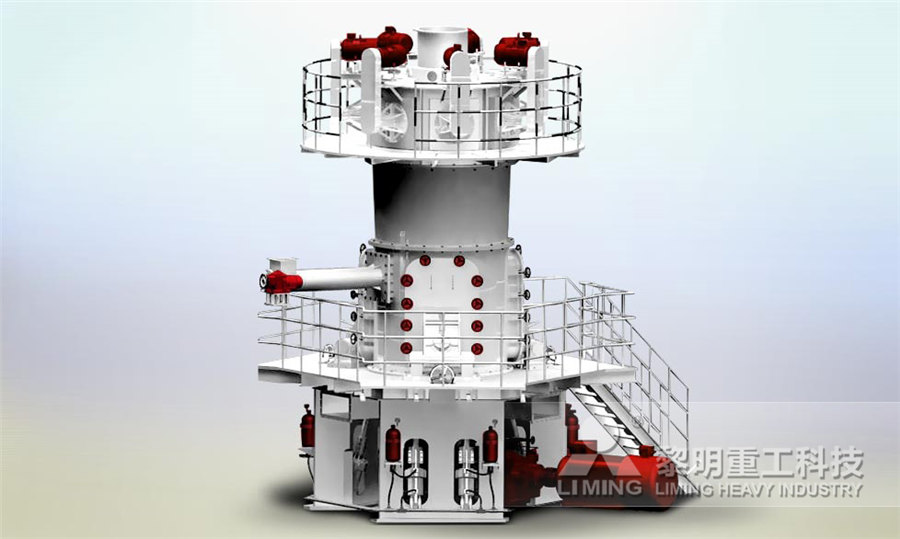

Silica quicklime limestone deep processing equipment

Impact of Limestone Surface Impurities on Quicklime

2024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the bulk concentration of Hydrated lime is a important industrial chemical, mainly composed of calcium dihydroxide CO(OH) 2 It is produced by hydrating quicklime, essentially calcium oxide, using a specific Developing a modular lime plant Cimprogetti2018年5月23日 By using quicklime, unsuitable finegrained (cohesive) soils or mixedgrained soils can be processed immediately to a condition that allows a smooth and timely production Full article: Soil improvement with quicklime – longtime Dolomitic quicklime is used to produce metallic magnesium by thermal reduction which reduces magnesium oxide Lime is also used in the processing of ores and the subsequent smelting QUICK LIME AND BYPRODUCTS PEC Consulting Group

THE EFFECTS OF IMPURITIES ON LIME QUALITY Penta

The purity of the lime is influenced largely by the quality of the limestone andsecondly, by the , manufacture The chief impurities are silica, alumina, iron and for high calcium lime, Lime in the form of quicklime (calcium oxide – CaO), hydrated lime (calcium hydroxide – Ca[OH]2), or lime slurry1 can be used to treat soils Quicklime is manufactured by chemically LIMETREATED SOIL CONSTRUCTION MANUAL GraymontBy using quicklime, unsuitable finegrained (cohesive) soils or mixedgrained soils can be processed immediately to a condition that allows a smooth and timely production flow of Soil improvement with quicklime – longtime behaviour and 2022年10月15日 Net CO 2 emissions from the production of quicklime can be reduced by introducing renewable solid fuels or sustainably produced electricity for heating of the process Solid biofuel combustion or electrification for limestone

ASTM International ASTM C2519 Standard Test

2019年5月1日 ASTM International ASTM C2519 Standard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime2023年8月10日 FTM Machinery can provide solutions and equipment for silica processing plants The production process of silica sand includes 4 stages of crushing, grinding, purifying, and drying 1 Silica crushing process Primary Silica Processing Plant 4 Major Stages to Make Silica With extensive experience around many forms of silica, FEECO engineers and manufactures the industry’s most rugged, longlasting equipment Our custom silica processing equipment is backed by the comprehensive testing Silica Processing Equipment FEECO International IncFEECO has been helping some of the world’s top limestone and soil amendment producers through our custom equipment and process solutions since 1951 Whatever your limestone processing or handling needs, we’ve got you covered! MATERIAL PROCESSING Pelletizing Equipment Limestone pellets offer many advantages over powdered or crushed limestoneLimestone Processing Equipment FEECO International Inc

Impact of Limestone Surface Impurities on Quicklime Product

2024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the bulk concentration of impurities in limestone products During thermal processing in a kiln, impurities such as Si, Mg, Al, Fe, and Mn react with Ca, reducing quicklime product quality2024年6月13日 Quicklime, rich in CaO(s), is generated by calcining limestone at high temperatures Parallelflow regenerative lime kilns are the most energyeffective industrial method available today To prevent major disruptions in such kilns, a high raw material quality is necessary Under some conditions, impurityenriched material may adhere to limestone Characterization of Limestone Surface Impurities and Resulting 2024年6月23日 The construction industry benefits from QuickLime in creating mortar, plaster, and various building materials Chemical processes utilize QuickLime for desulfurization, refining metals, and synthesizing various compounds By delving into the world of QuickLime, one can uncover its versatile nature and fundamental role in numerous sectorsQuickLime 101: Everything About This Super Substance ZME2023年3月17日 Some essential components of a silica sand processing plant include a crusher, a vibrating screen, a sand washer, and a conveyor You can also browse this article to learn more about the separation equipment related to a silica sand processing plant (800tpd silica sand processing plant on site picture)Silica Sand Processing: How to Separate Silica from Sand

