Processing heavy calcium powder into sand

Electrocementation of calcareous sand using colloidal silica (CS

2023年11月9日 The research investigates the effectiveness of a ground improvement technique that involves the electrocementation of an onshore calcareous sand containing 953% calcium carbonate through a series of laboratory experiments2024年10月31日 As an industrial byproduct of crushing limestone and producing mechanism sand in quarries, heavy calcium powder is not only inexpensive and stable in composition, but Study on properties of slag heavy calcium powder cement The technological process is that water, dispersant and heavy calcium carbonate powder are first mixed and dispersed via stirring and then sand ground The dispersant used is a mixture ofCNA Wet process for superfine heavy calcium carbonate Simultaneous productions of highpurity CaCO 3 (calcium carbonate) and amorphous nanosized SiO 2rich (silicarich) gel from waste concrete powder remain quite challenging, and thus the Simultaneous productions of highpurity calcium carbonate and

.jpg)

Microbially/CO2derived CaCO3 cement strengthens calcareous

2022年7月9日 The calcium rich calcareous sand can be used as calcium source for the MICP process to improve cementation properties of sandy soil (Liu et al 2018) The content and 2023年3月21日 By adding a bacterial liquid containing urease and a cementing fluid containing calcium ions and urea to loose sand, calcium carbonate crystals are induced to form between sand particles by the mineralization of Feasible Utilization of Waste Limestone as a Calcium 2024年9月1日 To further improve the effectiveness of solid waste management and alleviate its impact on the environment, the feasibility of ecological utilization of recycling stone powder Recycling stone powder as a partial substitute for cementitious This study first investigates the high calcium alkaliactivated cementitious materials, exploring the effects of different mineral admixtures, liquidtosolid ratios (L/S), RCP/slag, Na 2 SiO 3 Turning waste concrete powder into high calcium alkaliactivated

