Which equipment processes lime powder with fine particle size and high output

Lime Production Process and Required Equipment

2023年2月15日 PE jaw crusher is an ideal primary crushing equipment, which can reduce the various rocks into the desired size Heavyduty hammer crusher: With high productivity and a large crushing ratio (usually 1025, sometimes 2016年10月20日 Dependences are obtained for briquette density on compaction pressure and process productivity with different roll briquetting parameters Technology and equipment Briquetting Metallurgical Lime Screenings and Parameters Making 2020年3月1日 Fine powder was used to prepare different concentrations of lime slurry to remove four combinations of boiler outlet acid gas Results show that the lime separation can reduce Performance analysis of an online lime separation system in a 2019年11月1日 In the process, lime (1200 g/t) and starch (200 g/t) are used first, at pH 105–112, after which the pH is reduced to 55 with SO 2 (200 g/t) and the copper sulphide Lime use and functionality in sulphide mineral flotation: A review

.jpg)

SIZE REDUCTION BY GRINDING METHODS ResearchGate

Size Reduction is mainly done through crushers and mills Crushing and grinding are the two primary comminution processes Crushing is normally carried out on the "runofm ine" ore During hydration, the quicklime lumps will disintegrate to a fine powder For high quality limes some form of screening and/ or classification, during which the lime is sorted by particle size Lime An IntroductionQuick lime used in water and sludge treatment usually satisfies the following specifications: fine or sieved lime (090 mm particle size) In practice, two types of preparation are used: paste Lime, reagent in water treatment Degremont®2018年2月21日 The results indicate that the efficiency of limestone powder in partially replacing cement can be achieved by particle packing and particle distribution in the concrete and the Evaluation of the Efficiency of Limestone Powder in Concrete and

.jpg)

Lime an overview ScienceDirect Topics

There are two methods used for lime aging on construction site: slurry process and powder process of hydrated lime Quicklime often contains overburnt lime which is the fused mass 2021年3月3日 Quicklime and hydrated lime are used to stabilize finegrained soils in place of materials that are used as subbases, eg, hydraulic clay fills or otherwise poorquality clay Lime SpringerLink2020年4月1日 With respect to the uncertainty in particle numbers and size, we refer to our work done on comparing this exact same ELPI + setup with a condensation particle counter (UFCPC, PALAS GmbH) for comparison on the particle number concentration, and for comparing particle size, with a modelling tool (AerCoDe) from the University of Karlsruhe (Brachert et al, 2014)Fine and ultrafine particle number and size measurements from 2024年6月26日 The sieving surface of the sieves, the mesh, is made up of square openings, formed by perpendicularly braided wires The sieves used constitute a standardized series, according to Table 31, whose openings are related to each other by a geometric progression, allowing the comparison of the classification results The mass of material to be tested in a Particle Size Analysis SpringerLink

Global survey of limestone used in poultry diets:

2022年2月17日 For coarse limestone, mean solubility (30 min incubation) was 655% (range 23296%) which was not correlated (R ² =009) with particle size Particle size and solubility rate of limestone have 2020年12月3日 Therefore, the study aims at a detailed characterization of ten metal powders (Metal powder 316 L, Zn, Sn, Al, Cu, Mn, Fe, Bronze, Ti and Mo powder), for which the particle size distribution Characterization and flowability methods for metal powders2020年10月1日 Inline analysers are typically configured with reduced measurement flexibility and tighter control of the measurement parameters For complex scenarios where particulate substances evolve significantly with the process and/or vary with process conditions, the selection of a suitable inline particle analyser for the entire process is not straightforwardQuantification of particle size and concentration using inline The performance of many end processes depends on particle size Particlesize analysis is a complex subject for both philosophical and technical reasons For instance, Etzler and Deanne [41] have discussed many of the challenges associated with particle size analysis Measuring the particle size in the nanometer range is particularly challengingParticle Size Analysis an overview ScienceDirect Topics

