Efficiency thickener

Thickeners and clarifiers Complete range of reliable and

Correct thickener and clarifier sizing ensures dependability and efficiency with a margin of safety for process upsets, allowing the greatest operational flexibility Our experienced engineers are 2010年7月1日 In this paper we define and discuss a range of efficiency measures that allow different aspects of raking in gravity thickeners to be quantifiedEfficiency of raking in gravity thickeners ScienceDirectIn general, thickener handling rate is expres area (GPMFt2) or cubic meters per hour per throughput in Ft2/STPD or M2,MTPDPyrometallurgy Towards Clean Metallurgical Processing 2012ANDRITZ EcoSET is a costefficient thickener range that handles light to mediumduty solidliquid separation With its plugandplay control system, the ANDRITZSEPARATION RECOVERY OF HIGHLY CLARIFIED LIQUID Andritz

.jpg)

Techniques and methodologies for improving

2003年9月29日 The AMIRA P266 'Improving Thickener Technology' series of projects has sought to provide a firm scientific basis for feedwell and thickener design, a requirement as pressures on water usage in2015年1月1日 Thickeners are designed to separate clear and reusable water from concentrate underflow Conventional feedback control has not been effective in stabilizing the process Expert Control Tuning of an Industrial Thickener ScienceDirect2016年10月22日 This paper will introduce a new high efficiency thickener recently developed by Beijing Guohua Technology Group (BGTG) in China and proven with its simplicity and high DEVELOPMENT APPLICATION OF HIGH EFFICIENCY THICKENER 2000年12月1日 These projects have resulted in the development of a range of research tools and techniques to address flocculation and thickening issues Laboratory and plant studies Recent developments in techniques and methodologies for

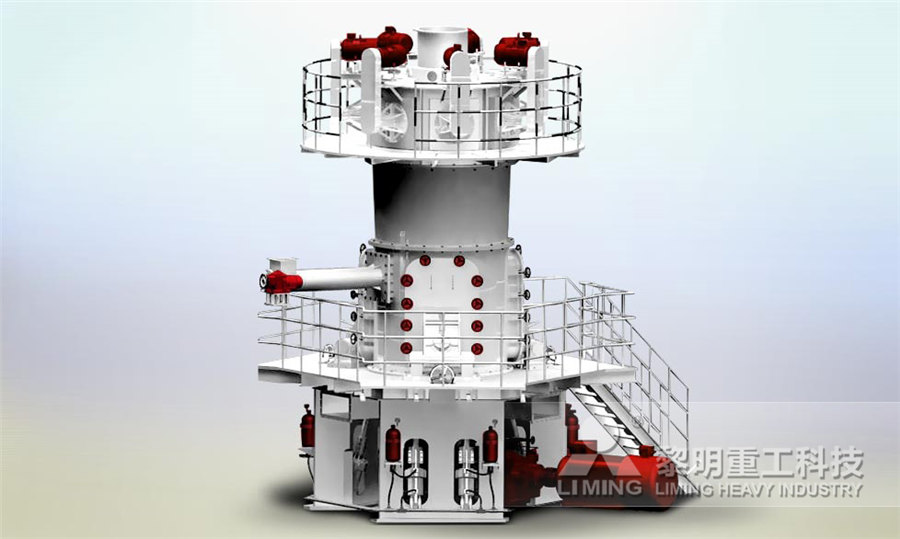

Thickener Prominer

Prominer can provide different kinds of thickeners include center driving thickener, peripheral traction thickener and high efficiency thickener Our thickener is applicable for dewatering concentrate and tailing slurry in the is fed to thickener I and a wash solution to thickener N; clear preg nant solution overflows thickener I and washed tails exit as under flow from thickener N CCD circuits of this type are typically employed when the solids tend to slime heavily and where a filter is not economic A typical CCD circuit usually employs from two to five thickI I HYDROMETALLURGY [sD~2017年6月16日 Many thickener installations operate with water recovery below design limits largely through conservative control and low prioritization of thickener optimization The operation of the thickener must accommodate Beginners guide to thickeners Metso2010年7月1日 The efficiency measures are first applied to a CFD model of a pilotscale thickener before being applied to an example of a fullscale thickener geometry It is noted here that the aim of this paper is not to design an optimal raking system, but rather to illustrate the efficiency measures and their utilityEfficiency of raking in gravity thickeners ScienceDirect

