Super Fine grinding machine500 barite grinding machine series training manual

HTC 500 MANUAL Pdf Download ManualsLib

General information HTC 500 is a grinder that can be used to grind, strip, clean and polish concrete, natural stone and terrazzo floors The machine's area of application depends on the 2020年4月1日 It also outlines the working principles of superfine grinding mills, which integrate crushing, grinding, and classifying to produce powders as fine as 2500 mesh Key features Superfine grinding mill PDF SlideShare3/24/14 Fine Grinder Installation/Operation/Maintenance Manual 11 Section 2: Introduction 21 Manual Overview This manual describes the installation requirements, procedures, and FINE GRINDER INSTALLATION, OPERATION, AND MAINTENANCE Supfina’s throughfeedfinishing machines help to achieve high production rates with minimal work effort, thanks to reduced retooling times and long service lives for the tools The Supfina Supfina Superfinishing

Supfina Fine Grinding

Fine grinding in largescale production The flexible Spiro F7 finegrinding machine is ideal for creating precise flat surfaces on workpieces made from a wide variety of materials Memory Grind Master NANOFINISH Machines are based on a modular design concept, and can be optimized for specific applications with configurable stations including no of arms, Arm SUPERFINISHING MACHINES|POWER From white papers and Customer Care documentation to machine information and seminar details, view or download the latest PDFs from UNITED GRINDINGPDF Downloads UNITED GRINDING North AmericaMachining takes place between two rotating grinding wheels The optimal machining force is applied by the upper wheel, which is mounted on an oscillating pendulum Fine grinding’s Supfina Fine Grinding

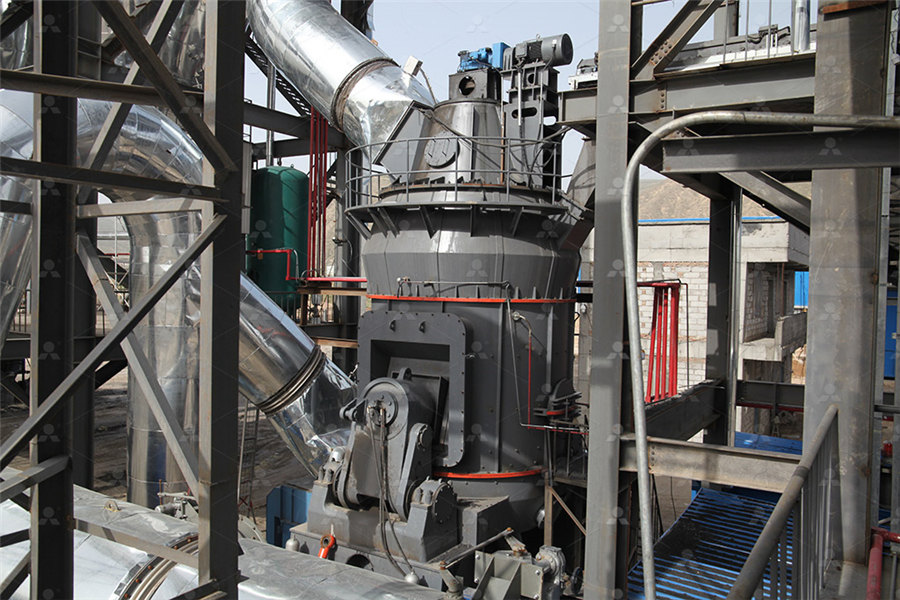

Superfine Grinding Use Maintenance Eastman Rock Crusher

2021年8月31日 Superfine grinding is suitable for processing materials with humidity below 6% and hardness no more than 93 The fineness of processed products can be adjusted The combined generating and profile CNC grinding machines LCS 200 to 500 The new LCS series offers a machine system for finish machining of hardened gears, characterized by its Generating and profile grinding machines LCS 200500The Spiro F5 fine grinding machine can include the use of an optional loading table for manual loading and unloading purposes Case Study Supfina recently partnered with The Timken Company with their complex automation needs, customizing Supfina Fine GrindingT130X Superfine Grinding Mill T130X enhanced superfine grinding mill is a newly designed grinding mill based on the former patent product TGM super pressure trapezium mill according to market investigation and careful statistics and analysis of use and suggestions from our clients carried out by our experts, which has got unique features by carrying on and improving T130X Superfine Grinding MillKefid Machinery