Process engineering: Particle size reduction techniques and equipment

2005年2月14日 Sometimes, as in sugar grinding, very fine particles are agglomerated to increase the share of larger particlesMany particlesize distributions can be represented by the GaudinSchuhmann equation:y = 100 (x/x m)ª where y is the cumulative percentage of material that is finer than size x, x m is the theoretical maximum size, and ª is the distribution 2017年2月25日 On the other hand, the particle properties are known to be affected by the processing routes and processing conditions used for generating particles (Buckton, 2000, Buckton, 1995, Heng et al, 2006, Planins̄ek et al, 2010, Smith et al, 2000)Milling can cause particulate breakage resulting in surface defects as well as surfaces with a heterogeneous Influence of particle properties on powder bulk behaviour and 2003年12月1日 The knowledge of product particle size distribution (PSD) in crystallization processes is of high interest for the pharmaceutical and fine chemical industries, as well as in research and developmentPowder Sampling and Particle Size Determination ResearchGate2023年4月19日 Furthermore, bubble size measurements indicate that pneumatic ImhoflotTM generated very fine bubbles in a high shear environment, improving particlebubble collision frequencies View Show abstractA Brief Review of Fine Particle Flotation ResearchGate

.jpg)

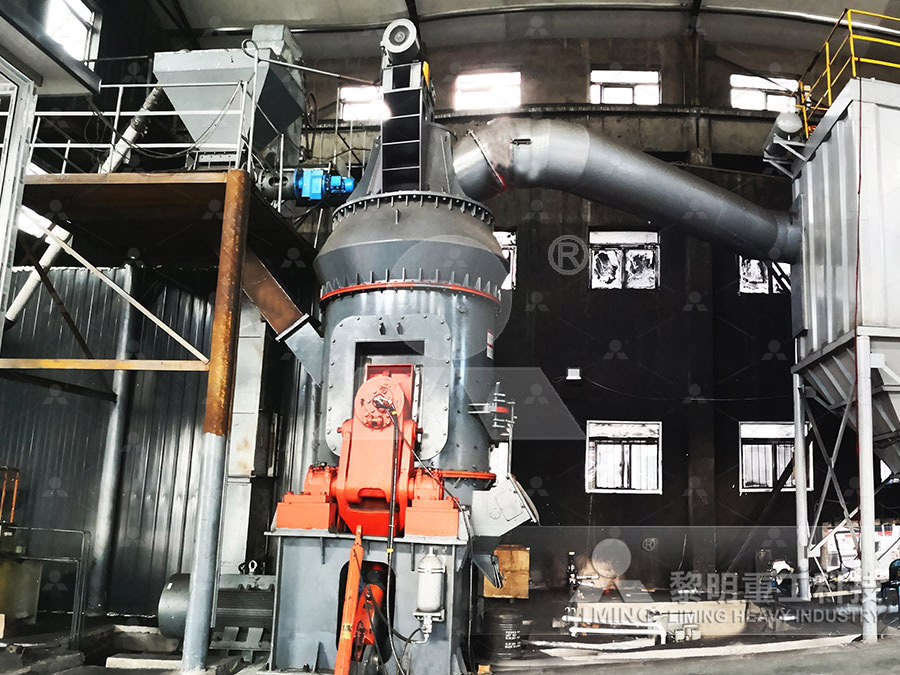

Lime Production Line for HighOutput Lime Production Plant

Product: Lime Production Plant Capacity: 50 – 1200 TPD FUEL: Coal Gas, Natural Gas, and Pulverized Coal Application: Active Lime Production Line/ Quicklime Production Line/ Hydrated Lime Production Line Main Equipment for Lime Production Line: Rotary Lime Kiln / Vertical Lime Kiln, Raymond Mill, Jaw Crusher, Bucket Elevator, Separator, Dust Collector, etcNanoscale: Size range from approximately from 1 nm to 100 nm This definition is accompanied by two notes: Note 1: Properties that are not extrapolations from a larger size will typically, but not exclusively, be exhibited in this size range For such properties the Powder/fineParticle Size Distribution HORIBA2022年5月20日 The particle size achieved in a batch will normally depend on the type of wetmilling equipment that is used However, in general particle size will be a function of the residence time of the slurry in the mill (Stenger et al 2005) This residence time can be controlled by operating the system in either singlepass or recycling modeMechanical ParticleSize Reduction Techniques SpringerLinkFine particle size lime slurries and their production US10/475,484 USA1 (en) : : Fine particle size lime slurries and their production CAA CAA1 (en) : : Fine particle size lime slurries and their production EPA EPA1 (en)Fine particle size lime slurries and their production

.jpg)

Particle size analysis: A comparison of laboratorybased

2024年4月15日 Particle size and morphology are fundamental physical properties of sediment and sedimentary rocks that affect sediment erosion, transport, and deposition (Blott and Pye, 2001)Particle size analysis and the measured particle size distributions (PSD) therefore provide insights into sediment provenance and transport, and can allow for classification prediction 290 Journal of Research of the Natiunal Bureau of Standards [Vol £9 TABLE IEmley plasticity values and particlesize data for hydmted limes Emley Geo Geo Emley Geo GeoLime plasmetric metric weightmetric