HUBER Disc Thickener SDISC HUBER Technology

HUBER Disc Thickener SDISC: The unique sludge thickener offers efficient sludge treatment for wastewater treatment plants up to 200,000 PE HUBER News; Events; Newsletter; Hire Trial; Performance and efficiency Sludge volume reduction > 2016年10月22日 Compared to the conventional and namely high capacity thickeners with motordriven rakes, the newly developed high efficiency thickener has much higher unit handling capacity and much less maintenance due to its nonmoving parts and high thickening efficiency; industrial application of the new high efficiency thickener showed that its DEVELOPMENT APPLICATION OF HIGH EFFICIENCY THICKENER 2010年7月1日 The efficiency measures are first applied to a CFD model of a pilotscale thickener before being applied to an example of a fullscale thickener geometry It is noted here that the aim of this paper is not to design an optimal raking system, but rather to illustrate the efficiency measures and their utilityEfficiency of raking in gravity thickeners ScienceDirectEVolute evenly distributes feed within the thickener and minimises flocculant shearing The tapering shelf and sloped inner shelf promote superior feed stream energy dissipation, optimal mixing energy and improved shear profiles to ensure thickener performance and efficiency Our EVolute feedwell technology incorporates the EIMCOThickeners and clarifiers Complete range of reliable and

.jpg)

Thickeners Types, Working Principle Applications Savona

2017年10月17日 Factors determining efficiency of Thickener Several types of thickeners have been developed and classified according to the arrangement of feed and discharge in the various compartments For effective thickener control, key considerations are bed mass inventory, underflow density and flow, bed level, overflow clarity and flocculent dosingSpecial attention is given to the design of the thickener feedwell (for high efficiency) and specially profiled rake blades for maximum transfer of viscous and heavy material at minimal torque consumption As part of its development initiatives, MIP Process Technologies Thickening and Clarification MIP Industries2023年8月20日 Aside from the benefit of oil thickeners in food, it is also a beneficial additive in engine oil People use thicker engine oils on cars with old engines and high mileage Due to the oil thickener, regular engine oil Oil Thickener Tips For EfficiencyThickener Sizing Calculator valid for settling thickeners, high rate thickeners, and clarrifiers Exit Thickener Calculator Process Input Parameters Rake Drivetrain Efficiency:Required Drivetrain Reduction Ratio:Required Operational Torque: Thickener Sizing MetEngineer

.jpg)

Increasing efficiency of thickener operation in

KEYWORDS: Settling Rate, Thickener, Tailings, CoagulationFlocculation Date of submission: 18 Apr 2016, Date of acceptance: 15 Jun 2016 Citation: Moosavirad SM Increasing efficiency of thickener operation in concentrate plant of iron 2018年8月8日 Factors determining efficiency of Thickener Several types of thickeners have been developed and classified according to the arrangement of feed and discharge in the various compartmentsThickeners — Types, Working Principle ApplicationsLZ thickener promoted the structure of internal feed tube on the basis of traditional vertical flow sedimentation tank, which greatly increase settling efficiency The tank is circular, suspended solids settle down into bottom conical sludge tank by gravity, clear water flow away from overflow port around the upper tankThickener LZZGHUBER Disc Thickener SDISC: The unique sludge thickener offers efficient sludge treatment for wastewater treatment plants up to 200,000 PE Press/News; Events; Newsletter; Plants for rent; Performance and efficiency Sludge volume reduction > 85 %, Typical thickening results > HUBER Disc Thickener SDISC HUBER Technology

.jpg)

Efficiency of raking in gravity thickeners Request PDF

2010年7月1日 Request PDF Efficiency of raking in gravity thickeners There is little published literature on the design and operation of rakes in gravity thickeners In practice, design principles and Figure 9 shows the wash efficiency of the thickener of rank "n" in the CCD circuit as a function of number "n" of thickener The set value of specific gravity of underflows decreases with the Wash efficiency of CCD circuit versus number of Thickener for Efficiency of thickener in iron ore mine Moosavirad J Adv Environ Health Res, Vol 4, No 3, Summer 2016 147 of feed properties, combined streams and elevation changes Any components not optimized will affect the efficiency of the settling in the thickener and therefore its capacity and performance However, one ofIncreasing efficiency of thickener operation in concentrate plant The Hycor ® ThickTech™ Rotary Drum Thickener (RDT) is the industry leading sludge thickener Its performance is unmatched, with sludge volume reduction of 90% and a 98% capture rate In addition, this superior performance is achieved with very low amounts of polymerHycor® ThickTech™ Rotary Drum Thickener Parkson Corporation

Most common problems in Thickener operations (Part 1)

2024年7月11日 We have discussed in early articles the strategies to optimize water consumption (part 1 and part 2) and learned the vital role that thickeners play in the optimization of the water recovery processIn this blog, we will explore the most common problems that affect the operations and efficiency of thickeners The blog will be divided in two parts Part 1 will 2024年9月25日 Fact sheet regarding thickening of solids Gravity thickening is the process by which biosolids are condensed to produce a concentrated solids product and a relatively solidsfree supernatantFact Sheet: Gravity Thickening US EPA2024年9月11日 Paddle Dryer: The Ideal Solution for Sludge Drying Our paddle dryers are engineered to provide an efficient and costeffective solution for sludge drying in wastewater treatment plants Here’s why our paddle dryer system The Ultimate Guide to Sludge Thickeners in Thickener modernizations, upgrades and retrofits Restore your thickener to its original condition or upgrade for increased performance Improve performance and extend the life of equipment by upgrading your aged thickener The thickener bridge and mechanism are often upgraded in conjunction with the entire feed system Upgrading theseThickeners and Clarifiers Metso