Carbon dioxidehardened sodium silicatebonded sand

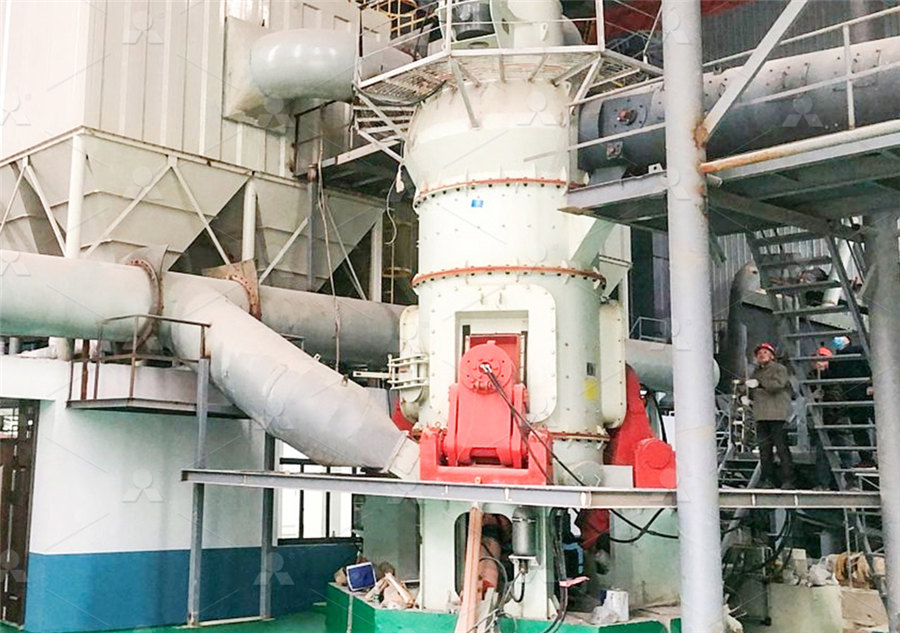

2022年6月1日 The recycled sand obtained by regeneration of sodium silicatebonded sand using calcium carbide slag is expected to become an excellent substitute for highquality 2023年3月21日 Application of ultrafine vertical mill in the processing and production of ultrafine heavy calcium Considering the diversified needs of heavy calcium powder products, the “CLUM ultrafine vertical mill + secondary (or tertiary)” classification process is often used in the design of vertical grinding powder engineering systems There are two reasons:The advantages of ultrafine vertical mill in the processing and 2024年7月12日 Due to the relatively high impurities, the whiteness of heavy calcium carbonate is generally 89% to 93%, and very few products can reach 95%; The purity of light calcium carbonate products is relatively high, so the Heavy calcium and light calcium, 10 essential 2021年7月9日 Talc is finally applied in powder form, therefore, fine grinding and ultrafine grinding are one of the necessary processing techniques for talc Talc has a Mohs hardness of 1, which is naturally crushable and has good The processing and application of talc ALPA

HOME Nguyen Vinh Holdings

2024年6月4日 NGUYEN VINH provides the most modern milling, screening, drying, mixing technology and processing plants for minerals NGUYEN VINH corporates with mine owners to export their products including: Titanium Zircon Sand, Zircon Flour, Zircon Silicate, Rutile Sand, Ilmenite, Cristobalite, Quartz grit, Quartz powder, Ground Calcium Carbonate (GCC), The ultrafine grinding of heavy calcium powder is essential to improve its application range and performance 1 Introduction Heavy calcium powder, also known as calcium carbonate, is a commonly used filling material in the industries of plastics, rubber, paper, paint, and pharmaceuticals The particle size of heavy calcium powder directly UltraFine grinding processing method and flow of heavy calcium powder 2021年10月4日 Heavy mineral sands are the source of various commodities such as white titanium dioxide pigment and titanium metal The three case studies in this paper show the value of Xray diffraction (XRD) and statistical methods such as data clustering for process optimization and quality control during heavy mineral processing The potential of XRD as an automatable, Heavy Mineral Sands Mining and Downstream Processing: Value Haicheng Tadiding Huaxin Minerals Processing Co Ltd was established in 2017 Our main business is the processing and sales of NonMetallic mineral products such as talcum powder,Caco3 powder,Dolomite powder,Chlorite powder,etc; The products are mainly applied in the ceramic industry,plastic industry,etc We have accumlated many years of processing Haicheng Taiding Huaxin Mineral Products Processing Co, Ltd

.jpg)

Learn the 17 differences between light calcium and heavy calcium!

2023年10月16日 It is usually divided into heavy calcium carbonate and light calcium carbonate according to different processing methods Calcium carbonate, whether it is heavy calcium carbonate or light calcium carbonate, is the most widely used powder filler in plastics, rubber, papermaking and other industries 1 Production method2021年8月10日 The safe utilization of solid wastes containing heavy metals plays a crucial role in environmental preservation As an efficient technology to achieve this goal, the preparation of glass ceramic foams from solid wastes can produce an excellent solidification effect on heavy metals At present, there have been plenty of efforts made to achieve an excellent combination A review of glass ceramic foams prepared from solid wastes: Processing Heavy calcium carbonate, for short is heavy calcium, is made of natural carbonate minerals such as calcite, marble, limestone after grinding, which is commonly used as a powdered inorganic filler Heavy calcium has the advantages of high chemical purityhellip;Heavy Calcium Processing SANDMINE2021年11月11日 Heavy mineral sands are the source of various commodities, such as white titanium dioxide pigment and titanium metal König and Verryn [10] provide information about the use of XRD to determine Heavy Mineral Sands Mining and Downstream