Specific Lime plas weightmetric Specific numher ticity standard surface number ticity standard surface value mean deviation value mean deviationPARTICLE SIZE AND PLASTICITY OF LIMEBased on the principle of Dynamic Image Analysis (ISO 133222), the CAMSIZER X2 provides precise particle size and shape information of powders, granules and suspensions in a measuring range from 08 μm to 8 mm The CAMSIZER X2 produces a particle flow which is characterized by an optical system with high resolutionParticle Size and Shape Analyzer CAMSIZER ® X2 MICROTRAC2014年11月30日 Cement properties have been explained by the effect of packing density, which is defined as the ratio between the solid phase volume and the total volume of the system (Fig 1)The inclusion in the system of particles with improved particle size gradation confers on it increased packing density and, thus, decreased porosity, as was also described by the linear Influences of limestone particle size distributions and contents

.jpg)

Fine particle size lime slurries and their production

The particle size distribution was determined using a Malvern Mastersizer Microplus Particle • Size Analyser "RTM" The software package used was version 218 and the method used was based around the guidelines laid out in the manuals supplied with the Malvern Mastersizer This procedure was limited to a particle size range of 001 556mm2024年7月17日 FTM MachineryGreen and Intelligent Mining Machinery Manufacturing and Export BaseBased on high quality and perfect aftersales service, our products have been exported to more than 120 countries and Types of Crushers: Choosing the Right One for Each Download scientific diagram Particle size distribution curves of hydrated lime, Portland cement (CP) and RCW [Figura 1: Curvas de distribuição granulométrica da cal hidratada, cimento Particle size distribution curves of hydrated lime, Particle size reduction is one such method that increases the surface area of the pharmaceutical compounds and subsequently leads to a higher dissolution rate and bioavailability Conventional processes such as milling, highpressure This results in the formation of fine powder of the product Fig 4 A schematic of the spray freeze Particle Size Reduction Techniques of Pharmaceutical

ScalingUp of Solid Orals: Granulation, Drying, Size Reduction

2023年6月17日 The end point is determined by several factors (Table 52), including the target particle size mean, particle size distribution, granule viscosity, and granule density However, determining the end point can be challenging, especially when encountering changes in equipment size and model, which can affect the reproducibility of the endpoint2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact The selection and design of Crushing equipment Performance 2018年2月21日 reduction effect will vary based on particle size of the limestone powder used as fine limestone powder, which requires extra milling Limestone powder with a particle size of 8 µm produces aboutEvaluation of the Efficiency of Limestone Powder in Concrete and 2024年3月21日 With the continuous evolution of additive manufacturing technology, the production of spherical powders has become increasingly vital Various studies suggest that factors such as the preparation process, powder materials, and sphericity are crucial in determining product performance This paper provides a comprehensive review of the Review on preparation technology and properties of spherical