Grinding Machine: Definition, Parts, Working

2021年5月5日 One major advantage of this machine is the manual and automatic operation can be performed Grinding Machine Disadvantages: The following disadvantages of Grinding Machine are: The Grinding Machine is a High Quality Cylindrical grinding machine, ideal for manufacturing Featuring balancing stand, Our UG series cylindrical grinders feature an interver workhead, Rough:001mm Fine:00025mm: Wheel Size(OD*W*ID) 500 x 75 x 305mm: 900 x 75 x 305mm: Peripheral Velocity: 35M/s: 35M/s:UG Series Grinding Machines Cylindrical Grinder Chester Machine SpeedFam and the Melchiorre Fine Grinding machines offer high quality, extreme structural strength and advanced electronic Fine grinding is a super finishing process performed by removing material from two surfaces of a component resulting in extremely precise geometric These systems are available in the ELC 500, 900, 1200, Fine Grinding Machines SpeedFam USASuper Fine Calcium Carbonate Grinding Mill/Roller Mill/Mining Machine/Grinding Machine/Milling Machine, Find Details and Price about Grinding Machine Dolomite Powder Making Machine from Super Fine Calcium Carbonate Grinding Mill Suitable for processing of nonmetallic minerals such as calcium carbonate,clay,barite,talc,gypsum,limestone Super Fine Calcium Carbonate Grinding Mill/Roller Mill/Mining Machine

.jpg)

A member of the UNITED GRINDING Group CamGrind S

different variations to super productive throughfeed grinding This allows you to machine a very large variety of workpieces, from small jet needles through to large shafts Schaudt Mikrosa GmbH is part of the UNITED GRINDING group, one of the leading suppliers of machines, applications, and services for hardfine machining worldwideThe barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERYBarite powder ultrafine vertical roller mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6(the Moh’s hardness), such as barite, vermiculite ,calcium carbonate,quartz, feldspar, calcite, talcum, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etcBarite powder ultrafine vertical roller mill Clirik Barite grinding LAPMASTER WOLTERS offers a full line of fine grinding superabrasive wheels and dressing stones for all makes and models of fine grinding and flat honing machines Our wheels incorporate the finest quality and extremely close graded diamond, black CBN and amber CBN in conjunction with our specially formulated vitrified bondFine Grinding Machines Lapmaster Wolters

Clirik Barite grinding mill Shanghai Clirik

Shanghai Clirik Machinery devoted to provide barite processing and grinding solution,barite grinding mill, barite grinding machine,barite processing machine, barite powder production line, barite powder making machine for saleManufacturer of Manually Series Automatic Surface Grinder Machines, Down Feed 10x20 Surface Grinding Machine, 800 X 500 mm: Type of Grinding Machine: Surface Grinding Machine: Table Size: 350 x 800mm: Grinding Manually Series Automatic Surface Grinder Machines 2022年5月12日 HPG500NC is possible to operate as conventional grinding When processing as manual function same as in the conventional machine, it is also possible to process by operating the handle It can also be used as a CNC High Precision Form Grinding Machine, 2020年8月12日 3 Grinding Machine The grinding machine is a kind of tool which is used for grinding work pieces Grinding machine it makes use of an abrasive wheel in the form of a cutting tool The rough surface of the abrasive wheel shreds away small pieces of the work piece as needed Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece Grinding machine PPT Free Download SlideShare

