Cement plant crushing

.jpg)

Cement Crusher Crushers for Cement Plant AGICO

AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher The hammer crusher is a kind of In the cement industry, the application of the hard rock impact crusher is for size reduction of iron ore and quartzite as corrective ingredients for the proper cement raw mix composition; also Complete Lecture about Crushers in Cement IndustryMobile crushing plants make it possible to crush minerals directly at the site of extraction and synchronize to the rate of mining advance, into sizes ready for conveyor transport of the crushed material from the mining face to the Crushing Technologies thyssenkrupp PolysiusThe Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide Providing a The Cement Plant Operations Handbook International Cement

Cement Crusher – Crusher In Cement Plant AGICO

As a cement plant manufacturer, AGICO not only produces cement production lines, stone crushing plant, but also manufactures many cement equipment, such as a series of cement crushers required for cement raw material crushing: We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing Hammer Crusher Working Principle AGICO Cement 2019年10月30日 Common cement crushers include jaw crusher, cone crusher, impact crusher, and hammer crusher In recent years, mobile crusher is popular in the cement plant The raw material can be broken by extrusion, shearing, How To Choose Cement Crusher? Jaw Crusher, Cone Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line Before sending it into the raw mill, the cement raw material should be crushed into small sizes Cement Crusher Cement Crusher For Sale Jaw

Jaw Crusher Jaw Crusher Mannufacturers AGICO

Jaw crusher is suitable for crushing all kinds of ores and rocks whose compressive strength limit is less than 250 mpa It is mainly used as the primary crusher or secondary crusher in cement plant and concrete industries The The cyclone preheating system Phase IV: Calcination The calcination is the core phase of the cement making dry process The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant The rotary kiln is a How Is Cement Produced in Cement Plants Cement Here are some successful cases of AGICO CEMENT, we can provide EPC solutions for cement plants, lime production, gypsum board plant, crushing plant, etc FREE to ask! Skip to content +86 s about blog contact EN ES Menu Menu Home; Cement Equipment Raw Material processingCement Plant Projects Crushing Plant Projects, Rotary Kiln At the lower end of the kiln, a roaring flame heats the material to about 2,700 degrees Fahrenheit, making it partially molten In addition to fossil fuels, US plants coprocess alternative fuels including tirederived fuel, reducing landfill waste while creating more than 15% of the energy used by US cement plantsHow Cement is Made Portland Cement Association

制粉-10.25公众号.jpg)

Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

Cement Manufacturing Process by TIZITA MOGES , SELAMU ABULE DEREJE ENDALAMAW IF YOU NEED THIS GUIDE AND ALL OTHER USEFUL EXCEL SHEETS WHICH WILL MAKE YOU MASTER THE PRODUCTION , PROCESS , MAINTENANCE ACTIVITY IN YOUR CEMENT PLANT KINDLY CLICK HERE Raw Material Preparation and 2019年10月30日 How to design cement crushing plant? Customers who need cement crusher should know more about this area, comprehensive analysis of the specific situation and the ability to select the crusher and cement crushing plant As a manufacturer of cement plants, AGICO Cement provides a onestop turnkey project cover design, manufacture, and How To Choose Cement Crusher? Jaw Crusher, Cone Crusher2020年8月25日 How much do you know about cement production process? A full cement production process includes the cement crushing process, raw mill process, clinker process, and cement grinding process, cement packing process, and related process Find more!Cement Production Process Cement Manufacturing Process AGICO CEMENTStage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inchesHow Cement is Made Cement Manufacturing Process

Cement Plant, Cement Equipment Cement Plant Manufacturer

Cement plant is necessary for cement production, and mainly consists of a series of cement equipment apply for the preparation of cement raw materials, clinker production, and finished cement production, such as a cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipmentReduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, StrikeBar™ Crusher FLSmidth CementAs a cement grinding plant manufacturer, AGICO Cement can provide a cement EPC project as you need We have rich experience in design cement plants and process cement manufacturing machines, such as cement crusher, cement Cement Grinding Plant Overview Cement Grinding Specifically designed for the needs of cement plant operations, our crushing equipment delivers reliable, heavyduty performance Our range of impact crushers includes hammer and strikebar impact crushers, as well as dryer crushers – and the easytoinstall, longlasting wear parts to keep them running smoothlyImpact crushers FLSmidth Cement

.jpg)

