Shandong 200 mesh grinding mill is a series of domestic dry grinding mills for mining.

.jpg)

Grinding Mills 911Metallurgist

Grinding mills reduce particle size by impact, rolling and sliding Of the many types in use, the cylindrical mill, which employs a cascading mass of balls or rods, is universally used for the size reduction of hard, moderate to highly abrasive materials, such as minerals, ores, stone, and Capacities up to 250 t/h, at 80% − 200 mesh, • Higher wear rates: 05–15 kg steel/t of product, • • Energy consumption 20–30 kWh/t Szego Mill™ (dry and wet) • Highspeed ringroller mill with Grinding Mill an overview ScienceDirect TopicsLooking for a reliable and efficient grinding mill for your industrial needs? Shandong Kemai Machinery Equipment Co,Ltd is proud to introduce our topoftheline grinding mills that are Grinding Mill KemaiPrater Fine Grinders (M Series Mills) are designed to grind dry, freeflowing material as fine as 400 mesh (37 microns) with a very tight distribution of particle size The highly efficient design M Series Fine Ginder Commercial Dry Grinder Prater Industries

.jpg)

Grinding Metso

Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills Grinding mills for mining and minerals processing Metso2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional Stirred media mills in the mining industry: Material grindability most versatile line of mills available today Wet or dry grinding With or without particlesize classification Closed or opencircuit processing From small lab batches to full production GRINDING MILL TO SUBMICRON PARTICLE RANGE SWECO

Grinding Mill MadeinChina

China Grinding Mill wholesale Select 2024 high quality Grinding Mill products in best price from certified Chinese Mining Machine manufacturers, China Crusher suppliers, wholesalers and SKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills The solutions are designed to protect pinions and trunnions Grinding mills SKFUnderstanding the operation of grinding mills in the mining and mineral processing industry Ball mills are the most commonly used type of grinding mill They work by rotating a cylinder containing lead balls, called grinding media, at speeds of up to 700 revolutions per minuteUnderstanding the operation of grinding mills in the mining and 2016年6月1日 Dry ROD MILL Grinding No other type of mill is so well adapted to dry grinding materials to 4 or 8 mesh in single pass with the production of a minimum amount of fines A major factor in dry grinding is the rapid removal of Rod Mills: Efficient Grinding Solutions for Mining

(PDF) A comprehensive review on the grinding process:

June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107Jet mills are predestined for grinding dry and very hard materials to obtain a particle The sJet ® 25 is the smallest laboratory unit of the sJet ® Steam Jet Mill series tested agitator bead mill technology to drygrinding and to complement the triumph of the IsaMill in wetgrinding in the mining sector with the dry agitator bead Dry Grinding NETZSCH Grinding Dispersing2019年11月1日 This paper presents the vibrating mill technology and summarizes the grinding principle of ultra fine grinding In addition, a variety of operations is described and the benefits of these Optimization of material grinding in vibration millsThe final product’s fineness can be adjusted at random between 018mm (80 mesh)001mm (800 mesh) HGM Series Superfine Grinding Mill Features: 1 High productivity and high efficiency With the booster spring, its grinding power is increased 2 Low energy consumptionHGM Series Superfine Grinding Mill Hongxing Mining

.jpg)

Grinding mills for mining and minerals processing Metso

Metso Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Metso Premier™ horizontal grinding mill is able to meet any projects needs, even if it means creating something novel and unseen before Learn more about the Premier™ horizontal grinding 2016年1月1日 The wear of balls used during a grinding process is considered one of the losses that cause an increase in the operating cost allocated to the ball mill [21]A comparison of wear rates of ball mill grinding media2018年8月17日 Stage 1 — Drilling This is the stage where it all begins A rock cutting process, drilling sets the stage for the next steps in the mineral processing operationGrinding Mills — Types, Working Principle ApplicationsHGM Series Ultrafine Powder Grinding Mill Fineness:1503000mesh Yield:0245t/h This Coal Powder Making Plant in Bhutan utilizes our CLRM1300 Raymond grinding mill to achieve 80400 mesh coal powder production with high HGM Series Ultrafine Grinding Mill; Feeding size: 200325 Mesh, D97; Output size: 800 mesh, D90; Capacity: 4000 SBM Ultrafine Powder Technology Industrial Grinding Mill,

.jpg)

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy EnergyEfficient Advanced Ultrafine Grinding of China Grinding Mills wholesale Mining Machine Grinding Machine Grinding Mill Top Quality Ultrafine Grinding Mill for Gypsum 400 Mesh US$ 65000 / Piece 1 Piece (MOQ) Discover the perfect Mining Mill addition with our Grinding MillsWholesale purchases of mining mills provide cost savings due to bulk ordering, Grinding Mills MadeinChinaFineness 50~200 Mesh Pulverizer Impact Pin Mill Ultrafine Grinding Line, Find Details and Price about Impact Pin Mill Pin Mill from Fineness 50~200 Mesh Pulverizer Impact Pin Mill Ultrafine Grinding Line Shandong ALPA Powder Technology Co, Pin mills can be used on both dry substances and liquid suspensionsPin mills are commonly use in Fineness 50~200 Mesh Pulverizer Impact Pin Mill Ultrafine Grinding