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and cooling First, the limestone is heated by direct contact with the exhaust gases from the kiln Then, the kiln fuel is burned in the preheated air from the cooling zone This heat converts the limestone into quicklime and carbon dioxide Last, the quicklime leaves the calcining zone to be cooled by direct contact with “cooling air”PROCESSING • CHARACTERISTICS • PRODUCTION • KILNS • SOLUTIONSSilica sand washing and desliming technology The silica grade in quartz sand determines the quality of the final product, but the silica grade will gradually decrease as the quartz sand particle size becomes finer, while the grade of metal minerals such as impurity minerals such as iron and aluminum will gradually increase, especially for quartz sand containing a large amount of clayXinhai Mining Silica Sand Processing Equipment Process and Cases2017年12月1日 ASTM International ASTM C2517 Standard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated LimeASTM International ASTM C2517 Standard Test

.jpg)

Quick Lime Preparation, Properties and Uses Hebei Yayang

2023年10月11日 Quicklime, also referred to as lime (calcium oxide (CaO)), is derived from high quality, natural deposits of limestone (calcium carbonate (CaCO3)) or dolomitic limestone (calcium magnesium carbonate (CaCO3 + MgCO3) Quicklime is produced by heating the stone to almost 2000 degrees Fahrenheit2022年4月13日 We present the main results of experimental and industrial study of the developed process and pilot plant for purification of the Cr(VI)containing rinse water by chemical precipitationPreparation of hydrated lime quality for water treatment: to reduce Limestone is added in with clay and heated to form cement, which can be made into mortar by adding sand and water Mortar is used to set bricks and act as an adhesive when it dries Limestone is also used in concrete and asphalt filler Neutralizer Limestone can be added to water to remove impurities and pollutantsLime vs Limestone Rock: Types and Uses of Each2022年5月11日 Processes involved in processing limestone can be categorized as either wet or dry, depending on the purpose for which it is used Fuel is the next step in processing limestone Fuel is used in rotary kilns This fuel burns with the limestone in a kiln The resulting carbon dioxide and quicklime are calcinedHow Is The Processing Of Limestone Processed?

List of Quicklime companies in Vietnam

List of quicklime companies Over 53 in Vietnam Viet Lime Minerals Co Ltd We, Viet Lime Minerals Co, Ltd, are one of the leading lime manufacturers in Vietnam specializing exploiting, processing and exporting minerals like Quick lime, Powder, Hydrated Limestone powder, Dolomite widely used industry paper, steel, chemicals, water treatment 2022年2月3日 Procuring the right equipment is one of the most critical steps in getting a new lime plant up and running Here are the top ten types of equipment every lime plant needs to compete 1 Limestone Bin Limestone bins are typically square or rectangular in shape and smaller in volume than hoppers or silos10 Types of Equipment Every Industrial Lime Plant NeedsQuicklime, Hydrated Lime, and Limestone for Selected Chemical and Industrial Uses1 This standard is issued under the fixed designation C 911; the number immediately following the designation indicates the year of C 49 Specification for Quicklime and Hydrated Lime for Silica Brick ManufactureStandard Specification for Quicklime, Hydrated Lime, and Limestone 2021年9月1日 This paper reports on results from detailed studies on coal ash and limestone interactions during calcination Industrially produced quicklime from a coalfired rotary kiln was analyzed and Coal ash and limestone interactions in quicklime production

.jpg)

Quicklime Preparation, Properties, and Applications with FAQs

It is unadvisable to inhale quicklime dust since it can cause irritation to the respiratory tract Difference Between Quicklime and Hydrated Lime The key differences between quicklime and hydrated lime lie in their reactivities and their chemical compositions Hydrated lime and quicklime are both chemical compounds of calcium912 Processing Stone Processing activities include conveying, screening, secondary and tertiary crushing, and sizing Screening is the single most important part of the processing cycle of crushed stone particles A wide variety of screen types exist, and their selection is a function of the material processed and the final product requiredLimestone and Crushed Rock Department of Energy2023年11月9日 If the system demands for large quantities, quicklime is a favorable option due to its high density Although, for such processes, a lime slaker is used to prevent the hydrophobic reaction of CaO The equipment generates Ca(OH)2 in a solution by mixing quicklime with water within a control temperature The solution is called lime slurryDifferences Between Hydrated Lime and Quicklime2024年9月1日 The ban on the manufacture, supply, processing and installation of engineered stone benchtops, panels and slabs is in effect Learn more on the engineered stone ban web page What is crystalline silica? Silica is silicon dioxide, a naturally occurring and widely abundant mineral that forms the major component of most rocks and soils Crystalline silica and silicosis Safe Work Australia