Cyclone Dust Collector For Cement Plant Industrial Cyclone

An industrial cyclone dust collector or cyclone dust filter, industrial cyclone separator, dust collector cyclone separator, is one of the most important dust collection devices just like baghouse dust collector, ESP electrostatic precipitator in the cement production line It is mainly used in the raw material crushing and clinker production systems of cement plant to collect and remove The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing : the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, Preparation Of Cement Raw Material Cement Mill, Cement Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production lineBefore sending it into the raw mill, the cement raw material should be crushed into small sizes by the cement crusher The cement raw material can be crushed by many methods including pressing shearing, rolling or impactingCement Crusher Cement Crusher For Sale Jaw Crusher, Cone 2020年12月11日 Recently, AGICO CEMENT has built a cement crushing plant project in Anhui This is a limestone crushing plant, the main component of limestone is calcium carbonate (CaCO3), Mohr hardness is 3, rich resources, raw ore grade can generally meet the requirements of various industrial departments, the limestone crushing plant generally use dry crushing 500tph Limestone Crushing Plant Project In Anhui AGICO CEMENT

Hammer Crusher Machine Cement Plant

Hammer crusher working principle The hammer crusher machine completes the crushing material operation by the impact energy During the operation of hammer crusher machine, the motor drives the rotor to rotate at a high speed, and the material enters the crusher cavity evenlyJaw crusher is mainly used for raw material coarse and medium crushing in the cement plant and crushing plant According to the width of the feed port, it can be divided into three types: large type (feed port is larger than 600mm), the medium type (feed port is between 300600mm), and small type (feed port is smaller than 300mm)Stone Crushing Plant Automatic Stone Crusher Plant AGICO2019年9月27日 Cement mill is another necessary cement equipment of the cement plant After raw material crushing, cement mill plays vital role in the further cement manufacturing process Cement ball mill, vertical cement mill, and cement roller press are common types of Cement Euipment Overview Cement Making Machines Cement PlantThe stacker and reclaimer is the prehomogenization system in the cement plantAs a necessary part of the cement production line, it can concurrently or respectively complete the stacking and reclaiming The stacker and reclaimer Stacker And Reclaimer Cement Plant Parts

Impact Crusher Impact Rock Crusher AGICO

In the working process of the machine, the rotor rotates at a high speed driven by the motor When materials enter the crushing chamber, they will be impacted and crushed by the blow bar on the rapidly turning rotor, and then thrown to the As newtype and energyefficient cement grinding machine, cement roller press has advantages of energysaving, high efficiency, less steel consumption and less noise Both apply for new cement plant building and old cement plant Cement Roller Press, Roller Press In Cement Plant2023年2月23日 Hammer crushers play a critical role in the cement production process These machines are used to crush raw materials needed for the production of cement, such as limestone, clay, and shale Proper maintenance of these machines is essential for their efficient operation and to prevent breakdowns that can lead to costly repairs and reduced production The Importance of Regular Maintenance for Hammer Crushers in Cement PlantsMobile crusher, also called mobile crushing plant, mobile crusher plantIt is an advanced crushing equipment that is developed by many experts, and its outstanding advantage is convenient move, small area occupied, also no need of the operating place, directly applied to the cement production line, because the mobile crushing plant can be built directly on the ore, which can Mobile Crusher, Mobile Crushing Plant For Sale Cement Plant

Ready Mix Cement Treated Base Crushing Plant

Tjiwi Kimia Mojokerto, 1991 Gresik Combined Cycle Power Plant Project Gresik, 1990 – 1992 Paiton Private Power Plant Project Phase I and II – Probolinggo, 1995 1998 Copper Smelter Plant Project Gresik, 1996 1998 Urgent Development Plant of Semarang Port Project Semarang, 1998 1999Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC for example, cement structures are much cheaper to erect in Mexico than in Alaska Remote projects can suffer from Crushing Plant Design and Layout Considerations 911 Metallurgist2023年9月14日 With an extensive presence in the Indian Cement Industry, LT is the largest Limestone Crushing plant supplier Our crushers dominate the market, covering major cement plants across India Additionally, our crushers have gained international recognition, with exports to countries such as Australia, Nepal, Bangladesh, Bhutan, CrushersIndia – LT Construction Mining MachineryPROJECT REPORT ON CEMENT PLANT USING CLINKER (CRUSHING PLANT) Free download as PDF File (pdf), Text File (txt) or read online for free Cement is a material that binds together solid bodies (aggregate) by hardening from a plastic state Many materials act as adhesives or cement according to this definition The cement referred to above, which is used Project Report On Cement Plant Using Clinker (Crushing Plant)