SBM Ultrafine Powder Technology Industrial Grinding Mill,

HGM Series Ultrafine Powder Grinding Mill Fineness:1503000mesh Yield:0245t/h This Coal Powder Making Plant in Bhutan utilizes our CLRM1300 Raymond grinding mill to achieve 80400 mesh coal powder production with high HGM Series Ultrafine Grinding Mill; Feeding size: 200325 Mesh, D97; Output size: 800 mesh, D90; Capacity: 4000 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and (PDF) EnergyEfficient Advanced Ultrafine Grinding of Particles 2016年7月8日 UNTIL THE THIRD THEORY OF COMMINUTION of "Work Index" method of determining crushing and grinding mill size was or to approximately 67% passing 200 mesh These may include packing in a crusher, oversize feed or improper ball and rod sizes in a tumbling mill, and coating dry in grinding Laboratory Tests for Determining Equipment Sizing: Crusher or Grinding Mill 911Metallurgist2021年9月1日 After the bentonite is crushed, ground, modified, and other processing processes, 2003000 mesh bentonite powder can be obtained, which can and its export value has ranked first in China’s mining machinery industry you can choose the HGM series of ultrafine grinding mills The mill has stable operation, simple Bentonite Ultrafine Powder Grinding Mill

Breaking down energy consumption in industrial grinding mills

2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed As an example, for completely controlling a grinding mill circuit the operation of a SAG mill is considered here as these mills seem to be slowly displacing the normal ball mill operations The SAG mill characteristics have already been mentioned earlier in Chapter 9 Grinding Mill an overview ScienceDirect Topics2016年2月2日 Our EXAMPLE Grinding and Classification Circuit is designed to grind 500 tonnes of ore per day, operating 24 hours per day, with an availability of 95% This circuit will grind 5/8″ material from the Crushing Plant, classify the slurry in one of two cyclones, and pass 70% of the minus 200 mesh material to the mill feed Thickener Circuit at a rate of 22 mtphGrinding and Classification Circuit 911Metallurgistgrinding in high pressure grinding rolls and downstream ball mills, 7th European Symposium on Comminution, Ljubljana, vol 2, pp 777788 [4] F W Bowdish,”Theorectical and experimental studies of the Kinectics of Grinding in Ball mill,” Trans AIME, 217, 194202(1960) 5STUDY OF BREAKAGE CURVES IN ULTRAFINE BALL MILL DRY GRINDING

.jpg)

Grinding Machines: Types and Selection Principles

2020年9月22日 Grinding machine has been widely used in gold mines in South Africa since 1905 At that time, the grinding machine used river pebble as the grinding medium, which was essentially a gravel mill Later, in order to A key aspect of this method is its utility in determining the suitability of a particular grinding wheel for a given flutegrinding task Therefore, the method can also be used for grinding wheel selection in machining That is, before the flutegrinding of the endmill, the grinding wheel with suitable parameters should be selected in advanceA GPUbased approach for 5axis flute grinding of endmills with SHANGHAI CLIRIK grinder, grinding is dry grinding machine The finished production fineness can be reached 300meshes~3000meshes, 547 micron The capacity (ton/hour) ranges from 04T/H to 12T/H HGM series dry grinder, dry grinding mill mainly consist of main unit, classifier, dust cleaner, powder collector, blower, muffler, hammer crusher (can be replaced by jaw Dry grinder, dry grinding millDry grinder, dry grinding mill Dry milling mills 45 companies 105 products My filters dry milling Delete all Manufacturers A; Batch mill suitable for dry grinding of hard and brittle substances up to 250 ml with a fixed speed of 20000 rpm The Hanningfield UniMill USeries utilises the current industry standard underdriven cone mill design, Dry milling mill, Dry milling grinding mill All DirectIndustry

.jpg)

