surveys, to determine where valuable materials are and estimate how much of those materials are in that locationThe stages of mining: 5 lifecycle processes explained Opens

.jpg)

The Cement Manufacturing Process Thermo Fisher Scientific

2023年12月20日 Cement operators also use these analysis systems to analyze and adjust the coal mix instream, which enables the plant to reduce energy consumption by using exactly the amount of coal fuel required to meet the specific heating values required to process materials in the kiln and millDry coal processing benefits downstream utilizations through possible cost and energy savings along with a reduction in water pollution As a result, dry processing has inspired interest in the coal preparation industry and research into many methods has commenced Addendum A: Performance report on the applicable dry coal processingDry processing for coal preparation: a review2016年10月22日 Coal is the most abundant fossil fuel and about 42#160;% of the world electricity is generated through coal fired power stations However, mechanized mining has led to an increase in the quantity of fine coal production The value of the fine coal necessitated theTECHNOLOGIES IN USE FOR THE PROCESSING OF FINE COAL2019年12月4日 Coal has been mainly used in South Africa for electricity generation by the power utility, however, with the rapid decline of high grade coal, other processes such as gasification and coal coking Coal tar production processes and potential of

A review of stateoftheart processing operations in coal preparation

2015年6月6日 Download Citation A review of stateoftheart processing operations in coal preparation Coal preparation is an integral part of the coal commodity supply chain This stage of postmining, pre 2006年4月1日 PDF A coal preparation plant typically operates with multiple cleaning circuits to clean individual size fractions of runofmine coal Coal Find, read and cite all the research you need on (PDF) Coal preparation plant optimization: A critical review of 2023年3月3日 Coal is the most extensively used fossil fuel, and coalbased electricity is the main source of power in most countries of the world Coal is expected to account for around 27 % of the world’s energy mix by 2035 [1] China, India, United States, Indonesia, Australia, and Russia are the world’s six largest coal producersA systematic review exploring the utilization of coal mining and PhD 2019 Dry processing for coal preparation: a review N Hughes ii NWU in association with CoalTech mechanism provides unique advantages and limitations with respect to processing coal with certain physical and chemical properties and for efficiently yielding a Dry processing for coal preparation: a review

(PDF) A Review of Microwave Coal Processing ResearchGate

2014年1月1日 Microwave coal processing is a diverse area, which has the potential to aid in coal upgrading, cleaning and comminution, thus improving efficiency and reducing harmful emissions of coal usagecoal products to the needs of specific recipients consists of publication, factors having a negative impact on the environment as a result of the refining process of useful minerals carried out at the Mechanical Coal Processing Plant were analysed All departments and workstations in the Mechanical Coal Processing Plant (ZMPW) were analysedEnvironmental Impact of The Mechanical Coal Processing Plant2012年8月10日 Mining and mineralprocessing wastes are one of the world’s largest chronic waste concerns waste rock or coal slime generated after washing processes may contain carbon with calorific values of 3350 to 6280 kJ/kg, Reuse of coal mining wastes in civil engineering—Part 2: Utilization of minestone Waste Manag 15, 83 (1995)The Challenges of Reusing Mining and MineralProcessing Wastes2020年2月5日 The total coal consumption in China is on the rise The characteristics of CO2 and SO2 emissions in the whole process of coal processing and utilization in China are worthy of study Based on the five links of the whole process of coal production and utilization, including coal production, raw coal processing, logistics and transportation, conversion and utilization CO2 and SO2 emission characteristics of the whole process