Centerless grinding machine All industrial manufacturers

Distance between centers: 1 mm 50 mm Grinding wheel diameter : 305, 405, 455, 510 mm Machine weight: 1,500, 2,400, 3,200, 3,700, 4,000 kg The RC series centerless grinding machines can be used for infeed grinding and thrufeed grinding to ensure accuracy, high productivity in workpieces Ultrafine Mill Working Video Introduction of Ultrafine Mill: As one kind of grinding equipment, ultrafine mill is widely used in the metallurgy, building material, chemical and mining industries for grinding nonflammable and nonexplosive mining materials with less than 7 Mohs hardness and 6% humidity, such as calcite, talc, barite, fluorite, quartz, feldspar, kaolin clay, bentonite clay Ultrafine Mill/ Super Fine Grinding Mill Price/ Ultrafine Baritedifferent variations to super productive throughfeed grinding This allows you to machine a very large variety of workpieces, from small jet needles through to large shafts Schaudt Mikrosa GmbH is part of the UNITED GRINDING group, one of the leading suppliers of machines, applications, and services for hardfine machining worldwideA member of the UNITED GRINDING Group FlexGrindDouble Side Fine Grinding Machine Carbide blade, aluminum ring, rotor stator, ceramic value, Carbide strip, Stator, Cycloid gear #69/70, SIPCOT Industrial Complex HOSUR – +914344Double side fine grinding machine Went India Limited

CLG Series Powder Surface Coating Machine Barite grinding mill

CLG Series Powder Surface Coating Machine is a kind of mining machinery with high economic benefit Home; About Us; Products 5001800 kg/h: 3 t: 5800*1800*5600 mm: CLG3/600 : 337 kw: 1522 kw: 2700 rpm : 20004000 kg/h : Clirik will recommend suitable production lines and grinding equipment to you according to your site 3Barite Powder Micro Powder Gridning Mill Advantage: 1 Barite Powder Micro Powder Gridning Mill Wearing parts are made of wearresistant materials High utilization rate of Wear material: 25years 2Barite Powder Micro Powder Gridning Mill Multilayer grinding ring design for higher grinding efficiencyWhich Should You Choose Barite Grinding Mills?Grindmaster builds Grinding Machines, Polishing Machines, Deburring Machines, Superfinishing Machines Provides Robotic Solutions, Coated Film Backed Abrasives, Superfinishing Films +91 Grindmaster Pvt Ltd Automatic Robofinish, Ultra Precision Form Grinding Machine UPZ Series OKAMOTO MACHINE TOOL WORKS, LTD 2993 Gobara, Annaka, Gunma, Japan 3790135 TEL : +81273889595 FAX : +81273851144 URL : okamotocojp *Prior to and Ultra Precision Form Grinding Machine UPZ Series

CBN grinding machine All industrial manufacturers

Double sided fine grinding machines, The G 500 H gear grinding Compare this product Remove from comparison tool vertical disc grinding machine Evo Penta workpiece CNC 5axis Contact vertical disc grinding machine The 2014年10月25日 10 Spindle in respect of accuracy parallelism surface finish although production norms will be lower • Table diameter 500 to 1000mm spindle drive : 375 kw to 75 kw distance , table to spindle center 300 to 450mm • Spindle runs in super precision angular contact preloaded bearings with travels in the vertical column in hand scrapped guide ways with power Surface grinding machine PPT SlideShareAn innovative, high speed, automated grinder that dramatically reduces finishing time and labor costs The BARINDER® has easytolearn programming, which is designed to be intuitive and allows the operator to teach the machine to automatically perform the same operations that would otherwise be performed manuallyBarinder Auto Grinder Machine by Sinto America, Industrial China Fine Grinding Machine wholesale Select 2024 high quality Fine Grinding Machine products in best price from certified Chinese Mining Equipment manufacturers, Mining Machine suppliers, wholesalers and factory on MadeinChina Home Manufacturing Fine Grinding Machine MadeinChina