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Heavy calcium powder processed into more than 1000 mesh powder belongs to ultrafine heavy calcium powder, and special ultrafine powder processing equipment needs to be selected In the field of ultrafine powder processing, Zhengzhou SMMVIK Machinery Industry Technology Co, Ltd has developed and launched two types of equipment LUM ultrafine vertical mill and Which equipment is good for processing heavy calcium into powder With versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate powder of various particle sizes is in great demand around the world As the result, more and more shrewd businessmen want to build or expand their calcium carbonate powder processing plant all over the worldCustomize Suitable Calcium Carbonate Plant DASWELL1 Importance of 1500 Mesh Heavy Calcium Carbonate Powder The 1500 mesh heavy calcium carbonate powder refers to a powder with a particle size of approximately 10 microns This ultrafine powder offers several advantages: Enhanced Whiteness and Purity The ultrafine powder has a higher degree of whiteness and purity, making it suitable for Processing of 1500 mesh heavy calcium carbonate powder with

.jpg)

Some recent fluidization developments in powder handling

2015年2月28日 Powder properties However, where powders must be moved efficiently, properties can be evoked that offer particular benefits In such applications, the powder is moved by making it "flow like a liquid," using air to fluidize the powder The materials involved are of high uniform porosity, minimizing energy required to make the powder flow2013年1月1日 In the FTIR spectrum of Anadara granosa seashell powder as shown in the figure 1, a peak observed at 1080cm 1 was due to symmetric stretching CO (ν1) of calcium carbonate which correlated with Processing and Characterization of Cockle Shell Calcium The commonly used processing technology of limestone is to use industrial mills to mechanically pulverize it into powder Limestone can be directly crushed to obtain heavy calcium carbonate According to the different grinding fineness, there are four different specifications in the industry: single flight, double flight, three flight, and four flight, which are used in various industrial sectorsLimestone Ultrafine Grinding MillToday we will introduce you to calcium powder processing machinery and equipment in detail Detailed explanation of calcium powder processing machinery and equipment: Ordinary heavy calcium carbonate with d97≥5μm is mainly produced by dry methodNews Calcium powder processing machinery and equipment

The difference between heavy calcium carbonate and light calcium

2021年1月26日 According to its original average particle size (d), heavy calcium carbonate is divided into: coarsely ground calcium carbonate (> 3μm), finely ground calcium carbonate (1~3pm), superfine calcium carbonate (05~1μm) powder of heavy calcium carbonate Body characteristics: a Irregular particle shape; b2021年8月10日 Combining the advantages of glass foams and glassceramics, glass ceramic foams are made from a variety inorganic material comprised of glass phase, crystal phase and porous structure (Silva et al, 2021)There are plenty of tiny crystal particles distributed across the inner wall of the evenly distributed pores, thus making the glass and crystal intertwined with A review of glass ceramic foams prepared from solid wastes: Processing 2017年3月3日 Beneficiation and Mineral Processing of Mineral Sands, Sand and Silica Sand Processing Sand, Sand into SiliconSilicon carbide ; Heavy Mineral Sand; Fumed silica ; Separation of Heavy Minerals Beneficiation and Mineral Processing of Calcium Characteristics and application of heavy calcium carbonate Heavy calcium carbonate, referred to as heavy calcium, is a white powder made from highquality calcite Its main component is CaCO3, which is insoluble in water and ethanol It has the characteristics of high whiteness, good purity, soft color and stable chemical compositionThe Difference between Heavy and Light Calcium Carbonate

.jpg)

Characterization and quantification of calcite distribution in MICP

2023年5月21日 A new approach integrating micro Xray fluorescence (μXRF) and digital image processing is proposed to quantify the spatial distribution of calcium carbonate crystals for microbialinduced calcite precipitation (MICP)treated sand Scanning the entire MICPtreated sample slice with the μXRF imaging method presents an overview of the distribution of Si and 2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding process2023年5月1日 In order to reduce costs and improve whiteness, industrialgrade heavy calcium carbonate powder (IHCP) is used in white highstrength concrete (WHSC), the influence of IHCP on the workability Effect of industrialgrade heavy calcium carbonate powder on 2020年6月10日 The zircon powder from Zircon Minerals Malaysia is a pure premium grade zircon sand milled 15 µm that contain ZrSiO4, ZrO2, HfO2, SiO2, Al2O3, TiO2, and Fe2O3Study of the Synthesis of Zirconia Powder from Zircon Sand