.jpg)

How to Improve the Efficiency of A Thickener? by Ch Medium

2023年7月12日 In summary, improving the efficiency of a thickener requires considering multiple factors such as operating procedures, process parameters, flocculant selection, automation control, Hest HVB – High Efficiency Thickener Global Seven Hest HVB is a 100% active thickener for all types of aqueous surfactants that outperforms other similar materials Ideal for hard to thicken systems such as SulfateFree surfactant systems as well as conventional surfactants including the following: Alkyl glucosides Alpha olefin sulfonatesglobalseven Hest HVB – High Efficiency Thickener2019年8月7日 sludge thickener in tailing wastewater treatment The highefficiency deep cone concentrator is a new product in the solidliquid separation process Due to low investment, small floor space, high efficiency, the quality of the underflow concentration andHigh efficiency sludge thickener tank new design LZZGA thickener is a device used for solidliquid separation, mainly used in mining, metallurgy, chemical industry and other industrial fields Thickeners play an important role in industrial production They can not only improve production efficiency, but also save resources and reduce environmental pollutionThickener jingjin Filter press

Mine Water Management and Recycling: The Importance of Thickener

2022年6月27日 The utilization of a highefficiency thickener for red ore integrated by centrifugation can achieve greater underflow concentrations and raise the dehydration velocity of the concentrate Furthermore, the adoption of an angled sheet design highefficiency thickener improves dehydrationThe thickener is applicable to concentrate and tailings dewatering treatment in mining applications, widely used in metallurgy, the chemical industry, coal, nonmetallic mineral processing plants, environmental protection, and other industries The highefficiency mining thickener is not a gravity separation equipment, but a piece of dewatering equipment Thickener JXSC MineralRealtime Thickener Optimization: How We are Driving Process Efficiency, Stability and Water Recovery Shared Learning from Procemin Geomet 2022 In the mining industry, thickener process control and stability have always been Realtime Thickener Optimization IntelliSenseioGravity belt thickeners (GBTs) are expected to see advancements aimed at enhancing efficiency and sustainability The focus will be on optimizing energy consumption and increasing automation Future GBTs may incorporate Gravity Belt Thickeners in Wastewater Treatment:

Thickener – mintex

Each of our products undergoes rigorous testing to ensure quality, reliability and efficiency in every mining application We integrate the latest innovations in design and production technology to meet the increasingly complex demands of this industryThese projects have resulted in the development of a range of research tools and techniques to address flocculation and thickening issues Laboratory and plant studies have focused on how key factors, such as mixing intensity, mixing duration and solids concentration, affect flocculation efficiency and, hence, thickener performanceCritical review of thickener design methods AcademiaThickening Efficiency Thickening efficiency is gauged by the consistency of the sludge output In practical terms, solids capture rate (SCR) and increased solids concentration are central parameters An optimal Rotary Drum Thickener should achieve a high SCR, indicating a minimal loss of solids in the filtrateRotary Drum Thickeners in Wastewater Treatment: Maximizing Efficiency How a Continuous Thickener Works As a feed stream enters the thickener, the solids settle to the bottom Clarified liquor overflows to the top and settled solids undeflow is removed from the bottom The following illustration shows a cross section, schematically illustrating the operation of a continuous thickenerThickening Resource Book 911 Metallurgist

.jpg)

A Practical Guide to Thickener Selection PCI Magazine

2000年10月23日 Highshear effective HASEs can also be the sole or primary thickener for some acrylic semigloss paints Although they have relatively poor thickening efficiency and leveling, they do impart good gloss, film build, and block resistance They also retain more viscosity after tinting than NSATs Exterior PaintsThe released filtrate exits from the thickener through an outlet at the bottom of the unit, where it is collected and discharged to further processing The periodic cleaning of the drum filter media with pressurized water is very important in order to prevent Municipal Sludge Thickening Technologies SpringerLinkGNZ series high efficiency thickener It consists of a rake system, a central frame, a central transmission device, a central column, a feeding system, a working bridge, a lifting device, an automatic slag discharge device, etc in an environmentally Thickener Technology恒丰泰2003年9月29日 The current phase of this work, the three year P266D Improving Thickener Technology project, affect flocculation efficiency and, hence, thickener performanceTechniques and methodologies for improving thickener performance