106: Coal The Carbon Rock of Ages Chemistry

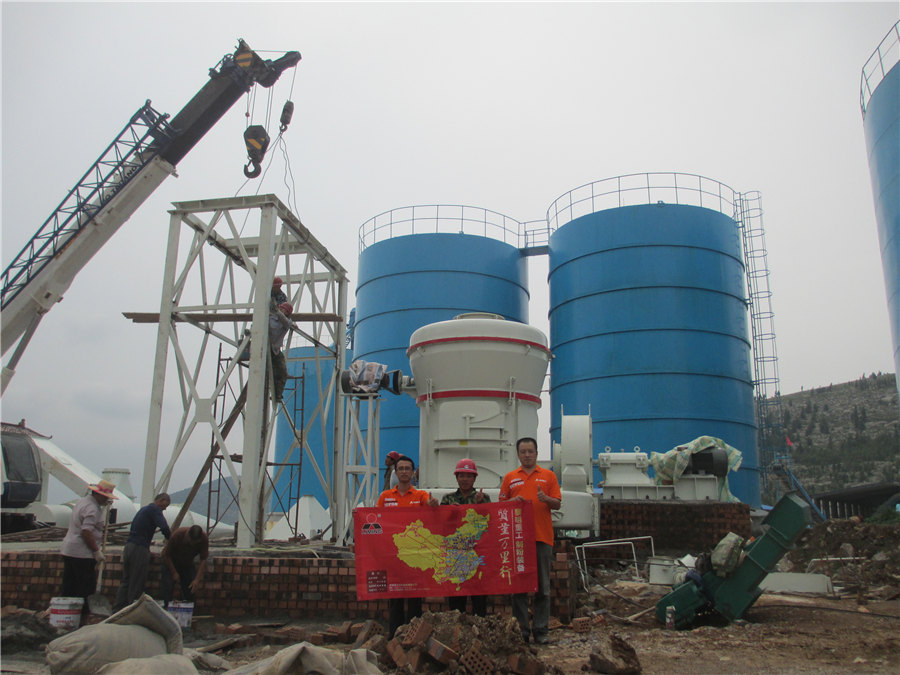

The Global Carbon Cycle Figure \(\PageIndex{3}\) illustrates the global carbon cycle, the distribution and flow of carbon on Earth Normally, the fate of atmospheric CO 2 is to either (1) dissolve in the oceans and eventually Mineral and coal processing encompasses unit processes required to size, separate, and process minerals for eventual use Unit processes include comminution (crushing and grinding), sizing (screening or classifying), Technologies in Exploration, Mining, and ProcessingThose processes using water as medium are WET processes and are known as Washing Processes The coal beneficiation plants using wet processes are named as Coal washeries For raw coal fines of –05 mm, the difference in surface property is utilized since conventional gravity dependent processes are inefficient for this size rangeCoal beneficiation processes 29 Coal Processing and Utilization2021年8月30日 In the coal industry, the role of vibrating screens is not only to classify, most of the vibrating screens are also used for dewatering or deintermediation of coal, and even for desilting In the coal preparation plant’s screening operations, raw coal preparation and product processing, it is mainly divided into five categories 1Five processes of vibrating screen in coal preparation operations

Breakthrough and innovative clean and efficient coal

2021年5月1日 Catalysts and catalytic processes play an extremely important role in clean coal conversion, and are widely used in making full use of resources, reducing pollution, and improving production efficiency (Xie, 2010)The catalytic processes involved in coal conversion are mainly hydrogenation, oxidation, carbon–carbon bond fracture and reconstruction, and the removal of 2022年9月20日 Processing the Coal Source: bloomberg After coal comes out of the ground, it typically goes on a conveyor belt to a preparation plant that is located at the mining site The plant cleans and processes coal to remove dirt, rock, ash, sulfur, and other unwanted materials, increasing the heating value of the coalCoal Mining and Processing How Does It Work? Energy Trends 2016年6月30日 Activated carbon (AC) is used in different states of applications after its discovery as a strong and reliable adsorbent An overview on AC is presented together with revisiting the sources of AC A review on activated carbon: process, application and prospectsNew processing methods meant new kinds of metals could be mined The main stages in mining are: exploration, extraction, refining, manufacturing and marketing We will take a Coal and copper are often mined in this way Underground mining mainly consists of digging tunnels and shafts Smelting and chemical processes Table 143: 143 Mining and mineral processing The lithosphere Siyavula

.jpg)

Coal Production and Processing Technology MR Riazi,

Coal Production and Processing Technology provides uniquely comprehensive coverage of the latest coal technologies used in everything from mining to greenhouse gas mitigation Featuring contributions from experts in industry and academia, this book:Discusses coal geology, characterization, beneficiation, combustion, coking, gasification, and liquefThe EHS Guidelines for Coal Processing cover the processing of coal into gaseous or liquid chemicals, including fuels They apply to the production of Synthetic Gas (SynGas) through various gasification processes and its subsequent conv ersion into liquid hydrocarbons (FischerTropsch synthesis), methanol,Environmental, Health and Safety Guidelines for Coal Processing25 Formation of Minerals In order for a mineral crystal to grow, the elements needed to make it must be present in the appropriate proportions, the physical and chemical conditions must be favourable, and there must be sufficient time for the atoms to become arranged25 Formation of Minerals – Physical Geology BCcampus Open The EHS Guidelines for Coal Processing cover the processing of coal into gaseous or liquid chemicals, including fuels They apply to the production of Synthetic Gas (SynGas) through various gasification processes and its subsequent conv ersion into liquid hydrocarbons (FischerTropsch synthesis), methanol,Environmental, Health and Safety Guidelines for Coal Processing

How Does a Coal Power Plant Work? Bright Hub Engineering

Thermalbased power plants can produce electricity from coal or other fuel sources The coalfired process requires three different steps to turn energy released from burning coal to generating electricity for consumption Coal fired power plants, while producing power, require a lot of water and produce a lot of pollutants like ash and CO2 Learn how the process works as well as 2016年2月29日 It is well known that small miners employ mercury to recover free gold and part of this liquid metal is released to the environment The process is an alternative to the amalgamation process The agglomeration process is based on the formation of agglomerated particles with coal and is known as Coal Gold Agglomeration (CGA)Gold Extraction Recovery Processes 911Metallurgist2018年9月17日 Turkey coal reserves are mainly lignite (brown coal) and the majority of these reserves contain highash/sulfur coals, therefore, it is important to evaluate these lowquality lignite coals(PDF) The beneficiation of tailing of coal preparation plant by 2021年6月24日 Coal in the seam is then excavated Surveyors are present to ensure the coal is mined optimally The coal is blasted into smaller layers, which are dug up and transported by trucks to a processing plant Throughout the coal mining process, we minimise the impacts on the environment including the air and water quality, noise and heritage sitesHow Is Coal Mined? Bravus Mining Resources

.jpg)

A systematic review exploring the utilization of coal mining and

2023年3月1日 Semantic Scholar extracted view of "A systematic review exploring the utilization of coal mining and processing wastes as secondary aggregate in subbase and base layers of pavement" by Experimental and numerical studies of the processes of spraying coalwater slurries with Journal of Materials in Civil Engineering2018年4月18日 The transition from construction to operation is the commissioning and startup Processing plant commissioning embraces activities such as cleaning, flushing, verifications, leak tests, performance evaluation and functional tests essential for bringing a newly installed plant or facility into routine operationProcessing plant commissioning considerationsCoal preparation is defined as the process of removing the undesirable elements from runofmine (ROM) coal by employing separation processes to achieve a relatively pure, uniform product These separation processes are based on the differences between the physical and surface properties of the coal and the impuritiesCoal Preparation an overview ScienceDirect Topics