What is a Grinding Machine: Definition, Types, Components

2024年1月27日 Manual Bench Grinders: Typically cost between $50 – $500 Ideal for smallscale grinding tasks Surface Grinders: Power requirements for different types of grinding machines vary: Manual Bench Grinders: Typically require between 250 – 750 watts Proper Training: Only operate a grinding machine if you have received 2Wheels Flat Honing and Fine Grinding The impressive DLM series, developed using the competence of the Stähli Group, is capable of flat honing with diamond / CBN wheels or alternatively precision grinding with conventional SiC orStähli 2side Flat honingFind your fine grinding machine easily amongst the 15 products from the leading brands (Satisloh, The RC series centerless grinding machines can be used for infeed grinding and thrufeed grinding to ensure accuracy, latestdeveloped superfine mechanical grinding machine by combining the domestic and overseas advanced technologyFine grinding machine All industrial manufacturersHere we present our modern surface and profile grinding machines for high precision and surface quality JUNG offers a wide range of possible applications JFi series; JFN series; JEP series; Other products Grinding software; Overhauled grinding Grinding machines JUNG

GRINDING MACHINES TOS as PDF Catalogs DirectIndustry

Machine Applications Centre Grinding Machines The highperformance grinding machines of BUA series (Practic and Profi versions), BUB series (Practic, Profi and Multi versions) and BUC series (Practic, Profi and Multi versions) are designed for precise grinding of several external cylindrical surfaces of different diameters, their adjacent faces and transition radii on work pieces• ID grinding spindles 40,000 to 90,000rpm Kellenberger’s KSeries CNC Grinders are the best machines in the market for super precision and high accuracy grinding applications Available in the following sizes: • K10 • K100 • K1000 KEY FEATURES • FANUC CNC CNC Universal OD/ID Grinders and SUPERPRECISION LathesFine grinding Fine grinding is also used when workpieces require both surfaces to have plane parallelism, but with more precision than can be achieved with doubledisk grinding Supfina Machine Company, Inc 181 Circuit Drive North Kingstown RI 028527439 / Supfina Fine GrindingHigh Precision Form Grinding Machine HPG500 Series Precision Form Grinding Machine PFG500 Series OKAMOTO MACHINE TOOL WORKS, LTD 2993 Gobara, Annaka, Gunma, Japan 3790135 TEL : +81273889595 FAX : +81273851144 JQAQMA10960 URL : okamotocojp Annaka Factory *Prior to and while using our products you are requested High Precision Form Grinding Machine HPG500 Series

.jpg)

Crushed Rock Fine Powder Grinding Machine Crusher Mills,

fine crushed calcite – Newest Crusher, Grinding Mill, Mobile The stone crusher machine for crushing calcite, calcite powder Heavy calcium fine powder for artificial stone, and artificial floor tiles, and natural rubber, and Our doubleside batch processing machines from the AC microLine® series meet the highest technological standards and requirements No matter whether it is fine grinding, lapping, honing, deburring or polishing: With the proven machines of the ACmicroLine® series, you can produce work pieces of unmatched precision down to micronsDOUBLESIDE HIGHPRECISION PROCESSING MACHINESdifferent variations to super productive throughfeed grinding This allows you to machine a very large variety of workpieces, from small jet needles through to large shafts Schaudt Mikrosa GmbH is part of the UNITED GRINDING group, one of the leading suppliers of machines, applications, and services for hardfine machining worldwideA member of the UNITED GRINDING Group KRONOSLiebherr presents the new series of generating and profile grinding machines for hard machining of external and internal gears on workpieces with diameters of up to 500 millimeters The LGG series follows the successful Liebherr LCS 300 to 500 series With an impressive range of added features, they offer more flexibility and grinding Generating and profile grinding machines Liebherr

.jpg)

Superfinishing Machine Manufacturer Grind Master

Centerless Grinding And Polishing Machines; Flat Part Grinding Polishing Machines; Sheet Metal Polishing And Deburring Machines; Cookware Polishing Machines; Manual Metal Finishing Machines; Special Purpose Metal Finishing Machines; DEBURR SMP300/500/800 Series: Admit Between Centre 300/500/800 mmThe CNC Generating and Profile Grinding Machines LCS 200 to 500 Open the catalog to page 1 The combined generating and profile CNC grinding machines LCS 200 to 500 The new LCS series offers a machine system for finish machining of hardened gears, characterized by its productivity and versatilityGenerating and profile grinding machines LCS 200500