.jpg)

Heat of hydration of Portland highcalcium fly ash cement

2014年9月15日 Fly ash is a byproduct generated from burning coal in the generation of electricity Two classes of fly ash are defined by ASTM C618 [1] that is lowcalcium Class F fly ash and highcalcium Class C fly ash The main difference between these classes is the amount of calcium, silica, alumina, and iron content in the ash and the type of coal usedA powder particle size of 50 μm is regarded as a critical value; the adhesion force between powders will increase with decreasing particle size, becoming the primary component affecting the collision behaviour at less than 50 μm, while the powder mobility will be better beyond it (Ziaee and Crane Citation 2019; Chen, Li, and Yang Citation 2015); 53 μm is a typical commercial Study on powder particle behavior in powder spreading with 2023年12月11日 Figure 4 shows the particle size distribution of OPC and composite micronized powder, and it can be seen that the particle size range of composite micronized powder is smaller Figure 5 shows the XRD pattern of Preparation and Performance of UltraFine High 2017年3月4日 In materials processing, a grinder is a m achine for producing fine particle size reduction through attrition and compressive forces at the g rain size level In general, grinding processes requ ire aSIZE REDUCTION BY GRINDING METHODS

.jpg)

Soil microaggregate size composition and organic matter distribution

2019年12月1日 By summarizing the size distribution after dispersion in three textural size classes, we observed that in the free fraction of the lowclay soils there were more fine sand particles >100 μm and 5% less claysized particles compared to the highclay soils (decrease from 228 to 176% clay) (Fig 4 a)2007年10月30日 The effects of particle size and drying temperature on the water holding capacity (WHC) of dietary fiber powder are shown in Table 6 The effect of particle size on the WHC of lime residue powder was not observed in this study These results were in contradiction with some previous works, which reported the strong effect of particle size on WHCFull article: Effects of Drying Temperature and Particle Size on If your processes require particle size reduction machinery, rely on particle size reduction equipment from Prater to do the job right Request a Quote (877) 2475625; freeflowing material down to 200 mesh with very tight particle distribution, our fine grinders are also ideal for heatsensitive materials such as powder coatings Fine Grinders, Hammer Mills, and More for Particle Size ReductionThe pressure at the nozzle determines the particle size At high pressures, up to 30 MPa, (300 bar), the powder will be very fine and has a high density At low pressures, 5 – 20 MPa, (50 – 200 bar), larger particles will be formed and the fines content will be lower The pressure is built up by means of multiplunger highpressure pumpsMILK AND WHEY POWDER Dairy Processing Handbook

.jpg)

Physical Properties of Lime Powder Produced by PowderParticle

2000年6月1日 Porous quicklime powder is produced from 5 μm limestone particles in a PowderParticle Fluidized Bed (PPFB) PPFB is a new fluidization technique in which agglomerative fine particles adhere onto 2016年12月1日 Fielden et al reported that the particle size of lactose powder (fine and coarse) has a profound influence on the extrusion characteristics of the wet mass and on the size and the roundness of the resulting pellets when prepared using ram extruder and a cylinder extruder [27]Extrusion–spheronization a promising pelletization technique: In 2014年10月4日 The particle size distribution, surface area and shape are fundamental characteristics of supplementary cementitious materials (SCMs) Accurate measurement of these properties is required in computational efforts to model the hydration process, and the characterization of these parameters is also an important practical issue during the production Determination of particle size, surface area, and shape of 2021年1月1日 The effect of vibration fluidization on the separation of fine metal powder with a particle size of less than 40 microns from submicron particles in a nonuniform electric field using a dielectric Application of particlesize analysis in various industries