.jpg)

Synergistic enhancement of industrial grade heavy calcium

2024年4月26日 White industrial grade heavy calcium carbonate powder (calcium carbonate) was formed by calcite, marble, and limestone [23], [24] Metakaolin was prepared from dehydration of kaolin (Al 2 O 3 2SiO 2 2 H 2 O) to generate anhydrous aluminum silicate at appropriate temperatures (600–900 °C) [25], [26]Natural Calcite Powder is a naturally occurring type of calcium carbonate that is exceptionally white, pure, and freeflowing Because of its high dispersibility, minimal oil absorption, high impact resistance, smooth surface finish, ease of processing, compatibility with polymers and other organic additives, and great dimensional stability, natural calcite powder is frequently used as Natural Calcite Powder Calcite Powder Manufacturers in India2022年7月19日 Precautions for storage of ground calcium carbonate powder Moisture proof Because heavy calcium carbonate is a powder, it absorbs water more Therefore, it is essential to do a good job of moistureproof work Away from acidic substances Since heavy calcium powder is calcium carbonate, avoid storing it with acidic substancesTo Know Ground Calcium Carbonate from Six Aspects DASWELL2021年12月20日 The equipment used during the processing of calcium carbonate powder affects grain types and particle size distribution Prater Equipment for Calcium Carbonate Manufacturing Processes Prater Industries Calcium Carbonate Manufacturing Process and

Research on a Stone Processing Powder Recovery and Reuse

2023年4月1日 stone processing waste powder and directly prepare it into artificial sand The concrete that meets the requirements can turn sto ne processing waste powder into treasure, which greatly s aves mineralCalcium carbonate can be classified into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate, and crystalline calcium carbonate depending on the Fine powder processing generally uses LM sand or calcium carbonate grinding mill, calcium carbonate Production and processing equipment for ultrafine heavy calcium powder mainly include crushing, grinding, classification, and drying equipment Here is a detailed introduction to the main equipment involved in the production of ultrafine heavy calcium powder: 1 Crushing equipment: Before grinding, the calcium carbonate raw material needs to be Production and processing equipment for ultrafine heavy calcium powder 2020年2月10日 In this work, The modification of heavy calcium carbonate powder was studied by dry surface modification with stearic acid and anhydrous citric acid we have developed a facile and inexpensive dry Dry surface modification of heavy calcium carbonate powder

A review of additive manufacturing of ceramics by powder bed

3 Powder bed selective laser processing (PBSLP) The terms selective laser sintering and selective laser melting in additive manufacturing are not yet properly standardized2020年1月7日 It has been mentioned that the grinding equipment for wet grinding of heavy calcium carbonate / heavy calcium powder mainly includes chippers, agitating mills, and sand mills, but no matter which equipment is selected, the purity of the heavy calcium carbonate / heavy calcium powder must be The whiteness and whiteness are not contaminatedCalcium carbonate manufacturing process2024年11月1日 In this study, the ceramic cores were printed with heavy calcium carbonate (HCC, CaMg(CO 3) 2) powder as raw material and Al powder as additive by binder jetting (BJ)The ceramic cores were impregnated with nanoZrO 2 dispersion solution and then sintered at high temperature to prepare the ceramic cores with low sintering shrinkage The effects of Significantly improved sintering shrinkage of heavy calcium Address: Powder Process Design Services Brooklands Church Lane Tel: +44 (0)845 094 1248 Bramshall Staffordshire : ST14 5BQ England Web: powderprocessingcouk About Powder Process Design Services Ltd Milling and drying system to produce Limestone powders and grits supplied with stateoftheart control systemPPDS HeavyDuty Classifier Mill (HDCM)

Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses

2023年6月25日 The material is squeezed into powder Its working principle determines that the proportion of fine powder produced is relatively low For example, in the 400 mesh calcium carbonate powder, the fine powder below 10μm accounts for about 35%, and the fine powder below 5μm is only 5%, which is much lower than other calcium carbonate mills