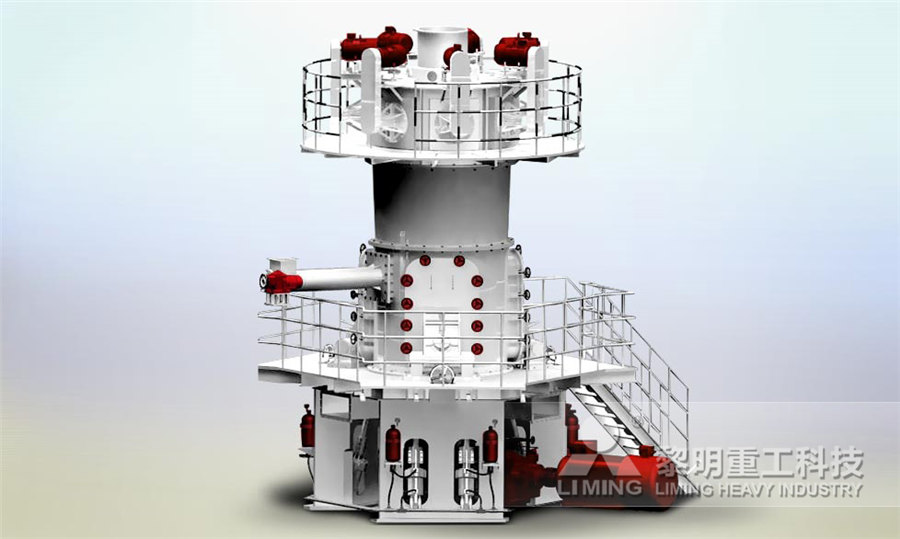

MTW Series Trapezoid Mill

Kefid 5tph Limestone Grinding Plant in Philippines Raw Material: gypsum powder Input Size: 1030mm Output Size: 200325 mesh; Capacity: 10t/h Equipment: MTW series mill MTW175 limestone 200 mm 325 mesh; D90 5 t/h MTW series mill MTW138 Related CasePrater Fine Grinders (M Series Mills) are designed to grind dry, freeflowing material as fine as 400 mesh (37 microns) with a very tight distribution of particle size The highly efficient design allows for ease of access to all internals and is well suited for heatsensitive materials such as resins and sugarM Series Fine Ginder Commercial Dry Grinder Prater Industries2021年7月28日 Dolomite grinding mill is an industrial ultrafine grinding mill, it can grind dolomite into a fine powder(1503000 mesh) In addition, it can grind other 100+ kinds of nonmetallic ores, such as limestone, HGM series powder mills have a lot of advantages: Small footprint low energy consumption simple operationDolomite Grinding Mill SBM Ultrafine Powder TechnologyHLMX series super fine mill is independently developed by our engineers which is used for large scale production of nonmetallic powders This 2500 mesh superfine powder grinding mill using static and dynamic separators which is able to produce adjustable fineness from 325 mesh (40μm) to 2500 mesh (5μm), capacity reaches 40t/hHLMX 2500 Mesh Superfine Powder Grinding Mill

.jpg)

HARD CLAY CLINKER FLINT CLAY 200 MESH GRINDING

2021年2月23日 A Flint Clay powder manufacturer purchased Guilin Hongcheng's HC1500 pendulum mill for hard clay clinker calcined refractory brick (flint clay) grinding powder production line formally put into operation, the production of Flint Claystone powder up to 200 mesh D95, the whole Flint Clay milling line produces capacity is about 253 tons per hourWet or Dry Grinding Mill Models: DM1, DM4, DM10, DM20, DM28, DM70 Low Amplitude Wet Mills Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet grinding, the low amplitude VibroEnergy Grinding Mills range from domestic wet and dry grinding mill KOOKS2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) MPS mills for coal grinding ResearchGate2016年6月6日 Common convention generally refers to highaspect ratio mills as SAG mills (with diameter to effective grinding length ratios of 3:1 to 1:1), lowaspect ratio mills (generally, a mill with a significantly longer length than diameter) are also worth notingSAG Mill Grinding Circuit Design 911Metallurgist

Dry Grinding Coke Grinding 911Metallurgist

2016年4月12日 This reaction is a result of a differently acting “bed of pulp” and lack of grinding media “coating” Due to a common “swelling action” of dry material being ground, the grinding media level is often reduced to approximately 4042% of mill volume Dry grinding offers less steel consumption than its equivalent wet grinding counterpartSourcing Guide for Maize Grinding Mills: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: milling machine, grinding machine, flour millMaize Grinding Mills MadeinChina2016年10月23日 Tests run by Sylvanite Gold Mines in Canada have shown 13% to 25% more 200 mesh produced on a power basis in a Grate Tube Mill than produced in an overflow tube mill On the basis of mill volume the grate mill shows 10% to 29% more capacity per cubic foot than overflow tube millsPebble Mill Grinding 911MetallurgistPDF On Jan 16, 2013, Gheorghe Voicu and others published Grinding Characteristics of Wheat in Industrial Mills Find, read and cite all the research you need on ResearchGateGrinding Characteristics of Wheat in Industrial Mills

Grinding Mills Dry Grinding Group Rhodes Innovators of

INCLA II AND INCLA III DRY GRINDING MILLS Heavy duty mills capable of grinding shales, marls and clays of a dry nature at high outputs Fitted with inclined grids, roller suspension device (optional), worm reduction gearbox and fully adjustable curved scrapers Optional hydraulic drive available Both mills have a 335 mtr diameter base2017年11月1日 Planetary ball mills at laboratory scale are widely used for grinding and alloying processes However, in contrast to other mill types, no applicable mechanistic model exists to describe the Dry grinding in planetary ball mills: Evaluation of a stressing