BASIC CEMENT PLANT LAYOUT – Process Cement Forum The Cement

2020年7月4日 00 Limestone Quarry and Crushing Plant The major raw material for cement production is limestone The limestone most suitable for cement production must have some ingredients in specified quantities ie, calcium carbonates, silica, alumina, iron, etc Typically, cement plant locations are based upon the availability of good quality limestone As a cement equipment supplier and cement plant manufacturer, AGICO offers quality cement kiln, cement vertical mill cement ball mill, hammer crusher, etc Besides, we provide cement production line, stone crushing plant, etcCement Equipment In Cement Plant AGICO Cement 2023年2月28日 Primary crushers are also used in some industrial applications, such as in the production of cement and other building materials 100t/h Slag Mobile Crushing Plant; Blog; About; Contact Us +86 The Complete Guide to Primary Crushing, Secondary 2019年11月21日 Cement plant equipment, also known as cement plant machinery, cement production machinery, etcIn a complete cement production line, there is various cement plant equipment to play own roles As we all Cement Plant Equipment Cement Crusher, Cement

.jpg)

Air Pollution Control in Cement: Solutions Impact Techflow

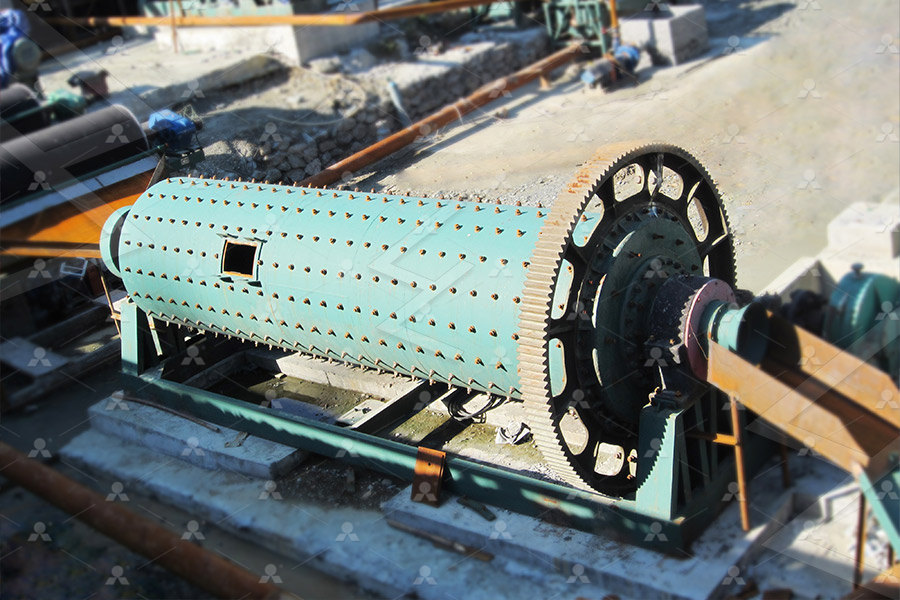

2023年9月22日 Discover how air pollution control systems, including ESPs and bag filters, are revolutionizing cement plants Learn about their applications and environmental benefits +91 90237 30719 sales The manufacturing of cement involves mining; crushing and grinding of raw materials (mostly limestone and clay); calculating the material In a cement plant, crushing is the primary sizereduction process carried out under the action of external mechanical forces Generally, three levels of crushing are recognized: coarse (top product size, up to 150 to 200 mm), intermediate (up to 40 to 70 mm), and fine (up to 5 to 25 mm)Everything you need to know about cement Materials Preparation Cement Industry The experience in the crushing of aggregate field, together with 3D computer system designs, have allowed us to manufacture machines the cement industry A very demanding sector, which requires: extremely reliable machines; very limited maintenance; high productionCement Industry STONE CRUSHING PLANTBall mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill, the closedcircuit ball mill has high efficiency, high output, low cement temperature, and good comprehensive benefit It is the best choice for a cement plant Skip to Ball Mill In Cement Plant Cement Ball Mill AGICO Cement

What Machines Do Stone Crushing Plants Need? Fote Machinery

2024年10月14日 A stone crushing plant needs essential primary crushers like jaw and gyratory crushers as well as finecrushing equipment like impact crushers and ball mills Other critical heavyduty machines for the effective operation of a stone mill include the belt conveyors, vibration feeder, vibrating screens, and a central control system for all these machinesRoll crusher, also called roller crusher machine, is a kind of traditional crushing mill, mainly used for the middle and fine processing of raw material applied in cement plant, chemical industry, building materials industry, etcIt is usually classified into three types: singleroll crusher, doubleroll crusher and fourroll crusherFourroll Crusher Roll Crusher AGICO Roller Crusher Machine5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by a scrubbing action (shearConstruction, Working and Maintenance of Crushers for Crushing