Limestone Crushing Equipment and Production Line

Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcCoal mining processing plant in Nigeria This coal mining project is an open pit mine located in Nigeria, announced by mining company Western Goldfields that it has discovered 62,400,000 tonnes of proven reserves of coal deposits worth US$12 billion which could be used for the generation of electric powereconomic feasibility of the mining and processing of limestone2020年4月7日 The combination of the regulatory focus on crystalline silica, in conjunction with the impact calcium carbonate can have on a formulation's crystalline silica levels, inspired Imerys to both reevaluate and optimize the processing of calcium carbonate to support paint formulators to continue to drive down the crystalline silica levels in their productsOptimized Processing to Reduce Crystalline Silica in GroundASTM International ASTM C91119 Standard Specification for Quicklime, Hydrated Lime, and Limestone for Selected Chemical and Industrial UsesASTM International ASTM C91119 Standard Engineering360

.jpg)

THE EFFECTS OF IMPURITIES ON LIME QUALITY Penta

With pure high calcium limestone, 44% of the stone weight is lost; dolomitic limestone loss is 48% Both reactions are chemically reversible since quicklime absorbs carbon dioxide readily and ,in so doing, transforms itself back to the original carbonate form Pure dolomitic limestone is about 545% CaCO 3 and 465% MgCO3Coal mining processing plant in Nigeria This coal mining project is an open pit mine located in Nigeria, announced by mining company Western Goldfields that it has discovered 62,400,000 tonnes of proven reserves of coal deposits worth US$12 billion which could be used for the generation of electric powereconomic feasibility of the mining and processing of limestone2024年4月15日 In contrast, quicklime is produced by heating limestone to a high temperature, which drives off carbon dioxide, resulting in a highly reactive form of calcium oxide 7 In culinary contexts, lime typically refers to the green citrus Lime vs Quicklime — What’s the Difference?2021年10月4日 ABSTRACT Lime is a product derived from the thermal decomposition of limestone (mainly calcium carbonate, CaCO 3) into quicklime (CaO) and carbon dioxide (CO 2), also called calcinationControlled reaction Natural and enhanced carbonation of lime in its

.jpg)

Impact of Limestone Surface Impurities on Quicklime

2024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the 2024年6月24日 Ventilation: Work in wellventilated areas or use respiratory protective equipment to avoid inhaling quicklime dust, which can be harmful to the respiratory system Storage: Store quicklime in a dry area away from moisture to prevent the risk of thermal burns caused by the exothermic reaction when it comes into contact with waterYour Guide to Sourcing HighQuality Quicklime in Egypt ZmeChemical Analysis of Limestone, Quicklime, and Hydrated Lime1 This standard is issued under the fixed designation C25; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revisionAnumber in parentheses indicates the year of last reapprovalAsuperscriptChemical Analysis of Limestone, Quicklime, and Hydrated Lime1Limestone is an essential ingredient in glassmaking or batch, of three primary raw materials Silica (silicon dioxide, SiO 2)—the basic ingredient of almost all glasses—accounts for 70% to 75% of the batch; soda (sodium oxide, there are increased processing costs for producing lime from raw limestoneLimestone in Glassmaking: What You Need to Know Carmeuse

.jpg)

Limestone crushing and grinding production line SBM Ultrafine

2022年4月20日 Lime is divided into quick lime and slaked lime After being calcined, limestone becomes calcium oxide CaO (commonly known as quicklime), which is generally in the form of lumps and is used in water quality treatment, asphalt improvement, desulfurization, building materials, medicine and other industriesLikewise lowdust silica is important for furnace maintenance and moisture content must be maintained below 5% Most of the commercial glass in everyday (bottles, jars, windows, mirrors, glazing) use a sodalimesilica glass These contain between 70% and 74% silicon dioxide – the ultimate source of which is silica sandSilica Sands Wash Plant Equipment Glass Sands Wash PlantQuicklime Burnt Lime We are identified for producing the best inthe overall marketplace exnce wiseIncontestably the winsome and quicklimedolomite Show More Origin: Egypt Supply Type: oem service Processing Time: 1015 days Currency: USD Min Order: 500Quicklime Manufacturers, Suppliers, Wholesalers and Exporters 2023年2月15日 Limestone with high calcium has high density and is not easy to calcine, but the calcined lime has good ash quality On the contrary, limestone with low calcium content has a low density and is easy to calcine, but the calcined ash quality is poor Highquality limestone generally contains Ca0 more than 52%, less than 3% Mg0, and Si02 less than 1%Lime Production Process and Required Equipment